Valor 32-810-58, Churchill Installer's Manual

INSTALLER GUIDE

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE

REPUBLIC OF IRELAND (IE) ONLY.

INSTALLER: Please leave this guide with the owner

Manufactured exclusively for British Gas & Scottish Gas by Valor Heating

For Service Phone 0845 960 5040

Because our policy is one of constant development and improvement, details may vary

slightly from those given in this publication.

© Valor Heating

3002402/02

Churchill

Balanced Flue

(GC No. 32-810-58)

ROOM SEALED RADIANT/ CONVECTOR GAS FIRE

(Manufacturer ref. 4733)

INSTALLER’S GUIDE

Page 2

CONTENTS

SAFETY.....................................................................................................................3

LIST OF ACCESSORIES .......................................................................................3

1. APPLIANCE DATA......................................................................................... 4

2. GENERAL INSTALLATION REQUIREMENTS ......................................5

Terminal Position ............................................................................................... 9

3. UNPACKING..................................................................................................10

4. PREPARE THE FIRE ...................................................................................11

5. PREPARE THE WALL.................................................................................12

Cut the Flue Hole –Timber Frame Buildings .................................................14

6. PREPARE FLUE UNIT.................................................................................15

7. TERMINAL GUARD FITTING................................................................... 18

8. CHECK IGNITION SPARK......................................................................... 19

9. CONNECT TO THE GAS SUPPLY ............................................................ 19

10. FITTING COALS........................................................................................... 20

11. CHECK APPLIANCE OPERATION..........................................................23

12. CHECK THE REFERENCE PRESSURE ..................................................23

13. REPLACE OUTER CASE ............................................................................24

14. MAKE FINAL CHECKS AND INSTRUCT USER ................................... 24

15. SERVICING.................................................................................................... 25

15.1 To Remove Outer Case. .......................................................................... 25

15.2 To Remove Window Unit .......................................................................25

15.3 To Remove The Ceramic Fuel Items ......................................................25

15.4 To Remove Burner(s) .............................................................................. 25

15.5 To Remove Injectors(s) ...........................................................................26

15.6 To Remove Thermocouple......................................................................26

15.7 To Remove Electrode Pin........................................................................ 26

15.8 To Remove Pilot Pipe & Jet ....................................................................26

15.9 To Remove The Gas Tap And Piezo Unit............................................... 26

15.10 To Remove The Piezo Generator ............................................................27

15.11 To Grease The Control Tap .....................................................................27

SHORT LIST OF SPARES ...................................................................................28

INSTALLER’S GUIDE

Page 3

SAFETY

Installer

• Before continuing any further with the installation of this appliance please read

the following guide to manual handling

• The lifting weight of this appliance is 23 kg. One person should be sufficient to

lift the fire. If for any reason this weight is considered too heavy then obtain

assistance.

• When lifting always keep your back straight. Bend your legs and not your back.

• Avoid twisting at the waist. It is better to reposition your feet.

• Avoid upper body/top heavy bending. Do not lean forward or sideways whilst

handling the fire.

• Always grip with the palm of the hand. Do not use the tips of fingers for support.

• Always keep the fire as close to the body as possible. This will minimise the

cantilever action.

• Use gloves to provide additional grip.

• Always use assistance if required.

LIST OF ACCESSORIES

Description Part number

Timber frame Flue Clearance kit. 0583141

This kit includes : -

1 off Flue clearance sleeve

1 off Drip collar

1 off External wall plate

1 off Insulation blanket (This can be discarded)

For timber framed installations see section 5.

INSTALLER’S GUIDE

Page 4

1. APPLIANCE DATA

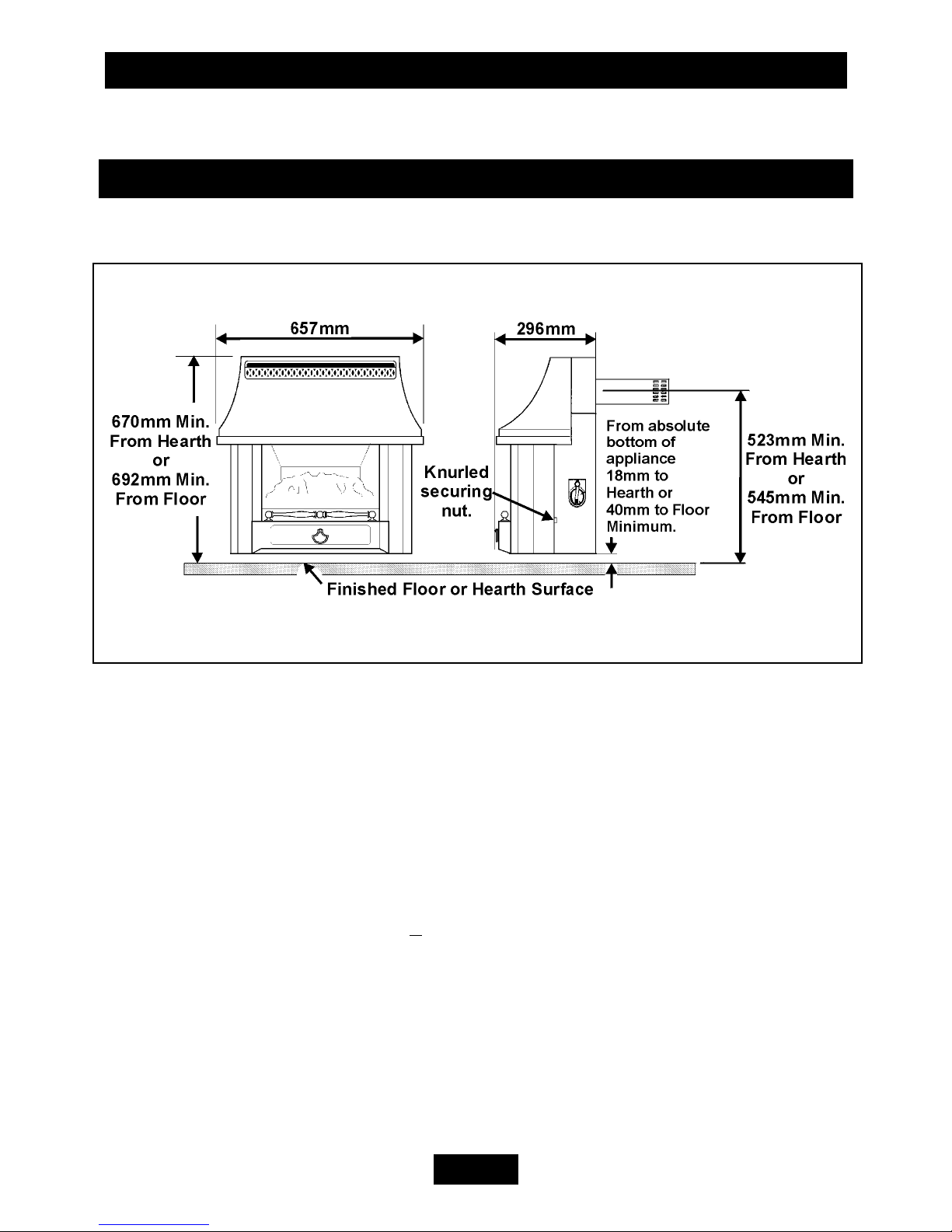

The overall dimensions are shown in figure 1.

Main Burner: Simplex aerated

Flame Effect Burner: Simplex aerated.

Gas Connection: RP 1/4 (1/4in. B.S.P) Isolating Elbow (Female).

Gross Gas Consumption: 4.9kW at maximum position.

Maximum output: 3.54kW

Injectors: -

Main Burner: Bray Cat. 960 Size 240

Flame Effect Burner: Bray Cat. 960 Size 130

Pressure Setting (Cold): 18.2 + 0.75mbar

Aeration Adjustment: None required.

Control Tap: Variable position fitted with flame supervision device

and integral piezo igniter.

Pilot Unit: Right side of firebox. Combined Pilot jet

thermocouple sensor and electrode.

No component on this appliance is manufactured from asbestos or asbestos related

products.

Figure 1. Overall dimensions

INSTALLER’S GUIDE

Page 5

The appliance data label is at the left side of the rear case and is visible after

removing the case front. In addition, for customer reference, there is a label giving

the appliance serial number on the outside of the case at the bottom right side.

This product uses fuel effect pieces, burner compartment walls and gaskets

containing Refractory Ceramic Fibres (RCF), which are man-made vitreous

silicate fibres. Excessive exposure to these materials may cause irritation to

eyes, skin and respiratory tract. Consequently, it is important to take care when

handling these articles to ensure that the release of dust is kept to a minimum.

To ensure that the release of fibres from these RCF articles is kept to a

minimum, during installation and servicing we recommend that you use a

HEPA filtered vacuum to remove any dust and soot accumulated in and around

the fire before and after working on the fire. When replacing these articles we

recommend that the replaced items are not broken up, but are sealed within a

heavy duty polythene bag, clearly labelled as RCF waste. This is not classified

as “hazardous waste” and may be disposed of at a tipping site licensed for the

disposal of industrial waste. Protective clothing is not required when handling

these articles, but we recommend you follow the normal hygiene rules of not

smoking, eating or drinking in the work area and always wash your hands

before eating or drinking.

2. GENERAL INSTALLATION REQUIREMENTS

2.1 Walls: -

Minimum 102mm (4in.) thick

Maximum 660mm (26in.) thick.

Suitable for use with combustible walls provided that there is no combustible

material or combustible cladding in the area indicated on the wall fixing template.

Please note that soft wall coverings (e.g. embossed vinyls etc.) are easily affected by

heat. They may therefore, scorch or become discoloured when close to a heating

appliance. Please bear this in mind when installing.

2.2 Installation to a timber-framed building should be in accordance with the

relevant sections of The Institute of Gas Engineers publication IGE/UP/7 “Gas

installations in timber frame buildings”.

Please note that advice should be sought before installing in a timber frame

building since the alterations required may nullify any NHBC cover relating to the

property. If in doubt, guidance should be requested from your local authority

planning or building department.

For timber framed installations see section 5.

INSTALLER’S GUIDE

Page 6

2.3 The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas appliances

are installed by competent persons in accordance with the current edition of the

Gas Safety (Installation and Use) Regulations. Failure to install the appliance

correctly could lead to prosecution. The Council for the Registration of Gas

Installers (CORGI) requires its members to work to recognised standards.

2.4 In the United Kingdom the installation must also be in accordance with:

a) All the relevant parts of local regulations.

b) The current edition of the Building Regulations issued by the Department of the

Environment and the Welsh Office or the Building Standards (Scotland)

(Consolidation) Regulations issued by the Scottish Development Department.

c) All relevant codes of practice.

d) The relevant parts of the current editions of the following British Standards:-

BS 5440 Part 1 BS 5871 Part 1 BS 6891

In the republic of Ireland the installation must also conform

a) With the relevant parts of the current editions of IS 813 and ICP3

b) All relevant national and local rules in force.

2.5 For combustible projections up to a depth of 178mm (Measured from the rear

fixing plane of the fire) a minimum clearance of 75mm should be maintained at the

left and right side of the fire. This is measured from the extreme side of the case.

This will allow easy access to the control knob and knurled nuts for removal of the

outer case. This clearance is mandatory for temperature requirements.

2.6 For any combustible projections beyond 178mm (Measured from the rear

fixing plane of the fire) a minimum clearance of 100mm should be maintained at the

left and right side of the fire. This is measured from the extreme side of the case.

This clearance is mandatory for temperature requirements.

2.7 For non-combustible projections a minimum clearance of 75mm should be

maintained at the left and right side of the fire. This is measured from the extreme

side of the case. This will allow easy access to the control knob and knurled nuts

for removal of the outer case.

If the fireplace opening is greater than the acceptable dimensions given in this guide,

do not use the back of a fire surround or marble to reduce the opening. This may

cause cracking of the surround back or marble.

INSTALLER’S GUIDE

Page 7

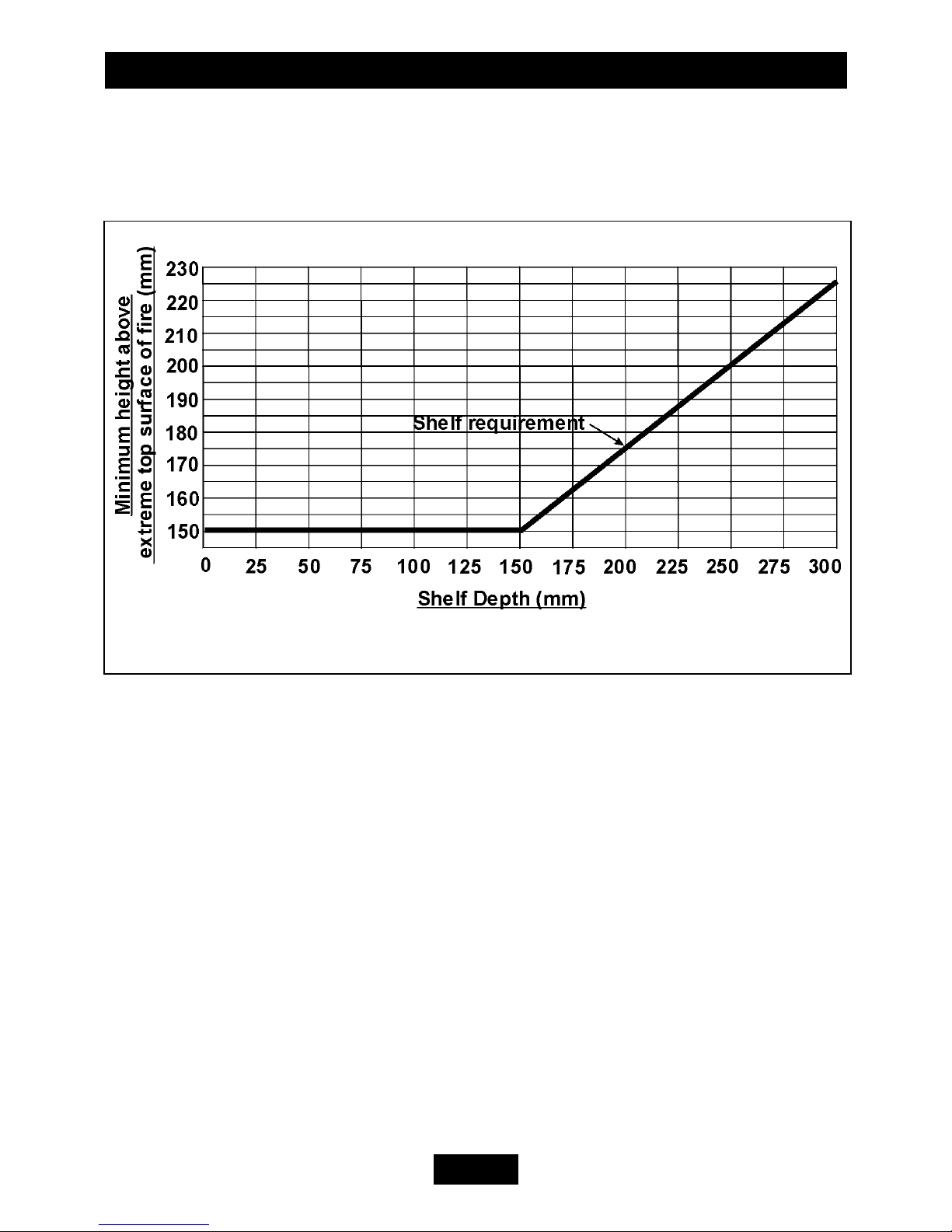

2.8 The minimum height from the extreme top surface of the fire to the underside

of a shelf or other projection made of wood or any other combustible material is

shown in graph 1.

2.9 There is no restriction on the depth of non-combustible projections but a space

of at least 30mm should be allowed above the top of the appliance to enable removal

of the case front.

2.10 It is advisable that combustible fabrics such as curtains are not fitted above the

fire. If, however, this is unavoidable, a clearance of at least 150mm must be

maintained from the extreme bottom edge of the fabric to the extreme top surface of

the fire.

2.11 The appliance can be installed with or without a non-combustible hearth. If a

non-combustible hearth is installed, there must be a minimum clearance from the

top surface of the hearth to the absolute bottom of the appliance of 18mm (see figure

1). The hearth must be at least 700mm wide x 300mm deep. The non-combustible

hearth material must be at least 12mm thick. Its top surface should be preferably

50mm above floor level to discourage the placing of carpets or rugs over it.

If the appliance is not installed with a hearth meeting the above conditions, the

minimum distance from the top surface of the finished floor covering (including any

carpet etc.) to the absolute bottom of the appliance must be at least 40mm (see

figure 1).

2.12 A hole 152mm (6in) is required through the wall for the flue unit.

Graph 1. Combustible shelf clearances.

INSTALLER’S GUIDE

Page 8

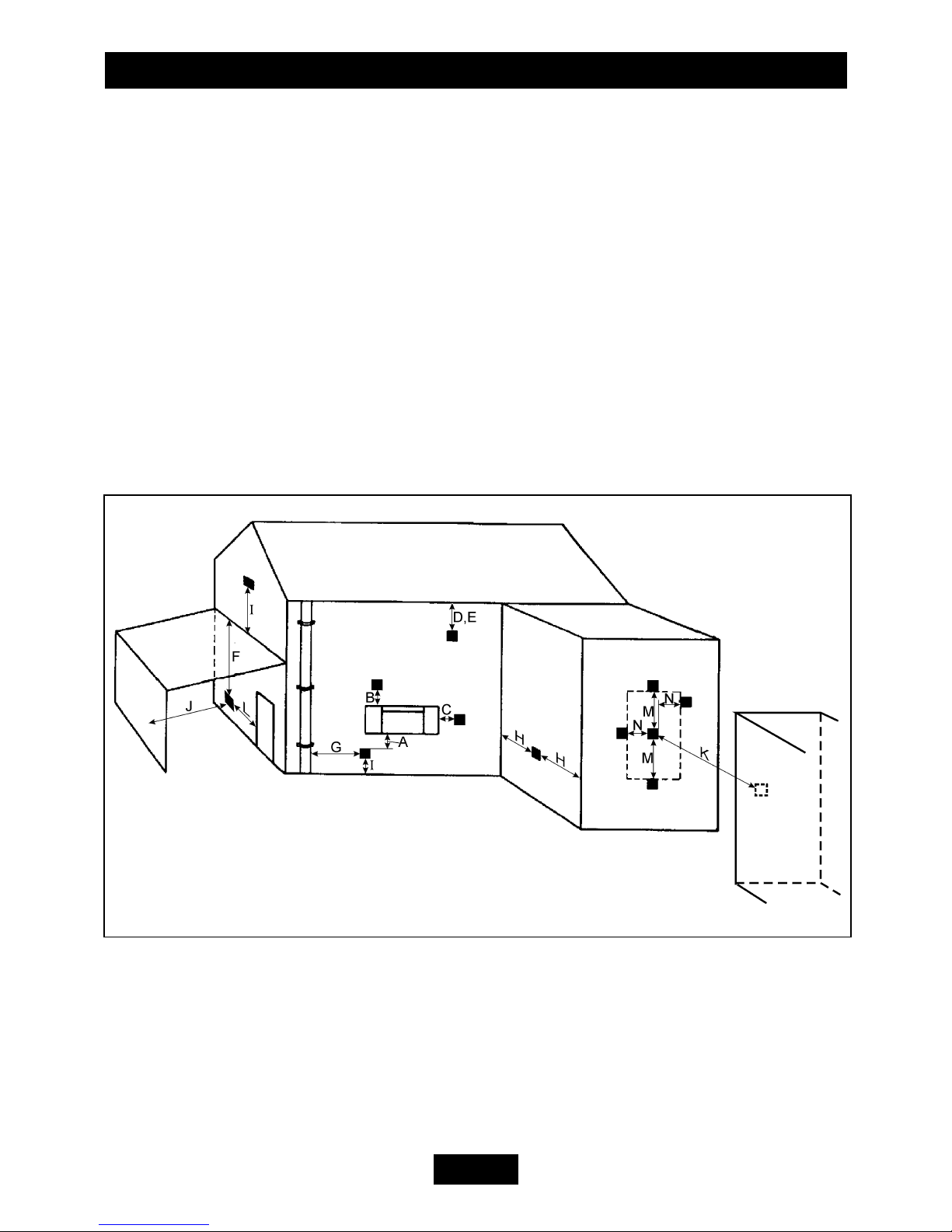

Figure 2 Terminal Positions

The minimum height of the hole centre is shown in figure 1 and on the wall fixing

template.

2.13 Minimum allowable distances from the terminal are shown in table 1 and

figure 2: -

2.14 In England and Wales the Building Regulations require a terminal guard to be

fitted if the terminal could come into contact with people near the building or be

subject to damage.

Fitting a terminal guard is recommended where contact with or damage to the

terminal is possible even if regulations do not demand it.

A suitable guard is supplied with this fire.

2.15 No special ventilation bricks or vents into the room containing the appliance

are required.

INSTALLER’S GUIDE

Page 9

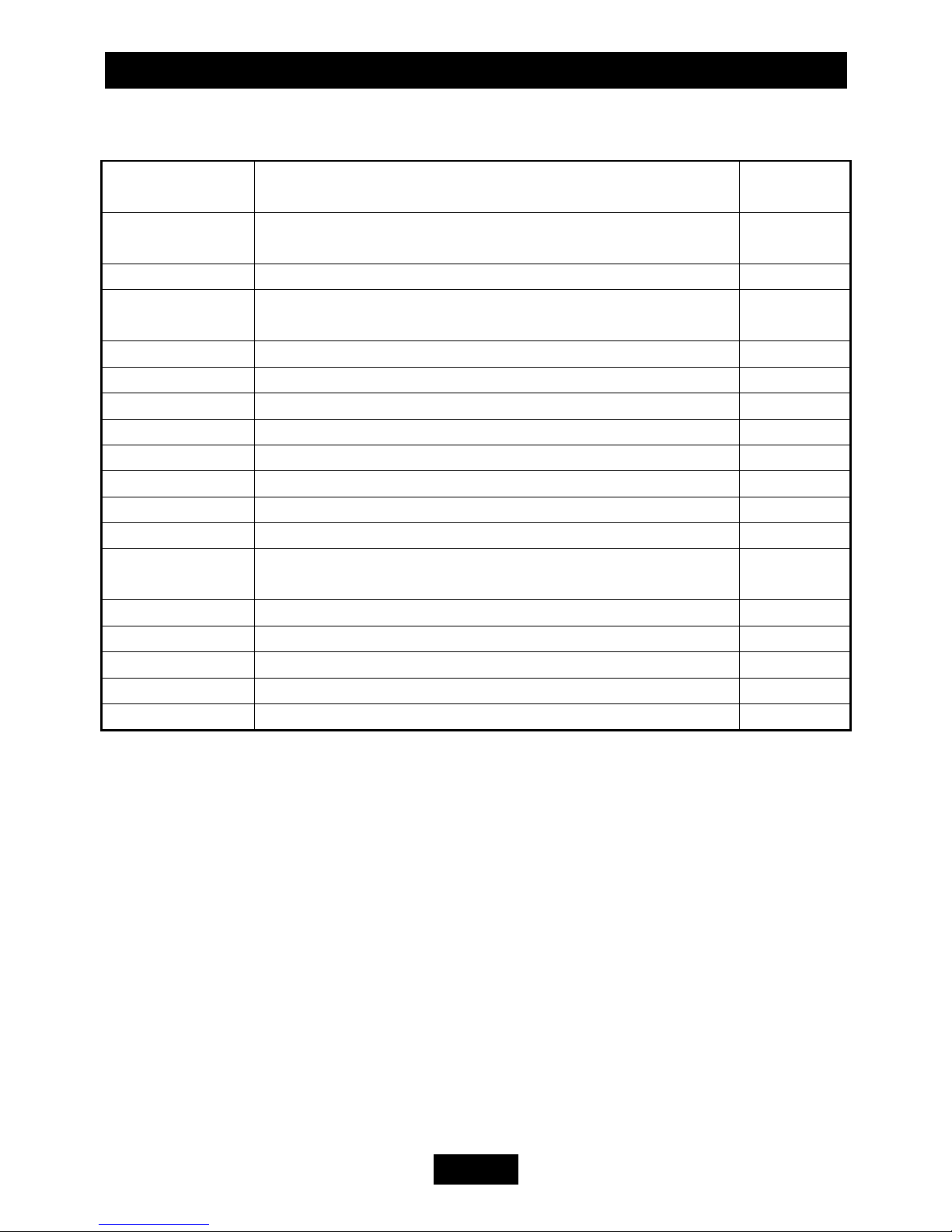

Table 1.

Dimension

(See figure 2)

Terminal Position Minimum

Distance

A* Directly below an opening, air brick, opening

window etc.

300mm

B* Above an opening, air brick, opening window etc. 300mm

C* Horizontally to an opening, air brick, opening

window etc.

300mm

D Below gutters, soil pipes or drain pipes 300mm

E Below eaves 300mm

F Below balconies or car port roof 600mm

G From a vertical drain pipe or soil pipe 300mm

H From an internal or external corner 600mm

I Above ground, roof or balcony level 300mm

J From a surface facing the terminal 600mm

K From a terminal facing the terminal 600mm

L From an opening in a car port (e.g. door, window)

into dwelling

1200mm

M Vertically from a terminal on the same wall 1500mm

N Horizontally from a terminal on the same wall 300mm

O From the wall on which the terminal is mounted N/A

P From a vertical structure on the roof N/A

Q Above intersection with roof N/A

*In addition, the terminal should not be nearer than 300mm to an opening in the

building fabric formed for the purpose of accommodating a built-in element such as

a window frame or door frame. See figure 3.

Loading...

Loading...