RADIANT / CONVECTOR GAS FIRE

MODEL 426

(GC 32 811 40)

INSTALLATION & SERVICING INSTRUCTIONS

INSTALLER: Please leave these instructions with the owner

We trust that these instructions give sufficient details to enable this appliance to be installed and maintained

satisfactorily. However, if further information is required, our

advice lin e will b e p le ased to he lp. Ring 0345

626 341 (Local call rates apply)

600A515/07

THIS APPLIANCE

IS FOR USE WITH

NATURAL GAS

(G20) AT A SUPPLY

PRESSURE OF

20mbar (8in w.g.)

THIS APPLIANCE

IS FOR USE IN

THE UNITED

KINGDOM (GB)

AND

THE REPUBLI C

OF IRELAND (IE)

2

LIST OF CONTENTS

Page

Overall dimensions …..................................................................................................................................................................... 2

Appliance data .............................................................................................................................................…...................……. 3

General installation requirements..........................................................................................................................................…… 3

Fireplace & hearth..........................................................................................................................................................…. 4

Wall mounted.................................................................................................................................................................…. 4

Precast flues...................................................................................................................................................................….. 4

Metal flue box.................................................................................................................................................................…. 4

Flues................................................................................................................................................................................. ….4

Unpacking & pre-installation preparation..................................................................................................................... .....…........ 6

Carton contents..............................................................................................................................................................….. 6

Fireplace flue pull check................................................................................................................................................….. 6

Appliance preparation.....................................................................................................................................................…..6

Ignition spark check..........................................................................................................................................................…7

Feet assembly (For floor mounted appliances)..............................................................................................................… 7

Closure plate fitting.........................................................................................................................................................….8

Appliance installation..............................................................................................................................................................……… 9

Installing to hearth..........................................................................................................................................................…..9

Wall mounting.................................................................................................................................................................….9

Gas supply connection...................................................................................................................................................…..9

Coal & window fitting......................................................................................................................................................…9

Full operating checks............................................................................................................................................................……… 10

Control setting checks...................................................................................................................................................….10

Reference pressure check..........................................................................................................................................….…10

Final assembly & checks.......................................................................................................................................................……... 10

Outer case fitting........................................................................................................................................................… ....10

Spillage check.............................................................................................................................................................….....10

Flame supervision & spillage monitoring system check................................................................................................. 11

Final review................................................................................................................................................................…......11

Servicing & parts replacement.............................................................................................................................................……..... 12

Window removal....................................................................................................................................................…..... .12

Outer case removal........................................................................................................................................................….12

Coal removal...................................................................................................................................................................…12 Gas

tap removal..............................................................................................................................................................….12

Burner, pipes & pilot removal........................................................................................................................................... 13

Injector removal............................................................................................................................................................…..13 Gas

supply pipe disconnection......................................................................................................................................… 13

Piezo generator removal.................................................................................................................................................… 13

Control tap greasing........................................................................................................................................................…13

Replacement parts - short list........................................................................................................................................… 14

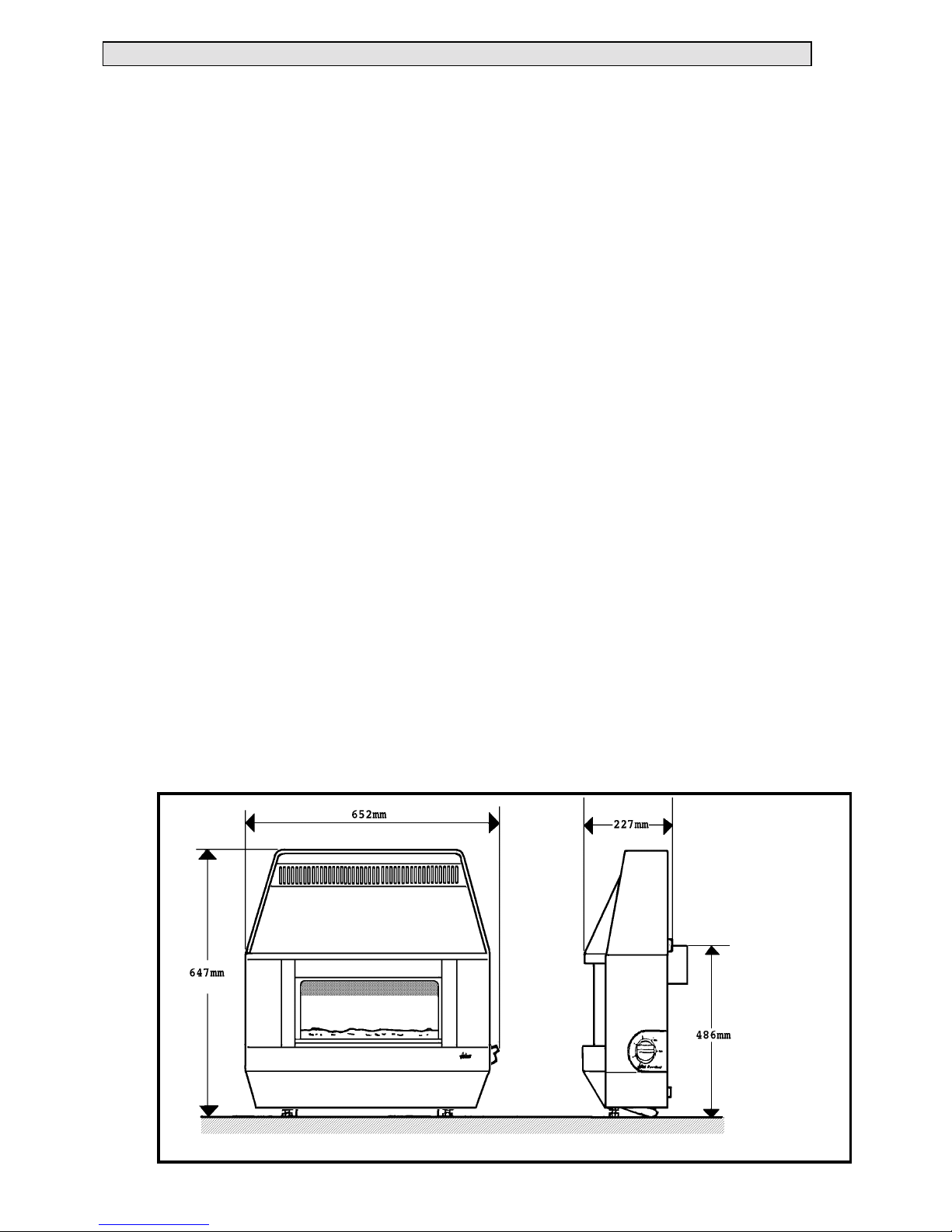

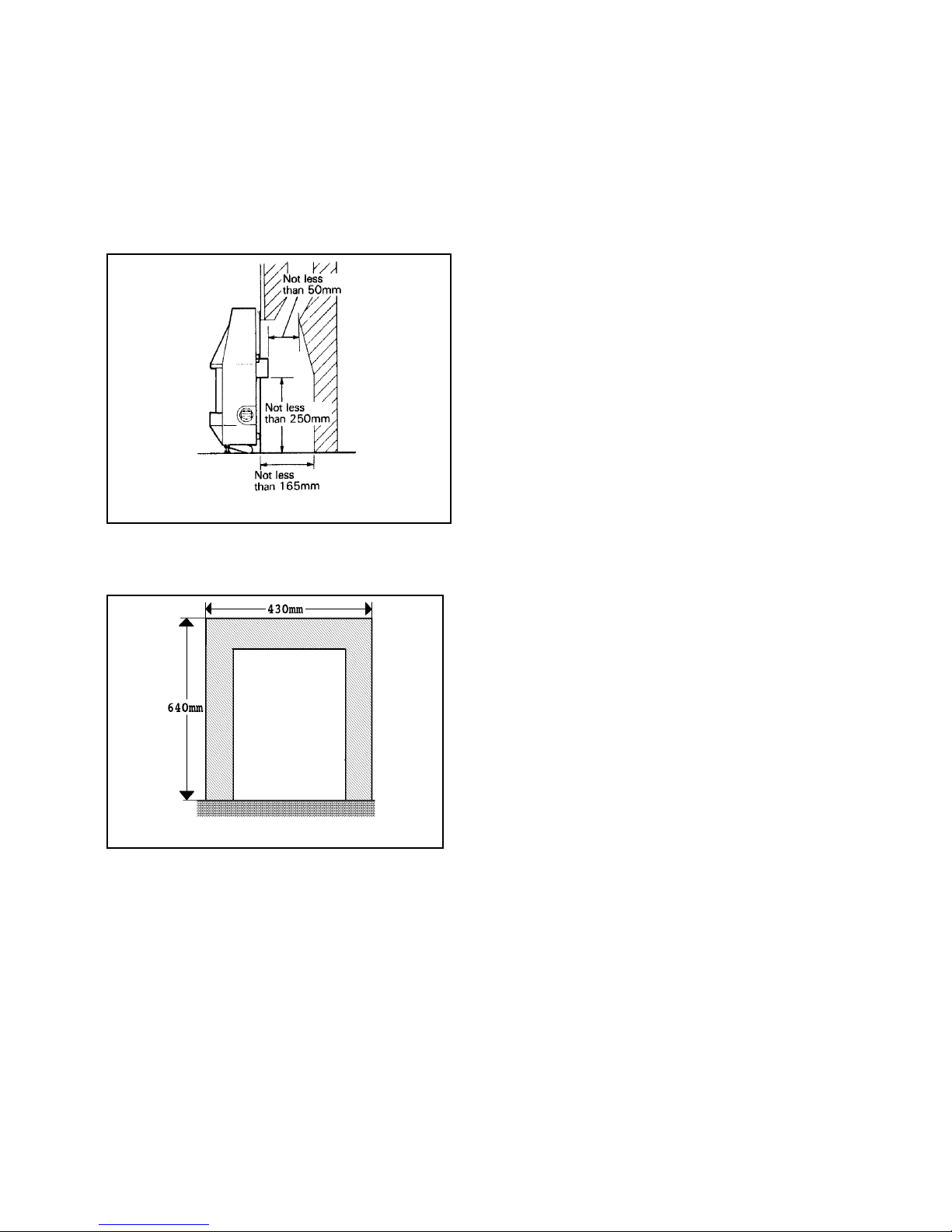

Fig. 1 Overall dimensions

3

1. APPLIANCE D ATA

1.1 This product uses a fuel effect piece containing

Refractory Cer amic Fibres (RCF ), which are man-made

vitreous silicate fibres. Excessive exposure to this

material ma y c a use temporary ir ritation to eyes, skin and

respiratory tract. Consequently, it makes sense to take

care when h andlin g th is article to en su re that the relea se

of dust is kept to a minimum. To ensure that the release

of fibres from this RCF article is kept to a minimum,

during installation and servicing we recommend that you

use a HEPA fi ltered vacu um to remove any dust and

soot accumulated in and around the fire before and after

working on the fire. When replacing this article we

recommend tha t the replaced i tem i s n o t br ok en up, but

is sealed with in a heavy duty polythene bag, c learly

labelled as RCF waste. This is not classified as

“hazardous waste” and may be disposed of at a tipping

site lic ensed for t he disposal of industri al waste.

Protective clothing is not required when handling this

article, but we recommend you follow the normal

hygiene rules of not smoking, eating or drinking in the

work area and always wash your hands before eating or

drinking.

This appliance does not contain any component

manufac tu red from asbestos or asbestos rela ted

products.

1.2 The appliance data badg e i s on the inner f a c e of

the back panel near the bottom l eft corner. There is also

a label giving a serial number and the appliance G.C

number on th e right side of th e ou ter case near the

bottom.

1.3 General Data

The overall dimensions are shown in fig.1.

Gas: Natura l (G20)

Supply pressure: 20mbar (8in. w.g)

Gas consumption at

Control Setting: Gross Heat Input

4 5.77kW (19,700Btu/h)

3 4.16kW (14,200Btu/h)

2 2.40kW ( 8,200Btu/h )

1 1.65kW ( 5,600Btu/h )

Burner type: Duplex

Injectors:- Upper: Bray Ca t 99 Size 150B

Lower: Bray Cat 99 Size 240

Burner test pressure: 17.46 + 0.75mbar

(cold) (7.0 + 0.3in. w. g)

Pilot & atmosph ere: SIT ref. OP 9044

sensing device

Control Tap:- Duplex fou r posi ti on. Fitted

with integr a l piezo-electric

igniter and thermocouple

activated el ec tr o-magnetic

shut-off valve.

Inlet connection: Rp1/4 (1/4”BSP)

Aeration: Non-adjustable

2. GENERAL INSTALLATION REQUIREMENTS

2.1 The installation should comply with the rules in

force.

In your own interest and that of safety, in the United

Kingdom, it is the law that all gas appliances are installed

by competent persons in accordance with the current

edition of the Gas Safety (Installation & Use)

Regulations. Failure to install appliances correctly could

lead to prosecution.

The Counci l of Registered Ga s Installer s (CORGI)

requires its members to work to recognised standards.

The installation must be in accordance with these

instructions.

In the United Kingdom the installation must also be in

accordance with:

a) All the relevant parts of local regulations.

b) The Building Regulations issued by the

Department of th e En vironment or th e Buildin g

Standa rds (Scotland) ( Co nsolidation) Reg ulatio ns issued

by the Scottish Development Department.

c) All relevant codes of practice.

d) The relevant parts of the current editions of the

following British Standards:BS 715

BS 1251

BS 1289 Part 1

BS 1289 Part 2

BS 4543 Part 2

BS 5440 Part 1

BS 5440 Part 2

BS 5871 Part 1

BS 6461 Part 1

BS 6891

In the Republic of Ireland the installation must also

conform with the national and local regulations in force.

2.2 The appliance must not stand on a carpet or any

other combustibl e ma terial.

If a panel h a s to be f i tted to the fireplace opening to meet

the requi red opening si zes shown below, it mu st be

made of non-combustible material.

4

2.3 In the United Kingdom, as supplied, the

appliance can be installed in the following situations.

2.3.1 Conventional fireplace and hearth

The appliance can be installed to a fireplace complete

with surround and hearth

The firepl a c e opening must be with i n the following

dimensions:

Width: Max. 432mm

Min: 305mm

Height Max: 610mm*

Min. 510mm

* Though the total height of the c l osu re plate will

accommodate a ma ximum opening height of 650mm,

heights above 610mm will leave the closure plate and

sealing ta pe vi sible above the appl iance.

The appliance must be mounted on a non-combustible

hearth (N.B. conglomerate marble hearths are

considered as non-combustible). The hearth must be at

least 710mm wide x 300mm d eep. The hearth ma terial

must be at least 12mm thic k. Th e periphery of th e

hearth (or fender) should be at least 50mm above floor

level to discourage the placi n g of carpets or ru gs over it.

The applian c e ca n be fitted to a purpose made

proprietary class “O” 100“C or 150°C surrou nd.

2.3.2. Wall mounted

The appliance can be wall mounted.

The opening must be within the following dimensions:

Width: Max. 432mm

Min. 305mm

Height: Max. 610mm*

Min. 372mm

* Though the total height of the c l osu re plate will

accommodate a ma ximum opening height of 650mm,

heights above 610mm will leave the closure plate and

sealing ta pe vi sible above the appl iance.

The centre of the flue spigot must be at least 512mm

above the finished fl oor covering.

2.3.3. Precast flue

The appliance can be installed to a fireplace that has a

precast concrete or clay flue block system conforming to

BS1289. The appli ance is suit a b l e for insta l lations

conforming to older versi ons of BS1289 as well as the

current edition. The flue blocks must have a minimum

width not less tha n 63mm and a cross-sectional a rea not

less than 13,000mm

2

.

Older ed itions of BS1289 r equired

a cross-sectional a rea of 13,000mm

2

. The current

revision of the standa rd requi res 16,500mm

2

. This

appliance is suitable in both cases.

The chimney should be on or two storeys h igh but not

less than 3m vertical height and be correctly terminated.

No mortar f angs between the bloc k s sh ou ld be extruded

into the flueway. If raking blocks are used, they must be

fitted in accordanc e with the manufacturer’ s

instructions. Mortar must not be allowed to drop down

and accu mulate in th e r aked positions.

The firepl a c e opening must be with i n the following

dimensions:

Width: Max. 423mm

Min: 305mm

Height Max: 610mm*

Min. 610mm*

* Though the total height of the c l osu re plate will

accommodate a ma ximum opening height of 650mm,

heights above 610mm will leave the closure plate and

sealing ta pe vi sible above the appl iance.

2.3.4. Metal flu e box

The appliance can be installed to a metal flue box

complying with th e c onstructiona l requirements of th e

curren t edition of BS715.

The opening must be within the following dimensions:

Width: Max. 432mm

Min: 380mm

Height Max: 610mm*

Min. 510mm

*Although the total height of the closure plate will

accommodate a ma ximum opening height of 650mm,

heights above 610mm will leave the closure plate and

sealing ta pe vi sible above the appl iance.

2.4. Flues

The flu e m ust be clear of any o bst ruction and its base

must be clear of debris.

The flue must be completely sealed so that combustion

products do not c ome i nto contact with combustible

material s ou tsi d e the chimney.

Suitable flues are as follows:(a) 225mm x 225mm conventi onal brick f lue. If a

flue li ner is used, it must be a mini mum of 127mm (5in)

diameter. The liner must be sealed to th e surrounding

area above the fireplace open ing and to the top of the

chimney with an approved terminal being used.

(b) A properly constructed precast flue conforming

to B.S 1289.

(c) A flue pipe with a min imum diameter of

127mm 5in.). See B.S 6461 Part 1 for suitabl e ma terials.

Metal flu e pipes must comply with B.S 715. See section

2.3.4 of thi s ma nual for flue box opening sizes.

2.4.1 The flue must have a minimum equiva lent

height of 3m.

2.4.2. The flue mu st serve only one fireplace.

2.4.3 Any damper or register pla te should be

removed. If removal is not possible without carrying out

structural work, the damper or plate may be left in the

flue provided that it is permanently s ecured in the fully ope n

position.

2.4.4. If the appliance is intended to be installed to a

chimney which was previously used for solid fuel, the

flue must be swept clean prior to installation. All flues

should be inspec te d for sou ndness and freed o m from

blockages.

2.5 If the fir epl ace opening is a n underf loor drau ght

type, it must be sealed to stop any draughts.

2.6. The flue spigot and any spigot extension must

be capable of passing through the closu r e plate by at least

5

25mm with a min i mum clearance of 50mm between its

open end an d the nearest obstr uction.

There must al so be a minimum c learanc e of 165mm

between the back of the closure plate and the bac k of the

catchment spac e.

The catchmen t spa c e below the flue spigot must extend

at least 250mm downwards measured from the bottom

of the flue spi got.

See figure 2.

2.7. If the fire is to be fi tted a gainst walls with

combustible cladding, the cladding must be removed

from the ar ea shown in f ig.3.

2.8. The front of th e fireplace should be fla t over an

area suff icient to ensur e a good seal with the closure

plate. The flat surface shoul d extend for a height eq ual to

that of the closure plate plus 20mm and a for a width

equal to tha t of the closure plate plus 40mm.

2.9. The minimum c learance from the top surface of

the applia nce to the und er side of any sh elf made fr om

wood or other combu sti bl e ma terials is as fol l ows: -

• For a shelf up to 150mm deep

Minimum c learanc e = 150mm

• For a shelf deep er than 150mm

150mm + 12.5mm for ever y 25mm d epth

over 150mm.

2.10. The minimu m allowable d i sta nce to a corner

wall or any other projection at either side of th e

appliance is 100mm.

2.11. The space between the fireplace f ront face and

the back of the outer case must not be filled in.

2.12. Please no te that soft wall coverings (e.g.

embossed vinyl etc .) are easily affected by h eat. They

may, theref or e, scorch or become discoloured wh en

close to a heating appliance. Please bear this in mind

when installing.

2.13. An extra c tor fan may on l y be used in the same

room as this appliance, or in any area from which

ventilation for the appliance is taken, if it does not affect

the safe performance of the appliance. Note the spillage

test requirements detailed further on in this manual. If

the fan is likely to affect the appliance, the appliance

must not be installed unless the fan is permanently

disconnected.

2.14. In the United Kingdom no special ventilation

bricks or vents are required in the room for this

appliance.

In the Republic of Ireland permanent ventilation must

comply with the regulations currently in force.

Fig. 3 Area to be free of combustible cladding

Figure 2 Fireplace catchment space

6

3. UNPACKING & PRE-INSTALLATION PREPARATION

3.1. C arto n Co n t e n t s

The carton contains the following:-

1. Fire assembly.

1. Ceramic fuel effect (In packaging inside

firebox).

1. Closure plate.

1. Flue spigot.

1. Pair of feet (for floor mounting the appliance).*

1. Pair of feet shrouds (for floor mounting th e

appliance).*

1. Pack of fixings containing:

2. Plastic caps for foot screws.

4 No 8 tapping screws for flue spigot

4 Woodscrews for wall mounting

4 Wall plugs

2 Knurled screws for feet shrouds

4 M5 screws for feet

1. Inlet elbow connector.

1. Smoke match tube.

Remove all the items carefully to prevent damage. Some

items may be contained in the packaging fitments Examine the packaging carefully before discarding.

Check that a ll the items are present and undamaged .

*The polystyrene top f itment contai ning the feet a nd

feet shrou ds indic ates which i t ems a re for the left and

right sides. To ease identificatio n at the assemb ly stage,

leave the par ts in the polystyrene until you are read y to

fit them.

3.2. Fireplace Flue Pull

After preparing the fi replace, appl y a lighted match ,

paper or smoke match to the chimney openi ng. Observe

the smoke. If there is a definite flow in to the opening

continue with the instal lation. If th ere is not a defi nite

flow, preh eat the chimney for a few min utes and recheck

If there is still no definite flow, the chimney may need

attention. Do not fit the appliance. Seek expert

advice.

3.3. Appliance Preparation

3.3.1.

Stand the fire upright.

3.3.2. Detach the window surround (See figure 4):

a) Remove the two knurled screws immedia tely

below the outer case canopy.

b) Lift the surround c l ear of the slots in the outer

case apron

3.3.3. Remove the control knob by pulling clear of the

gas tap spindle.

Fig. 4 Window su rrou nd remov al

7

3.3.4. Remove the control bezel by unscrewing two

screws (see fig. 5) .

3.3.5. Detach the outer c a se by r emovi ng the screws at

the case sides (see fig.5) .

3.3.6. Pull the bottom of the case forward s while

springin g th e bottom c orners outwar d s to clear the fixing

brackets. Lift the case upwards and forwards to clear

(see fig.5). P lace caref ully to one sid e.

3.3.7. Remove the window u n it by detachin g th e

knurled screws at the bottom corner s. L ift the window

unit up to clear the top flange of the firebox and pla c e

carefully aside (see fig.6).

3.3.8. Check ignition spark

Before attempting to install, i t i s wor th checking tha t the

piezo electri c spark igni tion system operates

satisfactorily.

To initiate the spark, temporarily refit the control knob

to the tap spind l e. Depress the contr o l k nob and whi l e

keeping it depressed, turn anticlockwise through

approximately 60° to the 1/IGN position. A spa r k sh ould

track fr om th e electrode pin to the thermocoupl e ti p. If

there is no spa rk or incorrect track i ng, check th e spa rk

gap between the electrode wire and thermocoupl e ti p

(see figure 7). If the spark gap is correct, check the

ignition wiring.

Remove the control knob after checkin g.

3.3.9. For floor mounted appliances

3.3.9.1 Fit the shroud s to th e f eet with the knur led

screws supp lied (see fi g ure 8). Sl ide the shr o uds up to

the feet as far as they will go. Tighten the knurled

screws.

Identification of the left and right side components is

shown on the pol ystyrene fitment c ontaining the parts.

Fig. 5 Outer case removal

Fig. 6 Window unit removal

Fig. 7 Pilot spark gap

Fig.8 S hr oud to foot asse mbly (Left side shown)

8

3.3.9.2 Fit the feet to the u n derside of th e a ppliance

feet mountin g brackets (See figu re 9).

3.3.10 Fit th e flue spigot to the back of the fire using

four screws provided.

3.3.11 If the fire is fitted to a recessed fireplac e, an

extension flue spigot up to a maximum total length of

125mm may be used. The extension must be a tight fit

over the flue spi got a n d be secured by two self tappin g

screws. Note th e minimum cl earance r eq uired as sh own

in figure 2.

3.4 Fit The Closure Plate

(Figs 10, 11 & 12)

3.4.1. If a centre gas pipe connection is required cut an

opening at th e bottom of the closure plate. (The gap

between the pipe an d the opening in the closure pl a te

should be sealed with tape after c on nection,)

3.4.2. Hearth mounting (figure 11)

The closur e plate must be fitted a nd sealed to th e hearth

and fireplace opening using a suitable heat resistant

material . If necessar y c ut the closur e plate. Leave th e

closure pl a te suffici ently large to over lap the fir eplace

opening by 25mm. Make sure that the rectangular air

relief openings are fully within the fireplace opening.

3.4.3 Wall mounting (Figure 12)

The closur e plate must be fitted and sealed to th e

fireplace opening using a suitable heat resistant material.

If necessar y cut the closure plate. Lea ve the closure plate

sufficiently large to overlap the fireplace opening by

25mm. Make sure that the rectangular air relief openings

are ful l y wi thin the fi replace openin g.

The underside of the ou ter case must be at l ea st 115mm

above any carpet or other fl oor covering. To achieve this,

the centre of the flue spigot hole will be at least 512mm

above the finished fl oor covering.

3.4.4. Check the flue pull with c l osure plate fi tted by

applying a lighted match or smoke match to the flue

spigot opening in the closure plate and observe the

smoke. If there is a definite flow continue with the

installa ti on. If not check the fitting of th e c l osu re plate.

The fireplace flue pull check described in section 3.2

should have confirmed that the fireplace itself is

satisfactory.

Fig. 9 Foot to bracket assembly (left side shown)

Fig. 10 Closure plate

Fig. 11 Closure plate fixing to hearth

Fig. 12 Closure plate fixing to wall opening

4. APPLIANCE INSTALLATION

4.1 Installin g T o A Heart h

4.1.1.

The levelling screw lock nuts should be

accessible below th e shroud s. If necessa ry, loosen t he

knur led screws sec uring t he shrouds, raise the shrouds

and resecure them. To prevent scratching th e hearth, fit

the two plastic caps (Supplied in the accessory pack)

over the heads of the levelling screws. See figure 13.

4.1.2 Place the fire centrally on the hearth making

sure that the spigot lines up with the spigot hole in the

closure pl a te. Gently slide the applia nce into plac e. The

spigot must enter the closure pl a te to a depth of at least

25mm.

4.1.3 Level the fire by loosening the lock nuts and

turning the levelling screws in the feet up or down as

required while they bear on the hear th. When th e f ire is

level and square to the wall, retighten the lock nuts.

Loosen the kn urled screws securing the feet shrouds and

lower the shrouds until they cover the levelling screws.

4.2 Wall Mountin g

The position of th e wa ll fixi n g h oles in relati on to the

closure pl a t e spi g ot h o l e are shown in fig.14.

4.2.1 Mark the positions of the two upper fi xing holes

using the dimensions as shown in fig. 14. The positions

can alternatively be marked by placing the fire in

position and ma rking the wal l through th e u pper holes

in the back pan el.

4.2.2 Drill and plug the holes. Fit a woodscrew in

one hole. L ea ve about 12mm gap between the screw

head and th e wall to han g th e fire.

4.2.3. Hang the fire on the upper screw making sure

that the fl ue spigot engages thr o u g h the closure pl a t e.

4.2.4. Mark the positions of the bottom fixing holes

through the back panel, ensuring that the fire is level.

4.2.5. Remove the fire. Drill and plug the bottom

fixing holes.

4.2.6. Replace the fi re. Fit three woodscrews, two

through th e bottom h oles and one thr ough the

remaining top hole. Tighten all four woodscrews.

4.3. Gas Supply Connection

4.3.1.

An Rp1/4 (1/4in. B.S.P.) elbow con nector is

provided. Th is can be revolved through 360° to the

connection position required. If a rear centre connection

is required through an opening cut in the closure plate

(see section 3.4. 1.), seal the ga p between the plate an d

the pipe with tape a f ter connection.

4.3.2. Provision for isolation of the gas supply must be

provided u pstream of the appl iance for sa fety and

servicing.

4.3.3. The supply pipe must be of a rigid material (e.g.

copper). A flexible connection must not be made.

4.3.4. Pressure check the installation pipework for gas

soundness in accordance with the current edition of

BS6891.

4.4 Fit Coal And Wind o w

4.4.1.

Place the coal bed in position Make sure that

the coal r ests on the ledges at the sides of the f irebox and

that its back face is touching the back of the firebox..

(see fig.15).

4.4.2. Replace the window unit, making sure its top

channel locates over the top fl a nge of the firebox

opening. Ref i t the two knurled screws and tighten .

Fig. 13 Protectiv e ca ps

Fig. 15 Coal bed loca ti on

Fig. 14 Wall fixing holes

10

5. FULL OPERATING CHECKS

5.1 Check Control Settings

5.1.1.

To help in checking the control positions while

the outer case is detached, pl ace the control bezel over

the gas tap spindl e a nd against th e ta p bracket.

Temporarily secu re to the tap bracket with one of the

screws.

5.1.2. Fit the control knob over the ga s tap spi ndle.

5.1.3. Depress the control kn ob a nd turn

anticlockwise partially towards the 1/IGN position until

some resistance is f elt. Keep dep ressed at this positio n

to purge air from the system then, while keepin g it

depressed, turn fully to the 1/IGN posi ti on. A spark

should be generated at the pilot while turning. The spark

should ignite the pilot.

5.1.4. When pil ot ignition has been achieved, keep the

control knob dep ressed for approxi m a t ely ten seconds to

allow the thermocouple probe to warm up and th en

release it. If the pilot does not remain alight, ensure that

the air h a s been purged, that the pilot orifice is clear and

that the thermocouple connections are sound. Replace

the pilot unit if necessary (see servicing section of this

manual).

5.1.5. Check all the control settings. These a re:-

Knob

Position Burner appearance

1/IGN Centre section on low. Outer

sections off.

2 Centre section fully on. Outer

sections off.

3 Centre section fully on. Outer

sections on low.

4 Centre and outer sections fully on.

5.2. Check Reference Pressure

The appliance is pre-set to give th e c orrect heat input at

the inlet pressure shown in section 1 of this manual. No

adjustm ent is necessary. Chec k t he burner pressur e b y

fitting a pr essu re gauge at the test poin t. The test point is

on the pipe connecting the gas tap to th e l ower injector.

Check the pressu re with the appl iance alight and set a t

maximum output (Control position 4).

After checking, turn off the appliance. Remove the

pressure gauge and replac e t he test point sea ling screw.

Relight the appliance. Turn to the maximum output

position and te st aroun d the sealing screw for gas

soundness with a suitable leak detection fluid.

6. FINAL ASSEMBLY & CHECKS

6.1 Fit The Outer Case

6.1.1.

Detach the con trol knob and control bezel .

6.1.2. Refit the outer c a se. Ma ke su re that the centre

strip at the top back of the case is located beh i nd the

vertical face of the back panel.

The rearwa rd angled ears near the top c o r ners of the

back panel shoul d be behind the outer case top plate,

(see fig.16).

6.1.3. Secure the case at th e bottom si d es wi th the two

screws previously removed.

6.1.4. Place the control bezel bac k in position a nd

secure it to the gas tap br a c ket wi th two screws.

6.1.5. Fit the control knob over the ga s tap spi ndle.

6.1.6. Make sure that th e c oa l is not dislod ged when

refittin g th e c a se.

6.1.7. Refit the window surround using the two

knurled screws previously removed (The reverse

method to that descr ibed in section 3.3.2). Make sure that

the outer edges of the surround sides are inside the outer case.

6.2. Test For Spillage

A spillage test must be made before the installed appliance

is left with the customer.

6.2.1. Close all door s and windows in the room

containing the fire.

6.2.2. Light the appl iance and set th e co n trol knob to

the maximum posi tion (Position 4).

6.2.3. Leave the appliance on f or five minutes.

6.2.4. There are two types of smoke match holders. One

has a copper finish, the other is plain steel. Please apply

the relevant parts of the spillage test instr u ctions

Place the smoke ma tch tube (with l i ghted match) on top

of the wall spa cer bracket at the r ea r right side of th e

appliance.

Copper finish tubes: Slide the tube in until the second

indent is level with the outer edge of the spacer bracket.

A raised ring round the tube (approx. 25mm from the

indent) shoul d be visible along t he casing side (see

fig.17).

Plain steel tubes: Slide the tube until the indent is level

with the edge of the casing si d e (see f ig.17).

Fi

g

.16 Outer case top location

Fig.17 Smok e match tube position

11

The installation is satisfactory if all the smoke is drawn

into rectangular opening in the closure plate. If any

smoke is escapes from the top or side of th e a ppliance,

leave the appliance alight at the maximum setting for a

further ten minutes an d then repeat th e test. If all the

smoke is still not drawn into the closure plate opening,

Disconnect the appliance and seek expert advice.

6.2.5. If the above test is satisfactory, open al l interna l

connecting doors, ha tc hes, etc. in the room. Keep all

doors and wi n dows that open to the outsid e of the

building closed. recheck for spillage as above. If an

extractor fan is installed in the same room as the

appliance or a connecting room, check that spillage does

not occur wi th the fan operating and al l doors and other

openings between the fan an d the applian c e open . If all

the smoke is dra wn into closu r e plate opening, continu e

with the insta l lation. If th e test i s n ot sa ti sf a c tory,

Disconnect the appliance and advise the customer of the

cause of failure.

6.3 Flame Superv is io n & Spillage

Monitoring System

This pilot unit incorporates a system which will

automatica l ly shut off the ga s suppl y if the pilot f l a me

goes out or if there is insufficient oxygen due to spillage

or lack of ven tilation.

Check that th e system operates properly a s f o l lows;

6.3.1 Light the appl iance. Set at positi on 4 and leave

for one minute.

6.3.2 Turn back to “O F F” to extingui sh th e pilot.

Note the time when the pilot goes out. Listen f o r a snap

sound at the gas ta p . Note the time when the sound is

heard. This sound is caused by an electromagnetic valve

shutting of f the gas supply throu gh the tap. The valve is

located in the body of the tap. The valve shou l d operate

within 60 seconds of the pilot going ou t. If the valve does

not operate within this time limit do not allow the

applian c e to be used until th e fault ha s been corrected.

This monitoring system must not be adjusted, bypassed or

put out of oper ation.

This monitoring system, or any of its parts, mu st only be

exchanged using Valor authorised parts.

7FINAL REVIEW

7.1 Make sure that the floor plate has been r efitted.

7.2 Recheck the operation of the f ire at all c ontrol

positions.

7.3. Visually inspect the appliance. Clean off any

marks incurred during installation.

7.4 Advise the cu stomer how to operate the f ire.

7.5 Explain to the customer that th e a ppliance ha s a

flame failure and spillage monitoring system. Point out

the explan ation of this system shown in th e owner’s

guide.

7.6 Advise the customer tha t , if the igniter fails, the

fire can be lit with a match as described in the users

instructions.

7.7 Advise the user that the window will require

cleaning periodically outside and inside as described in

the users instructions. Explain how to remove and

replace the window unit for cleaning the inside of the

glass etc.

7.8 Advise that th e f ire may give off a sl ight odour

while new. This is quite normal and it will disappear

after a shor t period of use.

7.9 Advise that any clean i ng must only be ca rried

out when the fire is off and cold.

7.10 Advise the cu stomer that they should read th eir

Owner’s guide before oper ating the fi re and al wa ys

follow the advice in the section headed “Cleaning your

fire”.

7.11 Recommend that the appliance should be is

serviced and the chi mney inspected by a co mpetent

person at least annually.

7.12 Hand these i nstructions and the own er’s guide

to the customer.

12

8. SERVICING & PARTS RE PL ACEMENT

• Always turn off the gas supply and make sure that the

appliance is cool before commencing any servicing.

• Always test for gas soundness and spillage after

servicing the appliance.

• It is recommended that, at least once a year, the

appliance is disconnected and the catchment space

behind the closure plate checked and cleared of any

debris. The closure plate must be resealed to the wall

after checking.

• This product uses a fuel effect piece containing

Refractory Ceramic Fibres (RCF), which are manmade vitreous silicate fibres. Excessive exposure to this

material may cause temporary irritation to eyes, skin

and respiratory tract. Consequently, it mak es sense to

take care when handling this article to ensure that the

release of dust is kept to a minimum. To ensure that

the release of fibres from this RCF article is kept to a

minimum, during servicing we r ecommend that you

use a HEPA filtered vacuu m to r emove any du st and

soot accumulated in and around the f ir e before and

after working on the fire. When replacing this article

we recommend that the replaced item is not broken up,

but is sealed within a heavy du ty polythene bag, clear ly

labelled as RCF waste. This is not classified as

“hazardous waste” and may be disposed of at a tipping

site licensed for the disposal of industrial waste.

Protective clothing is not requ ir ed w h en ha ndling this

article, but we recommend you f ollow the nor mal

hygiene rules of not smoking, eating or drinking in the

work area and always wash your hands bef ore eating

or drinking.

8.1 To Remove Window Unit

8.1.1.

Detach the window surround by removing the

two knurled screws immediately below the outer case

canopy and lifting the surround clear of the slots in the

outer case apron (See figure 4 in installation section).

8.1.2. Remove the window u n it by detachin g th e

knurled screws at the bottom corner s. L ift the window

unit up to clear the top flange of the firebox and pla c e

carefully aside (See fig.6 in installation section).

8.1.3. Replace in the reverse order .

8.2. To Remove Outer Case (See fig. 5 in

installatio n s ection)

8.2.1.

Remove the control knob by pulling clear of the

gas tap spindle.

8.2.2. Remove the control bezel by unscrewing two

screws.

8.2.3. Detach the outer c a se by r emovi ng the screws at

the case si des.

8.2.4. Pull the bottom of the case forward s while

springin g th e bottom c orners outwar d s to clear the fixing

brackets. Lift the case upwards and forwards to clear.

8.2.5. Replace in the reverse order . When refi tting,

make sure that th e pl a t e a t th e top back of the case is

located behin d th e vertical face of the back panel bu t i n

front of th e two r ea rward an gl ed ears near the top

corners of th e ba c k pa nel. The two rearward poin ti ng

tabs in the top of th e ou ter case rear pla te sh ould locate

against the inner edges of the ears on the bac k pa nel (See

fig.16 in installation section).

8.3. To Remove The Coal

8.3.1

Remove the window unit as described in

section 8. 1

8.3.2. Remove the coal.

8.3.3. Replace in the reverse order. When repl a c ing,

make sur e that the co al rests on t he ledges at sides of th e

firebox an d that its back fa ce i s tou c h i ng the back of the

firebox (see fig.15 in installation section).

8.4. To Remove The Gas Tap

8.4.1 Remove the outer case a s secti on 8.2 above.

8.4.2. Detach the electrode lead from the pilot un i t by

pulling the lead down and away from the electrode

situated a t the centre rear of the burner.

8.4.3. Disconnect the two pipes li nking the upper a n d

lower inj ec tors at the tap end a nd loosen thei r

connections at the injector ends. Swing the pipes clear of

the tap.

8.4.4. Disconnect the in l et pi pe and pilot pipe f rom

the gas tap.

8.4.5. Remove the l oc knut holdi ng the gas tap to the tap

bracket.

8.4.6. Carefully lift the tap clear to allow a c c ess to the

thermocouple connection. Disconnect the

thermocouple from the tap.

8.4.7. Replace in the reverse order .

13

8.5. To Remove The B urne r, Pipes And

Pilot

8.5.1.

Remove the outer case a s secti on 8.2.

8.5.2. Remove the coal as section 8.3.

8.5.3. Detach the gas tap and disconnec t th e

thermocoupl e f rom the tap as section 8. 4.

8.5.4. Remove the screw and sha k eproof wash er fixing

the burner at the righ t side

8.5.5. Remove the wing nut fixing the burner at the

left side.

8.5.6. Slide the bur ner unit complete with pilot pipe

and main burner pipes and pilot un it to the left and

forward clear of the radiant box.

8.5.7. Remove the pipes, injectors or pilot unit if

required.

8.5.8. Replace in the reverse order .

Note: 1. T h e pilot unit must be replaced as a whole assemb ly .

Its individual components are not separately

replaceable.

2. If removed, ensure that the dust cage is cleaned before

refitting and locates squarely onto the pilot unit without

any gaps between the cage edges and the pilot unit.

3. Make sure that the pilot shield is refitted if removed.

4. When refitting the burner make sure that the

shakeproof washer is fitted under the head of the screw

which engages with t he right hand burner bracket .

This washer prevents the end of the screw from catching

the upper inje ct or hexagon.

8.6. To Remove An Injector

8.6.1. Remove the outer case a s secti on 8.2.

8.6.2. Release the pipe compression fitting to th e

upper or lower injector as required. Lock the injector

with a second spa nner to ensure that it does not move.

8.6.3. Loosen the pipe compr ession fitting at the tap

end and move th e pipe clear.

8.6.4. Remove the injector from the burn er.

8.6.5. Replace in the reverse order .

8.7. To Disconnect The Gas Supply Pipe

Access for gas supply disconnection, may be ea sier if the

floor plate is removed.

8.7.1. Remove the outer case a s secti on 8.2.

8.7.2. Detach the pla te by unscrewing two sc rews

securing it to the side feet and pulling clear (see fig.18).

8.7.3. Replace in the reverse order. When ref itting the

floor plate, make sure that the rear tabs locate through

the upper pair of slots in the back pa nel (see fig.18).

8.8. To Remove The Piezo Generator

8.8.1. Remove the gas tap as section 8. 4..

8.8.2. Make sure that th e ta p i s i n the off position .

8.8.3. Remove the circl i p h olding the pi ezo unit to the

tap. Remove the piezo unit.

8.8.4. Replace in the reverse order .

8.9. To Grease The Control Tap

8.9.1. Detach the tap and remove the piezo gen er a tor

as section 8.8 making sure that the tap is in the off

position.

8.9.2. Remove the two scr ews from the head of the tap.

Remove the nitin g head and spi ndle complete with

collar and spring.

8.9.3. Note the position of the slot in the plu g - ma rk

its position on the ta p body.

8.9.4. Remove the plug rotating slightly while pulling.

8.9.5. Clean and grease the plug lightly with a suitable

grease. Do not apply excessive grease. Particularly, make

sure that the gas ports in th e tap are no t restrict ed by

grease.

8.9.6. Push th e plug into the tap bod y a nd position the

slot in line with the mark previously made on the tap

body.

8.9.7. Reassemble the niting head and spindle

complete with coll a r and sprin g ma ki ng sure that the

components ar e c orrectly engaged . Check the opera tion

of the tap.

8.9.8. Refit the piezo gen er ator.

Fig. 18 Floor plate fixing

14

REPLACEMENT PARTS - SHORT LIST

KEY

NO.

DESCRIPTION No. OFF MAKERS PART

No.

A

B

C

D

E

F

G

H

J

K

Injector - Upper - Bray 99 Size 150b

Injector - Bray 99 Size 240

Gas Tap Copreci & Spark Generator

Spark Generator

Pilot Unit

Inlet El b ow

Window Unit

Control Knob

Coal

Dust Cage

1

1

1

1

1

1

1

1

1

1

522109

522809

558799

521069

545949

532519

522209

520799

558809

567619

15

VALOR HEATING

ERDINGTON, BIRMINGHAM B24 9QP

Because our policy is one of constant dev elopment and improvem ent, details may vary s lightly from t hose giv en in this

publication.

© Valor Ltd

Loading...

Loading...