Valor 910 Brunswick Installer And Owner Manual

© GDC Group Ltd. 2014

08/52706/0

Brunswick

Model 910

GAS STOVE

Fitted with a Ceramic Coal fuel effect.

INSTALLER AND OWNER GUIDE

INSTALLER: Please leave this guide with the owner

We trust that this guide gives

sufficient details to enable this

appliance to be installed, operated

and maintained satisfactorily.

However, if further information is

required, our

Valor Fires Technical Helpline will

be pleased to help.

Telephone 0844 879 35 88 (National

call rates apply in the United

Kingdom).

In the Republic of Ireland

Telephone 01 842 8222.

© GDC Group Ltd.

All rights reserved. No part of this publication may be reproduced in any material form

(including photocopying), stored in any medium by electronic means (including in any

retrieval system or database) or transmitted, in any form or by any means, whether

electronic, mechanical, recording or otherwise, without the prior written permission of

the copyright owner.

Applications for the copyright owner's permission to reproduce any part of this

publication should be made, giving details of the proposed use, to the following

address: The Marketing Communications Manager, GDC Group Ltd, Millbrook House,

Grange Dive, Hedge End, Southampton, SO30 2DF.

Warning: Any person who does any unauthorised act in relation to a copyright work

may be liable to criminal prosecution and civil claims for damages.

Because our policy is one of constant development and improvement, details may vary

slightly from those given in this publication

Page 2

© GDC Group Ltd. 2014

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20).

WHEN CONVERTED USING CONVERSION KIT NO. 0591011 THIS APPLIANCE

IS FOR USE WITH PROPANE GAS (G31).

THIS APPLIANCE IS SUITABLE ONLY FOR INSTALLATION IN THE UNITED

KINGDOM (GB) AND THE REPUBLIC OF IRELAND (IE).

Page 3

INSTALLER GUIDE

© GDC Group Ltd. 2014

INSTALLER GUIDE

FOR OWNER GUIDE SEE PAGES 19 TO 30

Page 4

© GDC Group Ltd. 2014

LIST OF CONTENTS

Section Heading Page

INSTALLER GUIDE 3 - 18

OWNER GUIDE 19 - 30

1. SAFETY 5

2. APPLIANCE DATA AND EFFICIENCY 6

General information. 6

Efficiency. 6

3. UNPACKING 7

4. STOVE SET UP 8

Legs and lower casting cover 8

Flue collar, diverter box, flue spigot and flue restrictor plate. 8

Down draught deflector. 9

Burner module and rear burner support fitment. 10

Thermal switch. 10

Diverter box. 10

5. GENERAL INSTALLATION REQUIREMENTS 11

Regulations, Standards and Law. 11

The Hearth. 11

Clearances. 12

Flue / Chimney. 12

Ventilation. 13

Location. 13

Propane gas. 13

Gas connection. 13

Securing the stove. 13

Fitting the ceramic fuel effect. 14

6. OPERATING THE STOVE 14

Pre-lighting checks. 14

Lighting the burner. 14

Operating the burner. 14

Inlet pressure check. 15

Check for spillage. 15

Flame supervision and spillage monitoring system. 15

7. FINAL REVIEW AND SERVICING 16

Final Review. 16

Servicing. 17

Checking the aeration setting of the burner. 18

INSTALLER GUIDE

1. SAFETY

This product uses fuel effect pieces containing Refractory Ceramic Fibres

(RCF), which are man-made vitreous silicate fibres. Excessive exposure to

these materials may cause irritation to eyes, skin and respiratory tract.

Consequently, it is important to take care when handling these articles to

ensure that the release of dust is kept to a minimum. To ensure that the release

of fibres from these RCF articles is kept to a minimum, during installation and

servicing we recommend that you use a HEPA filtered vacuum to remove any

dust and soot accumulated in and around the stove before and after working on

the stove. When replacing these articles we recommend that the replaced items

are not broken up, but are sealed within a heavy duty polythene bag, clearly

labelled as RCF waste. RCF waste is classed as a stable, non-reactive

hazardous waste and may be disposed at a landfill licensed to accept such

waste. Protective clothing is not required when handling these articles, but we

recommend you follow the normal hygiene rules of not smoking, eating or

drinking in the work area and always wash your hands before eating or

drinking. This appliance does not contain any component manufactured from

asbestos or asbestos related products.

Installer

Valor stoves are efficient appliances giving off convected, conducted and radiated

heat. All the surfaces of the stove - except the controls - are working surfaces and

become hot in use. They must not be touched or have any combustible objects or

materials placed on or near them. A fire guard complying with BS 8423 should be

fitted for the protection of young children, the elderly, the infirm or pet animals.

The appliance is fitted with a flue safety device. If the appliance closes down after a

period of operation for no apparent reason, the consumer should be informed to stop

using the appliance until the installation and appliance have been thoroughly

checked. Under no circumstances should the flue safety device be altered or

bypassed in any way. Only a genuine manufacturers replacement part should be

fitted.

Before continuing any further with the installation of this appliance please read the

following guide to manual handling:

- The lifting weight of this appliance is 55 kg. We therefore recommend that two

people should be sufficient to lift the stove. If fitting or moving the stove alone we

recommend the use of suitable lifting apparatus.

- When lifting always keep your back straight. Bend your legs and not your back.

- Avoid twisting at the waist. It is better to reposition your feet.

Page 5

© GDC Group Ltd. 2014

INSTALLER GUIDE

- Avoid upper body/top heavy bending. Do not lean forward or sideways whilst

handling the stove.

- Always grip with the palm of the hand. Do not use the tips of fingers for support.

- Always keep the stove as close to the body as possible. This will minimise the

cantilever action.

- Use gloves to provide additional grip.

- Always use assistance if required.

2. APPLIANCE DATA AND EFFICIENCY

General information.

*When converted using kit 0591011.

The appliance information label is located on a plate at the base of the stove.

Efficiency.

The efficiency of this appliance has been measured as specified in BS EN 613 and

the result is as below :

Model

Efficiency % (Gross)

910 73.1

910 when converted to LPG. 73.1

Page 6

© GDC Group Ltd. 2014

Gas Natural (G20) Propane (G31) *

Inlet Pressure 20mbar 37mbar

Input - Max. (Gross) 5.50kW (18,766Btu/h) 5.4kW (18,425Btu/h)

Input - Min. (Gross) 2.3kW (7,850 Btu/h) 3.8kW (12,965Btu/h)

Inlet Test Pressure (Cold)

20.0 ± 1.0mbar

(8.0 ± 0.4in w.g.)

37.0 ± 1.0mbar

(14.85 ± 0.4in w.g.)

Gas Connection 8mm pipe 8mm pipe

Burner Injector Cat 82 - 065 Size 116

Pilot

Copreci Ref. O.D.S

21500/212

Copreci Ref. O.D.S

21500/212 Fitted with RBM

180 -02 injector

Ignition

Piezo Electric. Integral with

Gas Tap

Piezo Electric. Integral with

Gas Tap

Aeration See page 18 Non-adjustable

INSTALLER GUIDE

The gross calorific value of the fuel has been used for this efficiency calculation. The

test data from which it has been calculated has been certified by BSI.

The efficiency value may be used in the UK Government's Standard Assessment

Procedure (SAP) for energy rating of dwellings.

The conversion of net efficiency to gross was achieved by multiplying the net

efficiency by the following conversion factor from Table E3 of SAP 2005, rounding

down to the nearest whole number.

3. UNPACKING

Before installation, check that the following components, where required, have been

delivered.

Loose parts box - Contains the flue spigot, four feet, lower front panel,

restrictor plate and touch up paint.

+

Accessory Pack - Contains bolts, nuts, washers, wall plugs and screws.

Ceramic box - Contains ceramic coal set.

Stove Burner Assy box - Contains 910 burner module including rear burner

support & knob assy. Item number 05910X1.

Inside Stove Casting - Contains the down draught deflector and diverter box.

Page 7

© GDC Group Ltd. 2014

Gas Conversion factor from net to gross efficiency

Natural Gas 0.901

LPG 0.921

INSTALLER GUIDE

NOTE: The door is secured with a locking bolt and Hex nut. To open the door use a

3mm Allen key to loosen the hex nut on the side of the door, being carefull not to

remove it completely. Ref to Figure A below. Then select a suitably sized spanner and

turn counter clockwise by approximately a quarter turn on the handle to open.

4. STOVE SET UP

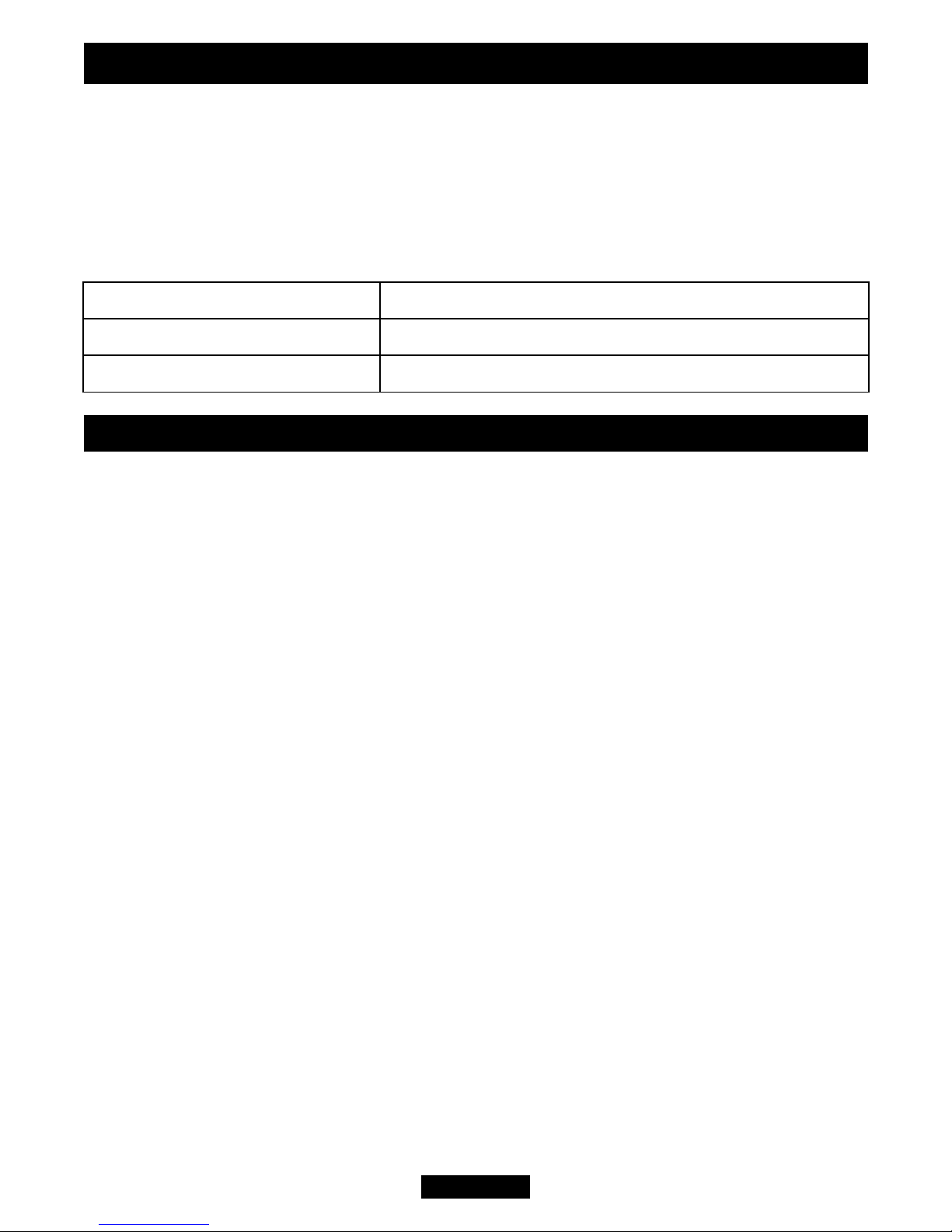

Legs and lower front panel cover (See figure 1).

- Locate the four leg securing studs into the four holes in the base of the body.

- Locate the four legs to the underside of the casting body. There are two feet with

holes in the base. We recommend that these be placed at the rear of the stove.

- Place the front panel cover on top of the front legs.

- Secure the legs and front panel cover to

the underside of the casting body using

the nuts and washers supplied.

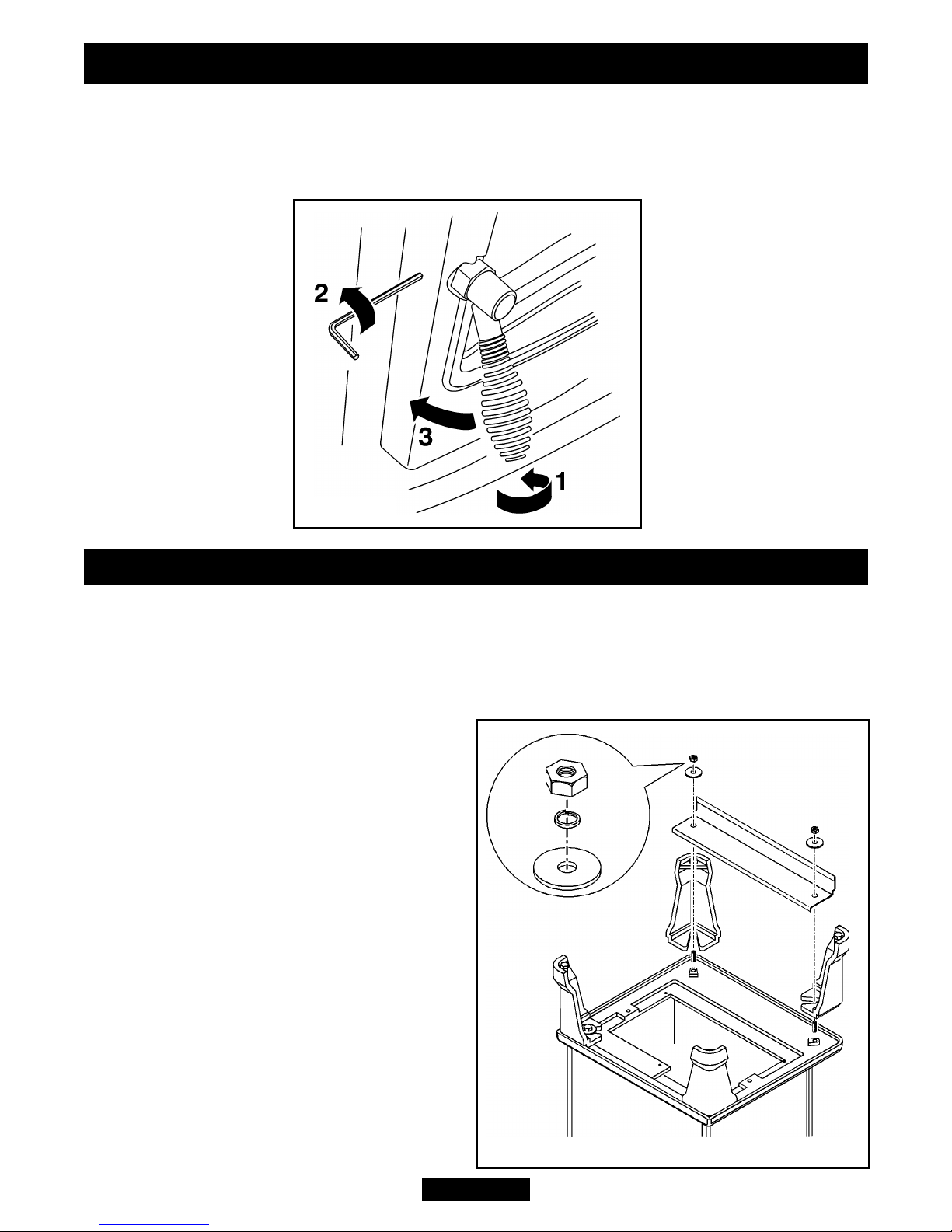

Flue collar, diverter box, flue spigot and

flue restrictor plate.

- These should be located to the stove as

in figure 2. Do not bolt in place until fitting

the deflector. The flue restrictor is for use

where the flue draught is excessive. The

flue spigot is screwed to the cast flue

collar and clamps the flue restrictor plate

in place (See figure 2).

There may however, be certain

circumstances where fitting the restrictor

causes the fire to fail the spillage test. In

such cases the restrictor will have to be

removed. After removal conduct the

spillage check again.

Page 8

© GDC Group Ltd. 2014

Figure 1.

INSTALLER GUIDE

Figure A.

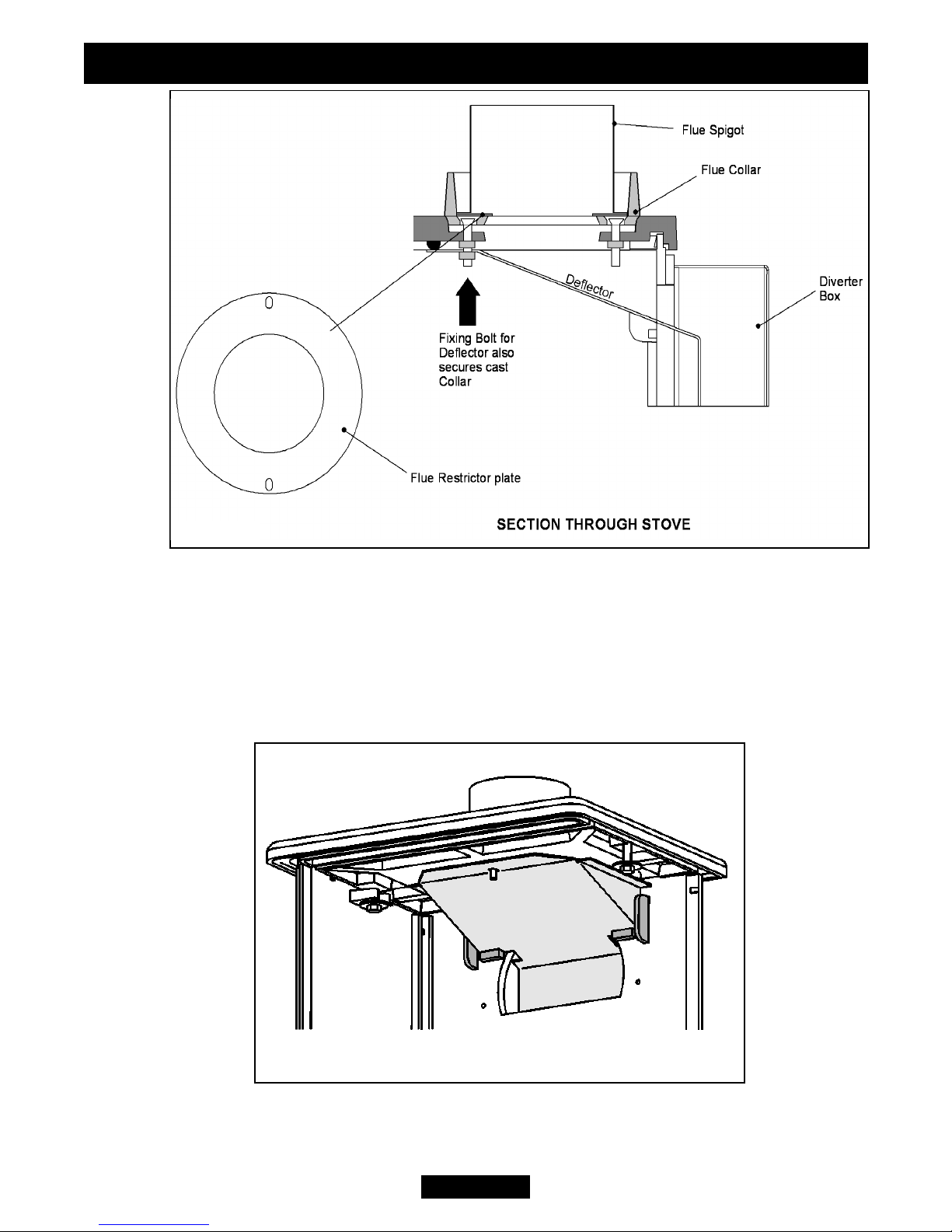

Down draught deflector.

- The down draught deflector is secured in place using the upper front bolt and nut

that secure the cast collar to the outside of the cast body. Unscrew and remove the

nut and washer from inside the top of the casting body. Position the down draught

deflector as in figure 3. It MUST be sealed against the top of the stove casting. It is

important that it sits on top and between the raised cast areas on the rear of the stove

body (See figure 3). Secure in place using the nut and washer removed previously.

Page 9

© GDC Group Ltd. 2014

Figure 2.

INSTALLER GUIDE

Figure 3.

Loading...

Loading...