#536CXB

President ZC Cast Front

CSA approved for use only with

Valor 530

Model Heaters

INSTALLATION BOOKLET

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Note: This kit must be installed or serviced by a qualied installer, service agency or gas supplier.

These instructions are to be used in conjunction with the main installation instructions for the

above listed heater models.

WARNING: If the information in these instructions is not followed exactly, a re or explosion

may result causing property damage, personal injury or loss of life.

FOR PRESIDENT ZC INSTALLATION WITH A VALOR 530 ENGINE.

FOR 530 ENGINE CONFIGURATIONS AND VENTING,

REFER TO MAIN INSTALLATION BOOKLET SUPPLIED WITH THE

190 – 2255 Dollarton Highway, North Vancouver, B.C., CANADA V7H 3B1

© 2006, Miles Industries Ltd. All rights reserved.

4001168/02

ENGINE.

Designed and manufactured by / for

Miles Industries Ltd.

Tel. (604) 984-3496 Fax (604) 984-0246

www.milesreplaces.com

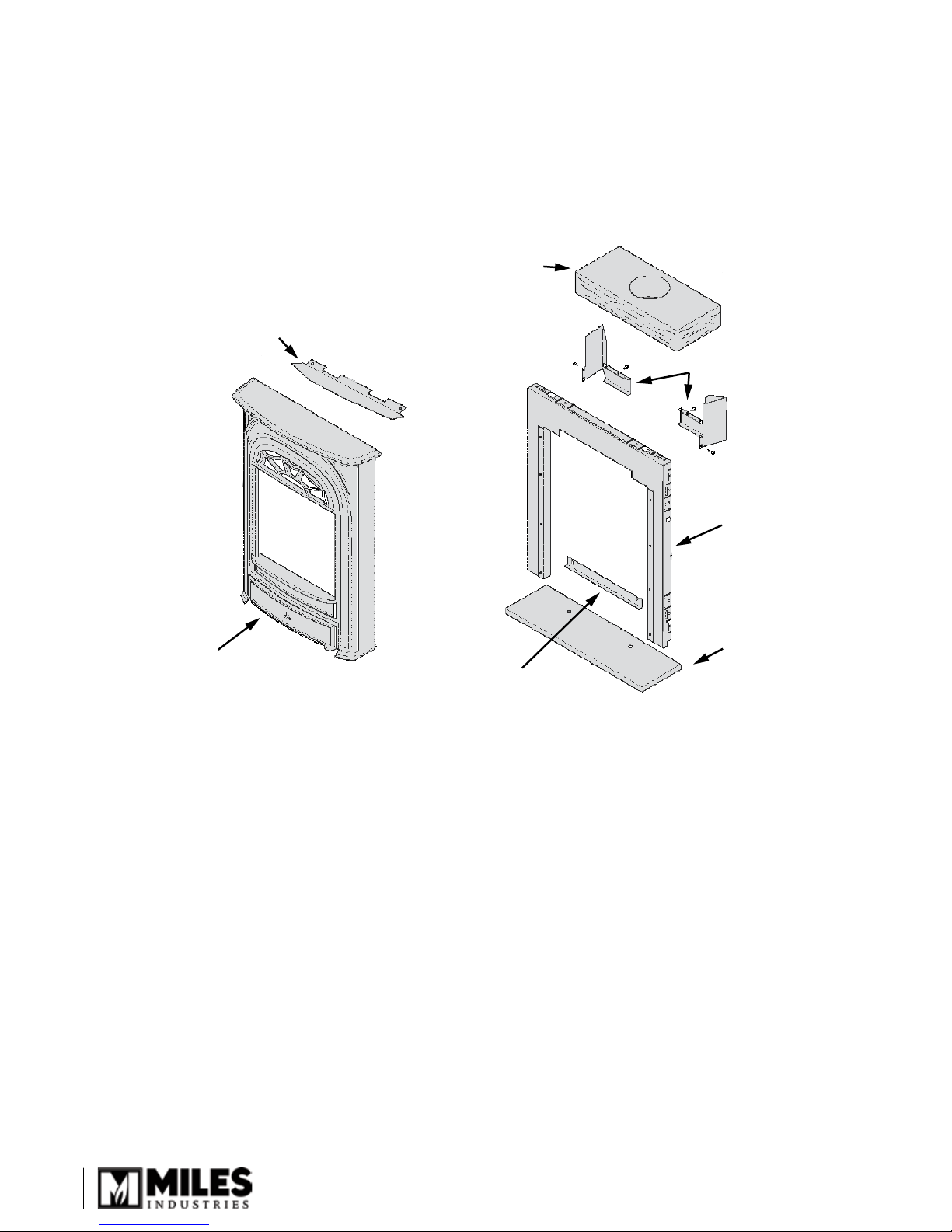

Casting Tolerances

Top Baffle

Front Casting

Rear Base Support

Plinth

Stand-offs (2)

Insulation

Framing Plate

w/Brackets

Due to the nature of cast iron, dimensional consistency may vary from one unit to the next and some variation

in surface nish and atness is to be expected. We have done our best to control and make allowance for this;

however some variation is inevitable.

Kit Contents

1 Front Casting Assembly

1 Top Bafe

1 Framing Plate w/Brackets

1 Plinth

1 Rear Base Support

1 ZC stand-off LH

1 ZC stand-off RH

1 Insulation Layer

1 Pack of Screws

2

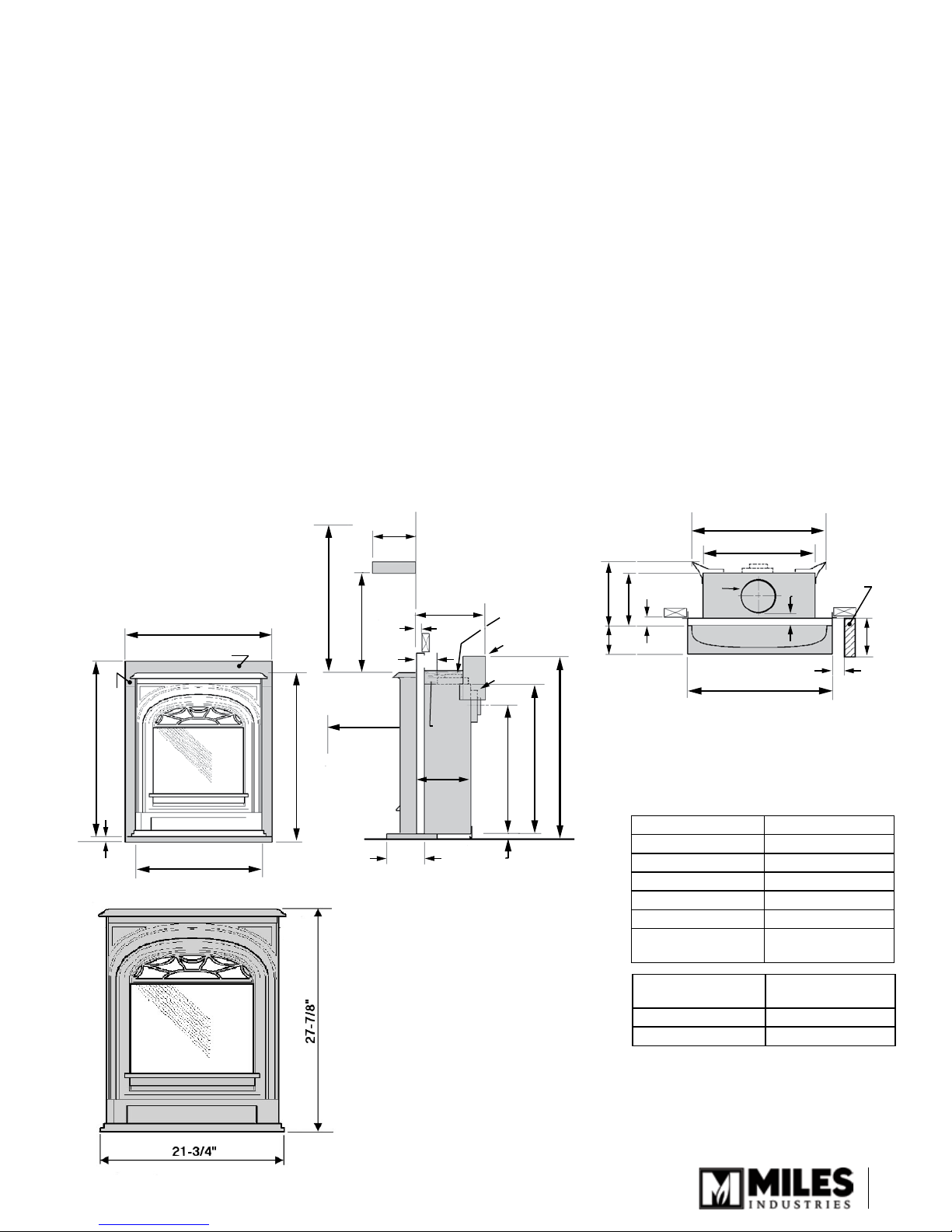

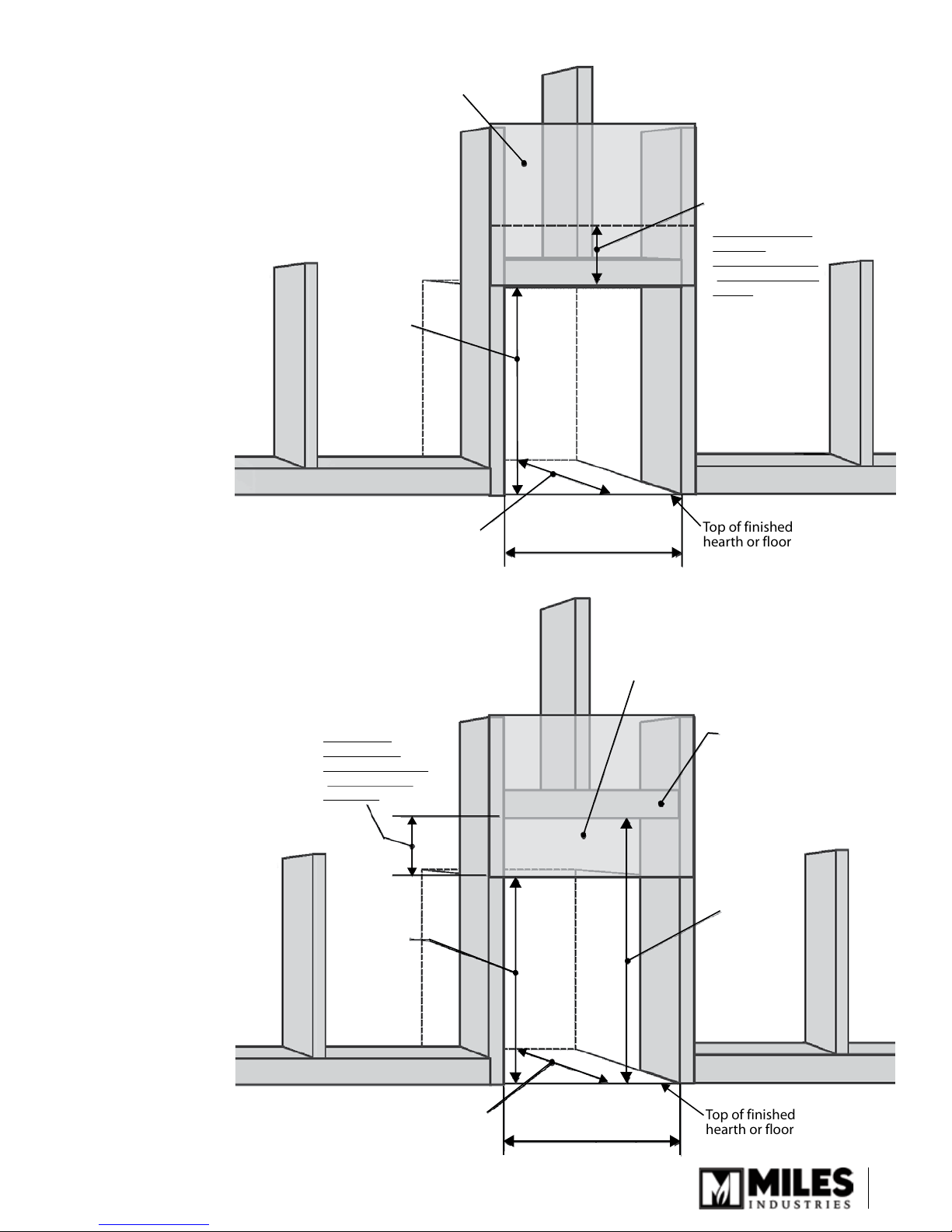

26”

(framing plate)

(framing plate)

31-1/4”

21-3/4”

(cast front)

(cast front)

27-7/8”

7/8”

High

raised

plinth

Ceiling

‘A’

‘B’

1” max.

1/2” min.

1” max.

1/2” min.

11” min.

36” min.

36” min. to

combustibles

9”

Mantel

Optional Top Outlet

ZC Stand-offs

6-5/8” dia.

6-5/8”

dia.

21-5/8”

25-1/4”

31”

5”

7/8”

plinth

insul.

2”

26-1/4”

20”

26”

11”

9”

5”

‘D’

‘E’

Mantel

leg

See table

2”

INSTALLATION WITH 530 ENGINE

The Valor model 530 heater with the 536CXB President ZC Cast Front comes ready for installation as a zero

clearance unit into combustible type framing, without need for a separate zero clearance kit. The 530 installed

without the standard zero clearance stand-off spacers may also be installed into existing solid-fuel burning replaces

provided space and local codes permit.

Hearth Requirements

A 7/8” high plinth is supplied to raise the heater and ensure a base at the proper height for the cast front to sit on

regardless of oor nish height. If not using the plinth supplied, you MUST make allowance for oor nish and raise

(shim) the heater up so the bottom of the heater sits at the nished oor/hearth height, otherwise, the cast front will

not sit at the proper height.

A non-combustible hearth is not required in front of this appliance.

Floor Requirements

The 530 heater is approved for installation directly on any combustible material other than soft ooring material

such as carpet or vinyl.

Mantel Requirements

The 536CXB President ZC Cast Front may be installed with a combustible mantel provided clearances are

maintained as indicated in the Dimensions and Clearances below and in the Framing diagrams on the following

pages. Be aware that although safe, some combustible materials and nishes at the listed clearances may, over

time, discolor, warp, or show cracks. Care should be taken when choosing materials—consult your replace dealer.

Dimensions &

Clearances

Mantel depth “A” Min. clearance “B”

Up to 7” 4”

Above 7” up to 8” 5”

Above 8” up to 9” 7”

Above 9” up to 10” 8”

Above 10” up to 12” 9”

More than 12” 9”+extra 1” for every

Mantel leg

projection “D”

Up to 8” 0”

More than 8” 6”

1” depth above 12”

Min. clearance from

appliance side “E”

3

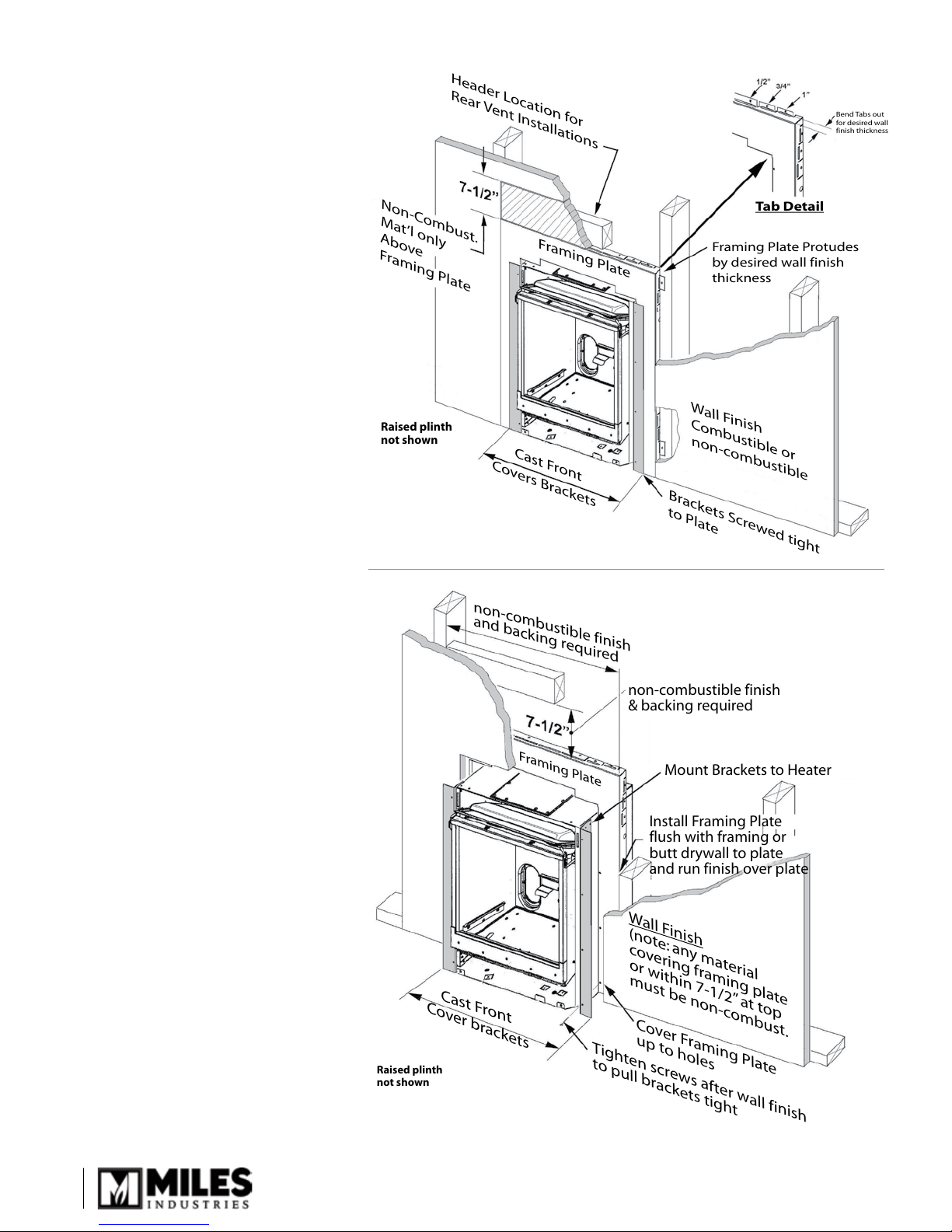

FRAMING

non-combustible finish

and backing required

Tighten screws after wall finish

to pull brackets tight

Cast Front

Framing Plate

Cover brackets

Cover Framing Plate

up to holes

Wall Finish

(note: any material

covering framing plate

or within 7-1/2” at top

must be non-combust.

non-combustible finish

& backing required

Mount Brackets to Heater

Install Framing Plate

flush with framing or

butt drywall to plate

and run finish over plate

Raised plinth

not shown

Framing Plate

Header Location for

Rear Vent Installations

Brackets Screwed tight

to Plate

Wall Finish

Combustible or

non-combustible

Framing Plate Protudes

by desired wall finish

thickness

Bend Tabs out

for desired wall

finish thickness

Tab Detail

Cast Front

Covers Brackets

Non-Combust.

Mat’l only

Above

Framing Plate

Raised plinth

not shown

The President ZC Front comes supplied

with a framing plate for zero clearance

applications. The framing plate is

painted black and may be left exposed

beyond the perimeter of the cast iron

front or may be covered with noncombustible material if desired.

A non-combustible hearth is not

•

necessary in front of this appliance.

The appliance is approved to install

•

directly on wood sub-ooring.

Any framing construction must be

•

clear of stand-offs.

Be aware that the area of 7½” x

•

26¼” (19 cm x 67 cm) immediately

above the framing plate must be

constructed with non-combustible

materials as shown in gures.

Framing plate exposed

4

Framing plate covered

Top of finished

hearth or floor

Wall Finish

26-1/4”

31-1/2”

to header &

wall finish

(includes

plinth -

reduce by

7/8” if not

using plinth)

7-1/2”

minimum

This part of wall

must be

non-combustible

(cement board or

similar)

Minimum 11”

(Allow extra for rear vent elbows)

Top of finished

hearth or floor

Wall Finish

Note: Header

is raised to

accomodate top

vent clearances

39”

to header

(includes

plinth;

reduce by

7/8” if not

using plinth)

31-1/2”

to header

(includes

plinth;

reduce by

7/8” if not

using plinth)

7-1/2” minimum

This part of

wall must be

non-combustible

(cement board

or similar)

Minimum 11”

26-1/4”

Rear vent framing

Top vent framing

5

INSTALLATION

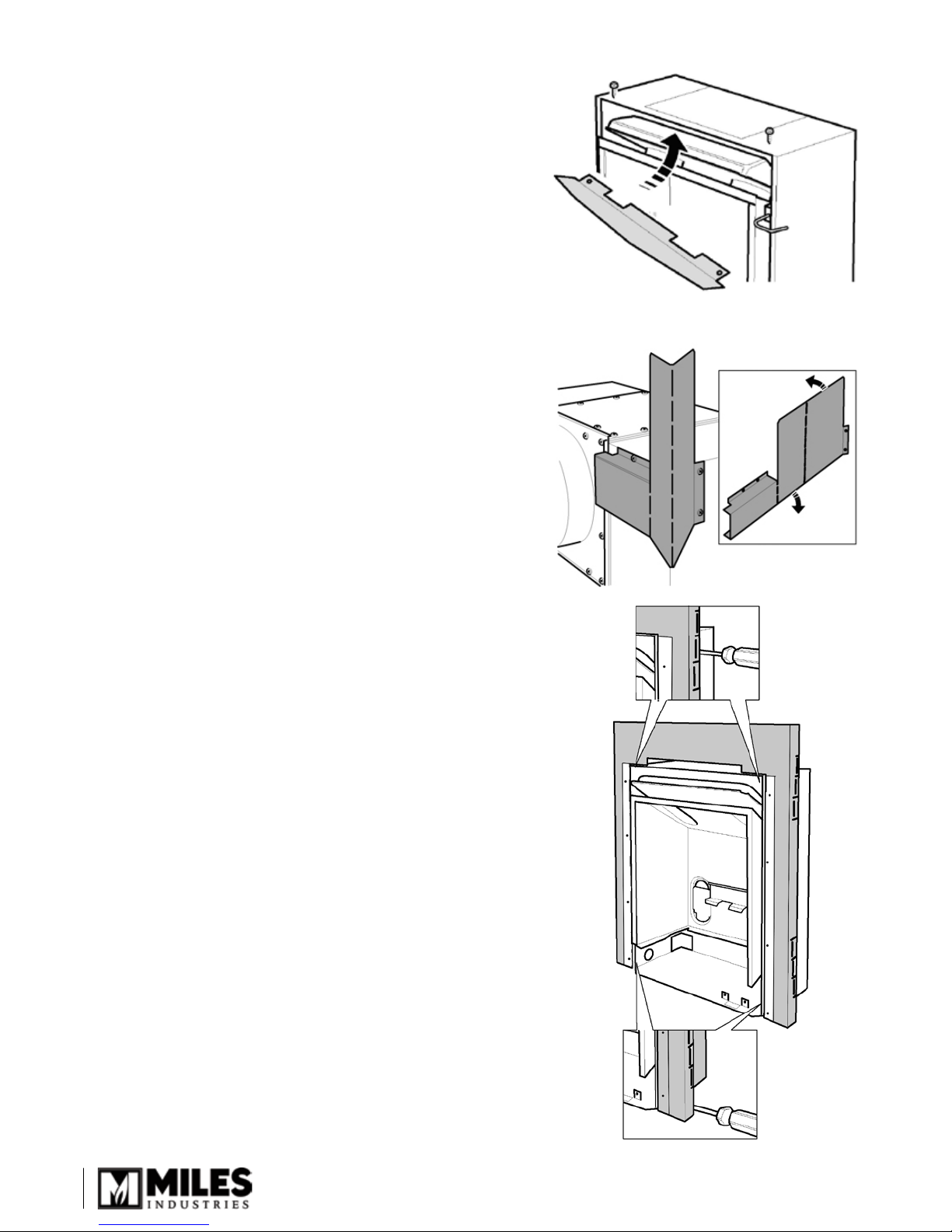

1.

Fit the top bafe under the top panel of the appliance

case. Secure with 2 thread forming screws.

2.

Fit the stand-off spacers. The stand-off spacers for

these installations are supplied at. They are left and

right handed.

! Warning: Failure to install the stand-off spacers

may result in a re hazard.

a)

Remove the 2 screws near each of the rear top

corners of the appliance and the 2 screws near

each side of the top back corners.

b)

Bend the spacers as shown.

c)

Screw the spacers to the rear of the appliance

using the screws just removed.

d)

Bend the side wings of the spacers to align the 2

holes in each spacer with those in the appliance

sides. Secure the spacers using the screws just

removed.

3.

Mount the framing plate to the appliance.

4.

Secure the framing plate and brackets to the sides

of the appliance case with 4 thread cutting screws

supplied. Screw from the outside through the access

holes in the framing plate.

Note: There are alternate methods of nishing around

the framing plate—either leaving it exposed or

recessing it and covering it up with the wall nish. See

page 4.

6

Loading...

Loading...