Valor 502CN Installation Instructions Manual

Direct

9

aIor

Vent

Wall

Furnace

APPROVE

R

For

MODEL

use

with

502CN

Natural

Gas

INSTALLATION

PLEASE

FOR

YOUR

Do

not

store

or

other

and

this

VALOR

ERDINGTON,

9QP

824

ENGLAND

liquids

or

any

HEATING

BRMNGHAM

flammable

or

in

the

other

SAFETY

gasoline

use

vapors

vicinity of

appliance.

LEAVE

Vous

pourrez

THESE

vous

de

cette

If

you

1.

Open

Don’t

2.

switches.

Extinguish

3.

INSTRUCTIONS

smell

un

chez

gas:

procurer

brochure

windows.

touch

INSTRUCTIONS

YOUR

flame.

THE

OWNER

SAFETY

Immediately

4.

supplier.

Distnbuted

NORTH

by

Third

829

Phone (6O4

exempiaire

votre

electrical

any

WITH

en

langue Francaise

concessionaire.

FOR

open

HSINDUSTRiES

West

Street

VANCOUVER

V7P3K7

9843496

call

BC.

your

LTD

AOOKRR9/(t9

gas

1,

INSTALLATION

GENERAL

1.1

installation

for

use

must

conform

installation

only

a

be

from

wall

must

16”

diameter.

WALL

an

outside

direction.

external

to

could

min

12

vertical

bythe

pressure

a

located

be

is

undisturbed

disrupt

fig.

in

is

and

the

In

having

inlet

and

a

WALL

vent

fireplace

vent

is

7/8”

fireplace

hits

any

certified

for

absence

must

149.1

personn

must

between

minimum

must

reach

the

of

and

clearance

THE

when

the

1.2

1.3

This

fireplace

Gas

Association

outside

Gas.

local

the

current

Only

the

wall

The

codes.

installation

CAN-lB

qualified

appliance.

SUPPLY

fireplace

This

Natural

Gas

appliance

W.C.

8in.

LOCATION

fireplace

The

outside

1.3.1

wall.

THE

The

surface

the

minimum

The

wall

1.3.2

OUTSIDE

This

operate

flow

from

installation

GAS

clearances

which

ions

shown

are

flow

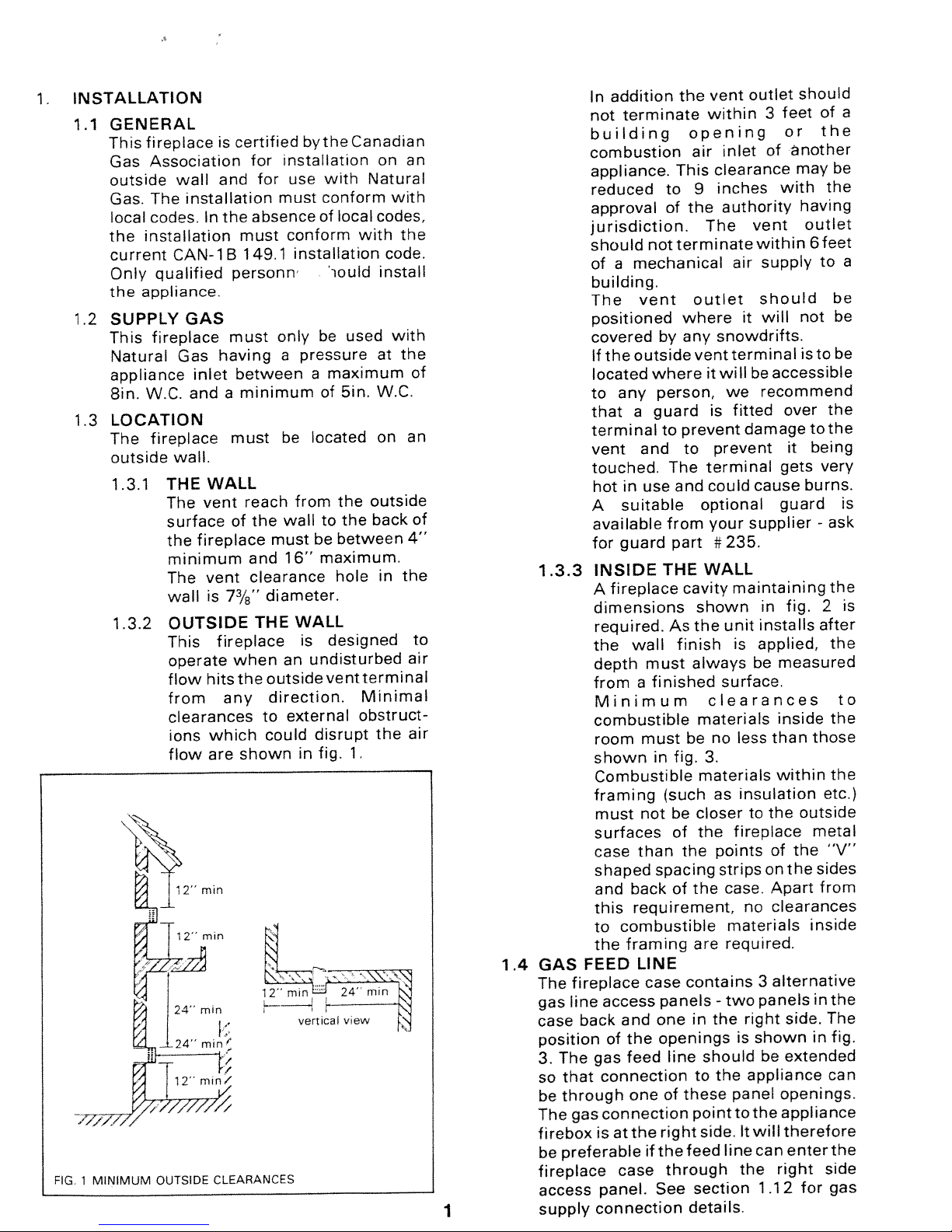

FIG.

MINIMUM

1

OUTSIDE

CLEARANCES

Canadian

with

Natural

conform

of

local

codes,

with

iould

be

used

maximum

of

5in.

W.C,

on

the

outside

the

to

back

between

maximum.

hole

designed

vent

terminal

Minimal

obstruct

the

1.

mn

24’

view

on

with

the

code.

install

with

the

at

the

in

N

an

an

4”

air

air

of

of

to

3

of

vent

within

supply

should

feet

or

another

may

with

having

outlet

6

of

the

the

feet

to

a

be

a

addition

In

not

terminate

building

combustion

appliance.

reduced

approval

jurisdiction.

should

of

not

mechanical

a

the

opening

air

This

to

9

of

the

The

terminate

outlet

vent

within

inlet

clearance

inches

authority

air

building.

not

isto

to

being

it

burns.

those

outside

metal

the

inside

in

for

the

the

very

ask

-

the

2

after

the

the

the

etc.>

“V”

sides

from

in

the

The

fig.

can

the

side

gas

be

be

be

is

is

to

The

vent

positioned

covered

outside

the

If

located

any

to

a

that

terminal

vent

and

touched.

in

hot

A

use

suitable

available

for

guard

1.3.3

INSIDE

fireplace

A

dimensions

required.

wall

the

depth

from

must

a

Minimum

combustible

room

must

shown

Combustible

framing

not

must

surfaces

than

case

shaped

back

and

this

requirement,

to

combustible

framing

the

FEED

GAS

1.4

The

fireplace

line

gas

back

case

position

The

3.

that

so

through

be

gas

The

firebox

preferable

be

fireplace

access

1

supply

LINE

case

access

and

the

of

feed

gas

connection

one

connection

the

at

is

if

case

panel.

connection

outlet

where

any

by

ventterminal

where

person,

guard

prevent

to

to

The

and

optional

from

part#235.

THE

cavity

shown

the

As

finish

always

finished

materials

be

in

fig.

materials

(such

be

closer

the

of

the

spacing

the

of

are

contains

panels

in

one

openings

line

to

these

of

point

side.

right

feed

the

through

section

See

details.

it

is

terminal

could

your

WALL

clearances

no

3.

the

should

should

will

it

snowdrifts.

be

we

accessible

recommend

will

fitted

damage

prevent

cause

supplier

maintaining

in

unit

installs

is

applied,

be

surface.

than

less

as

insulation

the

to

fireplace

case.

of

on

Apart

no

clearances

points

strips

materials

required.

alternative

3

panels

two

-

right

is

shown

be

the

appliance

panel

the

to

It

will

line

can

the

1.12

over

gets

guard

fig.

measured

inside

within

the

side.

extended

openings.

appliance

therefore

enter

right

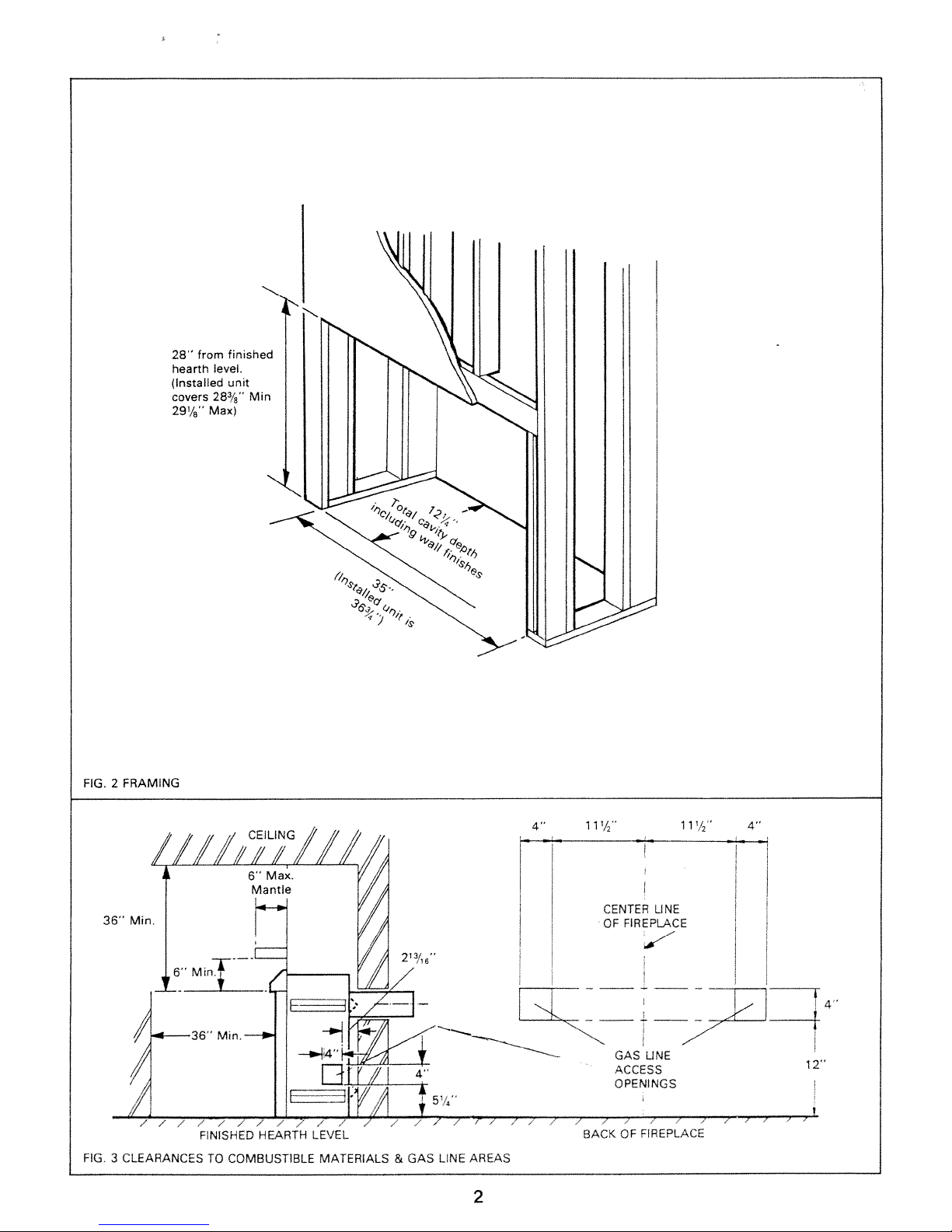

FIG.

FRAMING

2

from

28”

hearth

(Installed

covers

29’/”

level.

28%

Max)

finished

unit

Mm

Mm.

36”

FINISHED

FIG.

3

CLEARANCES

TO

HEARTH

COMBUSTIBLE

LEVEL

MATERIALS

&

2’’,’’

GAS

LINE

AREAS

2

4’’

Lç

11

SACK

!‘

CENTER

FIREPLACE

OF

GAS

ACCESS

OPENINGS

OF

1 1

LINE

f

UNE

FiREPLACE

‘/2’

4”

12”

1.5

FIREPLACE

The

1

1

1

1

1

1

5

2

1

3

1

1

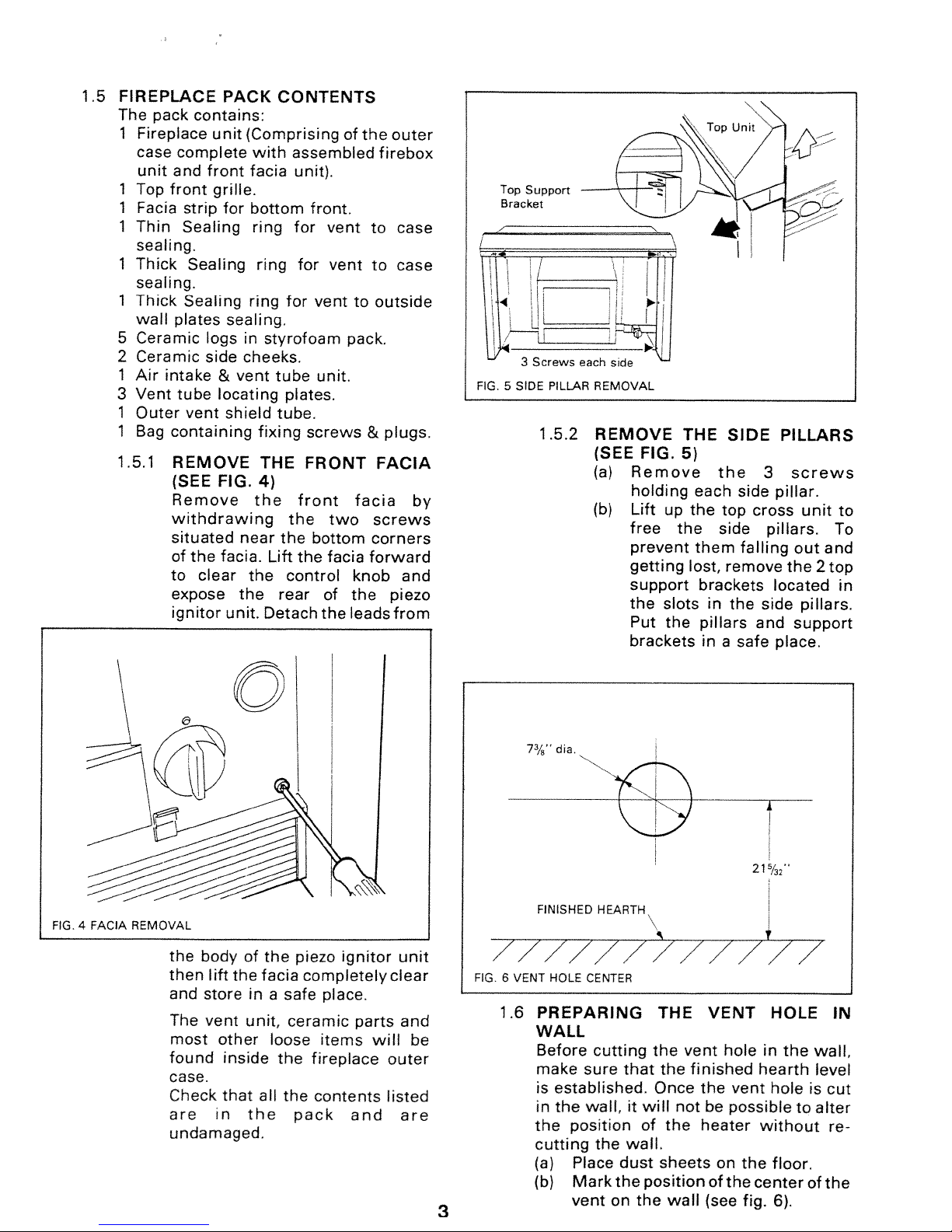

1.5.1

pack

Fireplace

case

complete

and

unit

Top

front

Facia

Thin

Sealing

sealing.

Thick

sealing.

Thick

wall

plates

Ceramic

Ceramic

Air

intake

Vent

tube

Outer

Bag

containing

REMOVE

(SEE

Remove

withdrawing

situated

of

to

expose

ignitor

contains:

unit

front

grille.

strip

Sealing

Sealing

logs

side

&

locating

vent

FIG.

the

facia.

clear

PACK

(Comprising

with

facia

for

bottom

ring

ring

ring

sealing.

in

styrofoam

cheeks.

vent

shield

fixing

THE

4)

the

near the

Lift

the

the

unit.

Detach

CONTENTS

of

assembled

unit).

front.

for

vent

for

vent

for

vent

pack.

tube

unit.

plates.

tube.

screws

FRONT

front facia

the

two

bottom

the

facia

control

rear

of

the

the

to

to

to

&

corners

forward

knob

the

leads

outer

firebox

case

case

outside

plugs.

FACIA

screws

and

piezo

from

by

Top

Support

Bracket

3

FIG.5SIDE

___J

Screws

PILLAR

1.5,2

each

side

REMOVAL

REMOVE

(SEE

(a)

(b)

FIG.

Remove

holding

Lift

up

free

prevent

getting

support

the

slots

Put

the

brackets

THE

5)

each

the

the

them

lost,

brackets

pillars

inasafe

SIDE

the

top

side

remove

in

side

falling

the

3

pillar.

cross

pillars.

located

side

and

place.

PILLARS

screws

unit

To

out and

the

2top

pillars.

support

to

in

FIG.4FACIA

REMOVAL

the

then

and

The

most

found

bodyofthe

lift

the

facia

store

in

a

vent

unit,

other

loose

inside

piezo

completely

safe

ceramic

the

fireplace

case.

that

in

the

all

the

pack

contents

Check

are

undamaged.

ignitor

place.

items

parts

and

will

unit

clear

and

outer

listed

are

be

dia,

7/’

212

FIG.

/

6

1.6

/

VENT

FINISHED

///

HOLE

PREPARING

HEARTH

CENTER

.4

//

THE

/7

////

VENT

HOLE

IN

/

WALL

Before

make

is

in

the

cutting

(a)

(b)

3

cutting

sure

established.

wall,

the

position

the

Place

Mark

vent

dust

the

on

that

will

it

of

wall.

position

the

the

vent

the

finished

Once

the

not

the heater

sheets

wall

be

on

of

(see

hole

the

in

hearth

vent

possible

without

the

center

fig.

the

hole

floor.

6).

to

wall,

level

is

alter

of

cut

re

the

Loading...

Loading...