Valor 936TTN Installation And Owner's Manual

~!alor

Legend

stove

Model

936TTN

FREESTANDING DIRECT VENT

WALL

FURNACE

WITH

TOP VENT

For

use

with Natural

Gas

WARNING:

If

the information in this

manual is not followed exactly, a fire or

expiosion may result causing property

damage, personal injury or loss of life

-

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this

ar

any other appliance.

-

WHAT

TO

DO

IF

YOU

SMELL

GAS

9

Do

not try to light any appliance.

.

Do not touch any electrical switch; do not

use any phone in your building.

9

Immediately call your gas supplier from

2,

neighbor's phone. Follow the gas

supplier's instructions.

9

If you cannot reach your gas supplier, call

the fire department.

-

1ns:allation and service must

be

performed

by

a qualified installer, sewice agency

or

the gas

Please read this

manual

bef~re installing and

operating

the

stove.

This appliance is a

domestic room heating

appliance.

~t

mi;t

used for

purpose such as drying

clothes etc.

Vous pounez vous procurer un exernplaire en langue Franqaise de cette brochure chez votre

concessionaire.

60QA398K)l

Due to high temperatures, the appliance should Keep the appliance area well clear and free from

be located out of traffic and away from furniture combustible materials, gasoline and other

and draperies.

flammable vapors and liquids.

Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid bums or -clothing ignition.

Young children should be carefully supervised

when they are in the same room as the appliance.

Clothing or other flammable material should not

be placed on or near the appliance.

The glass and front frame must be put back in

place prior to operating the appliance if they have

been removed for

sewicing or cleaning.

Never operate with broken or damaged window

glass.

If the window is broken or damaged in any way,

it

must be replaced as a whole unit. Remove the

window as

described

in

the appliance preparation

section of this manual. Search inside and

adjacent to the appliance for any glass fragment.

Only the authorized

Valor replacement unit listed

in the repair parts

booklot

must be fitted - never

use

substitutes. Contact your dealer quoting the

appliance

model number.

This appliance should

be

installed and repaired

by a

qualified senrice person.

The appliance should

be

inspected before use

and at least annually by a professional service

person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

mate-ial, etc.

tt

is imperative that control

compartments, burners and circulating air

passageways of the appliance are kept clean.

Keep curtains, clothing, furniture and other

flammable

materials at least 36ins (90cm) from all

parts of the appliance and its vent system.

Never attempt to burn paper or any other material

in the appliance.

Keep the grill at back of the pedestal clear to

prevent obstruction of air flow to the appliance.

INTERRUPTlON

OF

GAS

SUPPLY; If ever there is

a break in the flow of gas through the supply

system to the appliance (For example, for repair

work in the supply system either inside or outside

your property), we recommend that the window

unit

Is removed before lighting the pilot. This will

allow any air which has become trapped in the

supply piping to escape without building up in

the firebox before the pilot will light. Wait until the

pilot flame is stable before refitting the window

but refit

it

before turning the control to any

position other than pilot ignition. Details of how

to remove the window are given in the preparation

for installation section of this manual.

The vent terminal on the outside wall must be

kept

free

from obstructions. The terminal is hot

during operation and requires a guard (Part

#235)

if

it

is accessible to any person. No objects

should be placed within

2

feet (60cm) of the vent

terminal.

During extreme weather conditions ensure that

the vent outlet is

free

from ice and snow before

attempting to light.

Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas

control which has been under water.

NOTE

When operating your new stove for the first time, some vapors may be released which may cause a slight odor and could

possibly set off any smoke detection alarms in the immediate vicinity. These vapors are quite normal on new appliances.

They are totally harmless

and

will disappear after a few hours use.

....

::::*:i.::~;~,:~~;~<.j:.:.~<X;.,i'i'i:i:;:"'..

"...

:.""

""

.......

:;.:

...,

..........

t'....

:

...........

.A,...

;

....

<.

...

:

gg~g28z~~~$~

,~~$~~~,IoNs~~;~;;~~.:

.:4r:::,

.........................

:.:;!;:$.:

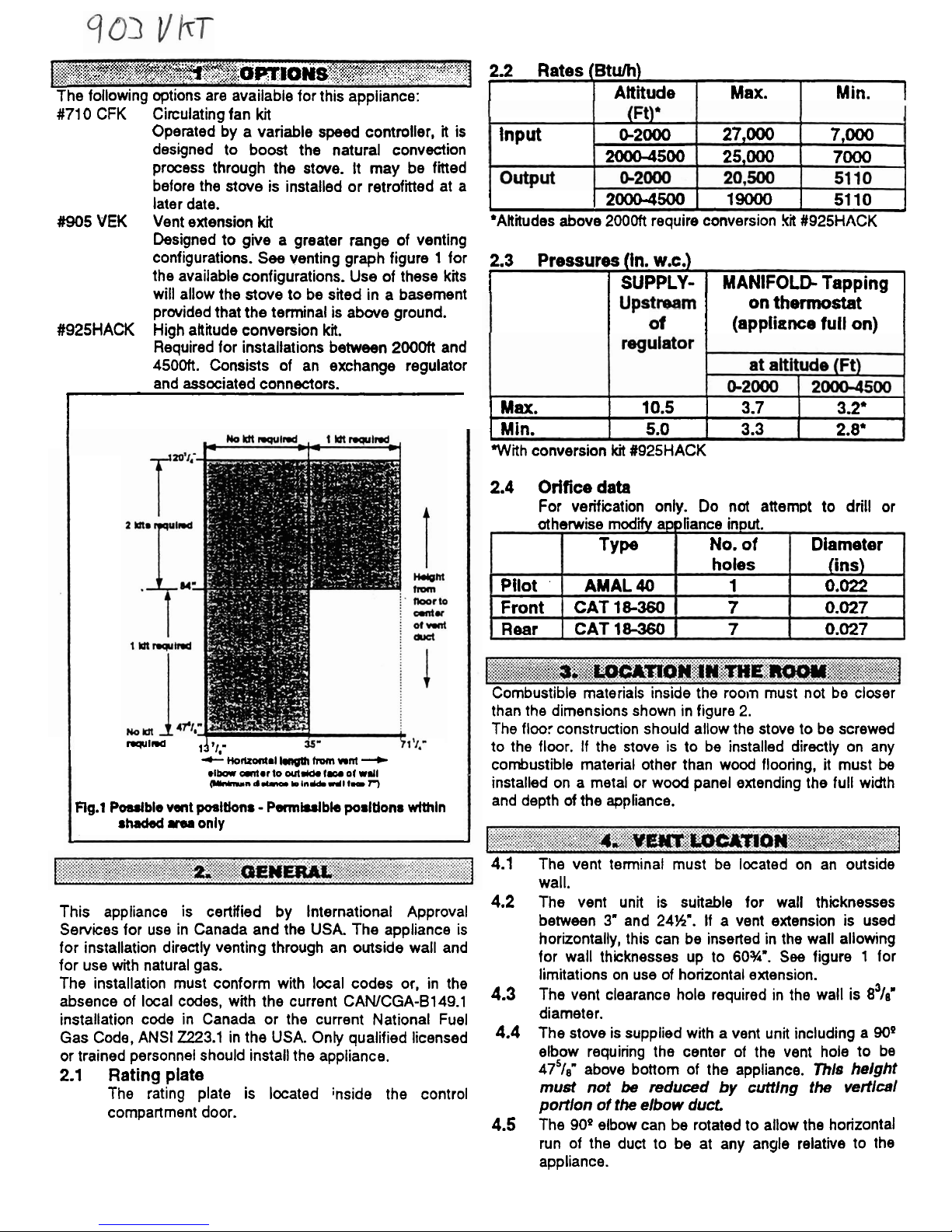

The following options are available for this appliance:

#710 CFK Circulating fan

kit

Operated by a variable speed controller,

it

is

designed to boost the natural convection

process through the stove.

It may be fitted

before the

stwe is installed or retrofitted at a

later date.

#905

VEK

Vent extension

kit

Designed to give a greater range of venting

configurations.

See

venting graph figure 1 for

the available configurations. Use of these

kits

will allow the stove to be sited in a basement

prwided that the terminal is abwe ground.

#925HACK High altitude conversion

ki.

Required for installations between

2000ft

and

4500ft. Consists of an exchange regulator

and associated connectors.

I

I=FJlna

14~1,-

*

Ho~al

fmm

nrd

-

eIba

marto

out&

fu

of

wdl

~nd.(mmln~dIlmaT)

Flg.1

Pdble

vent

posltlons - PwmhsJble

posltlons wlthln

shaded

m

only

This appliance is certified by International Approval

Services for use in Canada and the USA. The appliance is

for installation directly venting through an outside wall and

for use with natural gas.

The installation must conform with local codes or, in the

absence of local codes, with the current

CAWCGA-B149.1

installation code in Canada or the current National Fuel

Gas Code, ANSI

2223.1

in the USA. Only qualified licensed

or trained personnel should install the appliance.

2.1

Rating plate

The rating plate is located inside the control

compartment door.

2.2 Rates

(Btulh)

I

I

Altiiude

I

Max.

I

Min.

1

I

120004500

1

19000

1

5110

1

'Alitudes above 2000ft require conversion

kit

#925HACK

Input

2.3

Pressures (in.

w.c.)

I

I

SUPPLY- 1 MANIFOLD- Tapping

1

on thermostat

I

I

(appliance full on)

I

.

.

0-2000

20004500

I

MU.

I

10.5

1

3.7

I

3.2'

1

I

Min.

I

5.0

I

3.3 2.8'

With conversion

kit

#925HACK

27,000

25,000

2.4 Orifice data

For verification only. Do not attempt to drill or

7,000

7000

otherwise mdi appliance input.

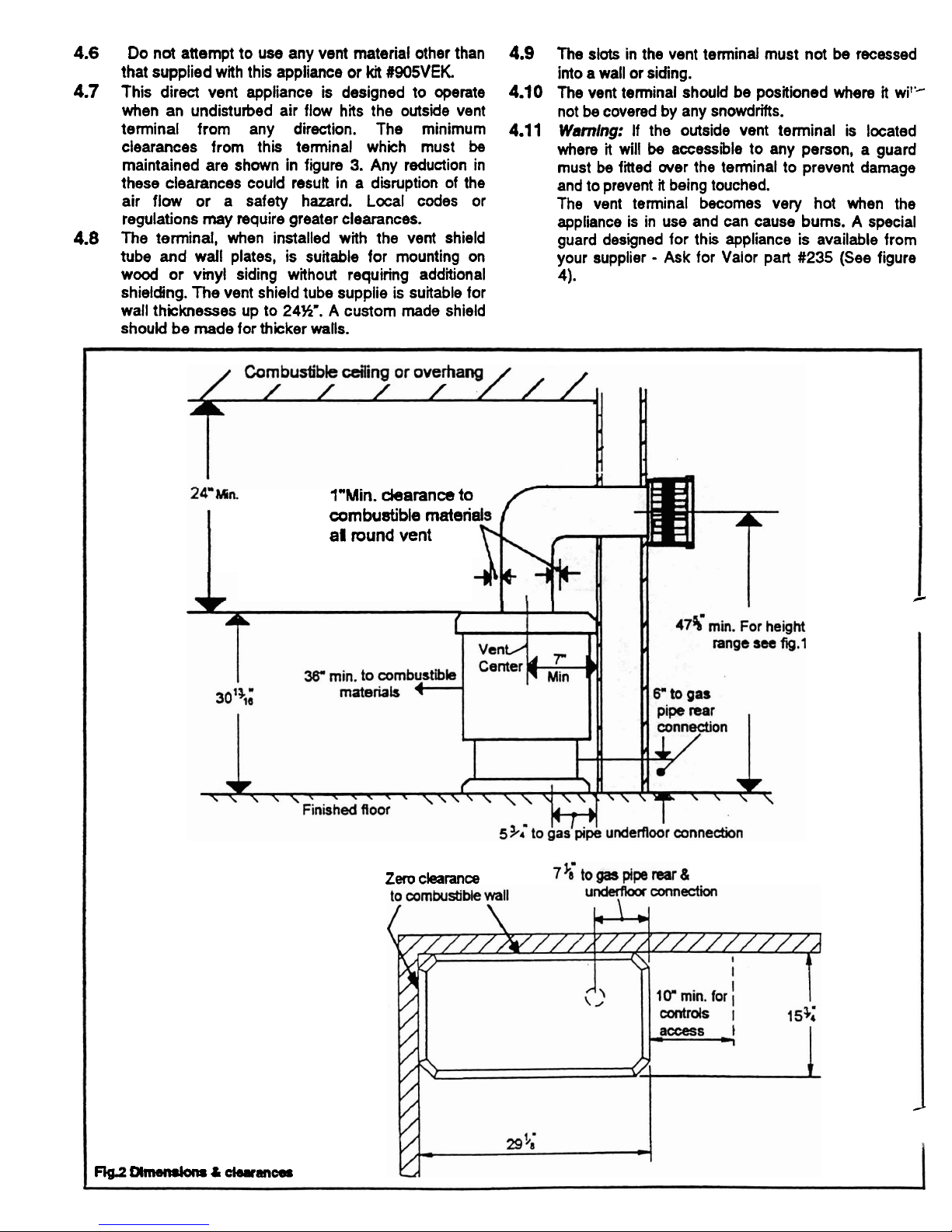

Combustible materials inside the rooln must not bo closer

than the dimensions shown in figure

2.

The floor construction should allow the stove to be screwed

to the

floor.

If

the stove is to be installed directly on any

combustible material other than wood flooring, it must

be

installed on a metal or wood panel extending the full width

and depth

of

the appliance.

Type

Pilot

'

Front

Rear

4.1

The vent terminal must be located on an outside

wall.

4.2

The vent unit is suit&le for wall thicknesses

between

3"

and

24%'.

If a vent extension is used

horizontally, this can be inserted in the wall allowing

for wall thicknesses up to 60%'.

See

figure 1 for

limitations on use of horizontal extension.

4.3

The vent clearance hole required in the wall is 8'/e9

diameter.

4.4

The stove is supplied with a vent unit including a 909

elbow requiring the center of the vent hole to be

475/8" above bottom of the appliance.

Thls

helght

must not

be

reduced

by

cutting

the

vertlcal

portlon of the

elbow

duct

4.5

The 909 elbow can be rotated to allow the horizontal

run of the duct to be at any

angle relative to the

appliance.

No. of

holes

AMAL40

CAT

18-360

CAT

18-360

Diameter

(ins)

1

7

7

0.022

0.027

0.027

4.6

Do not attempt to use any vent material other than

that supplied with this appliance or

kit

(1905VEK.

4.7

This direct vent appliance is designed to operate

when an undisturbed air flow hits the outside vent

terminal from any direction. The minimum

clearances from this terrninal which must

be

maintained are shown in figure

3.

Any reduction in

these clearances could

resutt in a disruption of the

air flow or a safety hazard. Local codes or

regulations

may

require greater clearances.

4.8

The terminal, when installed with the vent shield

tube and wall plates, is suitable for mounting on

wood or vinyl siding without requiring additional

shielding. The vent shield tube supplie is suitable for

wall thicknesses up to

24%.

A custom made shield

should be made for thicker walls.

-

4.9

The slots in the vent terminal must not be recessed

into a wall or siding.

4.10

The vent terminal should be positioned where

it

wit'

not be covered by any snowdrifts.

4.11

Wamlng:

If the outside vent terminal is located

where

it

will

be

accessible to any person, a guard

must

be

fied wer the terminal to prevent damage

and to prevent it being touched.

The vent terminal becomes very hot when the

appliance is in use and can cause bums. A special

guard designed for this appliance is available from

your supplier

-

Ask for Valor part

#235

(See figure

4).

lUMin.

clearance

to

combustible materia

al

round

vent

/

Zero

clearance

/

FIg.2U~&clsran~

b

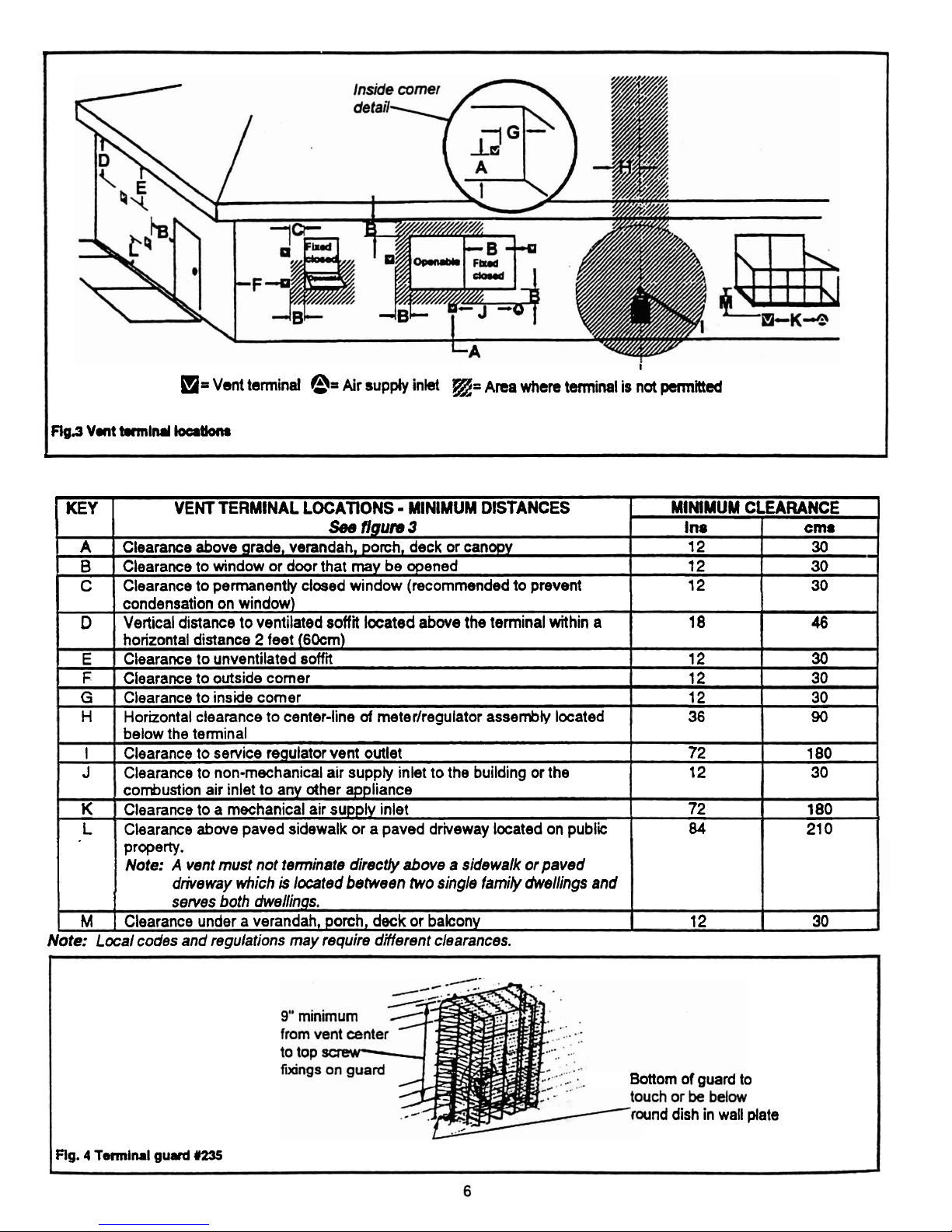

I

m=

Vent tennind

@=

Air supply inkt

@=

Area where

t-inal is not

permitted

mga

vat

brm~rul

loeruona

.

1

KEY

I

VENT TERMINAL LOCATIONS - MINIMUM DISTANCES

1

MINIMUM CLEARANCE

1

I

condensation'on windowj

I

I

D

I

Vertical distance to ventilated soffit located above the terminal within

a

I

18 46

A

B

C

~ee

ngum

3

Clearance above grade, verandah, porch, deck or canopy

Clearance to window or

door that may be opened

Clearance to permanently closed window

(recommended to prevent

E

F

G

H

I

J

I

I

property.

Note: A vent must not terminate directly above a sidewalk or paved

driveway which

is

located between two single family dwellings and

Ins

12

12

12

horizontal distance 2 feet (60cm)

Clearance to unventilated

soffit

Clearance to outside comer

Clearance to inside comer

Horizontal clearance to center-line

of

meterlregulator assembly located

K

L

I

serves both dwellings.

I

I

M

1

Clearance under a verandah, porch, deck or balcony

12

30

Note:

Local codes and regulations may require different clearances.

cms

30

30

30

-

below the terminal

Clearance to service regulator vent outlet

Clearance to non-mechanical air supply inlet to the building or the

Bottom of guard to

und dish in wall plate

Rg. 4 Tennlml

gurvd

#ZS

12

12

12

36

combustion air inlet to any other appliance

Clearance to a mechanical air supply inlet

Clearance

abwe paved sidewalk or a paved driveway located on public

30

30

30

90

72

12

180

30

72

84

180

21 0

Loading...

Loading...