Valor 4190, 4191 Installer's Manual

F

t

INSTALLER GUIDE

MODEL 4190 (For Natural Gas)

MODEL 4191 (For Propane Gas)

Inset Live Fuel Effect

Gas Fires

with

UltimateFireslide

or

Fusion

ron

Please ke e p in a safe p l ac e for fut ur e r e fe r e n c e

600A917/03

1

Please leave this Installer Guide with the user

y

Model 4190 is for use with natural gas (G20)

Model 4191 is for use with propane gas (G31)

These appliances are for use in the United

Kingdom (GB) and the Republic of Ireland (IE)

onl

.

CUSTOMER CARE

This Installer Guide gives sufficient details to enable the appliance to be installed

and maintained. If further information is required, our Valor AdviceLine will

be pleased to hel p.

Please telephone 0345 626341 (Local call rates apply)

2

CONTENTS

Page

Appliance Data ........................................................................................................................................................... 4

General Installation Requirements............................................................................................................................ 4

Contents of Pack..............................................................................................................................................……. 8

Preliminary Ignition Check....................................................................................................................................... 9

Fireplace Requirements............................................................................................................................................. 10

Gas Supply Pipe.......................................................................................................................................................... 11

Preparing Appliance for Installation........................................................................................................................... 12

Convection Box Installation....................................................................................................................................... 13

Burner Installation..................................................................................................................................................... 15

Front Surround & Control Linkage Installation........................................................................................................ 16

Ceramic Coals & Walls Installation .......................................................................................................................... 17

Operating Checks....................................................................................................................................................... 20

• Fire Control Check.............................................................................................................................................

• Reference Pressure Check....................................................................................................................................

• Spillage Check......................................................................................................................................................

Final Review............................................................................................................................................................... 22

Servicing & Parts Replacement.................................................................................................................................. 23

• Ignition Microswitch ...........................................................................................................................................

• Gas Shut-off Microswitch ...................................................................................................................................

• Fire Front..............................................................................................................................................................

• Control Slide Button ...........................................................................................................................................

• Control Slide Unit................................................................................................................................................

• Electronic Ignition Generator .............................................................................................................................

• Thermocouple Interrupter Block.........................................................................................................................

• Burner Unit..........................................................................................................................................................

• Pilot Unit..............................................................................................................................................................

• Gas Shut-off Tap..................................................................................................................................................

• Gas Flow Rate Controller ....................................................................................................................................

• Injector - Main Burner.........................................................................................................................................

• Burner Plaques.....................................................................................................................................................

• Removing Appliance from Fireplace ...................................................................................................................

• Spare Parts - Short List ........................................................................................................................................

20

21

21

23

23

24

25

25

25

26

26

26

27

27

27

28

28

29

3

1. APPLIANCE D ATA

This product uses fuel effect pieces, burner compartment walls and gaskets containing

Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres.

Excessive exposure to these materials may cause temporary irritation to eyes, skin and

respiratory tract. Consequently, it makes sense to take care when handling these articles

to ensure that the release of dust is kept to a minimum. To ensure that the release of

fibres from thes e RCF articles is kept to a m inimum, during inst allation and servic ing

we recommend that you use a HEPA filtered vacuum to remove any dust and soot

accumulated in and around the fire before and after working on the fire. When replacing

these articles we recommend that the replaced items are not broken up, but are sealed

within a heavy duty poly thene bag , clearly lab elled as R CF wast e. This is not clas sified

as “hazardous waste” and may be disposed of at a tipping site licensed for the disposal of

industrial waste. Protective cl othing is no t required when handling th ese articles, but we

recomm end y ou follo w the norm al hygie ne rule s o f not s mo king, e ating or drinking in

the work area and always wash your hands before eating or drinking.

This appliance does not contain any component manufactured from asbestos or

asbestos related products.

The applia n c e data label is chain ed bel o w th e burner a nd is visibl e when the bottom

front cover is removed.

Model 4190 Model 4191

Gas Natural (G20) Propane (G31)

Inlet Pressu re 20mbar 37mbar

Input - Max. (Gross) 6.0kW (20,500Btu /h ) 6.1kW (20,800Btu/h)

Input - Min. (Gross) 2.7kW (9,200Btu/h) 4.3k W (14,650Btu/h)

Output - Ma x. 3.5kW (11,900Btu/h) 3.17kW (10,800Btu/h)

Output - Min 1.3kW (4,450Btu/h) 2.24k W (7,600Btu/h)

Burner Test Pressure

(Cold)

Gas Connection 8mm pipe 8mm pipe

Burner Injector Bray Cat. 82 Si ze 400 Bray Cat. 92 Si ze 190

Pilot & Atmosphere

Sensing Devi c e

Ignition Piezo Electric. Integral wi th

Aeration Non-adjustable Non-adjustable

17.0±0.75mbar (6.8±0.3in

w.g.)

SIT Ref. OP9030 SIT Ref. OPLPG9221

Gas Tap

36.0±0.75mbar

(14.45±0.3in w.g.)

Piezo Electric. Integral wi th

Gas Tap

2. GENERAL INSTALLATION REQUIREMENTS

2.1 The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas appliances are

installed by competent persons in accordance with the current edition of the Gas Safety

(Installation and Use) Regulations. Failure to install the appliance correctly could lead

to prosecution. The Council for the Registration of Gas Installers (CORGI) requires

its members t o w ork to recognised stand ards.

In the United Kingdom the installation must also be in accordance with:

a) All the relevant parts of local regulations.

b) The current edition of the Building Regulations issued by the Department of the

Environmen t a nd the Welsh O ffice or th e Building Standar d s (Scotl and)

Regulat ions issu ed by the Scott ish Develo p ment Depar t ment.

c) All relevant codes of practice.

4

d) The relevant parts of the current editions of the following British

Standards:BS 715

BS 1251

BS 1289 Part 1

BS 1289 Part 2

BS 4543 Part 2

BS 5440 Part 1

BS 5440 Part 2

BS 5871 Part 2

BS 6461 Part 1

BS 6891

BS 8303

In the Republic of Ireland the installation must also conform with

the relevant parts of:

a) The current editi o ns of:-

** Does not apply to pre-cast flues - See

section 2.2.3

IS 813

ICP3

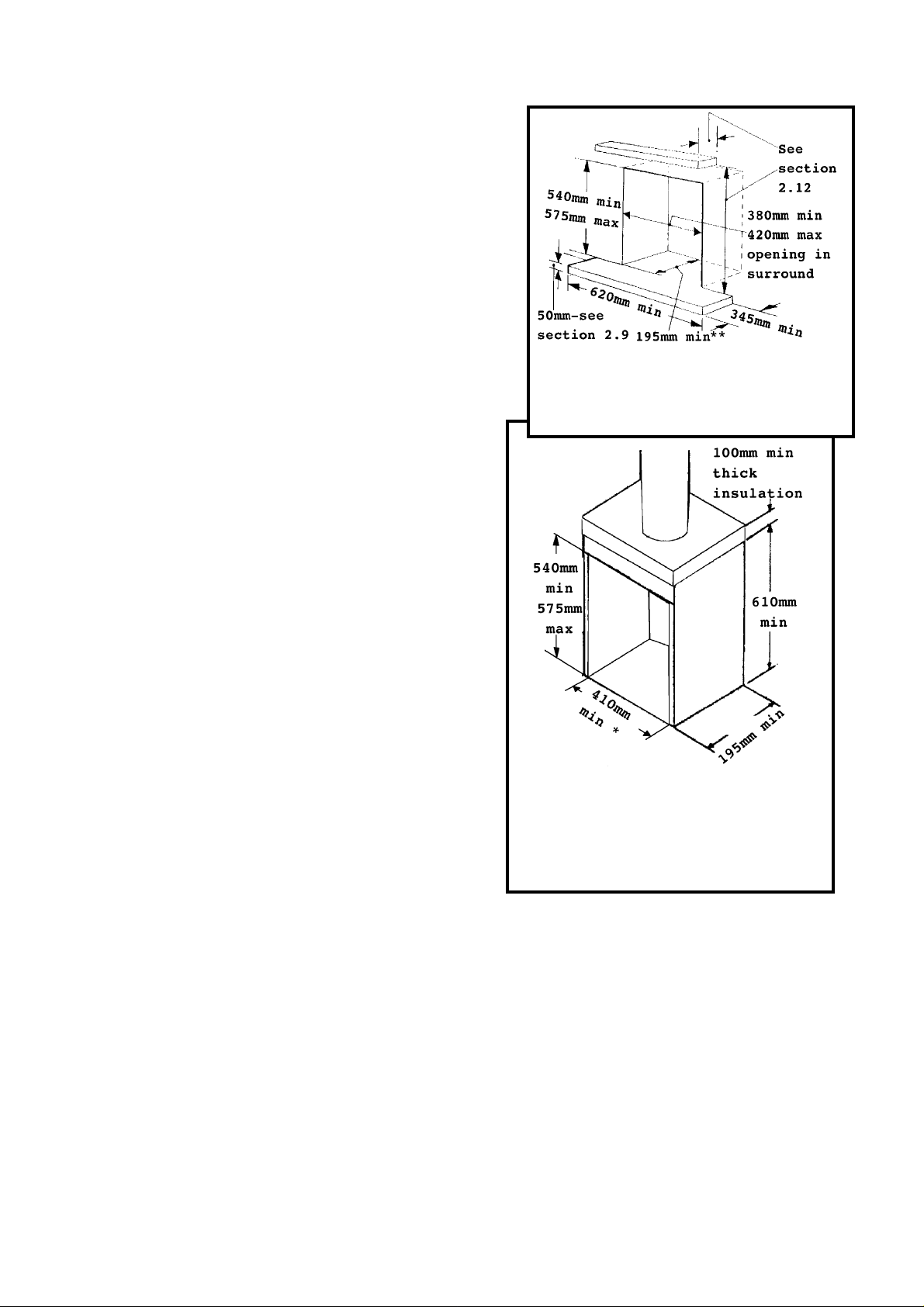

Fig. 1 Hearth & Fireplace Opening

IS327

b) All relevant national and local rules in force.

2.2 In the United Kingdom, as supplied, this appliance can be

installed in the following situations:-

2.2.1 To a fireplace complete with surround and hearth as shown

in figure 1 and c omplying with BS1251. The required fir epl ace,

hearth, debris catchment area a nd clearance di mensions are shown

in figure 1.

2.2.2 To a fireplace incorporating a twin walled metal flue box

complying with the constru ctional r equirements of th e c urrent

edition of BS 715 and standing on a non-co mbustible base The

dimensions of the flue box must conform to the opening shown

in figure 2. F or flue d etails see sectio ns 2.3 & 2.4.

2.2.3 To a fireplace that has a precast concrete or clay flue block

system conforming to BS1289. The a pplianc e i s suitable for

install ations conforming to ol der version s of BS1289 a s wel l as the

current edition. The flue blocks must have a minimum width not

less than 63mm and a cross-sectional area not less than

2

13,000mm

area of 13, 000mm

16,500mm

Older ed itions of BS1289 requir ed a cross-sec t ional

.

2

2

. The current revision of the standard requires

. This appliance is suitable in both cases. The total

depth of the open i ng measured from the fi n ished fr on t of the

fireplace (Including plaster, surround etc.) must be not less than

* If inte r n al width i s g r e ater th an 440mm the

opening width must be reduced to not more

than 40mm to ensure adeq u ate s e al ing to fire .

Fig. 2 Twin wall metal flue box

(Internal dimensions)

100mm.

The flu e starter blocks should no t be m odifi ed .

The current version of BS1289 recommend s that there sh ould be an a ir space or

insulation between the f l ue blocks and the plaster because heat tran sfer may cause

cracking on directly plastered flues. However, generally this appliance is suitable for

installati o ns und er all c ircu mst ances unless there is a history of c racki ng problems.

Remember that faults such as cracking may be caused by poorly built and restrictive

flues, e.g. mortar extrusions, too many bends, flue heights below three metres,

restrictive terminations, etc.

2.2.4 To a builder’s opening within the dimensions shown in figure 1.

5

2.3 Suitable flues and minimum flue sizes are as follows:a) 225mm x 225mm conventi onal bri c k flue.

b) 175mm diameter l ined bri c k or stone flu e.

c) 200mm diameter factor y ma de insul ated flu e ma nufactured to BS4543.

d) 175mm diameter flue pi pe. See BS6461 Part 1 f or suitable materia ls.

e) Single wall, twin wall or flexible flue liner with a minimum diameter of 125mm.

The materials to be used a re stainl ess steel or aluminium as specifi ed in BS715.

f) A properly constructed precast concrete or clay flue system conforming to

BS1289 Part 1 or 2. This system is only suitable when the co nditions stated in sec tion

2.2.3 are met.

2.3.1 It should be noted that, as with many appliances, sharp bends or horizontal runs

in metal f lues at the top of the system can be a cause of probl ems i n these types of

installation.

2.4 The minimum effective height of th e flue must be 3m.

2.5 The flue must not be used for any other appliance or application.

2.6 Any chimney damper or restrictor should be removed. If removal is not possible,

they must be secur ed in the open position.

2.7 If the appliance is intended to be installed to a chimney which was previously

used for solid fuel, the flue must be swept clean prior to installation. All flues should be

inspecte d for soundn ess and f reedom from block ages.

2.8 If the fireplace opening is an underfloor draught type, it must be sealed to stop

any draughts.

2.9 The appliance must be mounted behind a non-combustible hearth (n.b

conglomerate marble hearths are considered as non-combustible). The appliance can

be fitted to a purpose made pr oprietary class “O” 150°C surround. The hea rth materi a l

must be at least 12mm thick. The periphery of the hearth (or fender) should be at least

50mm above floor l evel to discourage the placi n g of carpets or r ugs over it.

The surfac e of the hearth must be suffi c i ently flat to enable the bottom of the front

surroun d , the burn er bracket an d th e bottom front cover c a sti ng to be aligned

horizontally. Any excessive unevenness (uneven tiles, Cotswold stone, etc.) should be

rectified.

The appliance must not stand on combustible

materials or carpets.

The appl i anc e must not be fi tte d d i r e c tly against

a combustible wall. If the applia nce is to be fitted

against a wa l l with combustible claddi ng, the cla d d ing

must be removed from the area c overed by the outer

surround (see figure 3). We suggest that the actual

surround is used as a template to mark the area for

combustible cladding removal.

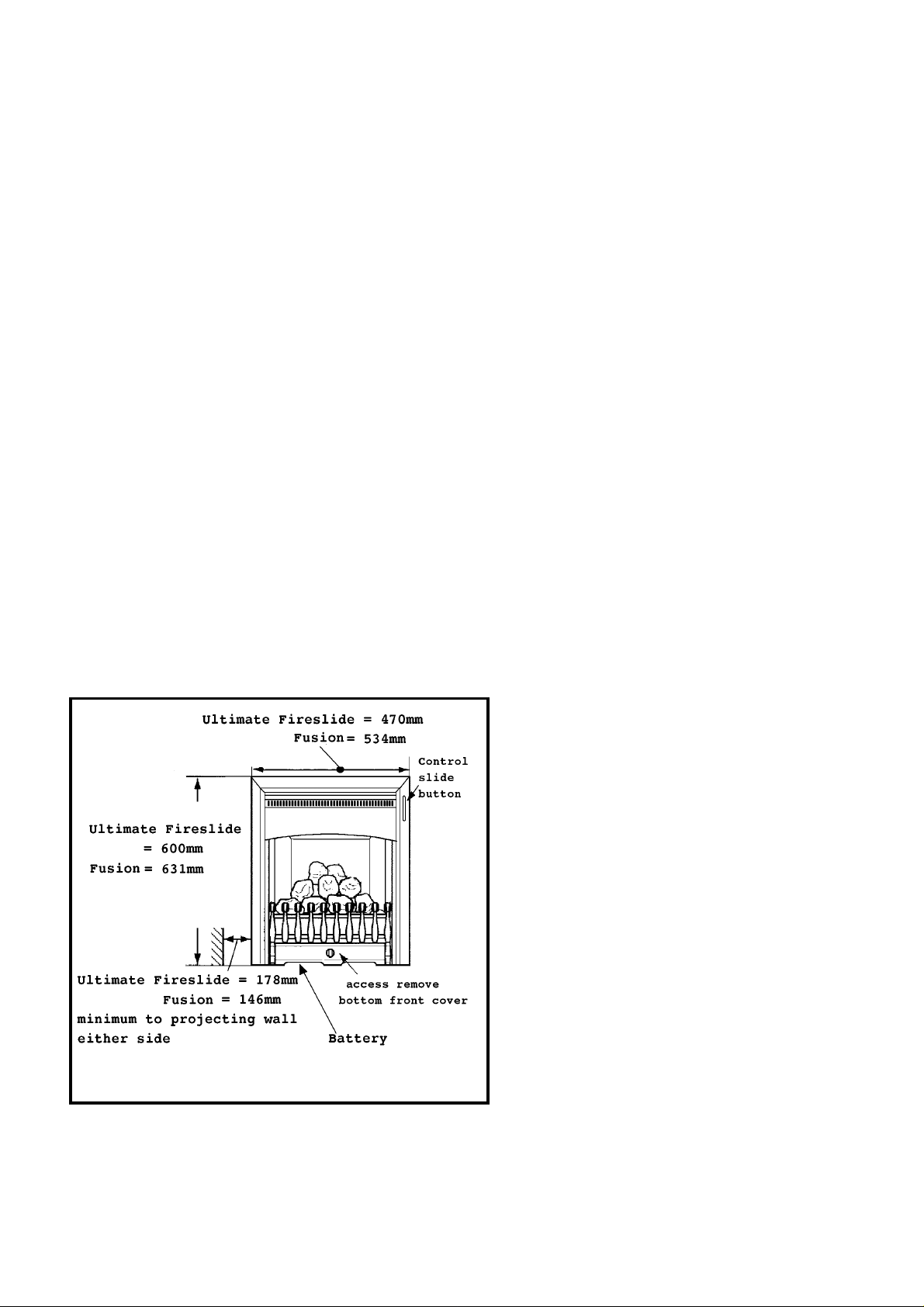

Fig 3 Front dimensions & side clearance to projections

2.12 The minimum height f rom the top surf ace of the hea rth to the un derside of any

shelf made f r om wood or other combu sti ble material s i s a s follows:-

• For a shelf up to 150mm deep

Minimum height = 750mm.

• For a shelf deeper than 150mm

750mm + 12.5mm for ever y 25mm depth over 150mm.

2.10 The minimum distan c e f rom the outsid e edge

of the fron t su rround to a corner wa ll or other

projection which extend s f u rther forw a r d than the

front of the appliance at either side is shown in

figure 3.

2.11 The front face of the fireplace should be

reasonabl y f lat over the area covered by th e c onvection

box top a nd sid e flan g e seals to ensure good sealin g .

These face s should b e m ade good if nec essary.

The fireplace floor should be reasonably flat to ensure

that a good seal with the convection box can be made.

6

2.13 Note that soft wall cover ings (e.g. embossed vinyl, etc .) are easi ly affected by

heat. They may scorch or become d i scoloured wh en c lose to a heatin g a ppl iance. Pl ease

bear this in mind when installing.

2.14 This appliance must not be installed in any room which contains a bath or

shower or where steam is regu larly pr esent.

2.15 An extractor fan may only be used in the same room as this appliance, or in any

area from which ventilation for the appliance is taken, if it does not affect the safe

performance of the appliance. Note the spillage test requirements detailed further on in

this manual. If the fan is likely to affect the appliance, the appliance must not be

installed unless the fan is permanently disconnected.

2.16 In the United K ingdom (GB) no special ventilation bricks or vents are required

in the room for this appliance.

In the Republic of Ireland (I.E.), permanent ventilation must comply with the

regulations currently in force.

2.17 Propane gas appliances must not be installed in a room which is built entirely

below groun d level (see BS 5871 Part 2).

7

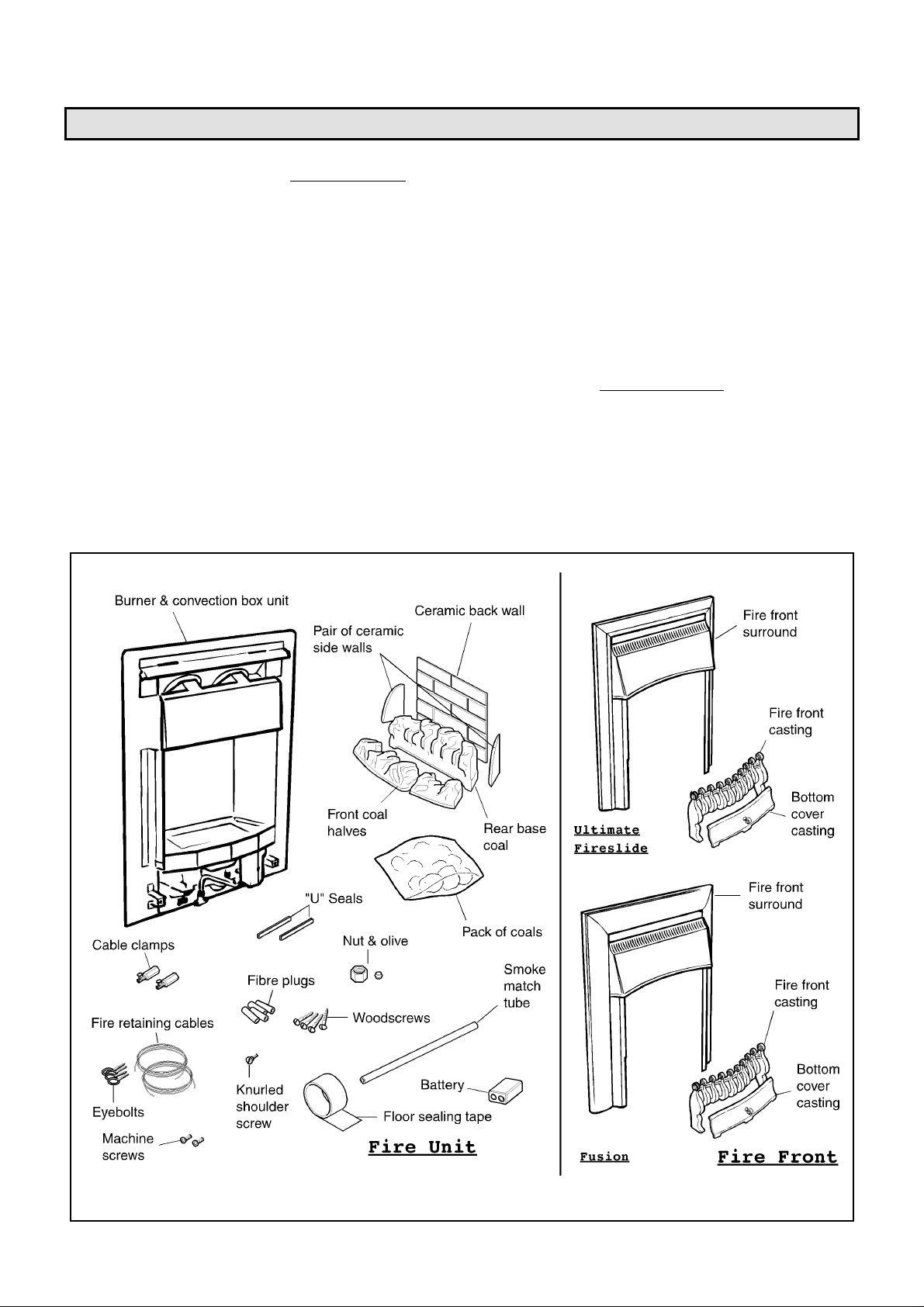

3 UNPACKING & PRELIMINARY CHECKS

The items required for this appliance are contained in two packs.

Pack 1 - Fire Unit contains:

1 Burner & Convection box Unit

with fron t surround

1 Nut & olive for 8mm inlet pipe

1 Ceramic back wall

1 Pair of ceramic side walls

1 Front base coal - left & right

halves

1Rear base coal

1 Pack of 7 loose coals

2 Small “U” seals for convec t ion

box side fla n ges

1 Strip of floor sealing tape

6Fibre plugs

4 Woodscrews

2 Fire retaining cables

2 Cable clamps

Carefully remove the contents. Take special care in handling the ceramic walls and the coals. Take care not to bend or

distort the slide control linkage when handling the fire front surround.

Check that all the listed parts are present and in good condition.

4Eyebolts

1 Knurled shoulder screw for

control linkage fixing

1 Installati on template

1 Battery

1 Smoke match tube

2 Machine screws for front

surround fixing

1 Literature pack

Pack 2 - Fire Front contains:

1 Fire front surround with

sliding control

1 Fire front casting

1 Bottom front cover casting

Fig. 4 Pack Contents

8

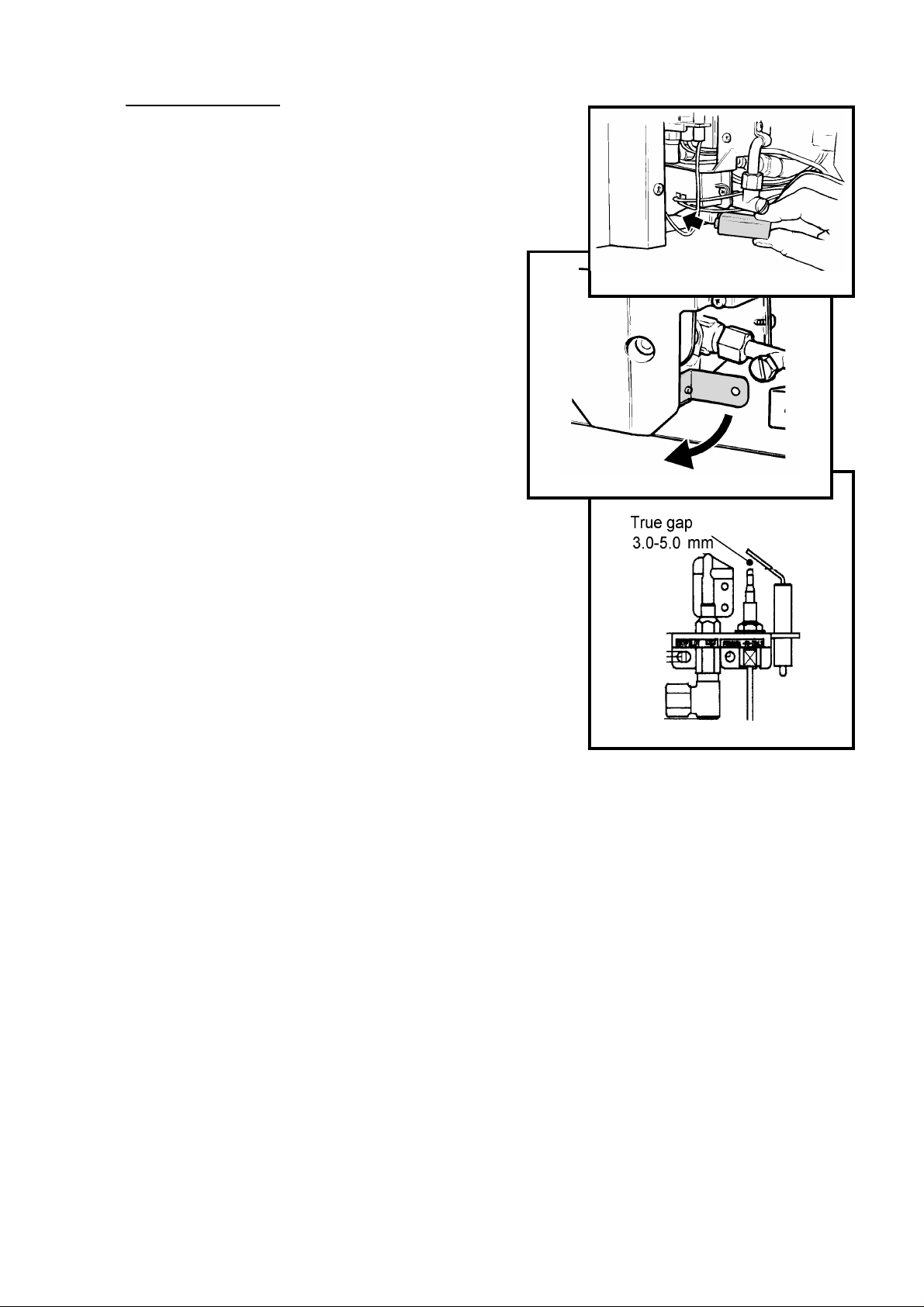

3.1 Check I gnition Sp ark

Before attemptin g to i nstall, i t is worth checki ng that the elec tr onic ignition

system perfo rms satisfactor ily.

3.1.1 Fit the battery to the ignition block located below the burner tray at

the left side (see figure 5). The positive terminal (+) is to the right as you

insert. The guide plate will help you to locate the battery

3.1.2 Rotate the control pivot bracket clockwise as far as it will go (see

figure 6). This should close the ignition circuit.

Sparks should be seen trac k ing from th e electrode pin to the

thermocoupl e tip (see figure 7).

If there are no spark s mak e the following checks.

a) Check condition of battery and that it is correctly fitted.

b) Check spark ga p between electrode wire and th ermocouple

tip (see figur e 7).

c) If a & b are satisfactory, check the ignition circuit and

components - see the servicing section in this manual

.

Fig. 6 Contr ol Pivot Rotation

Fig. 5 Batter y Fitting

Fig. 7 Pilot ignition system

9

Loading...

Loading...