Val-Matic Wastewater Combination Air Valve User Manual

Wastewater Combination Air Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION.................................... 2

RECEIVING AND STORAGE ................ 2

DESCRIPTION OF OPERATION........... 2

INSTALLATION...................................... 3

VALVE CONSTRUCTION...................... 3

MAINTENANCE..................................... 4

TROUBLESHOOTING........................... 5

DISASSEMBLY...................................... 5

REASSEMBLY....................................... 6

PARTS AND SERVICE.......................... 6

WARRANTY........................................... 7

®

Manual No.

WCAV-OM1-1

VAL-MATIC® VALVE AND MANUFACTURING CORP.

905 RIVERSIDE DR. ELMHURST, IL. 60126

TEL. 630 / 941-7600 FAX. 630 / 941-8042

1

VAL-MATIC'S WASTEWATER COMBINATION AIR VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install and maintain the valve to ensure a

long service life. The Wastewater Combination Air

Valve has been designed with stainless steel trim to

give years of trouble-free operation but regular

maintenance is recommended for valves subject to

fluids containing suspended solids or greases/oils.

The Wastewater Combination Air Valve is typically

mounted at the high points in a piping system to

automatically remove pockets of air as they

accumulate. The valve can also be used to slowly

release air in tanks and pump casings.

CAUTION: This valve is not intended for

The valve is a float-operated, resilient-seated valve

designed to handle waste fluids. The valve may be

equipped with backwash accessories. The Size,

Maximum Working Pressure and Model No. are

stamped on the nameplate for reference.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Handle all valves carefully without dropping. Valves

should remain boxed, clean and dry until installed to

prevent weather related damage. For long-term

storage greater than six months, the valve must

remain in the box and stored indoors. Do not

expose valve to sunlight or ozone for any extended

period.

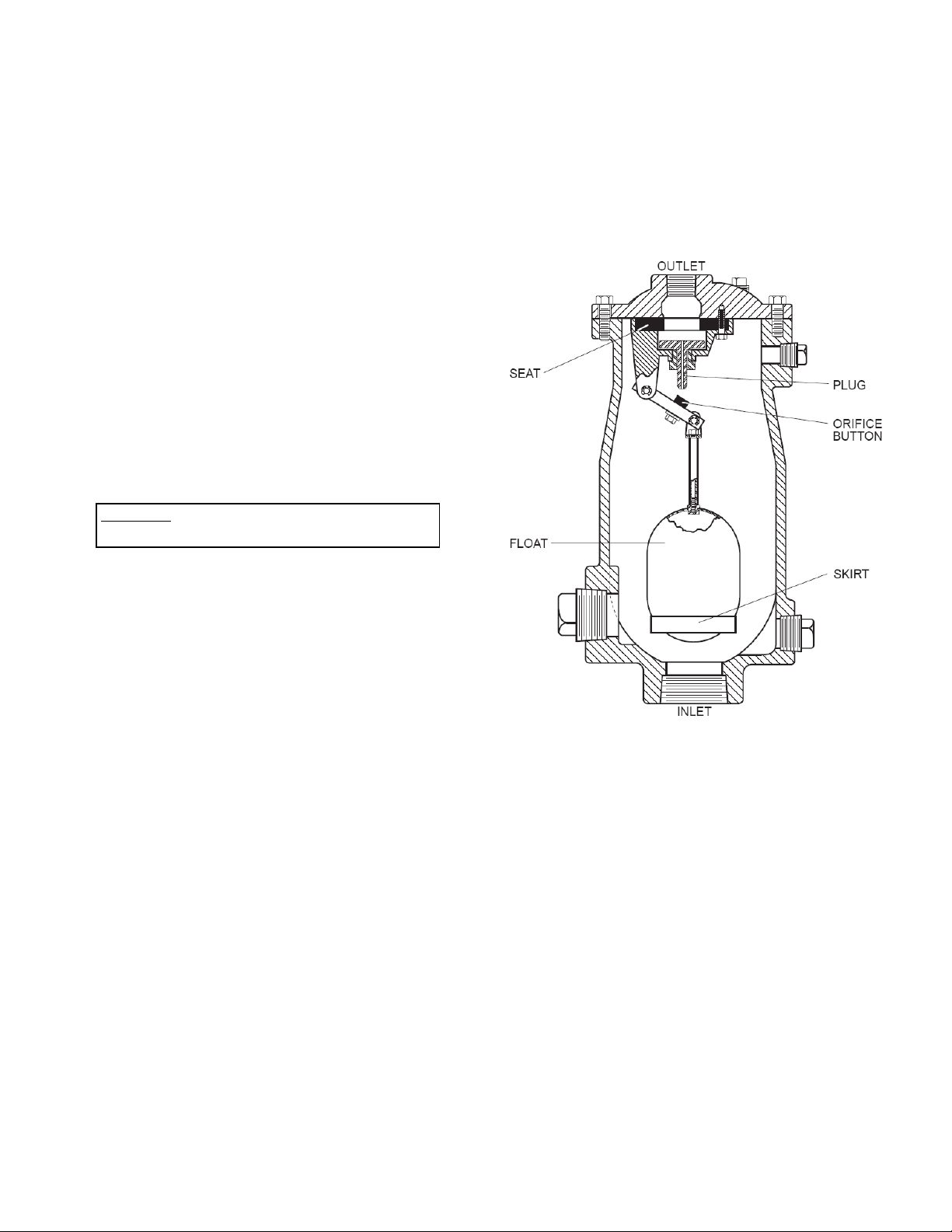

DESCRIPTION OF OPERATION

The Wastewater Combination Air Valve is designed

to automatically remove air pockets at the high

points in a piping system. The valve, as shipped, is

a normally open valve and will rapidly vent air

through the top opening. As fluid enters the valve,

the float will rise, closing the orifice. As air

accumulates in the piping system and enters the

valve, the float drops allowing the small venting

orifice to open.

The valve can be furnished with optional external

valves and hose connections for backwashing.

These items are packaged separately.

flammable liquids service.

FIGURE 1. WASTEWATER COMBINATION AIR

VALVE

When air enters the valve, it is released through the

large-diameter seat and the outlet on the top of the

valve. When fluid enters the valve, the float lifts the

plug, which seals off the seat. The orifice button

also seals against the small orifice drilled through

the center of the plug. The float has a skirt to assist

in closure and reduce leakage. As air or gas

accumulates in the valve, the float will drop and pull

the button away from the plug. This will allow

pressurized air to be vented through the plug.

Additional ports are provided for flushing, testing and

draining purposes.

2

INSTALLATION

The installation of the valve is important for its

proper operation. Valves should be installed at the

system high points in the vertical position with the

inlet down. For pipeline service, a vault with freeze

protection, adequate screened venting, and

drainage should be provided. During closure, some

fluid discharge will occur so vent lines should extend

to an open drain area in plant service. A shut-off

valve should be installed below the valve in the

event servicing is required.

CAUTION: Install valve with "INLET" port

down or leakage will occur.

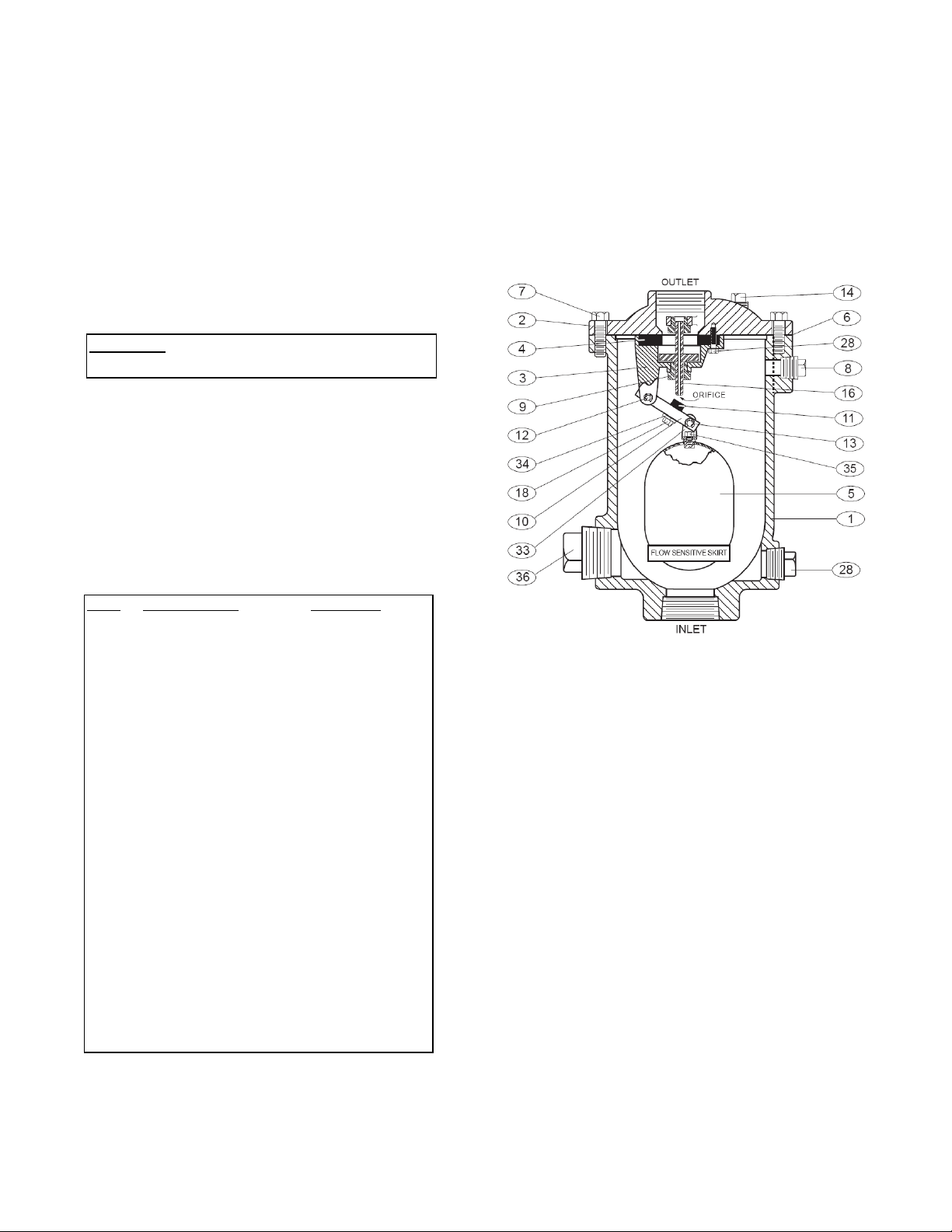

VALVE CONSTRUCTION

The standard Wastewater Combination Air Valve

body and cover are cast iron. See the specific

Materials List submitted for the order if other than

standard cast iron construction. All internal

components are stainless steel with the exception of

the orifice button, which is resilient. The general

details of construction are illustrated in Figure 2.

The body (1) is threaded for connection to the

pipeline. The seat (4) is threaded into the cast cover

(2).

ITEM DESCRIPTION MATERIAL

1 Body Cast Iron

2 Cover Cast Iron

3 Baffle (1”-2”) Cast Iron

Baffle (3”-4”) Ductile Iron

4 Seat* Stainless Steel

5 Float* Stainless Steel

6 Gasket* Non-Asbestos

7 Cover Bolt Alloy Steel

8 Retaining Screw* Stainless Steel

10 Float Arm* Stainless Steel

11 Orifice Button* SS and Buna-N

12 Pivot Pin* Stainless Steel

13 Retaining Ring* Stainless Steel

14 Pipe Plug Steel

15 Cushion* Buna-N

16 Plug Stainless Steel

17 Float Retainer* Stainless Steel

18 Lock Nut* Stainless Steel

20 Guide Shaft* Stainless Steel

28 Pipe Plug Malleable Iron

33 Clevis* Stainless Steel

34 Lock Washer* Stainless Steel

35 Guide Shaft Retainer* Stainless Steel

36 Pipe Plug Steel

*RECOMMENDED REPAIR PART KIT

TABLE 1. LIST OF PARTS

FIGURE 2. 1”-4” WASTEWATER COMBINATION

AIR VALVE

3

Loading...

Loading...