Valor 492CNA, 492CNB, 492CPA, 492CPB, 492CBC Installer's & Owner's Manual

...

n~an~ronr

GAS

FIRED VENTED

ROOM

HEATERS

r

WARNING: Hthe information

in

this

manual is not followed exactly,

a

fire

orexplosion may result causing

personal injury or loss of life.

-Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

-WHAT

TO

DO

IF

YOU

SMELL

GAS

Open Windows.

Do not

try

to light any

appliance.

Do not touch any electrical

switch; do not use any phone

in

your building.

Extinguish any open flame

Immediately call your gas

supplier from

a

neighbor's

phone. Follow the gas

supplier's instructions.

If you cannot reach your gas

supplier, call the fire

department.

-Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

INSTALLERS

&

OWNERS MANUAL

INSTALLER - PLEASE LEAVE THIS MANUAL WITH THE OWNER

(Vous pourrez vous procurer un manuel en langue Fran~aise chez votre concessionaire)

600A287

CAUTlON

Dueto high temperatures,the room heater should

Keep the area below the front apron and the

!

be

located out of traffic and away from furniture

rectangular slots down each side of

the

case

and draperies.

back clear to prevent obstruction of the air flow

-1

for combustion.

Children and adults should be alerted to the

hazards of high surfacetemperatures and shou:d

All vented room heaters require a source of fresh

stay away to avoid bums or clothing ignition.

air in order to vent properly. The venting system

should be checked periodically.

Young children should

be

carefully supervised

Recent trends in home improvement and

new

when they are in the same room as the room

tighterconstructiontechniqueshavecontributed

heater.

to problems with venting. If you suspect that

e

your heater is

not

venting properly, do not operate

Clothing or other flammable material should not

and

seek

expert advice.

be

placed on or near

the

room heater.

For added safety, this heater is equipped with a

vent sensor which will react to incorrect venting

The glass window

unit

must be

put

back in place

by shing d&n the

gas

supply.

prior to operating the heater if

it

has been removed

for servicing or cleaning.

Do not use this heater if any part has been under

water. Immediately call a qualified service

This room heater should beinstalled and repaired

technician to inspect the heater and to replace

by a qualified service person.

any part of the control system and any gas

control which has been under water.

The heater should be inspected before use and

at

least annually by a professionalsewice person.

If any chanaes aremade ta the room construction

More frequent cleaning may be required due to in thevicinity of the heater after installation (e.g.

excessive lint from carpetting, bedding material, additional mantle etc.), mn!te sure that such

-

etc.

It

is imperative

that

control compartments,

changes conform to the installation requirements

burners and circulating air passageways of the in this manual.

heater be kept clean.

When equipped

with

the optional vent primer

Keep curtains, clothing, furniture and other

(Part #300VP) or power vent kit (Part

#501

PVK),

flammable materials

at

least36ins (900mm) from

the heater must

be

installed and electrically

the front and top of the heater. grounded in accordance with local codes or, in

the absence of local codes, with the latest edition

Keep

the heater area well clear and free from of the National Electrical Code ANSIINFPA 70 (in

combustible materials, gasoline and other

U.S.A.)

or

CSA

C22-1 Canadian Electrical Code.

flammable vapors and liquids.

Never attemptto bum paper or any other material

in the heater.

Note

-

On

first lighting your new heater, there may be a slight odor and the appearance of a small amount of vapor.

This is normal

with

any new gas appliance. It is not harmful and will disappear within a short time.

INSTAUATION

INSTRUCTIONS

1.

GENERAL

This appliance is certified by

the

Canadian

/'.

Gas

Association and the American

Gas

Association for use with natural gas.

The

installation must conform

with

local codes

or, in the absence of local codes,

with

the

current CANICGA1 -B149 Installation Code in

Canada or the current National Fuel

Gas

Code, ANSI 2223.1 in

the

U.S.A

Only qualified

(licensed or trained) personnel should

install the appliance.

The appliance rating plate is on the inner face

of the back panel

at

the left side. There is also

a label giving the serial number, on the

,right

-

side

of

the outer case near the bottom.

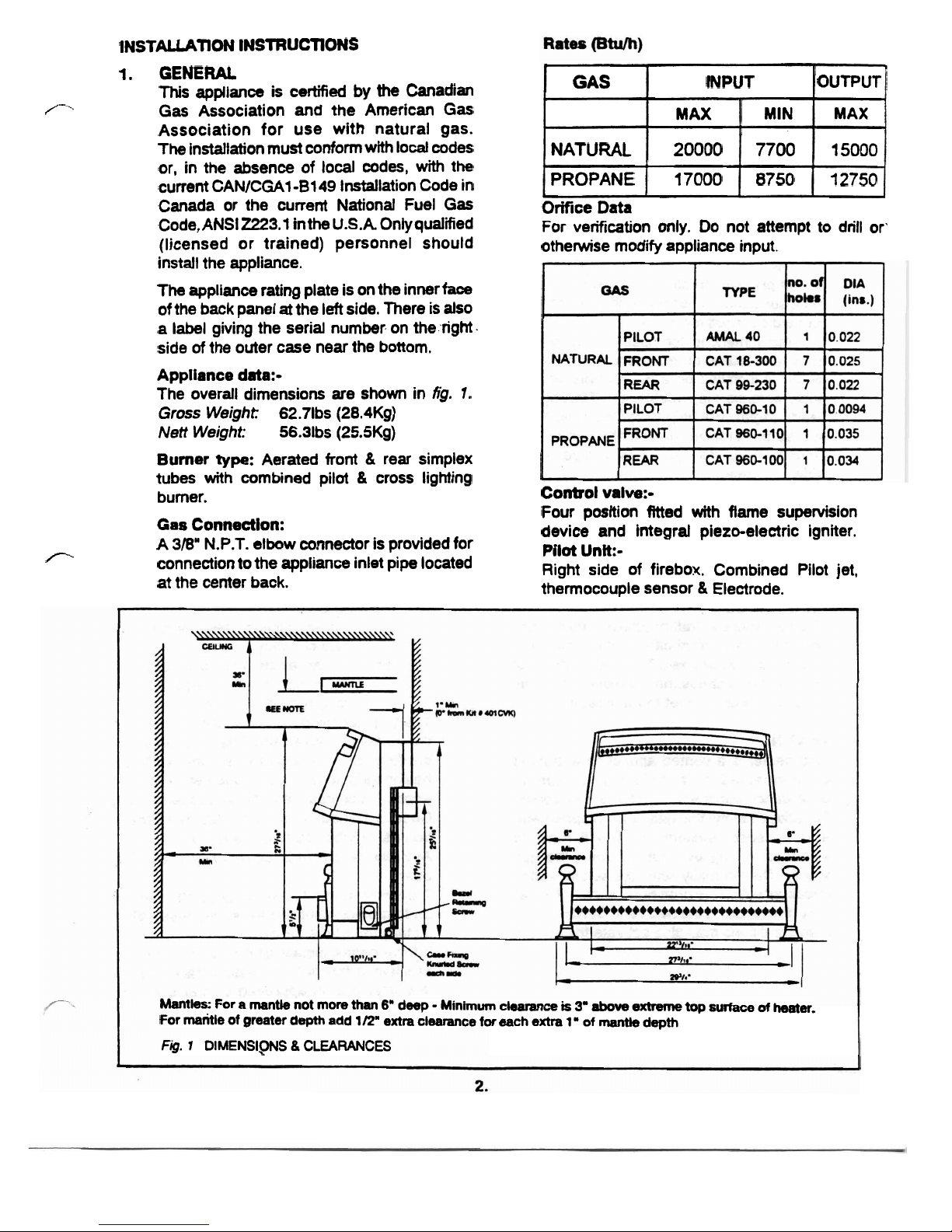

Appliance data:-

The overall dimensions are shown in

fig.

1.

Gross

Weight:

62.71bs (28.4Kg)

Nett Weight:

56.31bs (25.5Kg)

Burner

type:

Aerated front & rear simplex

tubes with combined pilot

&

cross lighting

burner.

Gas

Connection:

A

3/6"

N.P.T. elbow connector is provided for

r‘

connection to the appliance inlet pipe located

at the center back.

Orifice

Data

For verification only. Do not attempt to drill or'

otherwise modify appliance input.

Control valve:-

Four position fitted with flame supervision

device and integral piezo-electric igniter.

Pilot

Unit:-

Right side of firebox. Combined Pilot jet,

thermocouple sensor

&

Electrode.

1

OUTPUT

MAX

15000

12750

GAS

NATURAL

PROPANE

Mantles:

For a mantle not more

than

6"

deep - Minimum

clearance

is

3'

above

extreme

top

surface

of

heater.

For

mantle

of

greater

depth add

112"

extra

clearance

for

each

extra

1'

of

mantie

depth

Fig.

1

DIMENSIPNS 8 CLEARANCES

INPUT

MAX

20000

17000

MIN

7700

8750

CLEARANCES

Make sure that

the

minimum clearances to

combustible materials are maintained during

installation including adequate space for

the

proper operation and servicing of the heater.

The minimum clearances from the heater to

combustible materials are shown in

figure

7.

The combustion air opening below the apron

and the air intake slots

at

the sides of the case

rear must not

be

obstructed.

FLOOR

Do not place the heater on carpeting, vinyl or

other soft surfaced

floor coverings. Install only

on hard surfaced materials.

It is recommended for aesthetic considera-

tions and ease of maintenance that the

heater is installed on a hearth finished

with

brick, ceramic tile, marble etc. Raising the

hearth slightly

will

help to minimise dust and

lint accumulation under the unit. The

recommended minimum hearth size is

32"

wide x 12" deep.

If however, the heater is installed directly on

flooring

of

combustible material other than

wood, it must

be

installed on a metal or wood

panel extending the full width and depth of

the heater.

1.3.

DRAFT

HOOD

This heater has a draft hood built into its back

and draws its air from either side. It must not

be altered or obstructed. The draft hood must

be in the same atmospheric pressure zone

as

the combustion air inlet to the heater.

1.4.

VENTING

This heater is a vented appliance and must

be connected to a chimney or flue in

accordance with the national and local codes.

For added safety, this heater is equipped with

a vent sensor system which

will

react to

incorrect venting by shutting down the gas

supply. The thermally activated sensor switch

is located within the draft hood to detect either

a blocked or disconnected vent. Certain back-

draft conditions may also activate the switch.

1

b.

OPTlONAL ACCESSORIES

The

following kits

can

be

used

with

this

appliance:-

i)

#300VP

Vent Primer

-

Designed to momentarily overcome

a

backdraft condition allowing the heated

products of combustion to 'prime" the

vent and establish the natural venting

process.

ii).

#401CVK Concealed Vent Kit

Required for use with a new zero clearance type installation. It allows the

heater to

be

installed with type B metal

vent concealed behind a wall or partition

andlor in a chase.

iii)

#SO1

PVK

Power Vent

Kit

Allows the heater to be vented through

a sidewall (horizontally).

The

power vent system may be used

in combination with the

#401CVK

concealed vent kit.

Full installation

and

operating instructions are

supplied with the

ki.

For full details about these

kits,

contact your

dealer.

1.6.

POSSIBLE INSTALLATIONS

This appliance can be installed:

1.

As a retrofit

a)

To an existing masonry fireplace

and chimney.

b)

To an existing factory built zero

clearance type fireplace with a

factory built chimney.

The fireplace must be built in accordance

with

the national, state, provincial or territorial

building code recognised by the authority

having jurisdiction, or in the absence of such

a code, in accordance with

the

National Building

Code

of

Canada or the National Fire Protec-

tion Association code in the

U.S.A

Any flue damper must

be

remwed or blocked

open.

The chimney must

be

swept and both chimney

and fireplace checked for soundness before

installation of the heater.

If local codes dictate or

if

condensation is a

problem, a flue liner must be installed. Use a

flue liner that is approved by the enforcing

0

authority and that is installed in accordance

with the manufacturers instructions.

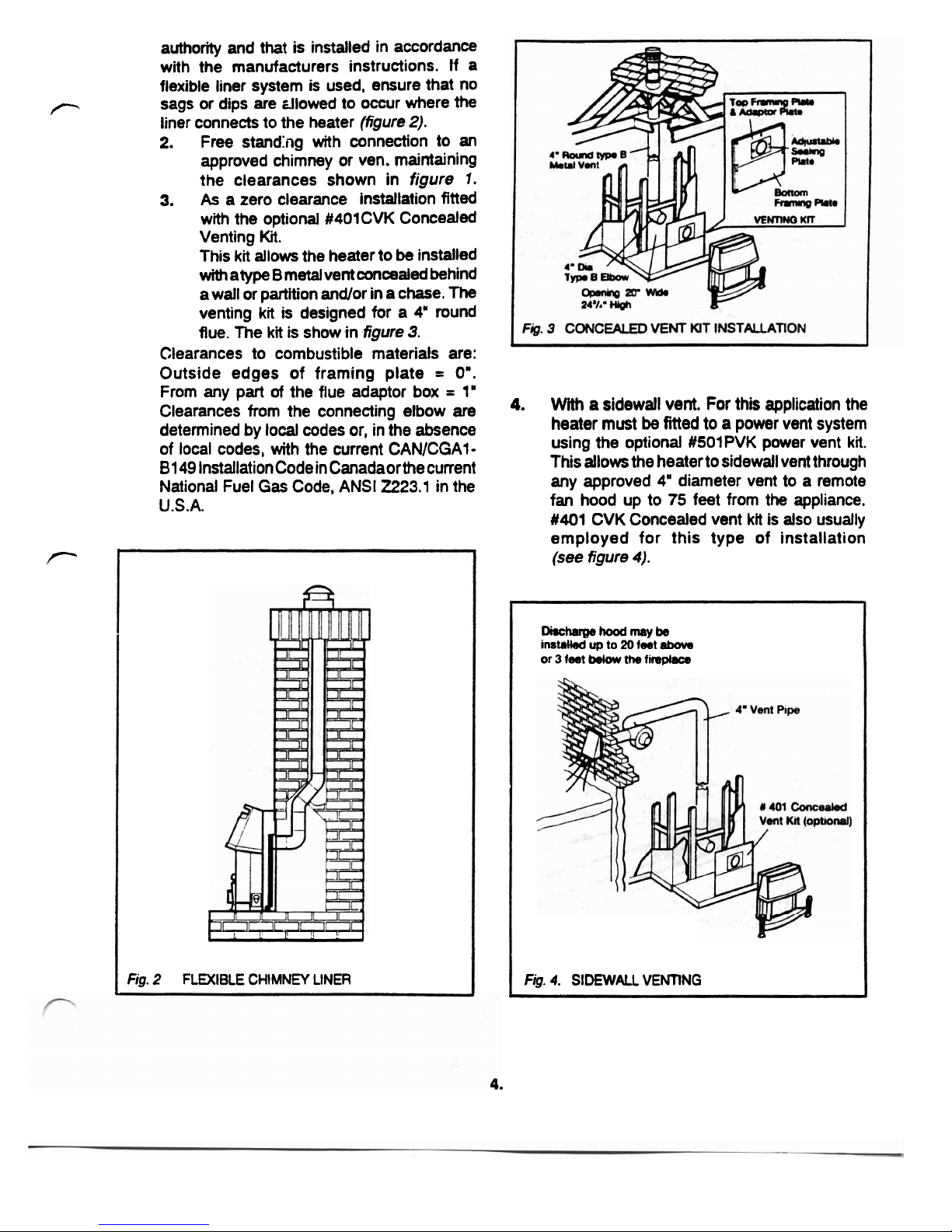

If a

flexible liner system is used, ensure that no

P

sags

or

dips are zllowed to occur where

the

liner connects to the heater

(figure

2).

2.

Free standhg with connection to

an

approved chimney or ven. maintaining

the clearances shown in

figure

I.

3.

As

a zero clearance installation fitted

with the optional

#401CVK Concealed

Venting

Kit.

This

kit

allows the heater to

be

installed

with

atype B metal vent concealed behind

a

wall or partition and/or in a chase.

The

venting

kit

is designed for a

4"

round

flue.

The

kit

is show in

figure

3.

Clearances to combustible materials are:

Outside edges of framing plate

=

0".

I

1

1

I--.-

7

Fig.

2

FLEXIBLE CHIMNEY LINER

Di=hwP-mcrybe

instnW

up

to

20

feet

atwe

or

3

feet

bdow

the

firsplace

Fig.

4.

SIDEWALL

VENTING

From any p&

of

the flue adaptor box

=

1"

Clearances from the connecting elbow are

4.

With

a

sidewall vent. For this application the

determined by local codes or, in the absence

heater must

be

fitted to a power vent system

of local codes, with the current CANICGA1-

using the optional #SOlPVK power vent

kit.

81

49

Installation Code in Canadaorthe current

This allows the heater to sidewall vent through

National Fuel

Gas

Code, ANSI

2223.1

in the

any approved

4'

diameter vent to a remote

U.S.A.

fan hood up to

75

feet from the appliance.

#401

CVK

Concealed vent

ktt

is also usually

P

employed for this type of installation

(see figure

4).

2.

UNPACKING

The

carton contains

the

following:-

1

Heater assembly.

3

Ceramic logs.

1

Flue collar.

1

Pack fixing screws.

2

Plastic

caps

for foot screws.

1

Smoke match tube.

Remove all the items carefully to prevent damage.

Some items may

be

contained in the packaging

fitments

-

Examine the packaging carefully before

discarding. Check that

ail the items are present and

undamaged.

PREPARATION

Stand the heater upright.

Detach the window trim unit by sliding

its

side

channels upwards to clear the location

brackets on the window frame sides. Pull the

bottom

ofthe trim unit forward slightly and then

pull down to clear the outer case hood

-

see

figure

5,

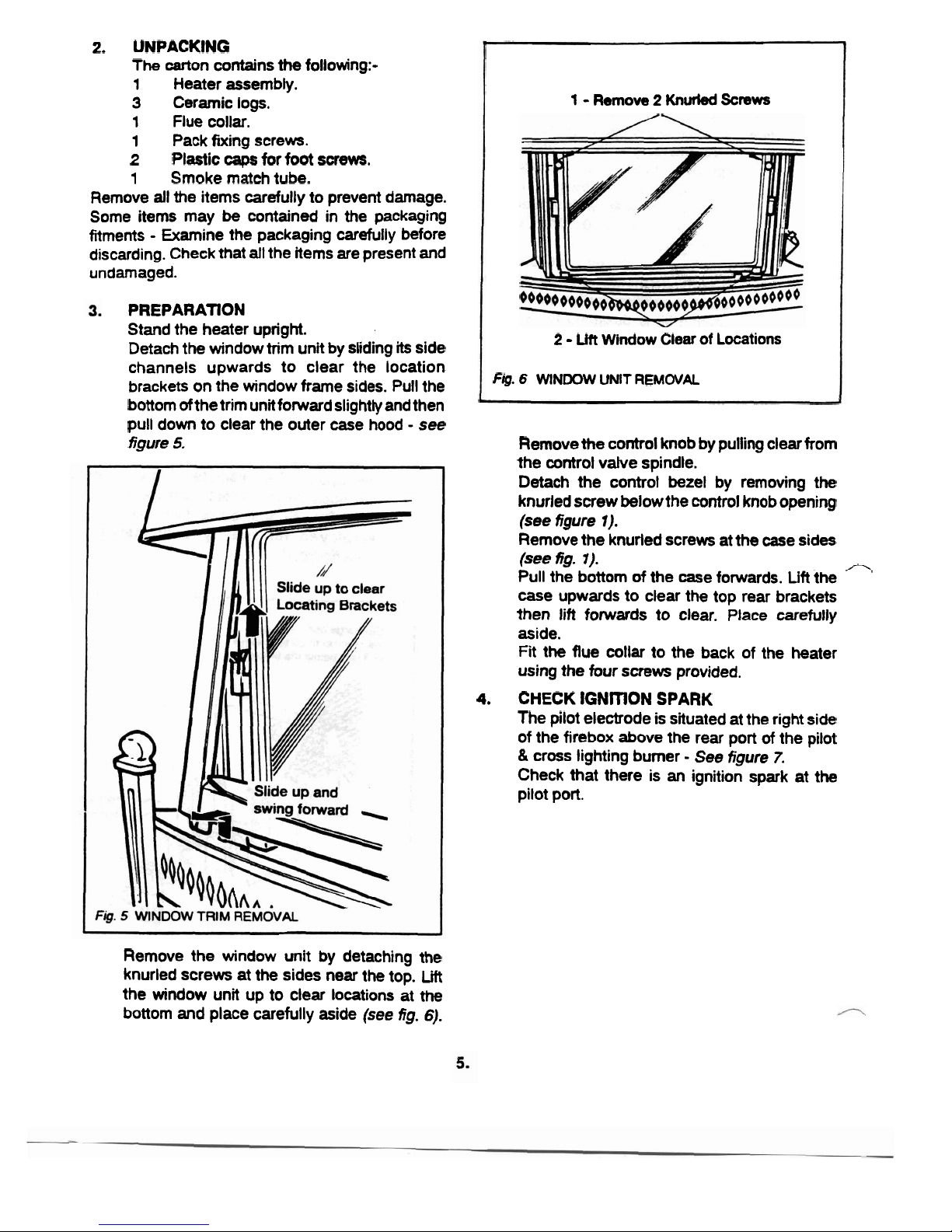

Remove the window unit by detaching the

knurled screws at the sides near the top.

Lift

the window unit up to clear locations at

the

bottom and place carefully aside

(see

fig.

6).

1

-

Remove 2 Knurled Screws

2 - Lilt

Window

Clear

of

Locations

Fig. 6 WINDOW

UNIT

REM

WAl

Remove the control knob by pulling clear from

the control

valve spindle.

Detach the control bezel by removing the

knurled screw below the control knob opening

(see

figure

1).

Remove the knurled screws at the case sides

(see

fig.

7).

/7

Pull the bottom

of

the case forwards.

Lift

the

case upwards to clear the top rear brackets

then lift forwards to clear. Place carefully

aside.

Fit

the flue collar to the back of the heater

using the four screws provided.

4.

CHECK

IGNITION SPARK

The pilot electrode is situated at the right side

of the firebox above the rear port

of

the pilot

&

cross lighting burner

-

See

figure

7.

Check that there is

an

ignition spark at the

pilot port.

Loading...

Loading...