Valor BR417 VA Installer's Manual

600B702/06

INSTALLER GUIDE

AS SUPPLIED, THIS APPLIANCE IS FOR USE WITH NATURAL GAS

(G20). WHEN CONVERTED USING VALOR CONVERSION KIT

NO.0591149 THIS APPLIANCE IS FOR USE WITH PROPANE GAS (G31)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND

THE REPUBLIC OF IRELAND (IE) ONLY.

We trust that this Installer Guide gives sufficient details to enable the appliance to

be installed and maintained satisfactorily. However, if further information is

required, our Valor Technical Helpline will be pleased to help.

Please telephone 08706 061 065 (National call rates apply).

INSTALLER: Please leave this guide with the owner

Valor Heating, Erdington, Birmingham B24 9QP

www.valor.co.uk

Because our policy is one of constant development and improvement, details may vary

slightly from those given in this publication.

© Valor Heating

MODEL BR417 VA

(G.C.32-032-07)

Inset Live Fuel Effect

Gas Fire

with

Ultimate

Front

INSTALLER’S GUIDE

Page 2

CONTENTS

1 SAFETY ......................................................................................................................3

2 ACCESSORY LIST ...................................................................................................3

3 APPLIANCE DATA ..................................................................................................4

4 GENERAL INSTALLATION REQUIREMENTS ................................................5

5 UNPACKING & PRE-INSTALLATION PREPARATION .............................. 10

5.1 Unpacking ............................................................................................................ 10

5.2 Ignition Spark Check............................................................................................. 11

5.3 Fireplace Condition Check .................................................................................. 11

6 GAS SUPPLY CONNECTION ............................................................................. 12

7 PREPARING APPLIANCE FOR INSTALLATION ......................................... 13

7.1 The Flue Restrictor .............................................................................................. 14

7.2 Fitting the Foam seal............................................................................................ 14

8 CONVECTION BOX INSTALLATION.............................................................. 15

Method (1) - Front Fixing to Fireplace Surround ......................................................... 15

Method (2) - Cable Retention and Floor Fixing ........................................................... 16

Sealing Floor Front........................................................................................................ 18

9 BURNER, FRONT SURROUND& SUPPLY PIPE INSTALLATION ............ 18

9.1 Burner & Supply Pipe Installation....................................................................... 18

9.2 Preliminary Burner Checks.................................................................................. 18

9.3 Reference Pressure Check..................................................................................... 19

10 FITTING THE CERAMICS.................................................................................. 20

11 FULL OPERATING CHECKS ............................................................................. 22

11.1 Recheck Control Settings..................................................................................... 22

11.2 Check For Spillage............................................................................................... 23

11.3 Flame Supervision & Spillage Monitoring System............................................. 24

12 FINAL REVIEW..................................................................................................... 24

13 SERVICING & PARTS REPLACEMENT ......................................................... 26

13.1 To Replace Burner Plaques.................................................................................. 26

13.2 To Remove the Front Surround ........................................................................... 27

13.3 To Remove the Complete Burner Unit ................................................................ 28

13.4 To Remove the Pilot Unit .................................................................................... 28

13.5 To Remove the Control Tap. ............................................................................... 28

13.6 To Remove the Piezo Generator.......................................................................... 29

13.7 To Grease the Control Tap................................................................................... 29

13.8 To Remove the Main Burner Injector.................................................................. 29

13.9 To Remove the Appliance From The Fireplace .................................................. 29

SHORT LIST OF SPARES............................................................................................ 30

INSTALLER’S GUIDE

Page 3

1 SAFETY

Installer

• Before continuing any further with the installation of this appliance please read the

following guide to manual handling

• The lifting weight of this appliance is 12.95 kg. One person should be sufficient to lift

the fire. If for any reason this weight is considered too heavy then obtain assistance.

• When lifting always keep your back straight. Bend your legs and not your back.

• Avoid twisting at the waist. It is better to reposition your feet.

• Avoid upper body/top heavy bending. Do not lean forward or sideways whilst

handling the fire.

• Always grip with the palm of the hand. Do not use the tips of fingers for support.

• Always keep the fire as close to the body as possible. This will minimise the

cantilever action.

• Use gloves to provide additional grip.

• Always use assistance if required.

2 ACCESSORY LIST

The following accessories are available: -

Description Part Number

LPG Conversion kit 0591149

INSTALLER’S GUIDE

Page 4

3 APPLIANCE DATA

This product uses fuel effect pieces, burner compartment rear wall and gaskets containing

Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres. Excessive

exposure to these materials may cause irritation to eyes, skin and respiratory tract.

Consequently, it is important to take care when handling these articles to ensure that the

release of dust is kept to a minimum. To ensure that the release of fibres from these RCF

articles is kept to a minimum, during installation and servicing we recommend that you

use a HEPA filtered vacuum to remove any dust and soot accumulated in and around the

fire before and after working on the fire. When replacing these articles we recommend that

the replaced items are not broken up, but are sealed within a heavy duty polythene bag,

clearly labelled as RCF waste. This is not classified as “hazardous waste” and may be

disposed of at a tipping site licensed for the disposal of industrial waste. Protective

clothing is not required when handling these articles, but we recommend you follow the

normal hygiene rules of not smoking, eating or drinking in the work area and always wash

your hands before eating or drinking.

This appliance does not contain any component manufactured from asbestos or asbestos

related products.

The appliance data label is on a plastic tie below the burner and is visible when the

bottom front cover is removed.

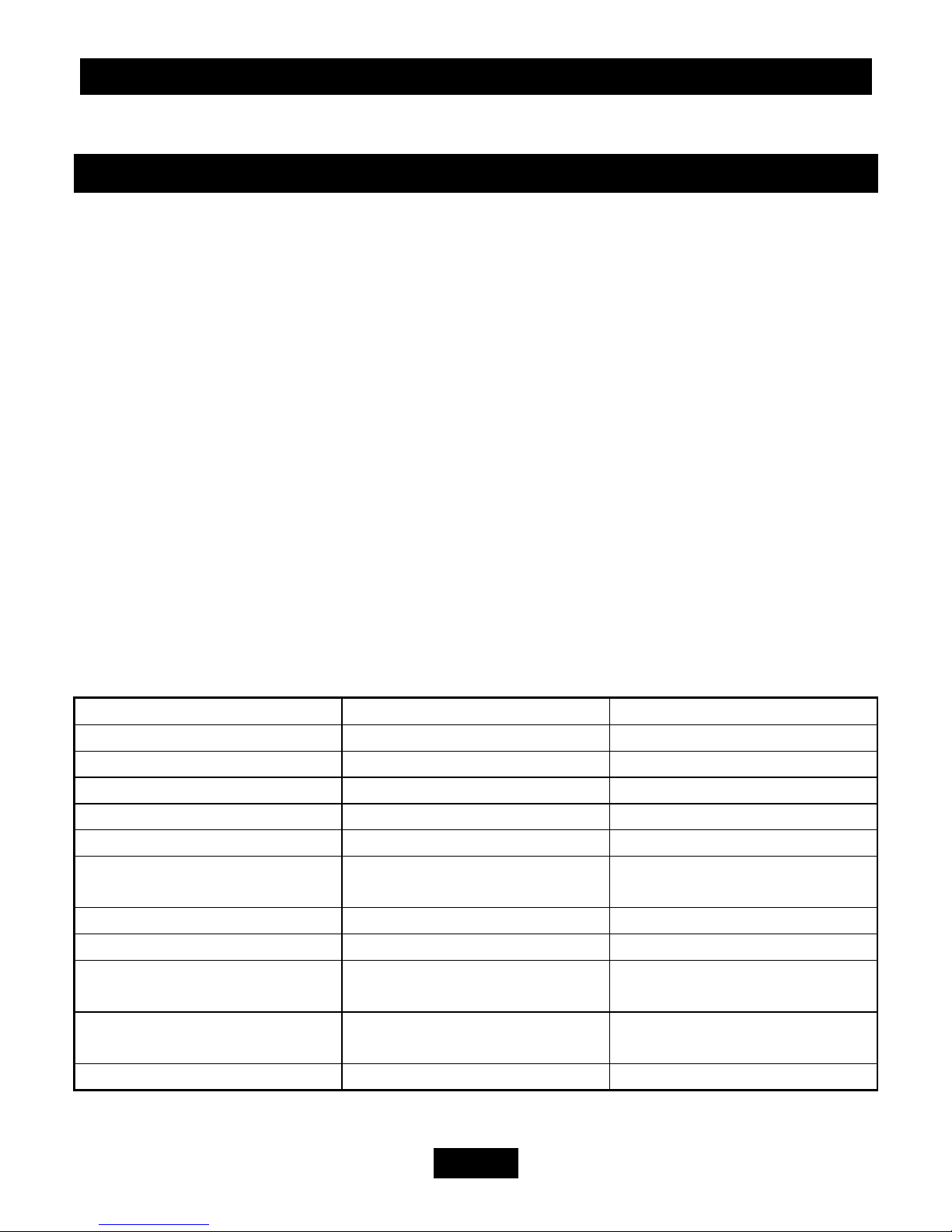

Gas Natural (G20) Propane (G31)

★★★★

Inlet Pressure 20mbar 37mbar

Input - Max. (Gross) 6.0kW (20,500Btu/h) 6.1kW (20,800Btu/h)

Input - Min. (Gross) 2.2kW (7500Btu/h) 3.6kW (12280Btu/h)

Output - Max. 3.5kW (11,900Btu/h) 3.6kW (12,280Btu/h)

Output - Min 1.1kW (3750Btu/h) 1.8kW (6140Btu/h)

Burner Test Pressure (Cold) 18.2 ± 0.75mbar

(7.3 ± 0.3in w.g.)

35.6 ± 0.75mbar

(14.3 ± 0.3in w.g.)

Gas Connection 8mm pipe 8mm pipe

Burner Injector Bray Cat. 18 Size 360 Bray Cat. 15 Size 170

Pilot & Atmosphere Sensing

Device

SIT Ref. NGOP9030 SIT Ref. OPLPG9222

Ignition Piezo Electric. Integral with

Gas Tap

Piezo Electric. Integral with

Gas Tap

Aeration Non-adjustable Non-adjustable

★★★★

When converted using Kit 0591149.

INSTALLER’S GUIDE

Page 5

4 GENERAL INSTALLATION

REQUIREMENTS

4.1 The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas appliances are

installed by competent persons in accordance with the current edition of the Gas Safety

(Installation and Use) Regulations. Failure to install the appliance correctly could lead to

prosecution. The Council for the Registration of Gas Installers (CORGI) requires its

members to work to recognised standards.

In the United Kingdom the installation must also be in accordance with:

All the relevant parts of local regulations.

All relevant codes of practice.

The relevant parts of the current editions of the following British Standards:BS 715

BS 1251

BS 1289 Part 1

BS EN 1806

BS 4543 Part 2

BS 5440 Part 1

BS 5440 Part 2

BS 5871 Part 1

BS 6461 Part 1

BS 6891

In England and Wales, the current edition of the Building Regulations issued by the

Department of the Environment and the Welsh Office

In Scotland, the current edition of the Building Standards (Scotland) Regulations issued

by the Scottish Executive.

In Northern Ireland, the current edition of the Building regulations (Northern Ireland)

issued by the Department of the Environment for Northern Ireland.

In the republic of Ireland the installation must also conform to the relevant parts of:

a) The current edition of IS 813

b) All relevant national and local rules in force.

4.2 If the appliance is intended to be installed to a chimney that was previously used

for solid fuel, the flue must be swept clean prior to installation. All flues should be

inspected for soundness and freedom from blockages.

4.3 Any chimney dampers or restrictors should be removed. If removal is not possible

they must be fixed in the open position.

4.4 In the United Kingdom (GB) special ventilation bricks or vents are not normally

required in the room for this appliance.

In the Republic of Ireland (IE), permanent ventilation must comply with the regulations

currently in force.

INSTALLER’S GUIDE

Page 6

Figure 1. Installation Requirements

INSTALLER’S GUIDE

Page 7

4.5 Note that soft wall coverings (e.g. embossed vinyl, etc.) are easily affected by heat.

They may scorch or become discoloured when close to a heating appliance. Please bear

this in mind when installing.

4.6 The minimum allowable distance to a corner wall from the outside edge at either

side of the front surround is 178mm. See figure 1.

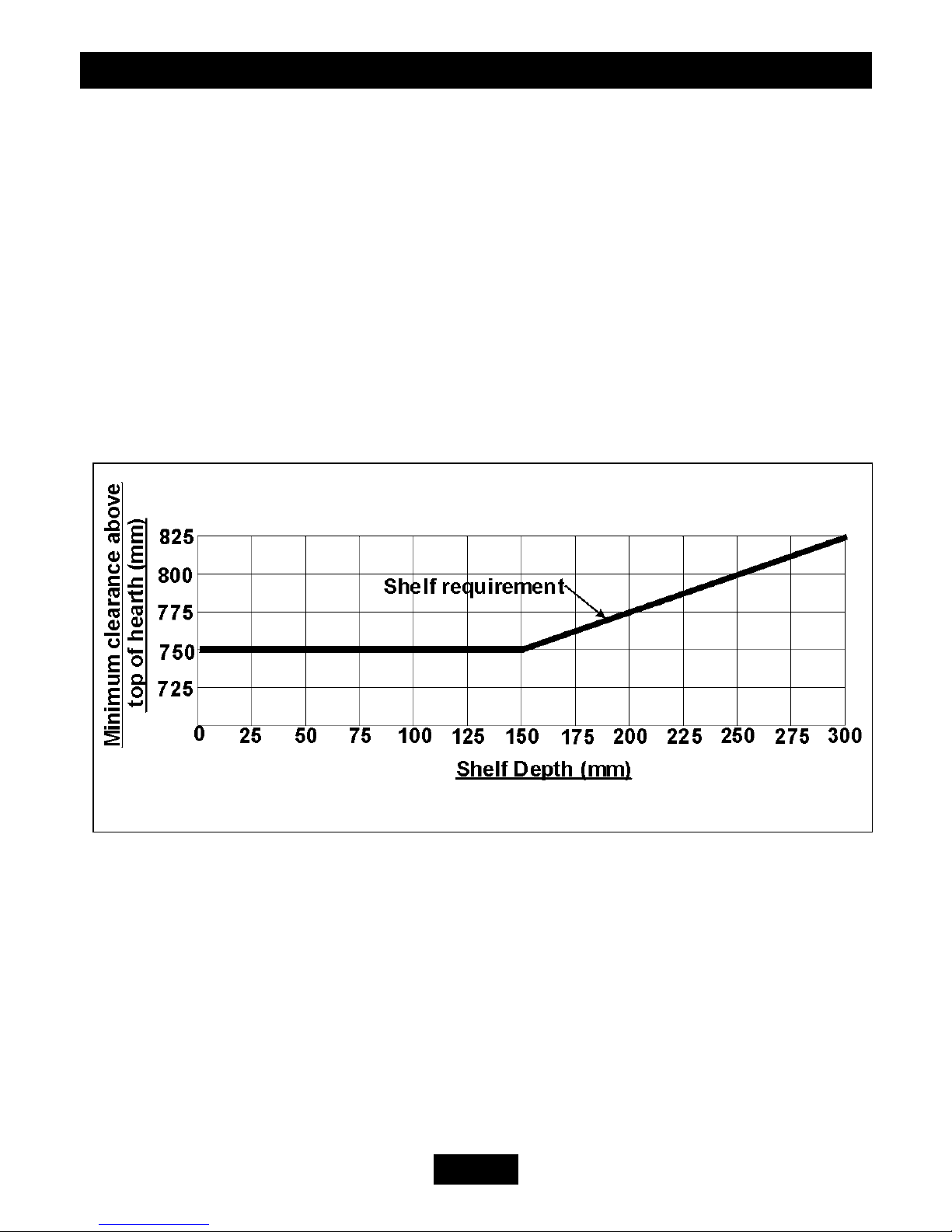

4.7 The minimum height from the top surface of the hearth to the underside of any

shelf made from wood or other combustible materials is as follows: -

• For a shelf up to 150mm deep

Minimum height = 750mm.

• For a shelf deeper than 150mm

Minimum height = 750mm + 12.5mm for every 25mm depth over 150mm.

(See Graph1).

4.8 The appliance must not be installed in any room, which contains a bath, or shower

or where steam is regularly present.

4.9 In the United Kingdom this appliance can be installed in the following situations: -

4.9.1 To a fireplace complete with surround and hearth complying with B.S 1251. The

required fireplace, hearth, debris catchment area and clearance dimensions are shown in

figure 1.

4.9.2 To a fireplace incorporating a twin walled metal flue box complying with the

constructional requirements of the current edition of BS 715 and standing on a noncombustible base. The dimensions of the flue box must conform to the opening shown in

figure 1. For flue details see section 4.10.

Graph 1. Clearances to combustible shelves

INSTALLER’S GUIDE

Page 8

4.9.3 To a fireplace that has a precast concrete or clay flue block system conforming to

BS1289 or BS EN 1806. The appliance is suitable for installations conforming to older

versions of BS1289 as well as the current edition. The flue blocks must have a minimum

width not less than 63mm and a cross-sectional area not less than 13,000mm

2

.

Older

editions of BS1289 required a cross-sectional area of 13,000mm2. The current revision of

the standard requires 16,500mm2. This appliance is suitable in both cases. The total depth

of the opening measured from the finished front of the fireplace (Including plaster,

surround etc) must be not less than 100mm.

The current version of BS1289 recommends that there should be an air space or

insulation between the flue blocks and the plaster because heat transfer may cause

cracking on directly plastered flues. However, generally this appliance is suitable for

installations under all circumstances unless there is a history of cracking problems.

Remember that faults such as cracking may be caused by poorly built and restrictive

flues, e.g. mortar extrusions, too many bends, flue heights below three metres, restrictive

terminations, etc.

4.9.4 To a builder’s opening within the dimensions shown in figure 1.

4.9.5 If the fireplace opening is greater than the acceptable dimensions given in this

guide, do not use the back of a fire surround or marble to reduce the opening. This

may cause cracking of the surround back or marble.

4.10 Suitable flues and minimum flue sizes are as follows: -

• 225mm x 225mm conventional brick flue.

• 175mm diameter lined brick or stone flue.

• 200mm diameter factory made insulated flue manufactured to BS 4543.

• 175mm diameter flue pipe (see B.S. 6461 part 1 for suitable materials).

• Single wall, twin wall or flexible flue liner of minimum diameter 125mm. The

materials to be used are stainless steel or aluminium as specified in B.S. 715.

• A properly constructed precast concrete or clay flue system conforming to BS1289 or

BS EN 1806.

It should be noted that, sharp bends or horizontal runs in metal flues at the top of the

system could be a cause of problems in these types of installation.

4.10.1 The minimum effective height of the flue must be 3m.

4.10.2 The flue must be completely sealed so that combustion products do not come

into contact with combustible materials outside the chimney.

4.10.3 The flue must serve only one fireplace.

4.10.4 Proprietary terminals must comply with BS 715 or BS 1289. Any terminal or

termination must be positioned in accordance with BS 5440 Part 1 to ensure that the

products of combustion can be safely dispersed into the outside atmosphere. Where the

appliance is connected to an unlined brick chimney it is generally unnecessary for the

chimney pot to be replaced or for a terminal to be fitted unless the flue has a diameter

INSTALLER’S GUIDE

Page 9

smaller than 170mm.

4.11 If the fireplace opening is an underfloor draught type, it must be sealed to stop any

draughts.

4.12 The appliance must be mounted behind a non-combustible hearth (n.b conglomerate

marble hearths are considered as non-combustible). The appliance can be fitted to a

purpose made proprietary class “O” 150°C surround. The hearth material must be at least

12mm thick. The periphery of the hearth (or fender) should be at least 50mm above floor

level to discourage the placing of carpets or rugs over it.

The surface of the hearth must be sufficiently flat to enable the bottom of the front

surround, the burner bracket and the bottom front cover casting to be aligned

horizontally. Any excessive unevenness (uneven tiles, Cotswold stone, etc.) should be

rectified.

The appliance must not stand on combustible materials or carpets.

The appliance must not be fitted directly against a combustible wall. If the appliance

is to be fitted against a wall with combustible cladding, the cladding must be removed

from the area covered by the outer surround (See figure 1). We suggest that the actual

surround is used as a template to mark the area for combustible cladding removal.

4.13 The front face of the fireplace should be reasonably flat over the area covered by the

convection box top and side flange seals to ensure good sealing. These faces should be

made good if necessary.

The fireplace floor should be reasonably flat to ensure that a good seal with the convection

box can be made (See figure 15).

4.14 An extractor fan may only be used in the same room as this appliance, or in any

area from which ventilation for the appliance is taken, if it does not affect the safe

performance of the appliance. Note the spillage test requirements detailed further on in

this manual. If the fan is likely to affect the appliance, the appliance must not be installed

unless the fan is permanently disconnected.

4.15 Propane gas appliances must not be installed in a room, which is built entirely

below ground level (See BS 5871 Part 2).

Loading...

Loading...