Valor APR-101012 Series, APR-60021012 User Manual

Page 1 of 14

1-Box

labeled EXTENSION ARMS

1-Box

labeled LEFT WALL BRACKET ASSEMBLY

1-Box

labeled RIGHT WALL BRACKET ASSEMBLY

1-Box

labeled GEAR MECH. & Support Bracket

1-EA

180 cm Roller Tube, w/Square Drive

1-EA

180 cm Roller Tube, w/Round Drive

1-EA

50 mm Roller Tube Joiner

1-EA

180 cm Valance Tube, drilled left

1-EA

180 cm Valance Tube, drilled right

1-EA

50 mm Valance Tube Joiner, drilled

3-PCS

372cm Plastic Spline (coiled)

1-BAG

Bubble Bag, labeled MISC. PARTS, includes:

-2-Wrist Assemblies

-2-Position Poles

-Level

-6-Spline Stops

-Right & Left Valance Tube End Caps

-2-Bags of 4-1/2” x3” Sleeve Anchors

1-EA

160 cm Crank Handle

WARNING:

DO NOT CUT THE PLASTIC ZIP TIES ON THE AWNING EXTENSION ARMS UNTIL INSTRUCTED TO

DO SO IN THIS GUIDE. THE FOLDING ARMS ARE UNDER SPRING TENSION AND SHOULD NOT BE

CUT UNTIL THE AWNING IS FULLY ASSEMBLED AND INSTALLED ON THE WALL.

RETRACTABLE PATIO SHADE AWNING

Patio Awning Guide-10ft. x12ft.(Proj. X Width)

Model: APR-101012***/APR-60021012 (version: GEN2-V1)

1. INTRODUCTION:

Thank you for purchasing a Retractable Shade Awning. Before proceeding, please ensure that all the parts are in

the box, as listed below:

Master Carton Contents:

In the event that there is ANY part missing or damaged, please DO NOT RETURN THE PRODUCT TO YOUR

RETAILER. By returning the product to your retailer we can not assist you in getting your awning properly installed.

Call our TOLL FREE Customer Service Hotline at 1-888-875-4844 for parts or replacement of parts that may have

been damaged when shipped.

You may also go to our website at www.valor.ca in the Valor Shade/Patio Awning section for all assembly and

installation instructions, set up, adjustment, and troubleshooting instructions. There you will be able to see common

problems and how to rectify them usually with a simple adjustment. You may also use this section to email us your

questions, and during business hours between 9:00 AM and 4:00 PM EST you will be able to connect with a

customer service representative for assistance.

2. PRODUCT:

The Valor / Severe Weather™ Shade Awning is a unique program that allows you to order awnings that are modular

in design making them easier to transport home. The product is offered with your choice of several available patterns

(sold separately). The product is factory configured with Left Side operation (when facing the house), but can be

converted to right side operation by following the steps outlined in this guide.

IMPORTANT WARNING:

Your new awning is intended as protection against the sun only. It is not to be used during periods of strong

wind, rain, hail, or snow. The warranty will not cover use during these periods. Bird droppings, pine needles,

and various air born materials that may settle on your awning; awning fabric should be cleaned using water

and a light soap. No abrasive cleansers or harsh chemicals should be used on the fabric. Damage to the

Awning (including the fabric) from any foreign material is not covered under our warranty.

GEN2-V1 12ft-Instructions (Severe Weather) doc:r1

Page 2 of 14

Drill

Philips screwdriver

1/2” Carbide (Masonry) drill bit

Level

5/8” Socket, Wrench or Adjustable Wrench

Plumb line

18mm Wrench or Adjustable Wrench

Tape Measure

Metric Allen keys 5mm, 6mm, 8mm, 10mm

Square

9/16” Socket, Wrench or Adjustable wrench

Pencil

Hammer/Mallet

3. INSTALLATION TOOLS REQUIRED:

4. ADDITIONAL MATERIAL / HARDWARE REQUIREMENTS:

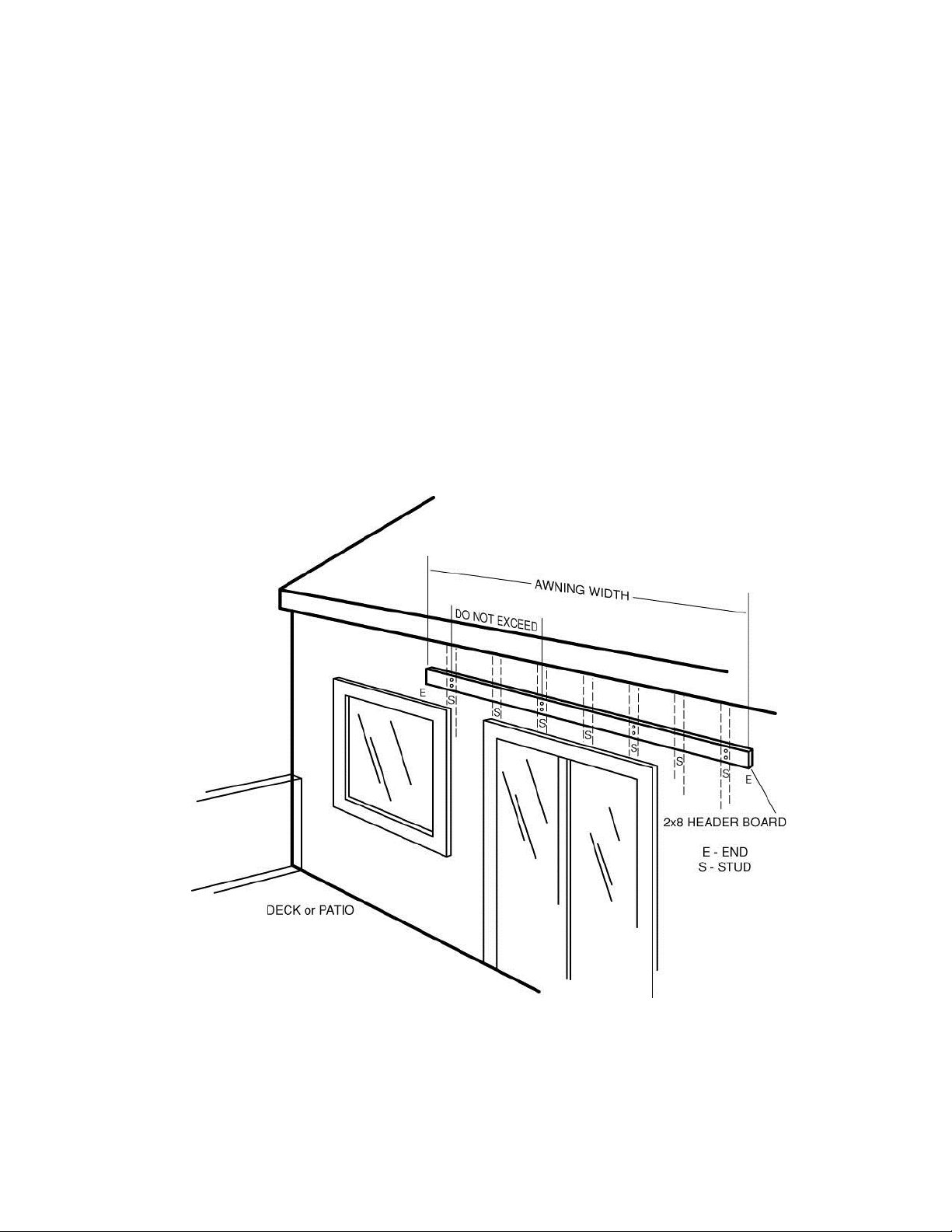

In the event that a Header board is required, you will require a 2x8” the same total length of the awning.

Go to “House Preparation” to determine if a Header Board is required for your installation.

The following outlines the additional mounting hardware that will be required for the various

header mounting installation methods.

8 pieces of a ½” x 2” Wood Screw & Washer to mount the Awning Wall Brackets to the

Header board.

OR, for superior holding power you may choose to use a ½” x 4” Sleeve Bolt, which

will require drilling a ½” hole through the header and continue to drill a minimum of

another 2-3/4” depth with a carbide (masonry) drill bit. This will

essentially use the header board to provide the level surface for

the awning but will use the greater strength of the masonry wall

for holding power. You may contact our office for technical

information pertaining to available fasteners. (Sleeve Bolt show to

the right)

If mounting the Header on Brick, Stone or Concrete:

One of the following; expansion bolts with a minimum 3-1/4” depth OR 3/8” lag bolts a minimum length of 3-1/4”, with

lag shields (which may require a 5/8” hole drilled in the brick).

For either of these options, you will need enough to install on the top and bottom of the header with maximum

spacing of 24” or less.

If mounting the Header on Solid Wood Siding or Stucco:

You will need to locate the studs and locate 3/8” Lag Bolts long enough to penetrate the Header board, siding, any

insulation and grab at least 2” of the wall studs. Due to the weight of the awning and the forces applied to it

when operating it is critical that the lag bolts be installed into studs.

You will need enough lag bolts to install on the top and bottom of the header with maximum spacing of 24” or less.

For technical information regarding fasteners, go to www.uncanfast.com

GEN2-V1 12ft-Instructions (Severe Weather) doc:r1

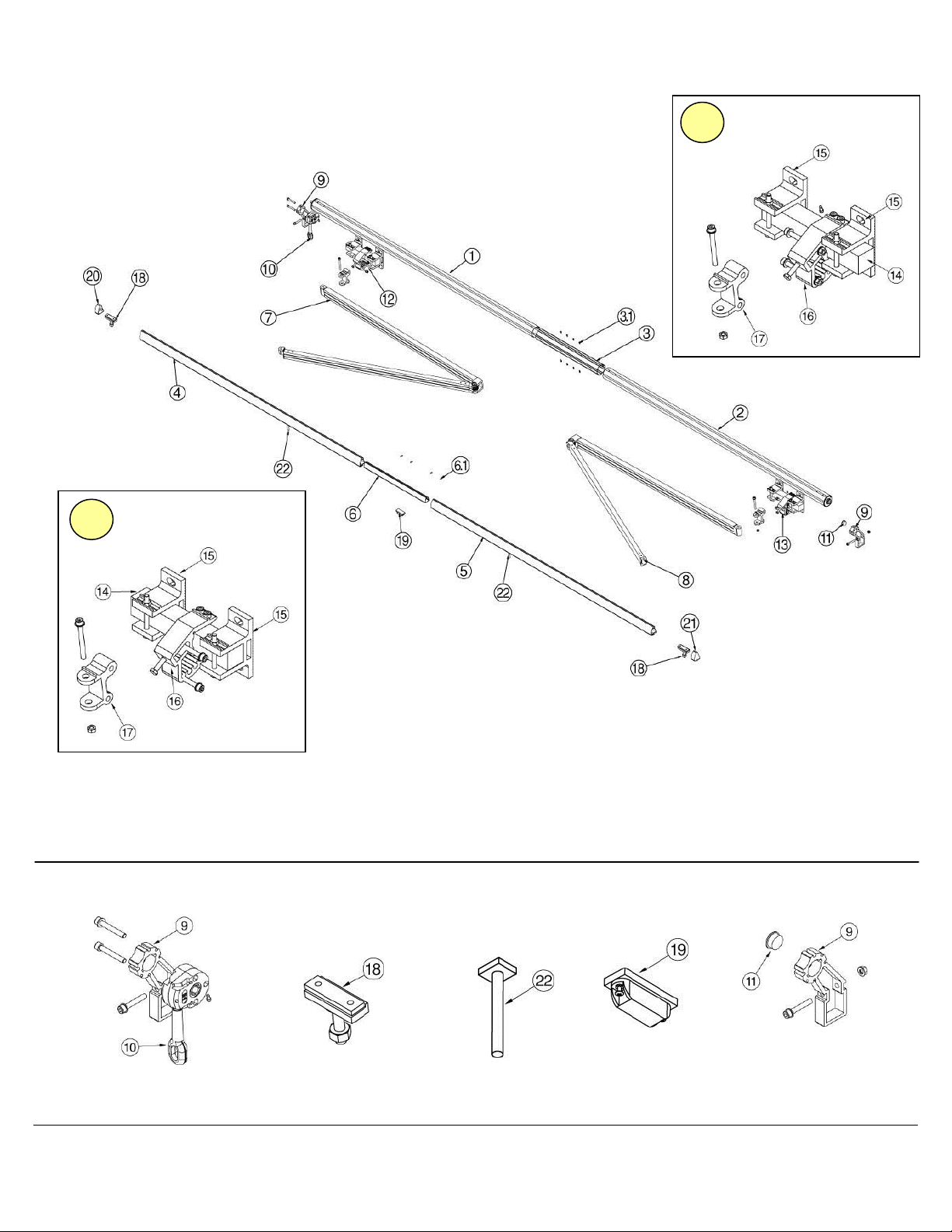

5. RETRACTABLE AWNING SCHEMATIC DRAWING

12 LEFT BRACKET ASSEMBLY

13 RIGHT BRACKET ASSEMBLY

GEAR MECH. & ROLLER

TUBE SUPPORT BRACKET

ROLLER TUBE SUPPORT &

13

WRIST ASSEMBLY

12

POSITION POLE

LEVEL

Size: 10-ft Projection X 12-ft. Width

Diagram: Exploded View

Page 3 of 14

GEN2-V1 12ft-Instructions (Severe Weather) doc:r1

Item

Part No.

Description

Qty

1 Roller Tube w/Square Drive Tube End

1

2 Roller Tube w/Round Drive Tube End

1

3 Roller Tube Joiner

1

3.1

Roller Tube Joiner Fasteners (attached)

8

4 Valance Tube-LEFT Side

1

5 Valance Tube-RIGHT Side

1

6 Valance Tube Joiner

1

6.1

Valance Tube Joiner Fasteners (attached)

4

7 Extension Arm-LEFT Side

1

8 Extension Arm-RIGHT Side

1

9 Roller Tube Support

2

10 Gear Mechanism

1

11 Plastic Roller Tube Bushing

1

12

LEFT Bracket Assembly

Sub-components of Assembly:

1

14

40x40x240mm Torsion Bar (w/plastic end caps)

1

15

Wall Brackets(w/hardware)

2

16

Extension Arm Shoulder Bracket (w/hardware)

1

17

Extension Arm Pivot Mount (w/hardware)

1

13

RIGHT Bracket Assembly

Sub-components of Assembly:

1

14

40x40x240mm Torsion Bar (w/plastic end caps)

1

15

Wall Brackets(w/hardware)

2

16

Extension Arm Shoulder Bracket (w/hardware)

1

17

Extension Arm Pivot Mount (w/hardware)

1

18 Wrist Pin Assembly (w/hardware)

2

19 Valance Level (w/hardware)

1

20 Valance Tube End Cap-LEFT End

1

21 Valance Tube End Cap-RIGHT End

1

22 Position Poles

2

23 Manual Crank Handle (not shown in diagram)

1

24 Spline for Fabric (not shown in diagram)

3

25 ½”x 3” Sleeve Anchor Bolts (not shown in diagram)

8

26 Spline Channel Plugs (not shown in diagram)

6

6. PARTS LIST

Page 4 of 14

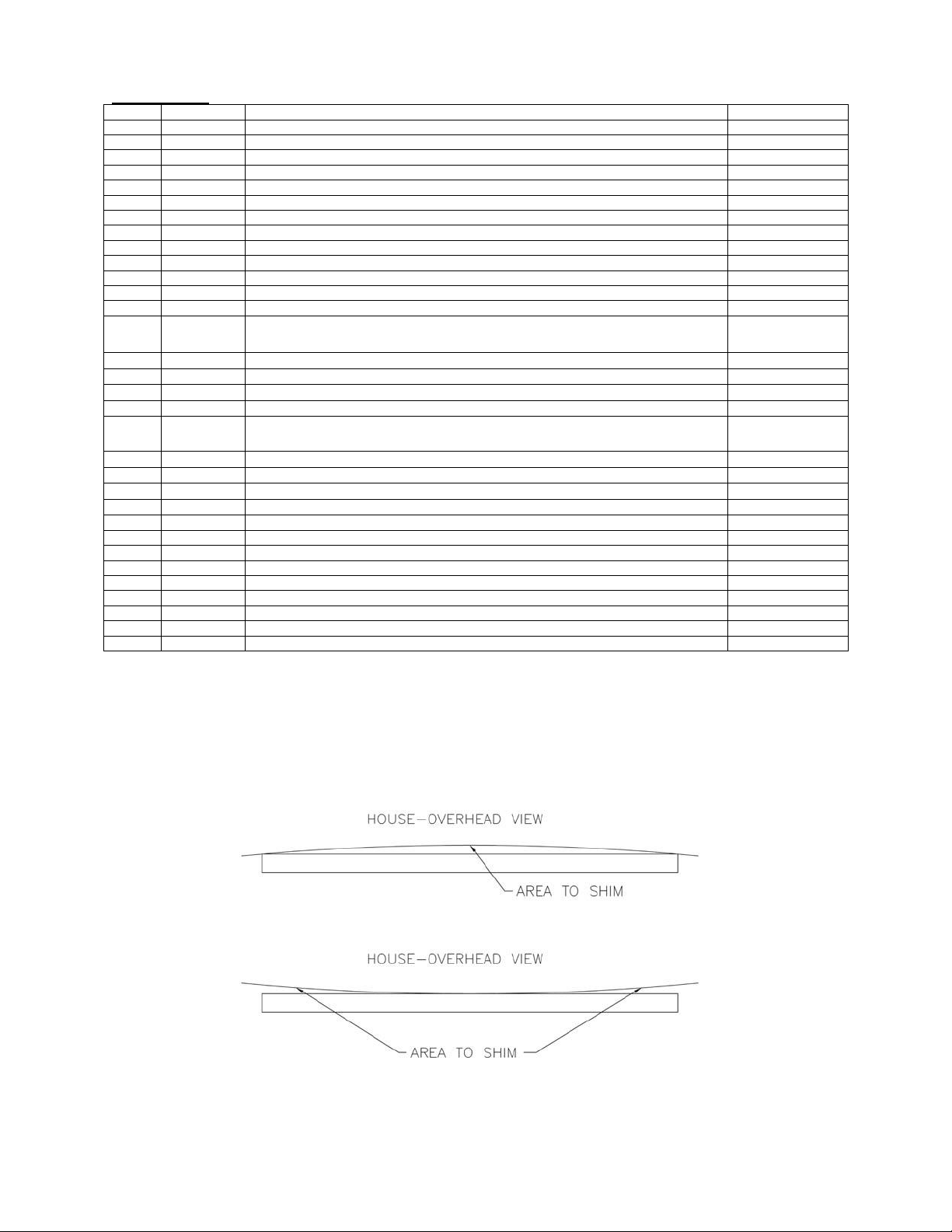

7. HOUSE PREPARATION:

Ensure that a smooth area exists for mounting the awning free from any obstructions, light fixtures, downspouts, etc.

Sight the wall and use a plumb line across the wall surface to see if there are any significant bows or sweeps in the

wall. In the event the wall surface is either a very rough brick which might keep the wall mounting brackets from

mounting level, or if the wall surface is very uneven a Header Board should be installed.

GEN2-V1 12ft-Instructions (Severe Weather) doc:r1

Page 5 of 14

If you decide its best to install a Header Board, we recommend a 2x8” board of spruce or fir material, we do not

recommend cedar unless you choose to lag through the header and into a solid surface such as brick, as this wood is

too soft and may not hold fasteners as well as a harder wood.

Be sure to add shims in the gaps behind the Header Board so it will continue to lay straight on the wall as its

mounting bolts are tightened.

You may choose to use pressure treated wood or clad the wood with aluminum or even paint it before mounting your

awning. For your 12ft. Awning which has a total actual width of 145.92in. / 3706.4mm, we recommend you cut your

header board to 146.00in./ 3708.4mm, although your bracket will fit on a 12ft. (144”) long board to ensure the product

can be properly mounted. Before mounting your header board you will need to determine the location of the awning.

Go to “Additional Material / Hardware Requirements” above for fastening options.

Non-Masonry Surface Installation:

As the awning is quite heavy and the forces put on the product when opened requires it to be firmly secured to the

structure. Therefore, for installation on any siding material we recommend a header board be installed. Wood lap

siding may have the header boards installed directly over the siding, provided is shimmed to be kept parallel to the

wall, and it must be secured directly into the studs; wall sheathing alone is NOT adequate for securing the load.

Go to “Additional Material / Hardware Requirements” above for fastening options.

Vinyl, Aluminum, or Steel Siding Installation:

If you’re installing on Vinyl, Aluminum or Steel siding, or any unsupported material, we recommend that the siding be

cut away and a header board should be mounted to the studs; the siding can then be trimmed around the header

boards and sealed with a caulking to ensure that it is water tight.

Go to “Additional Material / Hardware Requirements” above for fastening options.

8.

GEN2-V1 12ft-Instructions (Severe Weather) doc:r1

Loading...

Loading...