Valor 546LFB ZC Portrait Ledgeview Front Installation And Owner's Manual

PORTRAIT

Ledgeview Fronts 546LFB ZC

Approved for use with Valor heater models 530 only in ZC applications;

NOT compatible with 530INI/IPI insert engines

Installation and Owner’s Manual

INSTALLER

!

A barrier designed to reduce the risk of burns from the hot

viewing glass is provided with this appliance and shall be

installed for the protection of children and other at-risk

individuals.

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

Notes: This kit must be installed

or serviced by a qualifi ed installer,

service agency or gas supplier.

These instructions are to be used

in conjunction with the main

installation instructions for the

above listed heater models.

Leave this manual

with the appliance.

CONSUMER

Retain this manual for

future reference.

The 546LFB ZC Portrait Ledgeview Front

is designed to be used on the 530 Valor

heaters when installed in a zero clearance

application.

For installation with an insert, use 546LFB

Ledgeview Fronts.

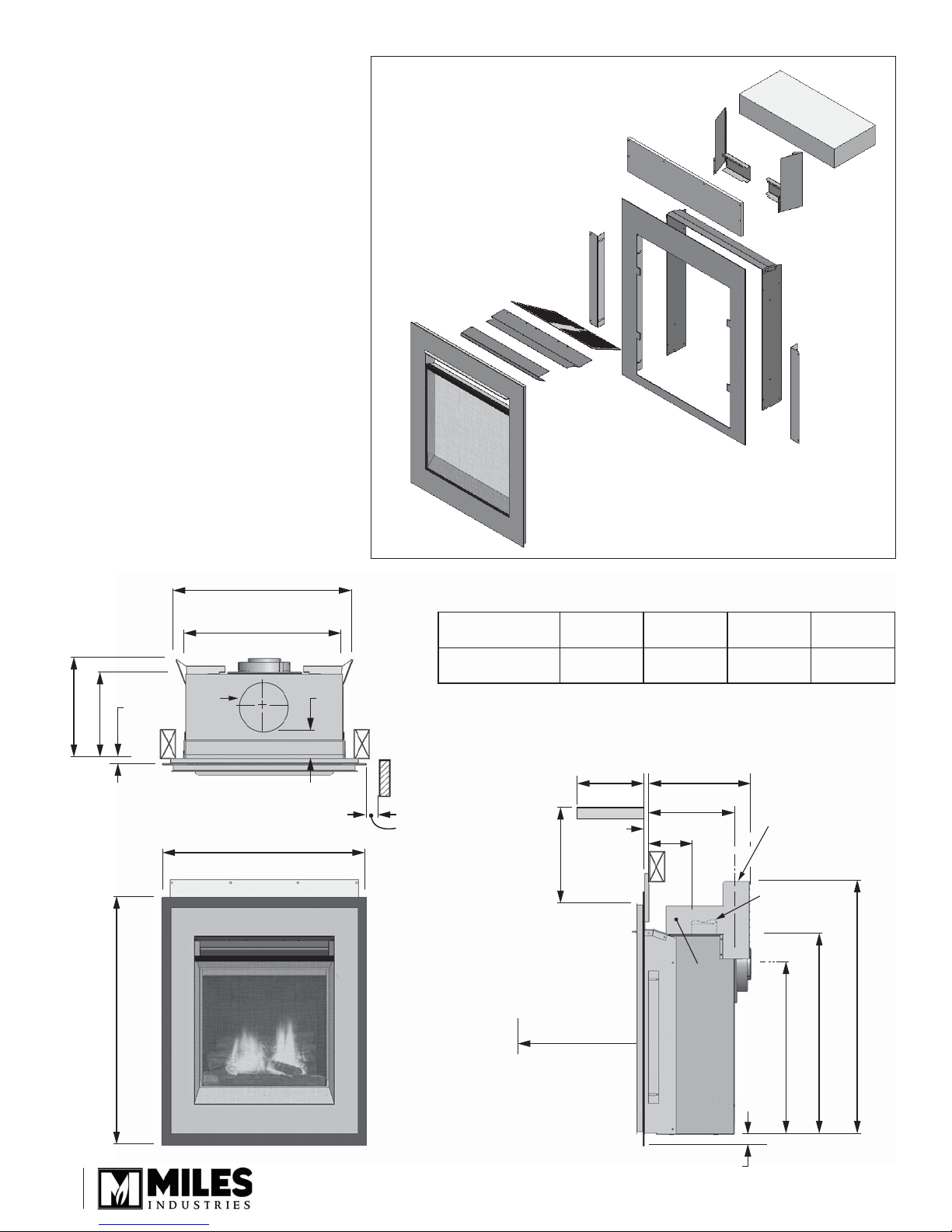

ZC Bae

Heat

exchanger

cover

Hardieboard Panel

Stud brackets (2)

Backing Plate

Insulation

Backing frame

Assembly

Stand o brackets

530 Engine

(sold separately)

4005278-01

©2016, Miles Industries Ltd.

Ledgeview Front with Barrier screen

Overview (530 engine sold separately)

Kit Contents

546 ZC

1 Backing Frame assembly

1 Backing plate

1 Ledgeview Front assembly

1 Heat Exchanger Cover

1 Ceiling Panel

1 ZC Baffl e

1 Barrier Screen (fi tted)

2 Stand Offs

1 Insulation

2 Stud Brackets

1 Cement board

2 Screws #8 x 3/8 tapping pn hd ph

8 Screws #8 x 1/2” black

4 Screws #8 x 1/2” s/t black

Heat

exchanger

cover

ZC bae

Hardieboard

Ceiling

panel

Ledgeview Front with

Barrier screen

Stand o brackets

Backing plate

26”

W x 32-1/8” H

Insulation

Backing frame

assembly

Stud brackets (2)

Dimensions and Clearances

22-7/16”

20”

6-5/8”

dia.

26”

11”

12-3/4”

1-1/2” max.

1/2” min.

32-1/8”

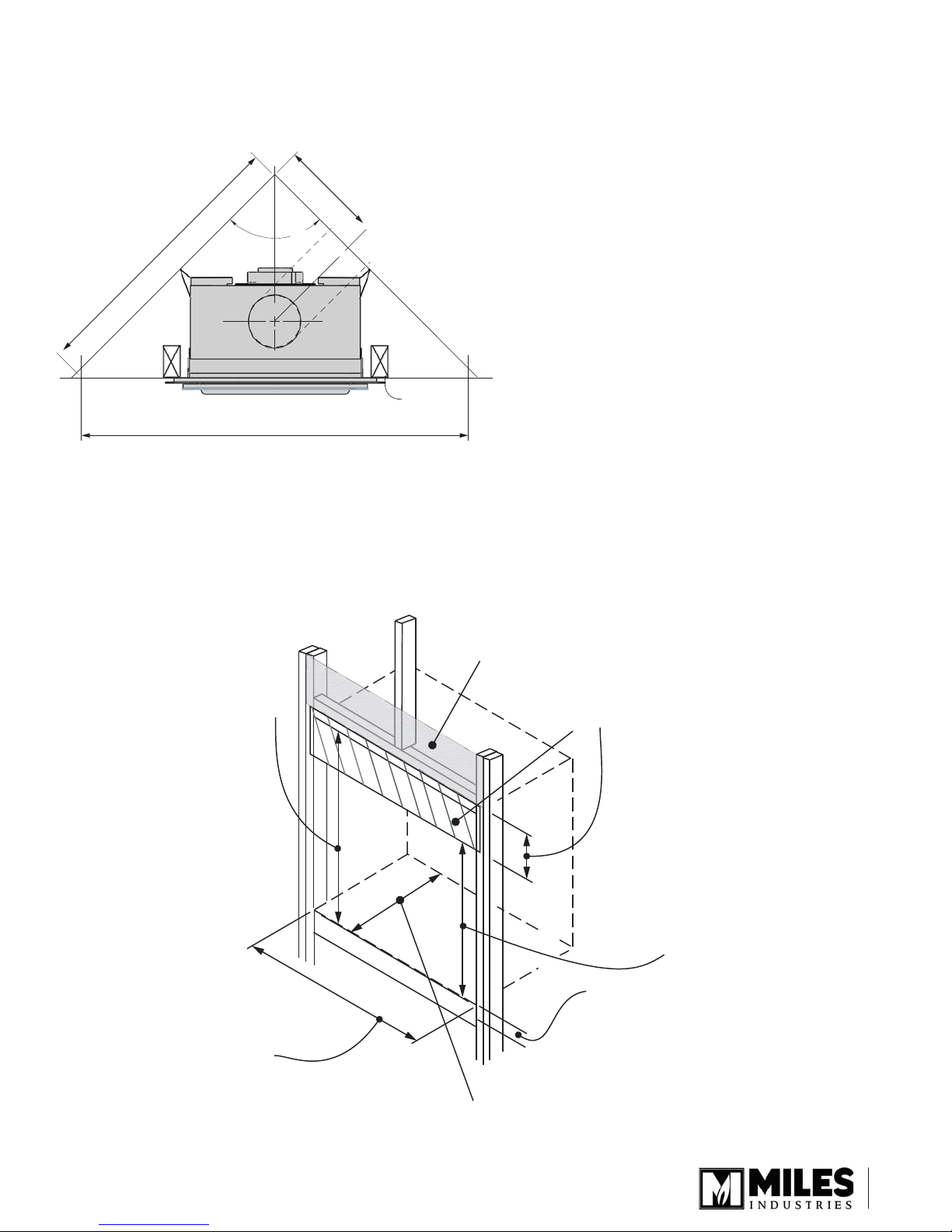

Mantel Clearances

Mantel Depth ‘A’

Mantel Height ‘B’

0–6”

(0–152 mm)8”(203 mm)

4”

(102 mm)8”(203 mm)

4”

12-3/4”

11”

4”

Insulation

2” sidewall minimum

clearance

‘A’

Mantel

1/2”

‘B’

Do not put

furniture or objects

within 36” of front

of appliance

10”

(254 mm)

10”

(254 mm)

ZC Stand-os

Top

Outlet

21-5/8”

12”

(305 mm)

12”

(305 mm)

32”

25-1/4”

2

1-1/2” between bottom of trim

and bottom of appliance

Corner dimensions

34” (864 mm)

90°

48” (1219 mm)

(305 mm)

12”

Face of

wall studs

Framing

32” (813 mm)

This is the framing

width. Drywall to

24” (610 mm) wide

(to edge of stud brackets)

to header

22-1/2”

(572 mm)

Minimum 12-3/4” (324 mm)

(Allow extra if using rear vent elbow)

Wall Finish

6-1/8” (154 mm)

cement board

supplied

Note There is a 1” (25 mm)

gap between bottom

of cement board and

top of backing frame

assembly

26-7/8” (684 mm)

to cement board

Note Finished surface of floor

or hearth/shelf, if used,

must be min. 1-1/2”

lower than bottom of

appliance otherwise the

front trim will not fit

3

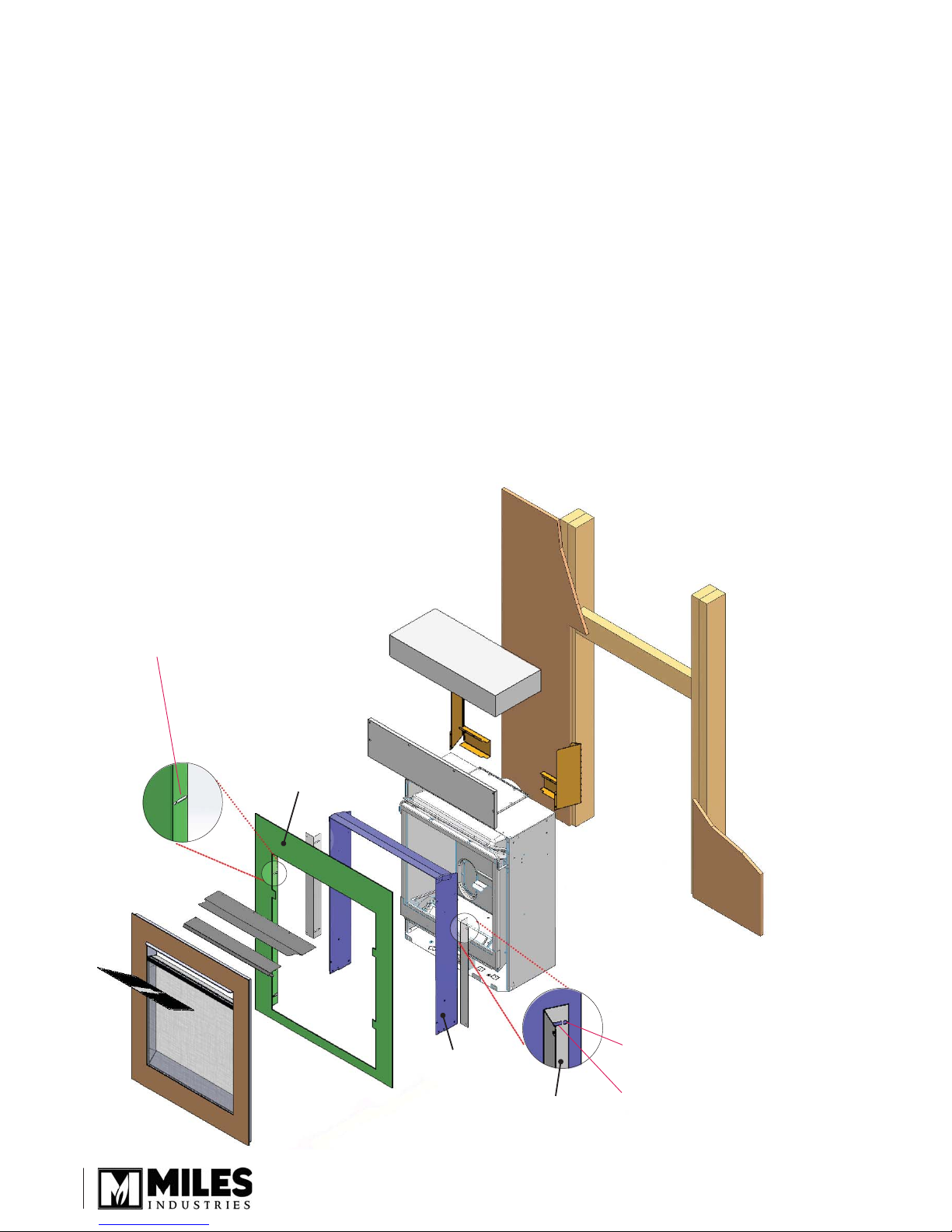

Adjustability of the Clearview Front ZC

• Method 1. The appliance’s position within the

framing cavity may be adjusted forward in the

framing up to 1” to accomodate additional wall fi nish

thickness “tucked” behind the backing plate.

• Method 2. The Backing Plate is also adjustable to

accomodate up to an additional 3/4” of tile or other

non-combustible material over top of the 1/2” noncombustible wall board.

• Method 1 and Method 2 may be combined for a total

of 1-3/4” of non-combustible material over top of the

1/2” wall board.

Attention! When positioning the appliance forward

of the framing cavity (Method 1), ensure that the front

edge of the backing frame does not protrude beyond

the planned fi nished wall surface. Otherwise the

backing plate, when installed, will not sit against the

fi nished wall.

Method 2 - Backing Plate Positioning

Backing Plate is adjustable up to 3/4”.

Backing Plate

Backing frame

assembly

Stud bracket

Method 1 - Appliance Positioning

Measured from face of stud

bracket to front edge of backing

plate frame assembly

Wall nish thickness: 1/2”

- use hole

Wall nish thickness: 1/2” to 1-1/2”

- use slot

4

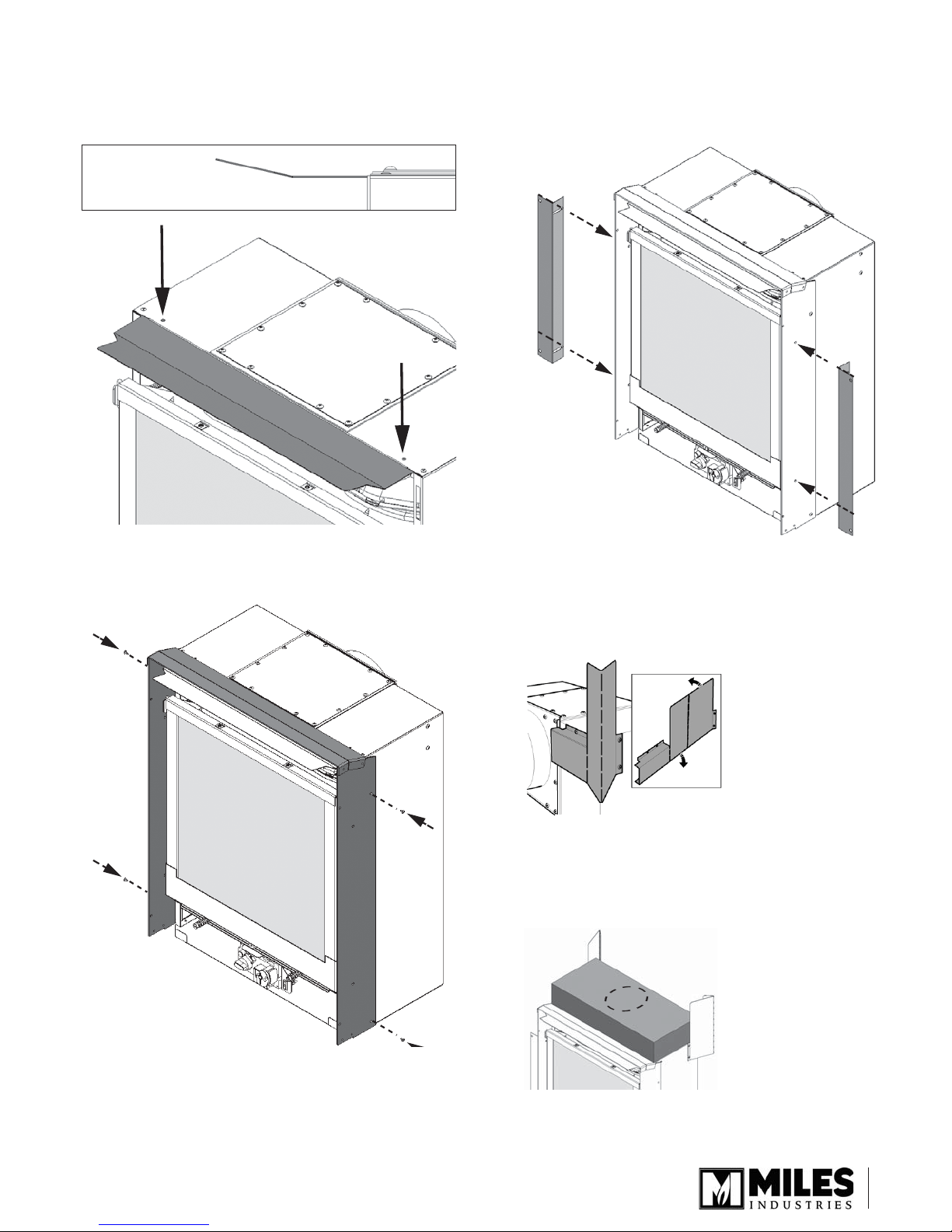

Installation

1. Fit the ZC baffl e under the top panel of the

appliance case. Secure as shown with 2 thread

forming screws provided.

ZC baffl e orientation

—side view

3. Install stud brackets over top of the backing plate

frame assembly with 2 screws per side.

See Adjustability of the Ledgeview Front ZC section

for more information on position of brackets.

2. Slide the backing plate frame assembly over

the appliance case and secure it with 4 screws

provided.

4. Required for installation in combustible

construction. Bend the stand-offs into shape and

fi x them to the appliance’s case as indicated (4

screws/side, pre-fi tted on engine).

5. Required for installation in combustible

construction. Add insulation pad on the top of the

appliance, cutting around the pipe if installing a top

vent.

5

Loading...

Loading...