Manual No.

SFCV-OM1-9

Swing-Flex

Check Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION 1

RECEIVING AND STORAGE 1

DESCRIPTION OF OPERATION 1

INSTALLATION 2

VALVE CONSTRUCTION 2

MAINTENANCE 2

TROUBLESHOOTING 3

DISASSEMBLY 3

RE-ASSEMBLY 3

BACKFLOW ACTUATOR (OPTIONAL) 4

MECHANICAL INDICATOR (OPTIONAL) 5

LIMIT SWITCH (OPTIONAL) 5

BOTTOM OIL DASHPOT (OPTIONAL) 6

PARTS AND SERVICE 7

WARRANTY 7

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

®

VALVE AND MANUFACTURING CORP.

VAL-MATIC'S SWING-FLEX

CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

The Swing-Flex

to give years of trouble-free operation. This

manual will provide you with the information

needed to properly install and maintain the valve

and to ensure a long service life. The valve is

opened by the fluid flow in one direction and

closes automatically to prevent flow in the reverse

direction.

An optional backflow actuator may be mounted on

the bottom of the valve to allow manual backflow

through the valve in the reverse direction.

Optional Mechanical Indicators and Limit Switches

may be mounted on the valve cover to provide

local and remote position indication.

An oil dashpot may be mounted on the bottom of

6” and larger valves to provide slow closure over

the last 10% of travel.

The valve is of the swing check type utilizing an

angled seat and fully encapsulated, resilient disc.

It is capable of handling a wide range of fluids

including flows containing suspended solids. The

Size, Flow Direction, Maximum Working Pressure,

and Series No. are stamped on the nameplate for

reference.

Do not use valve for line testing at

pressures higher than nameplate rating or

damage to valve may occur

The "Maximum Working Pressure" is the nonshock pressure rating of the valve at 150

valve is not intended as an isolation valve for line

testing above the valve rating.

Check Valve has been designed

CAUTION

o

F. The

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in

shipment. Unload all valves carefully to the ground

without dropping. Do not allow lifting slings or

chains to come in contact with the seat area; use

eyebolts or rods through the flange holes on large

valves.

Do not use threaded holes in cover for

lifting the valve. Serious injury may result.

Valves should remain crated, clean and dry until

installed to prevent weather related damage. For

long term storage greater than six months, the

rubber surfaces of the disc should be coated with

a thin film of FDA approved grease such as

Lubriko #CW-606. Do not expose disc to sunlight

or ozone for any extended period.

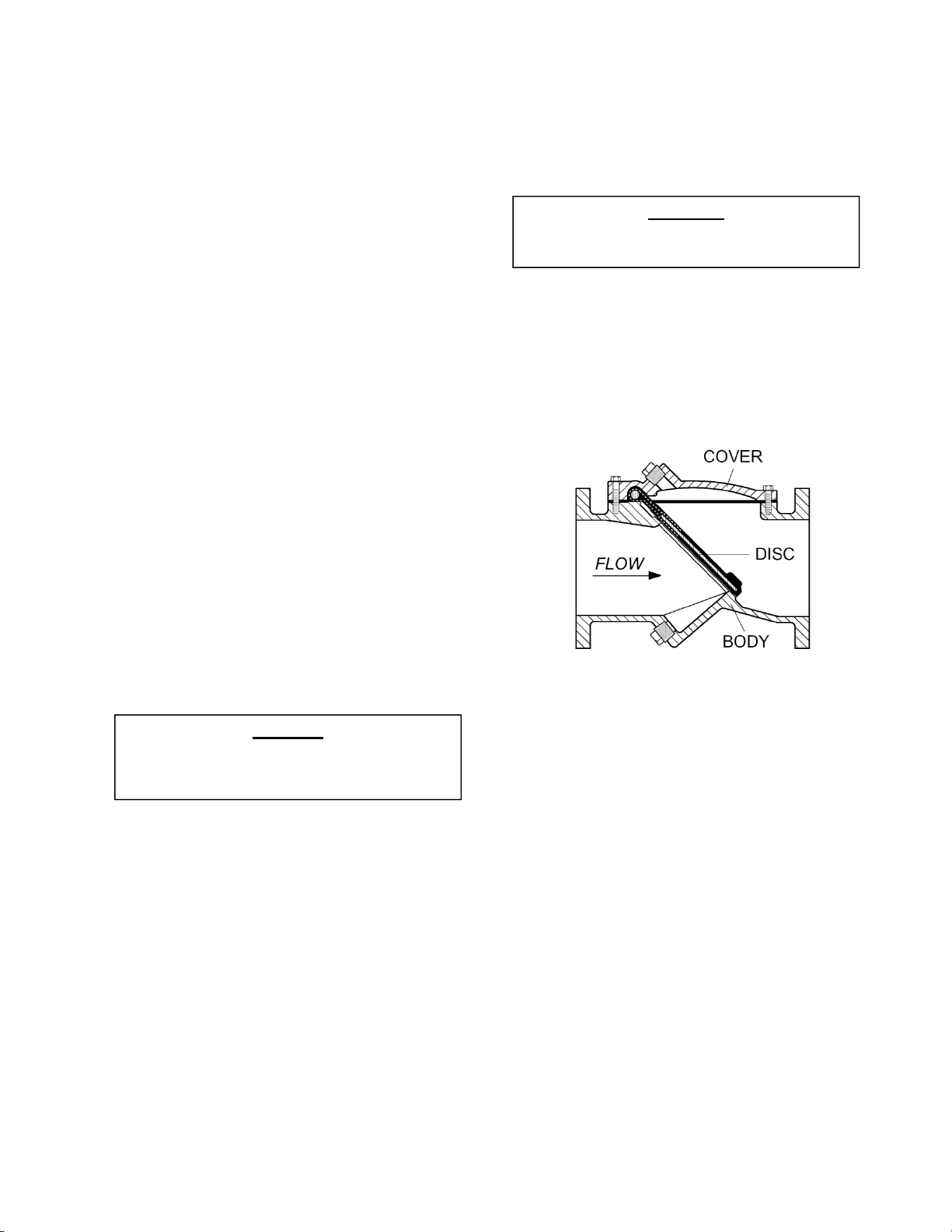

FIGURE 1. SWING FLEX

WARNING

CHECK VALVE

DESCRIPTION OF VALVE OPERATION

The valve is designed to prevent reverse flow

automatically. During system flow conditions, the

movement of the fluid forces the disc to the open

position allowing 100% un-restricted flow area

through the valve. Under reverse flow conditions,

the disc automatically returns to the closed

position to prevent reverse flow.

Several optional features are a backflow actuator,

mechanical indicator, limit switch and bottom oil

dashpot. All of these options ship loose of the

valve and require field installation.

INSTALLATION

Correct installation of the Swing-Flex

is important

for proper operation. It may be installed in either

horizontal or vertical flow-up applications.

However, when horizontal, the valve must be

installed with the nameplate facing up and the

cover level. In all installations, the flow arrow cast

in the valve cover must be pointed in the direction

of flow during normal system operation.

Do not use threaded holes in cover for

lifting the valve. Serious injury may result.

WARNING

FLANGED ENDS: Flanged valves should only be

mated with flat-faced pipe flanges equipped with

full-face resilient gaskets. The valve and adjacent

piping must be supported and aligned to prevent

cantilevered stress on the valve. Once the flange

bolts or studs are lubricated and inserted around

the flange, tighten them uniformly hand tight. The

tightening of the bolts should then be done in

graduated steps using the crossover tightening

method. Recommended lubricated torque values

for use with resilient gaskets (75 durometer) are

given in Table 1. If leakage occurs, allow gaskets

to absorb fluid and check torque and leakage after

24 hours. Do not exceed bolt rating or extrude

gasket.

The use of ring gaskets or excessive bolt

torque may damage valve flanges.

CAUTION

Valve Bolt Recom. Max.

Size Dia Torque Torque

(in) (in) (ft-lbs) (ft-lbs)

3 5/8 25 90

4 5/8 25 90

6 3/4 30 150

8 3/4 40 150

10 7/8 45 205

12 7/8 65 205

14 1 80 300

16 1 80 300

18 1 1/8 100 425

20 1 1/8 100 425

24 1 1/4 150 600

30 1 1/4 160 600

36 1 1/2 300 900

42 1 1/2 300 900

48 1 1/2 300 1,000

Table 1. Flange Bolt Torques

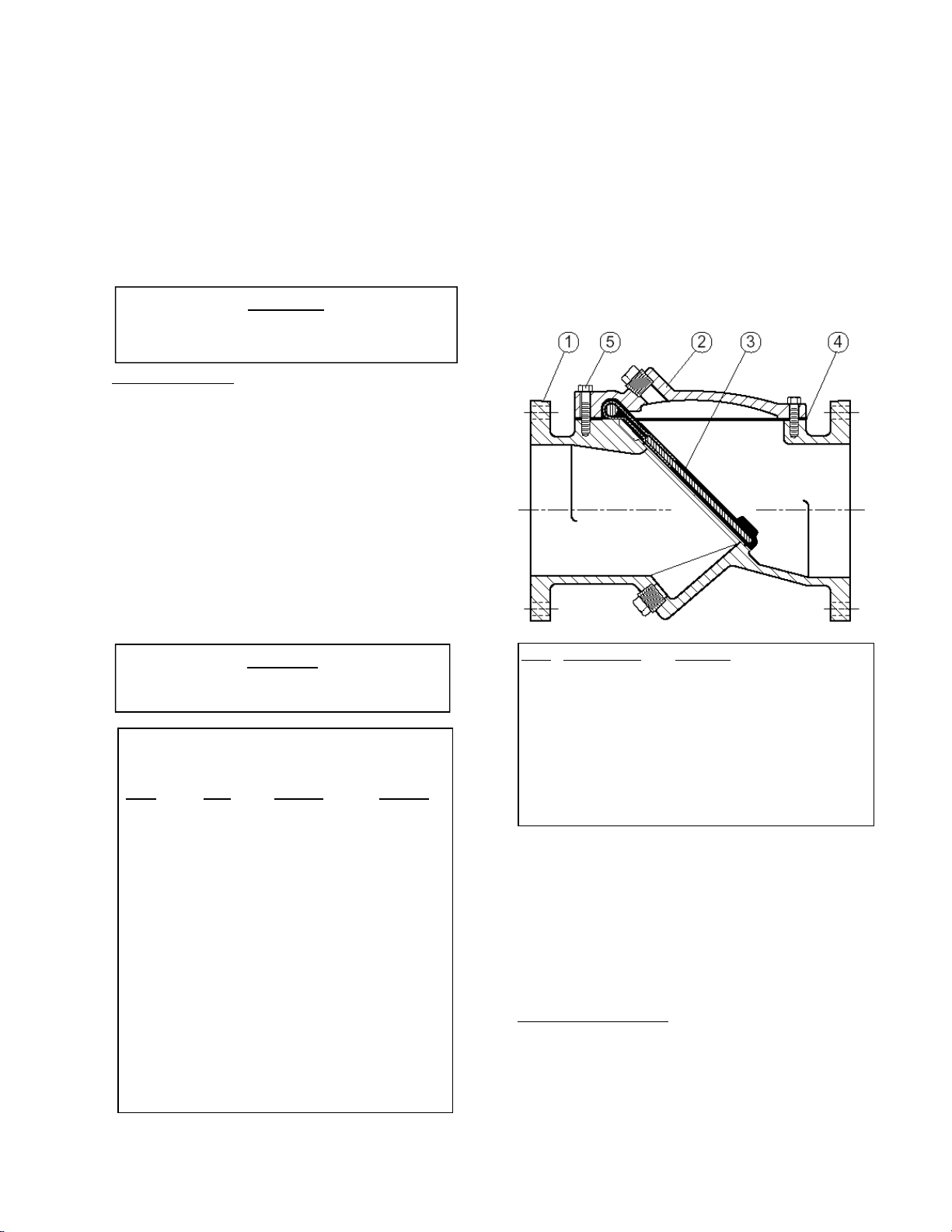

VALVE CONSTRUCTION

The standard Swing-Flex

Check Valve is

constructed of rugged cast iron with a rubber

encapsulated disc. See the specific Materials List

submitted for the order if other than standard cast

iron construction. The disc is the only moving part

assuring long life with minimal maintenance. The

general details of construction are illustrated in

Figure 2. The body (1) is flanged for connection to

the pipeline with an open top sealed with a cast

cover (2). The disc (3) is retained by the cover.

Item Description Material

1 Body Ductile Iron – 250 psi

Cast Iron – 150 psi

2 Cover Ductile Iron – 250 psi

Cast Iron – 150 psi

3 Disc* Steel With Buna-N Facing

4 Cover Seal* Buna-N or Non-Asbestos

5 Cover Bolt Alloy Steel

*Recommended Spare Part

FIGURE 2. CHECK VALVE CONSTRUCTION

MAINTENANCE

The Swing Flex

scheduled lubrication or maintenance. For service

or inspection, the valve can be serviced without

removal from the line.

VALVE INSPECTION: If inspection of the valve is

required, follow the Disassembly Instructions given

on page 3.

Check Valve requires no

TROUBLESHOOTING

Several problems and solutions are presented

below to assist you in troubleshooting the valve

assembly in an efficient manner.

Leakage at Bottom Actuator: Remove line

pressure and exercise actuator. If leak persists,

replace seals in actuator; see the Backflow

Actuator Seal Replacement Procedure on page

4.

Leakage at Cover or Flanges: Tighten bolts,

replace cover seal.

Valve Leaks when Closed: Inspect disc for

damage and replace. Inspect metal seating

surface and clean if necessary.

Valve Does not Open: Check for obstruction in

valve or pipeline; see Disassembly procedure on

page 4. Operating pressure may be less than

cracking pressure. If less than 0.5 psig, review

application with factory.

DISASSEMBLY

The valve can be disassembled without removing

it from the pipeline. Or for convenience, the valve

can be removed from the line. All work on the

valve should be performed by a skilled mechanic

with proper tools and a power hoist for larger

valves. Disassembly may be required to inspect

the disc for wear or the valve for deposits.

The line must be drained before removing

the cover or pressure may be released

causing bodily harm.

1. Relieve pressure and drain the pipeline. Refer

to Figure 2 on page 2. Remove the cover bolts

(5) on the top cover.

2. Pry cover (2) loose and lift off valve body. 12”

and larger valves have tapped holes in cover

for lifting eyes.

3. Remove disc (3) and inspect for cracks, tears

or damage in rubber sealing surface.

4. Clean and inspect parts. Replace worn parts

as necessary and lubricate parts with FDA

grease such as Lubriko #CW-606.

WARNING

RE-ASSEMBLY

All parts must be cleaned. Gasket surfaces should

be cleaned with a stiff wire brush in the direction of

the serrations or machine marks. Worn parts,

gaskets and seals should be replaced during

reassembly.

1. Lay disc (3) over seat with beaded seating

surface directed down.

2. Lay cover gasket (4) and cover (2) over bolt

holes and disc hinge. Where o-ring seal is

provided, place o-ring into body groove. O-ring

may be held in place with compatible grease

for re-assembly. Food grade grease should be

used for standard Buna-N o-rings. For EPDM

o-rings, silicone grease should be used.

3. Insert lubricated bolts (5) noting that the bolts in

the hinge area are longer than the other cover

bolts.

4. Cover bolts should be tightened to the following

specifications during assembly.

Table 2. Valve Cover Bolt Torques

Valve Size Torque (ft-lbs)

2”-2.5” 1/2" 75

3” 7/16" 50

4” 1/2" 75

6” 5/8" 150

8” 5/8" 150

10” 7/8" 400

12”-20” 7/8” 400

24” 1” 500

30” 1 1/8” 600

36” 1 1/4” 900

42” 1 1/2" 1,400

48” 1 1/2” 1,400

BACKFLOW ACTUATOR FIELD INSTALLATION AND MAINTENANCE (OPTIONAL)

BACKFLOW ACTUATOR OPERATION:

An optional backflow actuator assembly is

available which can be easily installed in the field.

The actuator is not designed to operate at the

valve’s Maximum Working Pressure rating.

Therefore, prior to using the actuator, close the

pump isolation valve and bleed off line pressure.

To operate, turn the handle clockwise. This will

open the valve disc allowing backflow through the

valve. The handle should turn easily. When the

actuator is fully extended into the valve, the disc

will be partially open. Upon completion of the back

flushing operation, turn the handle counterclockwise and the valve will automatically return to

the closed position. Lock the actuator in the

closed position with the jam nut provided. The

system is again ready for normal operation.

Relive line pressure before using backflow

actuator or damage may occur.

BACKFLOW ACTUATOR FIELD INSTALLATION:

The backflow actuator is supplied as an optional

assembly from the factory, which is shipped loose

with the valve.

Remove of the bottom plug while under

pressure may cause bodily harm.

1. Depressurize and drain the pipeline.

2. Score the coating around and remove the pipe

plug in the bottom boss of the valve.

3. Inspect the backflow rod and place in the nonextended position. (The rod should extend

about 1" past the end of the brass bushing.)

Apply Teflon thread sealant to brass threads.

4. Insert the threaded end of the assembly into

the valve boss. Slowly turn the assembly into

the boss taking care not to cross-thread the

bushing. Continue turning the assembly into

the valve for a tight fit.

BACKFLOW ACTUATOR SEAL REPLACEMENT:

There are two parts (8 & 9) on the backflow

actuator that are subject to wear. To replace the

seals, the pipeline must first be depressurized and

drained. Next, remove the backflow assembly

from the valve by turning the brass bushing (6)

counter-clockwise. Disassemble the actuator as

follows:

WARNING

WARNING

1. Remove one of the vinyl caps (12).

2. Remove the T-Handle (10) and jam nut (11)

from the rod (7).

3. Remove the rod (7) from the bushing (6) by

screwing in the rod fully clockwise and pull the

rod through the valve end of the bushing (6).

4. Lubricate new seals with FDA approved grease

such as Lubriko #CW-606 and install in the

bushing end grooves.

5. Clean, lubricate, and reinstall rod in bushing.

6. Re-install jam nut (11) and T-Handle (10).

7. Place vinyl cap (12) on handle (10).

8. Apply Teflon thread sealant to bushing and

carefully thread into valve taking care not to

cross-thread the bushing.

FIGURE 3. BACKFLOW ACTUATOR ASSEMBLY

Item Description Material

6 Bushing Lead-Free Brass

7 Rod Stainless Steel

8 Rod Wiper* Molythane

9 O-Ring* Buna-N

10 Handle Stainless Steel

11 Jam nut Brass

12 Cap* Vinyl

Backflow Actuator Parts List

*Recommended Spare Part

MECHANICAL INDICATOR (OPTIONAL)

y

The mechanical indicator is an option that fits into

the cover and can easily be installed in the field by

going through the following steps. The mechanical

indicator is used to visually indicate when the

valve is opened or closed.

1. Remove line pressure and drain valve.

Removal of the pipe plug while under

pressure ma

2. Score the coating around and remove the pipe

plug from the cover.

3. Apply pipe joint compound to indicator body

(21) threads.

4. Insert the indicator body (21), without the

indicator plate (27), into the valve cover and

tighten. Make sure that two of the tapped holes

in the indicator body (21) are aligned with the

valve and pipeline. This will ensure proper

orientation of the indicator plate.

5. Remove the two socket head screws (31) from

the indicator body (21).

6. Slide the indicator plate (27) over the indicator

rod (23) and spring (28).

7. Align the indicator plate (27) as shown on the

back of this card and secure with the 5mm

socket head screws (31).

8. Connect the spring (28) to the indicator plate

(27) notch.

WARNING

cause bodily harm.

LIMIT SWITCH (OPTIONAL)

The limit switch is used in conjunction with the

Mechanical Indicator. The standard limit switch is

MICROSWITCH Model Number 914CE20-3. The

limit switch is SCADA (Supervisory Control and

Data Acquisition) compatible for applications

requiring open/close indication.

NEMA Ratings: 1, 2, 4, 6, 6P, 12, 13

UL Ratings: 5 AMPS, 1/10 HP, 125 or 250 VAC,

SPDT

Installation:

1. Attach limit switch assembly to indicator using

the supplied screws (34) and bracket (32).

2. Position the assembly so that the switch trips

when the valve is closed.

3. Connect wiring to either the normally open or

normally closed contact as shown in the

schematic diagram.

FIG. 4. MECHANICAL INDICATOR ASSEMBLY

Mechanical Indicator Parts List

Item Description Material

21 Body Brass

22 Bushing Brass

23 Rod Stainless Steel T410

27 Plate Stainless Steel T316

28 Spring Stainless Steel T302

31 Screws Stainless Steel T316

FIGURE 5. LIMIT SWITCH ASSEMBLY

BOTTOM MOUNTED OIL DASHPOT FIELD INSTALLATION AND MAINTENANCE

(OPTIONAL)

DASHPOT FIELD INSTALLATION: The bottom

dashpot is supplied as an optional assembly from

the factory. This unit provides control of the disc’s

final 10% travel to the closed position to reduce

valve slam and water hammer. The 10% travel

time is adjustable between 1 and 5 seconds.

1. Depressurize and drain the valve and pipeline.

Removal of the bottom plug in the valve

while under pressure may cause bodily

harm.

2. Score the coating around and remove the pipe

plug in the bottom boss of the valve. Apply

Teflon thread sealant or tape to brass threads

on the dashpot.

3. Insert the threaded end of the assembly into

the valve boss. Slowly turn the assembly into

the boss taking care not to cross-thread the

bushing. Continue turning the assembly into

the valve for a tight fit and so that the tank is

upright.

4. Adjust the air pressure in the tank to be a

minimum of 50 psi over the line pressure. Set

the flow control valve in the mid position (i.e. 1

turn open). The dashpot rod should be

extended and hold the disc open about 1 inch.

The water line pressure will close the disc.

WARNING

CHECKING OIL AND GREASE LEVELS:

1. The check valve should be closed.

2. The air in the oil reservoir must be bled from

the reservoir, using the air fill valve mounted on

the reservoir.

3. Remove the pipe plug from the oil reservoir fill

port.

4. Add hydraulic fluid equal to Mobil #DTE 24 until

fluid is up to level indicated on the reservoir.

Replace pipe plug.

5. Recharge the reservoir with air pressure to a

minimum of 10 psi over the water line pressure.

6. The grease level cannot be checked but it is

recommended that the grease fitting be

charged with grease twice a year. Use a

cartridge grease gun and pump grease into the

fitting using two full strokes. An FDA approved

grease such as Lubriko #CW-606 should be

used (Master Lubricants Company,

Philadelphia, PA)

DASHPOT SEAL REPLACEMENT: There are

several seals in the unit that may require

replacement.

1. Depressurize and drain the valve and pipeline.

2. Unscrew the dashpot from the valve and

remove the 4 bolts holding the dashpot spacer.

3. Replace the (2) rod wipers and o-ring seal.

4. If the oil cylinder is leaking oil, tighten the tie

rod nuts. The cylinder should be returned to

the factory for rebuilding.

5. Reinstall the unit as listed above for a new unit.

FIGURE 6. BOTTOM MOUNTED OIL DASHPOT

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the

valve Model No and Working Pressure located on

the valve nameplate and contact:

Val-Matic Valve and Mfg. Corp.

905 Riverside Drive

Elmhurst, IL 60126

Phone: (630) 941-7600

Fax: (630) 941-8042

www.valmatic.com

A sales representative will quote prices for parts or

arrange for service as needed.

All products are warranted to be free of defects in material and workmanship for a period of one year from the

date of shipment, subject to the limitations below.

If the purchaser believes a product is defective, the purchaser shall: (a) Notify the manufacturer, state the

alleged defect and request permission to return the product; (b) if permission is given, return the product with

transportation prepaid. If the product is accepted for return and found to be defective, the manufacturer will, at

his discretion, either repair or replace the product, f.o.b. factory, within 60 days of receipt, or refund the

purchase price. Other than to repair, replace or refund as described above, purchaser agrees that

manufacturer shall not be liable for any loss, costs, expenses or damages of any kind arising out of the product,

its use, installation or replacement, labeling, instructions, information or technical data of any kind, description

of product use, sample or model, warnings or lack of any of the foregoing. NO OTHER WARRANTIES,

WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY, ARE MADE OR AUTHORIZED. NO AFFIRMATION OF

FACT, PROMISE, DESCRIPTION OF PRODUCT OF USE OR SAMPLE OR MODEL SHALL CREATE ANY

WARRANTY FROM MANUFACTURER, UNLESS SIGNED BY THE PRESIDENT OF THE MANUFACTURER.

These products are not manufactured, sold or intended for personal, family or household purposes.

LIMITED WARRANTY

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

®

VALVE AND MANUFACTURING CORP.

Loading...

Loading...