Threaded

Silent Check Valve

Operation, Maintenance and

Installation Manual

Manual No.

SCV-OM2-0

INTRODUCTION ........................................... 1

RECEIVING AND STORAGE ........................ 1

DESCRIPTION OF OPERATION .................. 1

INSTALLATION ............................................. 1

VALVE CONSTRUCTION ............................. 2

MAINTENANCE ............................................. 2

TROUBLESHOOTING ................................... 2

DISASSEMBLY .............................................. 3

REASSEMBLY ............................................... 3

PARTS AND SERVICE .................................. 3

WARRANTY .................................................. 4

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

®

VALVE AND MANUFACTURING CORP.

THREADED STYLE SILENT CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install and maintain the valve to ensure a

long service life. The Threaded Silent Check Valve

is ruggedly constructed of lead-free bronze to give

years of trouble free operation. The valve should be

installed in horizontal or vertical pipes carrying clean

water.

The Threaded Silent Check Valve is designed to

open fully to provide flow in the forward direction and

close rapidly upon flow reversal. The valves are

used to prevent reverse flow through pumps or in

piping systems. The size and cold working pressure

(250 CWP) are marked on the body for reference.

This valve is not intended for fluids containing

suspended solids such as wastewater.

CAUTION

This valve is not intended for fluids

containing suspended solids or hazardous

fluids.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

The valves should remain boxed, clean and dry until

installed to prevent weather related damage. For

long term storage, no special provisions are needed.

DESCRIPTION OF OPERATION

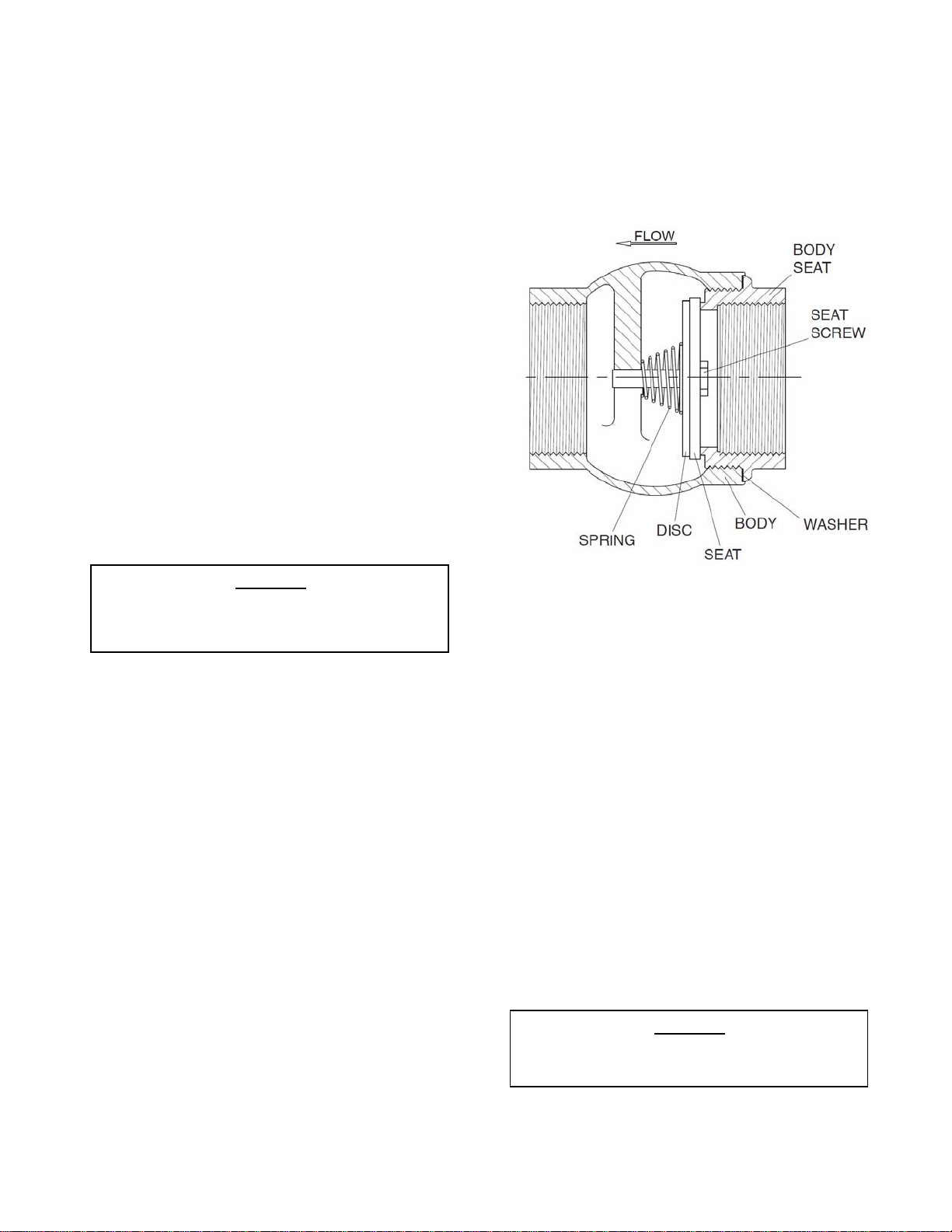

The Threaded Silent Check Valve is designed to

prevent reverse flow automatically. On pump startup, the flow of water enters the valve from the seat

end (right side in Figure 1) and forces the disc open,

allowing the passage of fluid through the valve.

On pump shut-down, the spring closes the disc

rapidly before a flow reversal takes place. This type

of closure, which prevents flow reversal, is the factor

which provides “silent” operation and reduces water

hammer associated with check valve slam.

The valve body is supplied with NPT tapered

threads on each end for installation in pipelines.

FIGURE 1. THREADED SILENT CHECK VALVE

INSTALLATION

The installation of the valve is important for its

proper operation. The flow arrow on the valve body

must point in the direction of flow when the system is

in operation. The valve can be installed in horizontal

or vertical lines with the flow up or down.

Three diameters of straight pipe upstream of the

valve are recommended to prevent turbulent flow

streams through the valve, which can cause

vibration and wear.

When installed in horizontal lines, the check valve

does not have a specific upward orientation. Insert

pipe nipples with thread sealant or thread tape and

tighten while securing valve with a wrench on the

body end nearest the pipe nipple.

CAUTION

The use of excessive torque can damage the

valve.

1

VALVE CONSTRUCTION

The standard threaded check valve body (1) is

constructed of lead-free bronze and is certified to

comply with NSF/ANSI 372, “Drinking Water System

Components – Lead Content.” The internal metal

components are bronze or stainless steel. The body

(1) is threaded and designed to accept pipe nipples

with NPT pipe threads. The disc (3) and spring (4)

are the only moving parts and require no

maintenance or lubrication. The general details of

construction are illustrated in Figure 2.

FIGURE 2. VALVE CONSTRUCTION

ITEM DESCRIPTION MATERIAL

1 Body Lead Free Bronze

2 Seat Teflon

3 Disc Lead Free Bronze

4 Spring Stainless Steel

6 Seat Screw Lead Free Bronze

Spare Parts are not available for this valve.

A replacement valve is recommended.

TABLE 1. CHECK VALVE PARTS LIST

MAINTENANCE

Threaded Silent Check Valves require no scheduled

lubrication or maintenance.

INSPECTION: Periodic inspection for leakage can

be performed by listening for leakage noise from the

valve while the pump is shut down. If leakage is

heard, drain the pipeline, remove the valve, and

inspect the seating surfaces for wear or mineral

deposits. Clean or replace the valve as needed.

TROUBLESHOOTING

Several problems and solutions are presented below

to assist you in troubleshooting the valve assembly

in an efficient manner.

Valve Chatters or Vibrates: Verify that velocity

is at least 4 feet per second. Noise sounding

like rocks in the line can be cavitation due to

high velocities, low downstream pressure, or an

upstream expanded. Verify that there are three

diameters of straight pipe upstream.

Valve Leakage: Drain line, remove valve, and

inspect seating surfaces for debris or damage. If

body washer is leaking, apply torque to the two

body pieces.

Valve Does Not Pass Flow: Check flow arrow

direction on valve body. Verify that downstream

isolation valve is open and there is no line

blockage downstream.

Valve Slams: Remove valve and inspect spring.

2

DISASSEMBLY

The valve should be removed from the pipeline for

disassembly. A skilled mechanic with proper tools

should perform all work on the valve. Refer to

Figure 2.

WARNING

The line must be drained before removing

the valve or pressure may be released

causing injury.

1. Clamp the downstream end of the valve body

(1) lightly in a vise using the hex connection

on the valve body. Do not over-clamp the

valve or permanent distortion and leakage

may occur. Remove the seat end of the valve

using a wrench on the hex ends and unthread

the body seat in a counterclockwise direction.

2. Lift up the disc assembly (3) from the body.

3. Examine the Teflon seat (2) and inspect the

mating body seating surface for damage.

Some minor dents and discoloration are

normal. Grooves or wear areas will cause

leakage and requires valve replacement.

4. Remove spring (4) and check for wear or

cracks.

REASSEMBLY

All parts must be clean and gasket surfaces should

be cleaned with a stiff wire brush in the direction of

the serrations or machine marks. Worn parts,

gaskets, and seals should be replaced during

reassembly.

1. Insert spring (5) into body (1).

2. Lay disc (3) over the spring.

3. Install the seat half of the body making sure

that the body washer (5) is in place. Tighten

the body pieces as a minimum to the torques

shown in Table 2. If leakage is found during

operation, elevate the torques until leakage

stops.

Body Assembly Torque

Valve Size Torque

1/2” 50 ft-lbs

3/4” 75 ft-lbs

1” 100 ft-lbs

1-1/4” 125 ft-lbs

1-1/2” 150 ft-lbs

2” 200 ft-lbs

TABLE 2. ASSEMBLY TORQUES

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the

Valve Size and Model Number located on the valve

nameplate and contact:

Val-Matic Valve and Manufacturing Corp.

905 Riverside Drive

Elmhurst, IL 60126

Phone: (630) 941-7600

Fax: (630) 941-8042

www.valmatic.com

A sales representative will quote prices for parts or

arrange for service as needed.

3

LIMITED WARRANTY

All products are warranted to be free of defects in material and workmanship for a period of one year from the date

of shipment, subject to the limitations below.

If the purchaser believes a product is defective, the purchaser shall: (a) Notify the manufacturer, state the alleged

defect and request permission to return the product; (b) if permission is given, return the product with

transportation prepaid. If the product is accepted for return and found to be defective, the manufacturer will, at his

discretion, either repair or replace the product, f.o.b. factory, within 60 days of receipt, or refund the purchase

price. Other than to repair, replace or refund as described above, purchaser agrees that manufacturer shall not be

liable for any loss, costs, expenses or damages of any kind arising out of the product, its use, installation or

replacement, labeling, instructions, information or technical data of any kind, description of product use, sample or

model, warnings or lack of any of the foregoing. NO OTHER WARRANTIES, WRITTEN OR ORAL, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY, ARE MADE OR AUTHORIZED. NO AFFIRMATION OF FACT, PROMISE, DESCRIPTION

OF PRODUCT OF USE OR SAMPLE OR MODEL SHALL CREATE ANY WARRANTY FROM MANUFACTURER,

UNLESS SIGNED BY THE PRESIDENT OF THE MANUFACTURER. These products are not manufactured, sold

or intended for personal, family or household purposes.

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

®

VALVE AND MANUFACTURING CORP.

4

Loading...

Loading...