INC.

FARM EQUIPMENT MANUFACTURER

ROUND BALE GRINDER

MODEL H

OPERATOR'S MANUAL

AND PARTS BOOK

VALMETAL INC.

SHREDDER

WARRANTY

Valmetal Incorporated (Valmetal) warrants a new SHREDDER to be free from defects in material and workmanship,

under normal use and service. Obligation under this warranty shall extend for a period of 1 year (12 months) following the date of delivery to the original purchaser and shall be limited to replacement or repair at Valmetal’s choice of

any parts found to be defective upon inspection by Valmetal.

WARRANTY CLAIMS

The purchaser claiming under this warranty shall submit a warranty claim in the prescribed form to Valmetal or an

Authorized Dealer, for inspection by an authorized company representative.

LIMITATIONS OF LIABILITY

This warranty is expressly in lieu of all other warranties expressed or implied and all other obligations or liabilities on

Valmetal’s part of any kind or character, including liabilities for alleged representations or negligence. We neither

assume nor authorize any other person to assume on our behalf, any liability in connection with the subsequent sale

of the SHREDDER.

This warranty shall not apply to any SHREDDER which has been altered outside the factory in any way if, according

to Valmetal, the alterations affected the SHREDDER’s operation and reliability, or if the SHREDDER has been subject to misuse or accident.

This warranty does not apply to parts that are under warranty by the original manufacturer and for which service can

be obtained directly through authorized service centers. No warranty is extended to regular service items such as

lubricants, belts, paint and the like.

OPERATOR’S MANUAL

The Purchaser acknowledges having received training on safe operation of the SHREDDER and further acknowledges that Valmetal does not assume any liability resulting from the operation of the SHREDDER in any manner

other than described in the Operator’s Manual supplied at the time of purchase.

INSPECTION PROCEDURE

Wheel bolts tight

Fasteners tight

Chains adjusted

Belts adjusted

Hydraulic fittings tight

Knives in good condition

All drives turn freely

Check tire pressures

Lubricate machine

All safety decals installed

Reflectors, lights and SMV clean

Guards and shields installed and secured

Review operating and safety instructions with customer

WARRANTY VOID IF NOT REGISTERED

SERIAL NUMBER LOCATION

Always state the serial number of your Valmetal Round Bale Grinder when ordering parts or requesting

service or other information.

The serial number plate is located where indicated. Please mark the number in the space provided for

easy reference.

MODEL TYPE:

SERIAL NUMBER:

Contents

SECTION 1 INTRODUCTION....................................................................................

SECTION 2

SAFETY.............................................................................................................................

2.1 GENERAL SAFETY.......................................................................................................................

2.2 OPERATING SAFETY...................................................................................................................

2.3 MAINTENANCE SAFETY..............................................................................................................

2.4 HYDRAULIC SAFETY....................................................................................................................

2.5 TRANSPORT SAFETY..................................................................................................................

2.6 STORAGE SAFETY.......................................................................................................................

2.7 TIRE SAFETY................................................................................................................................

2.8 SAFETY DECALS..........................................................................................................................

2.9 SIGN-OFF FROM...........................................................................................................................

SECTION 3 SAFETY DECAL LOCATIONS...............................................................

SECTION 4 OPERATION.........................................................................................

4.1 TO THE NEW OPERATOR OR OWNER......................................................................................

4.2 MACHINE COMPONENTS............................................................................................................

4.3 BREAK-IN......................................................................................................................................

4.4 PRE-OPERATION CHECKLIST....................................................................................................

4.5 EQUIPMENT MATCHING.............................................................................................................

4.6 CONTROLS...................................................................................................................................

4.7 ATTACHING / UNHOOKING MACHINE.......................................................................................

4.8 OPERATING..................................................................................................................................

4.9 TRANSPORTING..........................................................................................................................

4.10 STORAGE.....................................................................................................................................

SECTION 5 SERVICE AND MAINTENANCE...........................................................

5.1 SERVICE.......................................................................................................................................

5.1.1 FLUIDS AND LUBRICANTS................................................................................................................

5.1.2 GREASING.........................................................................................................................................

5.1.3 SERVICING INTERVALS...................................................................................................................

5.1.4 SERVICE RECORD...........................................................................................................................

5.2 MAINTENANCE.............................................................................................................................

5.2.1 SECTION REPLACEMENT................................................................................................................

5.2.2 BELT AND ROLLER CHAINS............................................................................................................

5.2.3 GEARBOX OIL...................................................................................................................................

5.2.4 BREATHER CLEANING.....................................................................................................................

5.2.5 SLIP CLUTCH MAINTENANCE.........................................................................................................

SECTION 6 TROUBLE SHOOTING...........................................................................

SECTION 7

SPECIFICATIONS.............................................................................................................

7.1 MECHANICAL...............................................................................................................................

7.2 BOLT TORQUE.............................................................................................................................

7.3 HYDRAULIC FITTING TORQUE...................................................................................................

7.4 HYDRAULIC CIRCUIT...................................................................................................................

Page

1

2

3

4

4

5

5

6

6

6

7

8

9

13

13

14

15

16

17

18

19

21

28

29

31

31

31

31

32

36

37

37

38

39

40

41

43

45

46

47

48

48

SECTION 1 INTRODUCTION

Congratulations on your choice of a ValMetal Round Bale Grinder to complement your farming operation.

This equipment has been designed and manufactured to meet the needs of a discriminating buyer for the efficient grinding of large round bales.

Safe, efficient and trouble free operation of your ValMetal Round Bale Grinder requires that you and anyone

else who will be operating or maintaining the Grinder, read and understand the Safety, Operation,

Maintenance and Trouble Shooting information contained in the Operator's Manual.

This manual covers the Model H Grinder manufactured by ValMetal.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your

ValMetal Dealer or Distributor if you need assistance or information.

OPERATOR ORIENTATION - The directions left, right, front and rear, as mentioned throughout this manual,

are as seen from behind the tractor driver's seat and facing in the direction of travel.

SAFETY

1

2

SAFETY

3

SECTION 2 SAFETY

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS:

The Safety Alert symbol identifies important

safety messages on the ValMetal Round Bale

Grinder and in the manual. When you see this

symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the

safety message.

Why is SAFETY important to you ?

3 Big Reasons

Accidents Disable and Kill

Accidents Cost

Accidents Can be avoided

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety

messages. The appropriate signal word for

each message has been selected using the

following guide-lines:

DANGER -

WARNING -

CAUTION -

An immediate and specific hazard

which WILL result in severe personal

injury or death if the proper precautions are not taken.

A specific hazard or unsafe practice

which COULD result in severe personal injury or death if proper precautions are not taken.

Unsafe practices which COULD

result in personal injury if proper

practices are not taken, or as a

reminder of good safety practices.

SAFETY

YOU are responsible for the SAFE operation and

maintenance of your ValMetal Round Bale Grinder.

YOU must ensure that you and anyone else who is

going to operate, maintain or work around the

Grinder be familiar with the operating and maintenance procedures and related SAFETY information

contained in this manual. This manual will take you

step-by-step through your working day and alerts you

to all good safety practices that should be adhered to

while operating the Grinder.

Remember, YOU are the key to safety. Good safety

practices not only protect you but also the people

around you. Make these practices a working part of

your safety program. Be certain that EVERYONE

operating this equipment is familiar with the recommended operating and maintenance procedures and

follows all the safety precautions. Most accidents

can be prevented. Do not risk injury or death by

ignoring good safety practices.

Grinder owners must give operating instructions to

operators or employees before allowing them to

operate the Grinder, and at least annually thereafter

per OSHA regulation 1928.57.

The most important safety device on this equipment

is a SAFE operator. It is the operator's responsibility

to read and understand ALL Safety and Operating

instructions in the manual and to follow these. All

accidents can be avoided.

A person who has not read and understood all operating and safety instructions is not qualified to operate the machine. An untrained operator exposes

himself and bystanders to possible serious injury or

death.

Do not modify the equipment in any way.

Unauthorized modification may impair the function

and/or safety and could affect the Iife of the equipment.

Think SAFETY! Work SAFELY!

2.1 GENERAL SAFETY

1 . Read and understand the Operator's Manual and

all safety signs before operating, maintaining or

adjusting the Grinder.

2. Have a first-aid kit available for

use should the need arise and

know how to use it.

3. Have a fire extinguisher

available for use should

the need arise and know

how to use it.

4. Wear appropriate protective gear. This list

includes but is not limited to:

- A hard hat

- Protective shoes with slip resistant soles

- Protective glasses or goggles

- Heavy gloves

- Hearing protection

5. Install and secure all guards before starting.

6. Wear appropriate ear

protection for prolonged

exposure to excessive

noise.

7. Raise grate, place all controls in neutral, stop

engine, set park brake, remove ignition key and

wait for all moving parts to stop before servicing,

adjusting, repairing, unplugging or filling.

8. Clear the area of people, especially small children, before starting the unit.

9. Review safety related items annually with all

personnel who will be operating or maintaining

the Grinder.

SAFETY

4

2.2 OPERATING SAFETY

1. Read and understand the Operator's Manual and

all safety signs before operating, servicing,

adjusting, repairing, unplugging or filling.

2. Do not allow riders when transporting.

3. Do not go into tub when engine is running.

Keep others out.

4. Keep hands,feet,hair and clothing away from

moving parts.

5. Raise grate, place all controls in neutral, stop

engine, set park brake, remove ignition key and

wait for all moving parts to stop before servicing,

adjusting, repairing, unplugging or filling.

6. Place all tractor controls in neutral before

starting.

7. Clear the area of bystanders, especially small

children, before starting.

8. Do not point the discharge toward people or animals when operating. Objects can be thrown out

at a speed fast enough to seriously injure some

one or cause death. Stay away from discharge

path when operating. Keep others away.

9. Never operate machine with a cracked, bent,

missing or broken section.

10. Keep all hydraulic lines, fittings and couplers

tight and free of leaks before using.

11. Clean reflectors, SMV and lights before

transporting.

12. Install optional lighting bar and use pilot vehicle

when transporting during times of limited visibility.

13. Use hazard flashers on tractor when transporting.

14. Install safety chains when attaching to tractor.

15. Review safety instructions with all operators

annually.

2.3 MAINTENANCE SAFETY

1. Follow ALL the operating, maintenance and

safety information in the manual.

2. Support the machine with blocks or safety stands

when changing tires or working beneath it.

3. Raise grate, place all controls in neutral, stop

engine, set park brake, remove ignition key and

wait for all moving parts to stop before servicing,

adjusting, repairing or unplugging.

4. Follow good Shop Practices

- Keep service area

clean and dry.

- Be sure electrical

outlets and tools

are properly

grounded

- Use adequate light

for the job at hand

5. Make sure all guards are in place and properly

secured when maintenance work is completed.

6. Never wear ill-fitting,baggy or frayed clothing

when working around or on any of the drive

system components.

7. Before applying pressure to a hydraulic system,

make sure all lines, fittings and couplers are tight

and in good condition.

8. Relieve pressure from hydraulic circuit before

servicing or disconnecting from tractor.

9. Do not go into tub when engine is running.

Keep others out.

10. Keep hands, feet, hair and clothing away from

moving or rotating parts.

11. Clear the area of bystanders, especially small

children, when carrying out any maintenance

and repairs or making any adjustments.

SAFETY

5

2.4 HYDRAULIC SAFETY

1. Always place all tractor hydraulic controls in

neutral before dismounting.

2. Make sure that all components in the hydraulic

system are kept in good condition and are clean.

3. Replace any worn, cut, abraded, flattened or

crimped hoses and steel lines.

4. Do not attempt any makeshift repairs to the

hydraulic lines, fittings or hoses by using tape,

clamps or cements. The hydraulic system

operates under extremely high-pressure. Such

repairs will fail suddenly and create a hazardous

and unsafe condition.

5. Wear proper hand and

eye protection when

searching for a high

pressure hydraulic leak.

Use a piece of wood or

cardboard as a backstop

instead of hands to

isolate and identify a

leak.

6. If injured by a concentrated high-pressure stream

of hydraulic fluid, seek medical attention immediately. Serious infection or toxic reaction can

develop from hydraulic fluid piercing the skin

surface.

2.5 TRANSPORT SAFETY

1. Make sure you are in compliance with all local

regulations regarding transporting equipment on

public roads and highways.

2. Make sure that a Slow Moving Vehicle emblem

and all the lights and reflectors that are required

by the local highway and transport authorities are

in place, are clean and can be seen clearly by all

overtaking and oncoming traffic.

Note

: Emblem, lights and reflectors are to be

supplied by owner, if needed.

3. Do not allow anyone to ride on the machine

during transport.

4. Do not exceed 32 km/h (20 mph) when transporting the machine. Reduce speed on rough roads

and surfaces.

5. Use a tractor of 60 horsepower or more to

transport machine.

6. Install lighting bar before transporting.

7. Use a drawbar pin with provisions for a retainer.

Install the retainer.

8. Attach safety chain between tractor and machine

before transporting.

SAFETY

6

WA

2.6 STORAGE SAFETY

1. Store the Grinder in an area away from human

activity.

2. Do not permit children to play on or around the

stored machine.

3. Make sure the unit is sitting, or blocked up firm

and solid and will not tip or sink into a soft area.

4. Cover with a weather-proof tarpaulin and tie

down securely.

2.7 TIRE SAFETY

1. Failure to follow proper procedures when mounting a tire on a wheel or rim can produce an

explosion which may result in serious injury or

death.

2. Do not attempt to mount a tire unless you have

the proper equipment and experience to do the

job.

3. Have a qualified tire dealer or repair service perform required tire maintenance.

2.8 SAFETY DECALS

1. Keep safety decals and signs clean and legible

at all times.

2. Replace safety decals and signs that are missing

or have become illegible.

3. Replaced parts that displayed a safety sign

should also display the current sign.

4. Safety decals or signs are available from your

Dealer Parts Department or the factory.

How to install Safety DecaIs :

* Be sure that the installation area is clean

and dry.

* Decide on the exact position before you

remove the backing paper.

* Remove the smallest portion of the split

backing paper.

* Align the decal over the specified area and

carefully press the small portion with the

exposed sticky backing in place.

* Slowly peel back the remaining paper and

carefully smooth the remaining portion of

the decal in place.

* Small air pockets can be pierced with a pin

and smoothed out using the piece of decal

backing paper.

SAFETY

7

2.9 SIGN-OFF FORM

ValMetal follows the general Safety Standards specified by the Society of Automotive Engineers (SAE) and

the Occupational Safety and Health Administration (OSHA). Anyone who will be operating and/or maintaining the Round Bale Grinder must read and clearly understand ALL Safety, Operating and Maintenance information presented in this manual.

Do not operate or allow anyone else to operate this equipment until such information has been reviewed.

Annually review this information before the season start-up.

Make these periodic reviews of SAFETY and OPERATION a standard practice for all of your equipment.

We feel that an untrained operator is unqualified to operate this machine.

A sign-off sheet is provided for your record keeping to show that all personnel who will be working with the

equipment have read and understand the information in the Operator's Manual and have been instructed in

the operation of the equipment.

SIGN-OFF FORM

SAFETY

8

DATE

EMPLOYEE'S SIGNATURE EMPLOYER'S SIGNATURE

SAFETY DECALS

9

The types of decals and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Decals, the type of warning and the area, particular function related to that area, that requires your SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

REMEMBER - If Safety Decals have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorized dealer.

SECTION 3 SAFETY DECAL LOCATIONS

HIGH-PRESSURE FLUIDE HAZARD

Relieve pressure on systeme before repairing or adjusting.

Wear proper hand and eye protection when searching for

leaks. Use wood or cardboard instead of hands.

Keep all compenents in good repair.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

RISQUE DE LIQUIDE SOUS HAUTE-PRESSION

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

15-60-0010

WARNING

AVERTISSEMENT

Éiminer toute pression sur le système hydraulique avant

d'effectuer une réparation ou un ajustement.

Toujours porter des gants et des lunettes de sécurité lorsque

vous recherchez une fuite. Utiliser un morceau de bois ou de

carton au lieu de vos mains.

Garder toutes les composantes en bonnes conditions.

DANGER

THROWN OBJECT HAZARD

To prevent serious injury or death from thrown

objects:

Do not place any part of body in front of discharge.

Do not point discharge at people or animals when

running.

PARTICULES PROVENANT DU

SYSTÈME DE DÉCHARGEMENT

Pour prévenir de sérieuses blessures ou décès dus aux

particules provenant du système de déchargement:

Ne jamais exposer une partie du corps devant la sortie

du système de déchargement.

Ne jamais diriger ou pointer la sortie du système

de déchargement vers toutes personnes ou animaux

durant l'utilisation.

1.

2.

1.

2.

17-60-0010

TUB HAZARD

Do not climb into machine when motor is

running.

keep others out.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

Ne pas monter sur la machine lorsque celle-ci

est en marche.

AVERTISSEMENT

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0120

WARNING

AVERTISSEMENT

ROTATING PART HAZARD

Keep all guards and shields in place.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

Garder tous les écrans protecteurs en place.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0120

WARNING

AVERTISSEMENT

Keep hands, feet, hair and clothing away from

moving parts.

Keep others away.

PIÈCE EN MOUVEMENT

Garder les mains, pieds, cheveux et vêtements

éloignés des éléments mobiles et rotatifs.

Garder les gens et les animaux à une distance

sécuritaire de la machine.

MOVING PART HAZARD

Keep hands out of machine when operating.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

En opération, ne pas mettre les mains dans la

machine.

PIÈCE EN MOUVEMENT

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0100

WARNING

AVERTISSEMENT

The types of decals and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Decals, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

REMEMBER - If Safety Decals have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorized dealer.

SAFETY DECALS

10

WARNING

HIGH-PRESSURE FLUIDE HAZARD

Relieve pressure on systeme before repairing or adjusting.

Wear proper hand and eye protection when searching for

leaks. Use wood or cardboard instead of hands.

Keep all compenents in good repair.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

RISQUE DE LIQUIDE SOUS HAUTE-PRESSION

Éiminer toute pression sur le système hydraulique avant

d'effectuer une réparation ou un ajustement.

Toujours porter des gants et des lunettes de sécurité lorsque

vous recherchez une fuite. Utiliser un morceau de bois ou de

carton au lieu de vos mains.

Garder toutes les composantes en bonnes conditions.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

15-60-0010

WARNING

WARNING

ROTATING PART HAZARD

Keep all guards and shields in place.

Keep hands, feet, hair and clothing away from

Keep all guards and shields in place.

Operate at 540 RPM maximum.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

Garder tous les écrans protecteurs en place.

Opérer à 540 RPM maximum.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0125

moving parts.

Keep others away.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

PIÈCE EN MOUVEMENT

Garder tous les écrans protecteurs en place.

Garder les mains, pieds, cheveux et vêtements

éloignés des éléments mobiles et rotatifs.

Garder les gens et les animaux à une distance

sécuritaire de la machine.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0120

The types of decals and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Decals, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

REMEMBER - if Safety Decals have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorized dealer.

SAFETY DECALS

11

WARNING

TUB HAZARD

Do not climb into machine when motor is

running.

keep others out.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

AVERTISSEMENT

Ne pas monter sur la machine lorsque celle-ci

est en marche.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

01-60-0120

WARNING

HIGH-PRESSURE FLUIDE HAZARD

Relieve pressure on systeme before repairing or adjusting.

Wear proper hand and eye protection when searching for

leaks. Use wood or cardboard instead of hands.

Keep all compenents in good repair.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

RISQUE DE LIQUIDE SOUS HAUTE-PRESSION

Éiminer toute pression sur le système hydraulique avant

d'effectuer une réparation ou un ajustement.

Toujours porter des gants et des lunettes de sécurité lorsque

vous recherchez une fuite. Utiliser un morceau de bois ou de

carton au lieu de vos mains.

Garder toutes les composantes en bonnes conditions.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS,

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LE MORT

15-60-0010

WARNING

MISSING SHIELD HAZARD

Install and secure shields before operating.

Keep hands, feet, hair and clothing away from

moving parts.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH

AVERTISSEMENT

GARDE ABSENT

Installer les gardes de façon sécuritaire avant

la mise en marche de la machine.

Garder les mains, pieds, cheveux et vêtements

éloignés des éléments mobiles.

À DÉFAUT DE SUIVRE CES INSTRUCTIONS.

CELA POURRAIT ENTRAÎNER DE SÉRIEUSES

BLESSURES OU MÊME LA MORT

01-60-0070

DANGER

ROTATING PART HAZARD

To prevent serious injury or death from rotating parts:

1.Do not open access door unless engine is off and

all parts have stopped moving.

2.Stop engine, place all controls in neutral, set park

brake, remove ignition key and wait for all moving

parts to stop before sevicing, adjusting, repairing,

unplugging or filling.

PIÈCES EN MOUVEMENT

Pour prévenir de sérieuses blessures ou décès dus

aux pièces en mouvement:

1.Ne pas ouvrir la porte d'accès à la vis sans que le

moteur ne soit au point mort et avant que toutes les

pièces en mouvements n'aient le temps de s'immobiliser.

2.Arrêter le moteur, mettre tous les contrôles au "neutre"

engager le frein de stationnement, enlever la clé de

l'ignition et attendre que toutes les pièces ne soient

plus en mouvement avant tout entretien, ajustement ou

réparation.

17-60-0005

SAFETY DECALS

12

The types of decals and locations on the equipment are shown in the illustration below. Good safety requires

that you familiarize yourself with the various Safety Decals, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

REMEMBER - if Safety Decals have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorized dealer.

DANGER

ROTATING PART HAZARD

1.Do not open access door unless engine is off and

all parts have stopped moving.

2.Stop engine, place all controls in neutral, set park

brake, remove ignition key and wait for all moving

parts to stop before sevicing, adjusting, repairing,

unplugging or filling.

1.Ne pas ouvrir la porte d'accès à la vis sans que le

moteur ne soit au point mort et avant que toutes les

pièces en mouvements n'aient le temps de s'immobiliser.

2.Arrêter le moteur, mettre tous les contrôles au "neutre"

engager le frein de stationnement, enlever la clé de

l'ignition et attendre que toutes les pièces ne soient

plus en mouvement avant tout entretien, ajustement ou

réparation.

17-60-0005

To prevent serious injury or death from rotating parts:

PIÈCES EN MOUVEMENT

Pour prévenir de sérieuses blessures ou décès dus

aux pièces en mouvement:

OPERATION

4.1 TO THE NEW OPERATOR

OR OWNER

ValMetal Round Bale Grinder are designed to efficiently grind large bales. Hay, straw, green feed and

paper can be used in this Grinder.

It is the responsibility of the owner or operator to

read this manual and to train all other operators

before they start working with the machine.

Follow all safety instructions exactly. Safety is

everyone's business. By following recommended

procedures, a safe working environments is provided for the operator, bystanders and the area

around the worksite. Untrained operators are not

qualified to operate the machine.

Many features incorporated into this machine are the

result of suggestions made by customers like you.

Read this manual carefully to learn how to operate the

machine safely and how to set it to provide maximum

grinding efficiency. By following the operating instructions in conjunction with a good maintenance program, your Grinder will provide many years of troublefree service.

SECTION 4 OPERATION

OPERATING SAFETY

1. Read and understand the Operator's Manual

and all safety signs before operating, servicing,

adjusting, repairing, unplugging or filling.

2. Do not allow riders when transporting.

3. Do not go into tub when engine is running.

Keep others out.

4. Keep hands, feet, hair and clothing away from

from moving parts.

5. Raise grate, place all controls in neutral, stop

engine, set park brake, remove ignition key and wait

for all moving parts to stop before servicing,

adjusting, repairing, unplugging or filling.

6. Place all tractor controls in neutral before starting.

7. Clear the area of bystanders, especially small children, before starting.

8. Do not point the discharge toward people or animals

when operating. Objects can be thrown out at a

speed fast enough to seriously injure someone or

cause death. Stay away from discharge path when

operating. Keep others away.

9. Never operate machine with a cracked, bent,

missing or broken section.

1 0. Keep all hydraulic lines,fittings and couplers tight

and free of leaks before using.

11. Clean reflectors, SMV and lights before transporting.

12. Install optional lighting bar and use pilot vehicle

when transporting during times of limited visibility.

13. Use hazard flashers on tractor when transporting.

14. Install safety chains when attaching to tractor.

15. Review safety instructions with all operators

annually.

13

4.2 MACHINE COMPONENTS

The ValMetal Round Bale Grinder is a large rotating

tub over a spinning rotor that is equipped with sickle

sections to tear the material into small pieces.

A moveable grate controls how fast the material feeds

into the rotor. An auger in the bottom of the frame

next to the rotor conveys the shredded material into

the blower for discharge.

A chute or spout is attached to the opening to direct

the flow of material. A moveable deflector on the top

of the spout is used to direct the flow.

Spring loaded baffles inside the tub move the bulk

material as the tub turns to provide consistent feeding. Power to the rotor is supplied through a PTO driveline from a tractor.

OPERATION

14

Fig. 1 MACHINE COMPONENTS

D

E

H

G

F

C

A

B

A Hitch

B jack

C PTO Driveline

D Tub

E Baffles

F Blower

G Spout or Chute

H Deflector

4.3 BREAK-IN

Although there are no operational restrictions on the

machine when used for the first time, it is recommended that the following mechanical items be

checked:

A. Before starting:

1. Read the Operators Manual and all safety

decal before starting.

B. After grinding 2 bales:

1. Tighten all wheel bolts to their specified

torque. (90 ft. - lbs.)

2. Tighten all fastener to their specified torque.

3. Check oil spacing of all belt and chain

tension springs.

4. Check condition of sections. Straighten or

replace as required.

5. Check and remove any material entangled

in the rotor, auger or blower.

6. Check the oil level in the gearbox. Add as

required.

7. Check that no hydraulic lines are being

pinched or crimped. Reroute as required.

8. Lubricate PTO driveline.

C. After grinding 10 and 50 bales:

1. Tighten all wheel bolts, fastener and other

hardware to their specified torque.

2. Check tension of all belts and roller chains.

Adjust as required.

3. Check condition of sections. Repair or

replace as required.

4. Check and remove any material entangled

in the rotor, auger or blower.

5. Check condition of hydraulic components.

Tighten fittings or reroute as required.

6. Check the oil level in the gearbox. Add as

required.

7. Lubricate all fittings and give sealed bearings

only 1 shot of grease gun.

8. Then go to the normal service schedule as

defined in the Maintenance section.

OPERATION

15

4.4 PRE-OPERATION CHECKLIST

Efficient and safe operation of the ValMetal Round Bale Grinder requires that each operator reads and understands the operating procedures and all related safety precautions outlined in this section. A pre-operation

checklist is provided for the operator. It is important to follow this checklist in order to ensure personal safety

and the good mechanical condition of the machine.

Before operating the Grinder and each time thereafter, the following areas should be checked off:

1. Lubricate the machine according to the

schedule outlined in the Maintenance Section.

2. Check all fluid levels. Add as required.

3. Walk around the machine and inspect for

material entangled in moving parts and shafts.

Remove all material.

4. Check condition of sections. Straighten or

replace as required.

5. Check and remove any material entangled in

the rotor, auger or blower.

6. Check tension of all belts and roller chains.

Adjust as required.

7. Check that all bearings turn freely and no

wrapping has occurred on rotor shaft.

8. Check that all hydraulic fittings and connections

are tight and in good condition.

9. Be sure all guards and shields are in place,

secured and functioning as intended.

OPERATION

16

4.5 EQUIPMENT MATCHING

To insure the safe and reliable operation of the

Grinder, it is necessary to use it with a tractor of

appropriate size and power. As a guideline, insure

that these requirements are met:

1 - Horsepower: The tractor should have a

minimum of 60 PTO hp for use with dry material

and at least 70 PTO hp for use with wet

material.

2. Drawbar Dimension: The tractor drawbar must

be 14 inches between the end of the shaft and

drawbar pin hole center. This will provide sufficient clearance for turning and allow telescoping

of the shaft. Consult your tractor manual for

the drawbar adjustment procedure.

3. PTO Shaft: The tractor must be equipped with

a 1 3/8 inch, 6 spline 540 RPM PTO.

IMPORTANT

Do not use shaft adapters with this machine. They

will alter the required drawbar dimensions and can

lead to overspeeding.

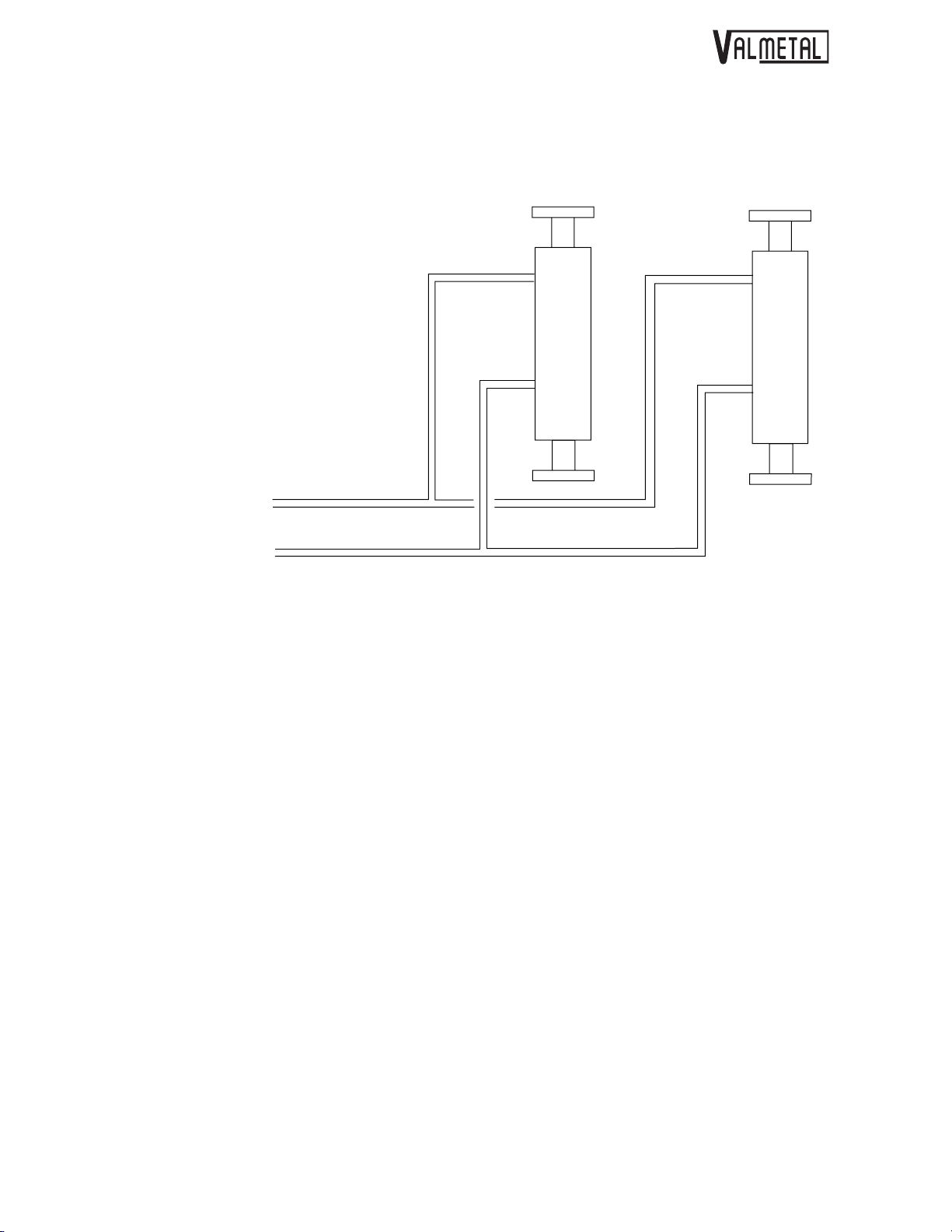

4. Hydraulic System: Hydraulically, the tractor

must have one remote outlet of 6 gpm (25 lpm)

@ 1000 psi (6800 kPa) to operate the rotor

grate.

Fig. 2 DRAWBAR

OPERATION

17

540 RPM

14 INCHES

4.6 CONTROLS

Before starting to work, all operators should familiarize themselves with the location and function of the

controls on the tractor and machine as appropriate.

1. PTO Control Lever: On tractor.

2. Throttle: On tractor.

3. Hydraulic Controls: On tractor.

4. Spout Deflector:

Move lever (A) up to release deflector and allow

the material to be blown as far as possible. Pull

lever down to have deflect for direct material

close to grinder. On optional hydraulic

chute, controls are on tractor.

5. Spout Lock: Pull lever (B) down to retract lock

pin from mounting flange. Push up to insert pin

into flange and lock spout in position.

6. Winch (C): Turn handle clockwise to spring load

baffles on tub wall. Turn counter-clockwise to

retract baffles. Secure winch with locking

lever on cable side of winch.

OPERATION

18

Fig. 3 CONTROLS ON STANDARD CHUTE

Fig. 4 HYDRAULIC CHUTE

B

A

C

When attaching the machine, follow this procedure:

1. Clear the area of bystanders, especially small

children.

2. Make sure there is enough room and clear-

ance to safely back up to the machine.

3. Use the jack to raise the hitch to align the clevis

with the tractor drawbar. See figure 7.

4. Slowly back the tractor up until the drawbar and

clevis are aligned.

5. Be sure the drawbar is positioned to give the

required spacing dimension. Adjust if required

to give dimension (refer to tractor manual for

adjustment procedure).

4.7 ATTACHING / UNHOOKING MACHINE

Fig. 5 MACHINE Fig. 6 DRAWBAR DIMENSION

540 RPM

14 INCHES

OPERATION

19

6. Install only a drawbar pin (Fig 8 "B") that has

provisions for a mechanical retainer such as a

Klik pin.

7. Install the retainer.

8. Attach the safety chain (C) around the drawbar

cage and clip securely in position.

9. Be sure the tractor is equipped with 1 3/8 inch 6

spline shaft.

10. Check that the driveline telescopes easily and

that the shield rotates freely.

11. Depress the lock pins on the yoke and slide the

yoke over the shaft until the lock pins click in

position.

12. Attach the hydraulic lines to the tractor:

a. Use a clean rag or paper towel to clean the

dirt from the couplers on the tractor and

the hose ends.

b. Insert the hose ends into the tractor

couplers. Be sure they are securely

seated.

c. Route and secure the hoses over the hitch

to prevent binding and pinching. Do not

allow the hoses to contact moving parts.

13. Raise the jack to its highest position. Remove

pin through the mount. Remove jack and stow

away in front of machine as shown in figure 10,

page 20. Then repin and install the retainer.

14. Install the light bar on the rear of the frame if

transporting.

15. Reverse the above procedure when unhooking

from the tractor. Place planks under the jack for

extra support if required.

OPERATION

20

Fig. 7 JACK

Fig. 8 DRAWBAR PIN

Fig. 9 SAFETY CHAIN

WARNING

Use extreme care when working around a highpressure hydraulic system. Make sure all connections are tight and all components are in good

repair. Wear hand and eye protection when

searching for suspected leaks.

A

B

C

4.8 OPERATING

Although the Grinder is simple and easy to use it is

recommended that the operator reviews this section

frequently to stay familiar with the recommended safe

operating procedures. It is the responsibility of the

owner to train new operators before they start and

review safety practices with regular operators at least

on an annual basis thereafter.

When operating the Round Bale Grinder, follow this

procedure:

1. Clear the area of bystanders, especially small

children.

2. Attach to tractor (refer to section 4.7)

3. Review and follow the pre-operation checklist

(See Section 4.4).

4. Position the machine at the work site such that:

a. The tractor is straight ahead of the machine

and the angles on the PTO drive line are

kept to minimum.

b. The spout can be turned and directed to the

desired position.

c. Sufficient space is available around the

machine to load the tub.

STOWED AWAY JACK

Fig. 10 WORK SITE

OPERATION

21

OPERATION

22

5. Material: The Grinder is designed to shred hay,

straw, haylage, hay silage and paper

during operation. Bales containing rocks, stones,

pieces of metal, roots, wire, twine, plastic

wrapping or mesh must not be used.

These can damage the working components or

wrap in the moving parts. Remove all foreign

material before placing in the tub.

6. Loading tub: Use a loader or fork lift to place

material into the tub. It can be loaded from

above or from the side by opening the doors on

the tubs.

IMPORTANT! Never load the tub while the

machine is running! Always stop the PTO before

loading the machine.

A. Side loading

a. Rotate the tub until doors are centered at

right angles to the machine.

b. Be sure power unit is shut off.

c. Use the winch to retract the baffles.

d. Open the tub doors.

e. Use a loader or fork lift to bring the new

bale up to the Grinder.

f. Completely remove all plastic wrap,

twine or mesh from the bale. Dispose of

them away from the work site.

g. Place bale towards the back side of the

tub.

h. Close and latch tub doors.

B. Top loading

a. Retract the baffles.

b. Bring the new bale up to the machine.

c. Remove the strings or mesh before

placing in the tub.

C. Release the tub baffles to allow them to

extend as required during operation.

IMPORTANT

Remove bale wrapping material prior to placing in tub.

It is easier to have access to all sides before it goes

into the tub. If any wrapping material remains, it probably will get caught in moving parts and could plug the

machine.

Fig. 11 LOADING FROM THE TOP

Fig. 12 LOADING FROM THE SIDE

C. Important loading instructions.

IMPORTANT! Never load the tub while the

machine is running! Always stop the PTO before

loading the machine.

Always retract baffles before loading bale (figure. 13).

Then release the winch.

Fig. 13 ADJUSTING THE BAFFLES

Fig. 14 WRONG WAY TO LOAD BALE

Fig. 15 RIGHT WAY TO LOAD BALE

OPERATION

23

OPERATION

24

7. Starting machine:

a. Clear the area of bystanders.

IMPORTANT

Be sure the winch has been

released so the baffles are free to

extend and move the bale during

operation.

b. Place all controls in neutral and set park brake

before starting tractor.

c. Start tractor engine.

d. Use the hydraulics to raise the rotor grate to its

highest position (cylinder rams completely

retracted).

e. While the tractor is running at low idle engine RPM,

slowly engage the PTO control.

e. When fully engaged, gradually increase the engine

speed until the PTO is running at 540 RPM. Always run

at 540 RPM to obtain the most efficient operation.

f. Lower the rotor grate until you obtain the desired cut.

8. Stopping machine:

a. Raise the feeding grate to its highest position and run until the rotor, auger and blower have

cleared themselves of all material. Allowing them to clear themselves will minimize the chance of

the blower plugging when starting the next time.

b. Slow the engine speed to low idle RPM.

c. Slowly disengage PTO clutch.

d. Stop tractor engine and remove ignition key before dismounting.

e. Retract the tub baffles if the tub is empty.

f. It is recommended that the tub be emptied prior to shutdown. This will minimize start-up problems.

WARNING

Do not enter the tub when the tractor engine is running. Keep others

out.

Fig. 16 ROTOR GRATE

9. Over Running Clutch

An over running clutch is located on the PTO

shaft on the machine. It protects the braking

system on the output shaft of tractor when

stopping the PTO shaft of tractor. When the

PTO shaft of tractor is stopped, the momentum

of the heavy rotor could actually damage the

brake system.

10. PTO Shear pin: A shear pin on the PTO shaft

protects the machine in case of an overload. In

case of breaking, always replace the shear pin

by one the same size and grade (12mm x 65mm

grade 8.8).

11. Auger Shear Pin: A shear pin on the auger shaft

also protects the machine in case of an overload.

In case of breaking, always replace the shear

pin by one the same size and grade (1/4” x 1 1/2”

grade 2).

12. Machine Plugging: Material can become

jammed or wrapped in the moving components

and plug the machine. Stop engine or disconnect PTO driveline before unplugging.

a. Rotor/Lever: It may be necessary to

remove the rest of the bale in the tub to

uncover the rotor and auger. Use care.

Bales are heavy.

b. Blower: An access door is located in the

rear of the blower. Remove it to gain

access to the blower. Figure 19.

13. Chute or Spout: Turn the chute or spout to

direct the material to the desired position (A).

Use the lock pin (B) through the mounting flange

to secure the spout during operation.

Use the deflector on the end of the spout to

assist in directing the flow.

On optional hydraulic chute, all controls are on

tractor.

WARNING

Raise grate, place all controls in

neutral, stop engine, set park

brake, remove ignition key and wait

for all moving parts to stop before

servicing, adjusting, repairing,

unplugging or filling.

Fig. 17 THE SHEAR PIN ON PTO (12mm x 65mm

grade 8.8)

Fig. 19 THE BLOWER ACCESS DOOR

Fig. 18 THE SHEAR PIN ON AUGER (1/4” x 1

1/2” grade 2)

OPERATION

25

WARNING

HIGH-PRESSURE FLUIDE HAZARD

Re

li

eve

p

res

s

ure

on systeme b

Wear p

rope

e

leak

fore re

r

hand and eye prote

s

.

Us

p

a

e wood or ca

iri

n

g

o

r ad

j

Ke

usting.

c

r

ti

e

dboar

o

p all comp

n

wh

d

en

instead of han

searching for

e

nents in

FAILURE TO FOLLOW THESE INSTRUCTIONS

g

d

o

s.

od

r

e

pair.

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

RISQUE DE LIQUIDE SOUS HAUTE-PRESSION

É

i

m

iner toute

d'

e

ff

pression su

e

ctue

r

u

n

e

répar

r

l

e syst

Toujo

a

t

i

on ou un ajuste

è

me

ur

hydrauliq

s

po

v

ous

rt

er

re

des gants et des l

u

ch

m

e avan

ent

erchez une fuite. U

carton

.

t

a

u lieu

u

nettes

d

e

vo

til

s

Garder

i

d

s

mains.

e

e s

r

un

éc

u

t

mo

o

rité

u

rceau

t

e

l

s

orsque

l

es com

d

e bois ou d

À DÉ

p

osantes en bo

F

AUT

e

CELA POU

D

E SU

nn

e

I

s

VRE CES INSTRUCTIONS,

co

R

RAIT ENTRAÎ

nditi

BLESSURES

o

ns.

N

ER DE

O

U

MÊME

S

ÉR

L

I

EUSES

E MORT

1

5

-6

0-0

01

0

WARNING

HIGH-PRESSURE FLUIDE HAZARD

R

e

l

i

eve pr

e

s

su

re on systeme before

We

a

r

pro

per

le

a

hand and eye pr

ks

.

U

se wood or

K

eep all compenents in

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

AVERTISSEMENT

R

ISQUE DE LIQUIDE SOUS HAUTE-PRESSION

Éimin

e

r

toute p

d'effe

ctu

er une rép

To

u

jours

v

ous

r

echerc

carto

n

au lieu de vos ma

G

a

rd

e

r toutes les composantes

À

C

ELA

re

p

airi

ng or

a

o

dju

t

c

ecti

ardboa

s

ting.

on

w

rd

hen searchi

in

s

tead of hands.

n

g for

g

ood

r

e

pai

r.

r

ession sur le syst

a

ration ou u

è

me

hy

p

d

n

or

ra

ajusteme

t

u

er

lique avant

d

es

g

n

ants e

t.

h

ez u

t

d

n

e

e

s l

fuit

unet

e

.

Util

t

es de sécurité l

i

ser un m

i

n

s

.

o

rc

e

o

au

rs

qu

d

e bois

e

D

ÉFA

ou

d

UT

e

e

n

DE

b

o

nnes

SU

P

OU

I

V

c

R

R

o

E CES INSTRUCTIONS,

R

nditi

A

BLES

IT

o

E

ns.

NTRAÎNER DE S

S

U

RES OU MÊME LE

ÉR

IEUSE

M

ORT

S

15-60-0010

OPERATION

26

14. Hearing protection:

All operators should wear appropriate hearing

protection to prevent long term hearing loss.

The noise level can be quite high with the

engine running and the action of the blower.

Be prepared. Wear hearing protection at all

times.

15. Operating hints:

a. The unit can be used to distribute the feed

on the ground, in feed bunks or as a part

of a larger feeding system. Use the spout

and deflector to direct the flow to the

desired spot.

b. The best results are obtained when the tub

is emptied at the end of the feeding job.

The machine and blower can be cleaned

out completely to minimize rust or corrosion. In addition the baffles can be retracted in preparation for loading the next time.

c. Always remove all twine, mesh or plastic

wrapping before placing in the tub to pre

- vent entanglement in moving parts.

d. Bales containing solid objects such as

rocks, roots or other material should not be

used with the machine. They can break or

damage the grinding components or the

blower.

Fig. 21 HEARING PROTECTION

Fig. 22 WRAPPING REMOVAL

Fig. 20 SPOUT AND DEFLECTOR

B

A

Fig. 23 MANGER FEEDING

OPERATION

27

OPERATION

28

4.9 TRANSPORTING

ValMetal Round Bale Grinders are designed to be

easily and conveniently moved from place to place.

When transporting, follow this procedure:

1. Be sure all bystanders are clear of the machine.

2. Be sure that the machine is securely attached

to the towing vehicle with a retainer in the

drawbar pin. Always use a safety chain

between the machine and the towing vehicle.

3. Install the light bar and connect to the towing

vehicle. Clean all lights and reflectors and

make sure no bulbs are burned out before

going on a public road.

4. Be sure the machine can be seen by oncoming

and overtaking traffic.

5. During periods of limited visibility use pilot

vehicles.

6. Do not allow riders.

7. Be sure the SMV emblem is mounted and

clean.

8. Do not exceed 20 mph (30 km/h) when transporting. Table 1 gives the acceptable transport

speed as the ratio of tractor weight to Grinder

weight.

Table 1 Speed vs Weight Ratio

9. Always use hazard flashers on the tractor

when transporting unless prohibited by law.

10. Turn the discharge chute or spout toward the

tub. Insure that the machine is as narrow as

possible before transporting.

11. Watch for overhead obstructions and stay

away from power lines. The machine is not

grounded. Electrocution can occur without

direct contact.

TRANSPORT SAFETY

1. Make sure you are in compliance with all

local regulations regarding transporting

equipment on public roads and highways.

2. Make sure the Slow Moving Vehicle

emblem and all the lights and reflectors

that are required by the local highway and

transport authorities are in place, are clean

and can be seen clearly by all overtaking

and oncoming traffic.

3. Do not allow anyone to ride on the Grinder

during transport.

4. Do not exceed 32 km/h (20 mph) when

transporting the machine. Reduce speed

on rough roads and surfaces.

5. Use a tractor of 60 horsepower or more to

transport machine.

6. Install lighting bar before transporting.

7. Use a drawbar pin with provisions for a

retainer. Install the retainer.

8. Attach safety chain between tractor and

machine before transporting.

Road Speed

Weight of fully equipped or load

implement(s) relative to weight

of towing machine

Up to 32 Km/h

(20 mph)

Up to 16 Km/h

(10 mph)

Do not tow

1 to 1, or less

2 to 1, or less

More than 2 to 1

4.10 STORAGE

At the end of the working season, the machine should

be thoroughly inspected and prepared for storage.

Repair or replace any worn or damaged components

to prevent any unnecessary down time at the beginning of the next season. Follow this procedure:

1. Thoroughly wash the machine using a hose or

pressure washer to remove all dirt, mud,

debris or residue.

2. Run at low RPM for 3 to 5 minutes to dry the

machine and prevent rusting.

3. Lubricate all grease points. Make sure all

grease cavities have been filled with grease to

remove any water residue from the washing.

4. Inspect all the hydraulic hoses, couplers, lines,

fittings and cylinders. Tighten any loose fittings.

Replace any hose that is badly cut, nicked,

abraded or is separating from a fitting.

Replace any damaged components.

5. Inspect all rotating parts for entangled material.

Remove.

6. Inspect the rotor. Repair or replace any dam

aged or broken sections.

7. Touch up all paint nicks and scratches to pre

-vent rusting.

8. Move the machine to its storage area.

9. Select an area that is dry, level and free of

debris.

10. Place planks under the wheels and jacks if the

surface is soft.

11. Unhook from the towing vehicle (refer to

Section 4.7).

12. Cover with a weather-proof tarpaulin and tie

down securely

STORAGE SAFETY

1. Store the Grinder in an area away from

human activity.

2. Do not permit children to play on or around

the stored machine.

3. Make sure the unit is sitting, or blocked up

firm and solid and will not tip or sink into a

soft area.

4. Cover with a weather-proof tarpaulin and tie

down securely.

OPERATION

29

OPERATION

30

SERVICE & MAINTENANCE

31

5.1 SERVICE

5.1.1 FLUIDS AND LUBRICANTS

1. Grease

Use an SAE multi purpose high temperature

grease with extreme pressure (EP) perfor-

mance. Also acceptable is an SAE multipurpose

lithium base grease.

2. Gearbox Oil:

Use and SAE 90 gear oil for all operating

conditions.

Gearbox Capacity: 180 ml (18 oz.)

3. Storing Lubricants

Your machine can operate at top efficiency

only if clean lubricants are used. Use clean

containers to handle all lubricants. Store them

in an area protected from dust, moisture and

other contaminants.

5.1.2 GREASING

Refer to Section 5.1.1 for recommended grease.

Use the Maintenance Checklist provided to keep a

record of all scheduled maintenance.

1. Use only a hand-held grease gun for all greasing. Air powered greasing systems can

damage the seals on bearings and lead to early

bearing failure.

2. Wipe grease fitting with a clean cloth before

greasing to avoid injecting dirt and grit.

3. Replace and repair broken fittings immediately.

4. If fittings will not take grease, remove and clean

thoroughly. Also clean lubricant pas

sage. Replace fitting if necessary.

5. Do not give sealed bearings more than 1 shot

of grease every 3 months.

SECTION 5 SERVICE AND MAINTENANCE

MAINTENANCE SAFETY

1. Follow ALL the operating, maintenance and

safety information in the manual.

2. Support the machine with blocks or safety

stands when changing tires or working

beneath it.

3. Raise grate, place all controls in neutral, stop

engine, set park brake, remove ignition key

and wait for all moving parts to stop before

servicing, adjusting, repairing or unplugging.

4. Follow good shop practices

- Keep service area clean and dry.

- Be sure electrical outlets and tools are

property grounded.

- Use adequate light for the job at hand.

5. Make sure all guards are in place and

properly secured when maintenance work is

completed.

6. Never wear ill-fitting, baggy or frayed clothing

when working around or on any of the drive

system components.

7. Before applying pressure to a hydraulic

system, make sure all lines, fittings and

couplers are tight and in good condition.

8. Relieve pressure from hydraulic circuit before

servicing or disconnecting from tractor.

9. Do not go into tub when engine is running.

Keep others out.

10. Keep hands, feet, hair and clothing away

from moving or rotating parts.

11. Clear the area of bystanders, especially small

children, when carrying out any maintenance

and repairs or making any adjustment.

SERVICE & MAINTENANCE

32

5.1.3 SERVICING INTERVALS

1 MONTH OR 75 BALES

I. Lubricate PTO driveline shaft

(2 locations).

3 MONTHS OR 200 BALES

1. Check gearbox oil level. Add gearbox oil

(SAE90) if necessary. Check oil level through

cap “B”. To add oil, remove vent “A” then add

oil through “B”.

2020

100

100

Fig. 24 PTO DRIVELINE SHAFT

Fig. 25 GEARBOX OIL LEVEL

A

B

3 MONTHS OR 200 BALES

1. Lubricate PTO driveline (2 locations).

See Fig. 24.

2. Lubricate sealed bearings with 1 shot

of grease:

A. Front rotor bearing.

B. Auger bearing.

C. Rear rotor bearing.

D. Rear blower bearing.

Machine is shown with guard

removed for illustrative purposes

only. Do not operate machine with

guard removed.

WARNING

Fig. 26 FRONT INPUT AND AUGER BEARINGS

Fig. 27 REAR ROTOR BEARING

SERVICE & MAINTENANCE

33

A

B

C

D

SERVICE & MAINTENANCE

34

E. Two (2) jack shaft bearings.

F. Front blower bearing.

G. Tub drive chain lubrication (use spray chain

grease) (figure 29).

H. Auger drive chain lubrication (figure 28).

3. Check belt and roller chain tension. Replace

springs or adjust anchor nut as required.

NOTE

Coil spacing on each spring

should be at least 3 mm

(1/8 inch).

Fig. 27 JACK SHAFT BEARING

Fig. 28 INPUT DRIVE BELT SPRING

Fig. 29 TUB DRIVE CHAIN SPRING

Fig. 30 REAR SPRING TENSIONERS

E

E

F

H

G

2 Years or 2000 Bales

1. Replace gearbox oil. Use SAE90

gearbox oil or the equivalent. You

must remove the gearbox in order to

change the oil (refer to section 5.2.3)

Fig. 31 GEARBOX

SERVICE & MAINTENANCE

35

SERVICE & MAINTENANCE

36

5.1.4 SERVICE RECORD

See Lubrication and Maintenance sections for details of service. Copy this page to continue record.

ACTION CODE: CHECK R REPLACE

L LUBRICATE

HOURS SERVICED BY

MAINTENANCE

1 MONTH OR 75 BALES

L PTO Driveline Shaft (2)

Gearbox Oil Level

3 MONTHS OR 200 BALES

L PTO Driveline (2)

L Sealed Bearings (1 Shot)

L Input Bearing

L Auger Bearing

L Rear Rotor Bearing

L Front Blower Bearing

L Jack Shaft Bearings

L Rear Blower Bearing

L Belt & Roller Chain Tension

L Tub Drive Chain Tension

L Auger Drive Chain Tension

2 Years or 2000 Bales

R Gearbox Oil

5.2 MAINTENANCE

5.2.1 KNIVES REPLACEMENT

The knives are located on the rotor in the bottom of

the tub. After long periods of use, they can wear.

They can also be damaged when a hard object goes

through the machine. If worn or damaged, they will

have to be replaced.

To replace knives, follow this procedure:

1. Clear the area of bystanders.

2. Stop the tub when the tub doors are at 90

0

to the

direction of travel.

3. Place all controls in neutral, stop engine, set

park brake, remove ignition key and wait for all

moving parts to stop before dismounting.

4. Disconnect PTO driveline to release the rotor.

5. Remove the nuts and bolts holding the grate

arms(A) to the hydraulic cylinders. Then, lower

the grate arm(A) in order to raise the grate to its

highest position. Tie one of the grate arm to the

machine's frame using a chain(B). This

way, the grate will be held-up allowing you to

change the broken knives. See figure 31-A.

6. Open tub doors.

7. Turn the rotor by hand to bring the damaged or

broken knives to the top side.

8. Remove the bolts and replace knives.

9. Tighten mounting bolts to their specified torque.

10. Inspect all knives by rotating the rotor by hand.

Replace as required.

11. Close and latch tub doors and connect driveline

to tractor.

Fig. 32 KNIVES

Fig. 31-A GRATE MUST BE HELD UP IN ORDER

TO REPLACE BROKEN KNIVES.

SERVICE & MAINTENANCE

37

A

B

SERVICE & MAINTENANCE

38

5.2.2 BELT AND ROLLER CHAINS

The tension of the belts and roller chains are controlled by the tension springs on each drive. The

springs should always be set to have a coil spacing of

at least 3 mm (1/8 inch) for the best operation.

To adjust the length of the springs, follow this

procedure:

1. Clear the area of bystanders.

2. Place all controls in neutral, stop engine, set

park brake, remove ignition key and wait for all

moving parts to stop before dismounting.

3. Remove guard covering drive.

4. Either replace the spring or use the nut on the

anchor bolt to change the spring length to

maintain the coil spacing of 3 mm (1/8 inch).

5. If this does not work, the roller chain or belt must

be replaced.

6. To replace, remove spring and remove the belt

or chain.

7. Replace with genuine ValMetal replacement

parts.

NOTE

Use only matched belts for

each multiple belt.

8. Install spring tensioner.

9. Install and secure guard.

WARNING

Machine is shown with guard removed for

illustrative purposes only. Do not operate

machine with guard removed.

Fig. 33 ROTOR DRIVE BELT SPRING

Fig. 34 TUB DRIVE CHAIN SPRING

Fig. 35 REAR SPRING TENSIONERS

G

5.2.3 GEARBOX OIL

The oil level in the gearbox must be checked every 3

months or after 200 bales to insure that the gears

have proper lubrication. If leakage is observed, check

the oil level more frequently.

To check the oil level, follow this procedure:

1. Place all controls in neutral, stop the engine,

remove the ignition key and wait for all moving

parts to stop before dismounting.

2. Remove front guard.

3. Remove oil level plug "B" on the side of the gear

box. Remove fill-up cap “A”.

4. Add through the fill plug "A" until the oil just starts

to come out of the level plug “B”.

5. Install and tighten the fill and level plugs.

6. To change the oil in the gearbox, it is necessary

to remove the gearbox. Remove the tub drive

chain, the belts and then remove the 8 bolts

holding the gearbox.

7. Drain into a container and place in an approved

disposal site.

8. Install the drain plug and tighten.

9. Add oil through the fill plug until oil starts to come

out of the level plug hole.

10. Tighten all plugs.

11. Install and secure the guard.

WARNING

Machine is shown with guard removed for

illustrative purposes only. Do not operate

machine with guard removed.

Fig. 36 GEARBOX

SERVICE & MAINTENANCE

39

A

B

SERVICE & MAINTENANCE

40

5.2.4 BREATHER CLEANING

The breather must be able to vent to atmospheric

conditions during the heating and cooling cycles while

operating. If it cannot, oil will seep out the seals and

the machine will run low on oil. Prolonged operation

with low oil levels will damage the internal working

components.

To clean:

1. Remove the breather.

2. Stop up the breather opening using a plastic plug

or a clean rag to prevent contaminants from

entering the gearbox.

3. Soak the breather in solvent for one hour.

4. Use a pointed instrument or a wire to remove

any residue from the breather passages.

5. Blow out using high-pressure air.

6. Blow through the breather to insure that the

passages are clear.

7. Install and tighten breather in the gearbox.

Fig. 37 BREATHER

5.2.5. OVER RUNNING CLUTCH & SHEAR PINS

The Over Running Clutch is pre-set from the factory and does not require adjustment.

The machine is also equipped with 2 shear pins. The PTO shear pin is located on the PTO drive (figure 38)

and the auger shear pin is located at the end of the auger shaft (figure 39). These shear pins will break in the

event of an overload. Replace when a pin breaks. IMPORTANT! Do not redrill and replace pin with a larger one. Replace with same size and same grade pin (12mm x 65mm, grade 8.8).

Fig. 38 PTO SHEAR PIN (12mm x 65mm, grade 8.8)

Fig. 39 AUGER SHEAR PIN (1/4” x 1 1/2”, grade 2)

SERVICE & MAINTENANCE

41

SERVICE & MAINTENANCE

42

TROUBLE SHOOTING

43

SECTION 6 TROUBLE SHOOTING

The ValMetal Round Bale Grinder uses a rotor with sickle sections to grind round bales into small pieces. It is

a reliable system that requires minimal maintenance.

In the following section, we have listed many of the problems, causes and solutions to the problems that

you may encounter.

If you encounter a problem that is difficult to solve, even after having read through this trouble shooting section, please call your ValMetal representative or the factory. Before you call, please have this Operator's

Manual and the serial number from your Grinder ready.

PROBLEM

Rotor does not turn.

Noisy rotor.

Blower plugging.

Auger plugging

CAUSE

Material plugged in rotor.

Shear pin on PTO broken.

Knives contacting housing.

Blower not empty.

Shear pin broken

Drive chain broken

SOLUTION

Remove material causing plug.

Replace Shear pin

Bent knife. Straighten or replace

knife.

Object lodged in rotor housing.

Remove object.

Allow machine to empty before

stopping.

Raise grate to slow feeding rate.

Use larger tractor.

Replace tension springs or belts

as required.

Unplug and replace shear pin

Replace chain

PROBLEM

Poor grinding production rate.

Tub won't turn.

CAUSE

Broken knives.

Knives covered.

Grate too high.

Baffles closed.

Drive problem.

SOLUTION

Replace knives.

Remove entangled material.

Lower grate.

Release baffles to turn bale.

Replace belt. Repalce spring

tensioner.

Replace gearbox.

TROUBLE SHOOTING

44

SPECIFICATIONS

45

SECTION 7 SPECIFICATION

7.1 MECHANICAL

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

MODEL

Overall Length:

Overall Width:

Height

(without Chute):

Height

(with Chute):

Tub Dimentions:

Maximum Bale

Dimentions:

Minimum H.P.

Recommended at

the PTO:

Adjustable Grate:

Fine Cut Rotor:

Blades:

PTO Shaft With

Friction Plates:

Tire Size:

Machine Weight:

H-5500

163"

(414 cm)

90"

(229 cm)

74"

(188 cm)

106"

(269 cm)

36" X 84"

(91 X 213 cm)

60" X 60"

(152 X 152 cm)

70 H.P

Standard

Optional

(regular) 156

(fine cut) 312

Included

11L-15 (8 Ply)

4260 lbs

(1936 kg)

H-5600

175"

(444 cm)

102"

(259 cm)

80"

(203 cm)

106"

(269 cm)

42" X 96"

(107 X 244 cm)

60" X 72"

(152 X 183 cm)

80 H.P

Standard

Optional

(regular) 180

(fine cut) 360

Included

11L-15 (8 Ply)

4740 lbs

(2155 kg)

7.2 BOLT TORQUE

CHECKING BOLT TORQUE

The tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the

torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt torque

chart as a guide. Replace hardware with the same strength bolt.

ENGLISH TORQUE SPECIFICATIONS

METRIC TORQUE SPECIFICATIONS

Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwise

specified. Therefore, do not grease or oil bolts or capscrews unless otherwise specified in this manual.

When using locking elements, increase torque values by 5%.

* Torque value for bolts and capscrews are identified by their head markings.

SPECIFICATIONS

46

Bolt

DiameterSAE 2

N.m.

"A"

1/4"

5/16"

3/8"

7/16"

1/2"

9/16"

5/8"

3/4"

7/8"

1"

8

13

27

41

61

95

128

225

230

345

Bolt Torque*

SAE-5

(lb-ft)

N.m.

(6)

(10)

(20)

(30)

(45)

110

(70)

155

(95)

215

(165)

390

(170)

570

(225)

850

12

25

45

72

(lb-ft)

(9)

(19)

(33)

(53)

(80)

(115)

(160)

(290)

(420)

(630)

N.m.

.5

3

6

10

25

50

90

140

225

435

750

1495

2600

Bolt Torque

(lb-ft)

(.6)

(2.2)

(18)

(37)

(66)

(103)

(166)

(321)

(553)

(1103)

(1917)