w

n

p

n

L

v

r

s

U

C

P

S

E

E

A

U

N

C

r

n

e

M

t

C

N

V

C

a

k

d

W

o

o

e

M

O

U

V

N

l

r

h

e

c

a

A

r

0

d

n

V

C

2

0

Ma

SWC

ual No.

-OM1-2

Swi

ith

Le

a

O

d/o

erati

In

INTROD

RECEIVI

VALVE

g

eve

er a

Sid

Cu

on,

talla

CTION

NG AND S

ONSTRU

hec

an

d

M

shi

aint

ion

TORAGE

TION

Va

Sp

eig

unt

n

nan

anu

ve

ing,

t,

d Ai

e an

l

2

2

3

r

DESCRI

INSTALL

VALVE

TROUBL

DISASS

RE-ASS

PARTS

START-

WARRA

TION OF

ATION

TART-UP

ESHOOTI

MBLY

MBLY

ND SERV

P OBSER

TY

OPERATI

PROCED

G

ICE

ATION R

VAL-MATI

905 Rive

Phone (63

www.valm

N

RE

ECORD

®

VALVE A

rside Dr.

0) 941-7600

atic.com

3

4

5

6

6

10

11

12

13

ND MANUF

● Elmhu

● Fax (63

CTURING

st, IL 601

) 941-8042

ORP.

6

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

Val-Matic's Swing Check Valve has been designed

to give many years of trouble free operation. All

parts are inspected prior to final assembly to

insure complete interchangeability of parts. After

assembly, each valve receives a hydrostatic seat

test, using a pressure equal to the valves rated

working pressure and a hydrostatic shell test,

using a pressure equal to the hydrostatic shell test

pressure outlined in AWWA C508 for the valve's

flange class. The valves are designed to meet

AWWA C508 which covers 2” through 24”. The

pressure rating of the 2” through 24” is 250 psi.

The 30” through 48” valves meet the intent of

C508 and are design for 150 psi in cast iron or 250

psi in ductile iron.

This manual will provide you with the information

needed to properly install and maintain the valve

and to ensure a long service life. The valve is

opened by the fluid flow in one direction and

closes automatically to prevent flow in the reverse

direction.

Optional lever and spring, lever and weight and air

cushion may be mounted on the valve to allow for

better control of surges and valve slamming

closed.

Optional Limit Switches may be mounted on the

valve to provide local and remote position

indication.

The valve is capable of handling a wide range of

fluids including flows containing suspended solids.

The size, flow direction, maximum working

pressure, and model no. are stamped on the

nameplate for reference.

CAUTION

Do not use valve for line testing at pressures

higher than nameplate rating or damage to

valve may occur.

The "Maximum Working Pressure" is the nonshock pressure rating of the valve at 150

valve is not intended as an isolation valve for line

testing above the valve rating.

o

F. The

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in

Page 2 of 13

shipment. Unload all valves carefully to the ground

without dropping. Valves should remain crated,

clean and dry until installed to prevent weather

related damage. When lifting the valve for

installation, make sure that lifting chains, slings or

straps are not attached to or allowed to come in

contact with the seat areas, hinge pin,

counterweight arm or the side mounted air cushion

assembly. Use hoist rings or lifting eyebolts in

cover lifting tapped holes or use hoist rings

through the flange holes on large valves.

WARNING

Use caution if using threaded holes in

cover for lifting the valve. All three eye

bolts should share the entire weight

directly and equally.

Use of additional slings and/or straps is

recommended for safety and ease of

orientation during installation.

Table 1. Cover Lifting Eye Bolts

Valve Lifting Valve Lifting

Size Eye Bolt Size Eye Bolt

14” M14 30” M24

16” M16 36” M24

18” M20 42” M30

20” M20 48” M30

24” M20

Do not rest the weight of the valve on the hinge

pin, counterweight arm or the side mounted air

cushion assembly.

This precision equipment must remain crated,

clean and dry until installed; to prevent weather

related damage to the valve or to the pneumatic

cylinder. Improper storage and installation

procedures will void warranty.

For long term storage greater than six months, the

rubber surfaces of the disc should be coated with

a thin film of FDA approved grease such as

Lubriko #CW-606. Do not expose disc to sunlight

or ozone for any extended period.

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

VALVE CONSTRUCTION

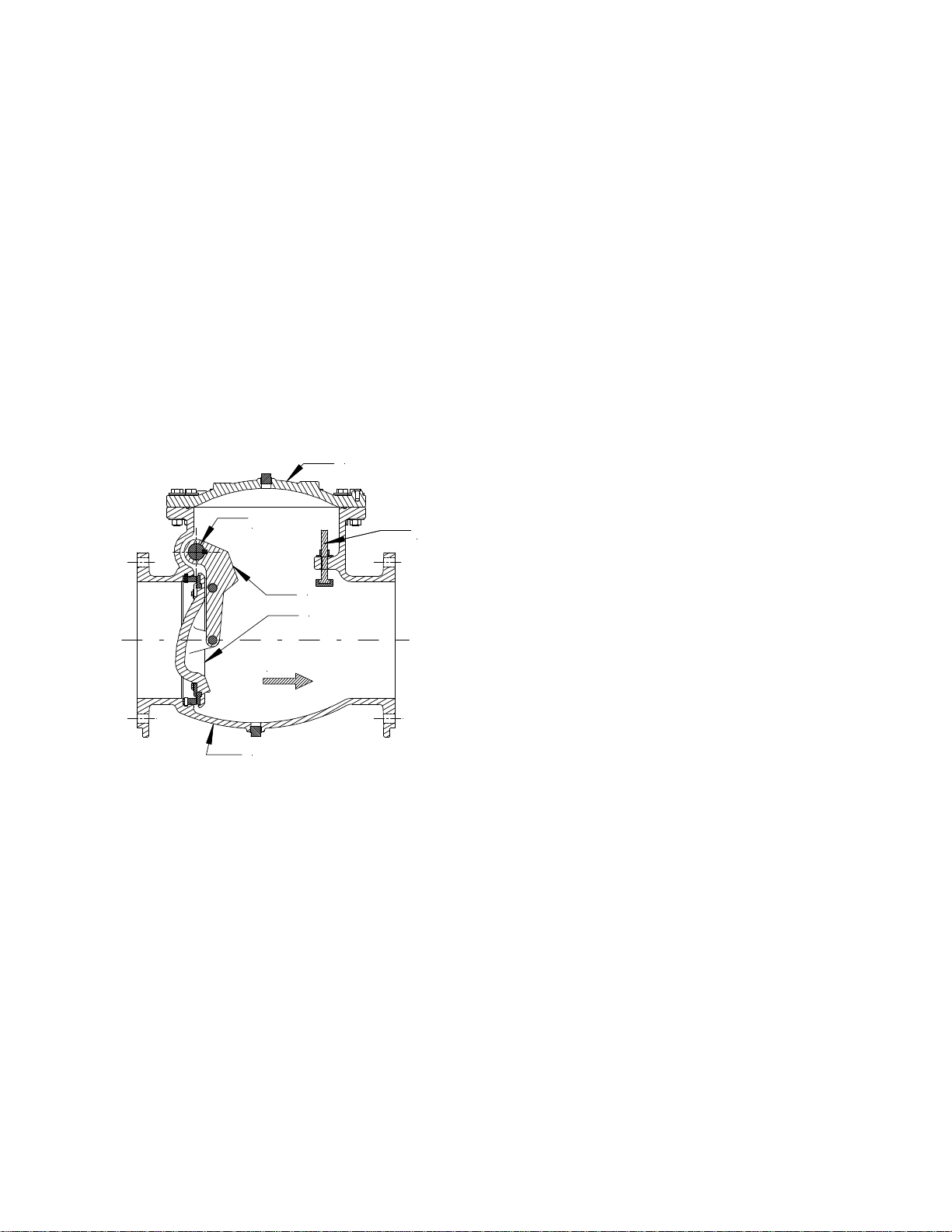

The Swing Check Valve housing consists of a

body section having integrally cast inlet and outlet

flanges. The top portion of the body has a large

integrally cast flanged access port, to which the

top access cover is bolted. The size of this access

port permits full access to the disc and seat

components for maintenance or replacement.

The flow area through the body inlet, body seat

ring and the body outlet is equal to 100% of the

nominal inside area of the standard pipe. The

center portion of the body is expanded to allow for

the area that is occupied by the disc and because

of the expanded area thru the center of the valve,

the disc at 20 to 25 degrees open reaches a full

flow area.

COVER

HINGE

PIN

YOKE ARM

DISC

FLOW

BODY

FIGURE 1. SWING CHECK VALVE

The body has two eccentrically located hinge pin

trunnions that contain the hinge bushings and

hinge packing. A continuous stainless steel hinge

pin passes through the bushings and the disc yoke

arm. The disc yoke arm is keyed to the hinge to

lock them together rotationally. The disc is

attached to the disc arm with two stainless steel

pins, making the disc and disc yoke arm a solid

assembly. The Buna-N disc seal ring fits into a

recessed register in the face of the disc and is

captured and retained by a large circular retaining

ring or segments and stainless steel screws. The

Buna-N disc seal has O-ring type sealing beads

that provide low pressure sealing when it contacts

the stainless steel seat ring, located in a machined

register in the body. The seat ring has a groove on

its outside diameter, which accepts an O-ring, that

STOP

BOLT

creates a seal between the interface of the inside

diameter of the body register and the outside

diameter of the seat ring.

The stainless steel body seat ring is threaded into

the body in 2” through 12” sizes and retained to

the body with stainless steel set screws that

engage a groove within the body seat register in

larger sizes. The exterior portion of the body has

machined mounting pads on each side of the

valve. The lower portion of the air cushion

assembly is mounted to these pads. An additional

pad accepts a spring assembly.

The counterweight arm assembly is keyed to the

extended portion of the pivot shaft. The

counterweight arm assembly has additional

keyways to allow for multiple mounting positions

such as horizontal or about 30° below when

closed. The counterweights are located on the

counterweight arm and are secured to the lever

with a bolt.

The body and the top cover are provided with

plugged ports. The body port serves as a drain

port and the top cover's port serves as a

connection point for an automatic air release valve

or as a vent port. A drain valve may also be

connected to the body port.

DESCRIPTION OF OPERATION

The valve is designed to prevent reverse flow

automatically. During system flow conditions, the

movement of the fluid forces the disc to the open

position allowing 100% un-restricted flow area

through the valve. Under reverse flow conditions,

the disc automatically returns to the closed

position to prevent reverse flow.

Upon pump start-up the forward flow of the water

will start to rotate the disc about the hinge until the

disc contacts the stop bolt in the valve body. The

disc rotates through a 60 to 70 degree arc from

the closed to the fully open position. On pump

shut down the forward velocity of the water will

start to diminish, as the forward velocity of the

water is further reduced, the disc will start its travel

to the closed position. When the forward velocity

of the water reaches zero, the disc has moved to

the closed position and the reversal of the flow is

checked. Under these ideal hydraulic conditions

the valve should close without water hammer.

However, ideal hydraulic conditions are not always

predictable and the potential for water hammer

exists. If the reversal of flow happens before the

Page 3 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

disc has a chance to react to the diminishing

forward velocity of the water, the disc will be

driven to the closed position by the rapid flow

reversal. Depending on how fast the reversal of

flow takes place, a water hammer of different

magnitudes will develop.

The valve is available with an adjustable lever and

weight, an optional and adjustable lever and

spring assembly and a side mounted air cushion.

These assemblies and adjustments may be used

to vary the valve’s closing operation in order to

reduce the magnitude of the closing water

hammer.

The side mounted air cushion was designed to

solve minor water hammer problems. It should be

stated, that because the control media is only a

small volume of air at atmospheric pressure, that

is compressed to a maximum of 200 PSI and then

vented to the atmosphere thru a small flow control

valve, it should not be considered as a total

solution for severe water hammer problems.

INSTALLATION

The swing check valve with spring, weight and

lever, or weight, lever and

cushion can only be used for horizontal flow or

vertical flow-up applications. The valve must be in

a laminar flow region of the piping system. Avoid

locating the valve immediately downstream of a

pipe elbow or in a cavitation zone because the

turbulence in these regions will cause excessive

disc motion and will result in premature wear.

For horizontal flow applications the valve must be

installed with both of the pivot trunnions located

above the horizontal center-line of the valve and

the common center-line of the hinge trunnions

must be level to the horizontal plane of the valve.

For vertical flow up applications the counterweight

arm should be in the horizontal or about 30° below

horizontal position when the valve is

position. The counterweight arm has multiple

keyways to allow for mounting in several

orientations.

Before installing the valve in the space provided,

check to make sure that the pump discharge

piping is free of foreign objects such as lumber,

tools, rocks, etc., which can damage the swing

check valve when it is placed in service.

side mounted air

in the closed

When lifting the valve for installation, make sure

that lifting chains or straps are not attached to or

allowed to come in contact with the hinge pin,

counterweight arm or the side mounted air cushion

assembly. Also do not allow the weight of the

valve to rest on the hinge pin, counterweight arm

or the side mounted air cushion assembly.

Each valve is provided with a flow arrow integrally

cast on the valve cover. The flow arrow must

point in the direction the water will flow, when the

system is operating.

AWWA C508 swing check valves are furnished

with flat faced flanges and should only be mated to

a flat faced companion flange. A full faced or ring

gasket, that has been lubricated with a gasket joint

compound, must be installed between the valve's

flange and the companion flange to effect a seal.

Flange bolting shall be in accordance with ANSI

B16.1 Section 5.2 for cast iron bodies and ANSI

B16.42 for ductile iron bodies. Note: Val-Matic

does not recommend the use of high strength

flange bolting with these valves.

Before installing the flange bolting, the valve and

the adjacent piping must be supported and aligned

to prevent cantilevered stress being transferred to

the valve's flanges when installing the flange bolts

or studs.

Apply a thread lubricant to the flange bolt threads

and install the flange bolts and nuts around the

flange. Once all the flange bolts or studs are

inserted around the flange bolt circle, tighten them

hand tight.

Recommended flange bolt lubricated target torque

values for use with resilient gaskets (75

durometer) are given in Table 1. If leakage

occurs, allow gaskets to absorb system fluid and

check torque and leakage after 24 hours. Do not

exceed the bolt rating, the maximum torque of

Table 1, compress to more than the gasket

manufacturer’s thickness recommendation or

extrude gasket.

Page 4 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

TABLE 2.

FLANGE BOLT TARGET TORQUE

Valve Bolt Recommended Maximum

Size Dia. Torque Torque

(in) (in) (ft-lbs) (ft-lbs)

2” to 4” 5/8 25 90

6”-8” 3/4 30 150

10”-12” 7/8 45 205

14”-16” 1 80 300

18”-20” 1 1/8 100 425

24”-30” 1 1/4 150 600

36”-42” 1 1/2 300 900

48” 1 1/2 300 1,000

The target torque for flange bolting is based on the

flange construction, system pressure, system

temperature, and the gasket material. The valve

flange construction is per ASME B16.1 Class 125

(cast iron bodies) or ASME B16.42 Class 150

(ductile iron bodies). The gasket material and

design is often the limiting factor for the flange bolt

target torque and should best be obtained from the

gasket manufacturer. Note: Flange joint leakage

can be caused by exceeding the recommended

target torque as well as inadequate or non-uniform

bolt torque.

The flange bolt torque should be applied in several

graduated steps using the cross-over bolt

tightening method to load the bolts evenly to

eliminate concentrated stresses which could

fracture or crack the valve's flange. See ASME

PCC-1-2010 for details of the cross-over bolt

tightening sequence and torque methods. Note

that the target torque values provided in ASME

PCC-1-2010 are based on the ANSI/ASME steel

flange pressure and temperature ratings which

exceed those of AWWA and are, therefore, often

higher than appropriate for AWWA rated iron

valves and flanges.

The use of ring gaskets or excessive bolt

torque may damage valve flanges.

VALVE START-UP PROCEDURE

When the swing check valve with weight arm,

spring, and/or side mounted air cushion is

completely installed, follow the steps outlined

below to place valve into service. A combination

of the weight, spring and side mounted

CAUTION

adjustments may be necessary depending on the

valve’s optional equipment configuration and the

installed system performance.

Become familiar with the following adjustments

that will affect the closing characteristics of the

swing check valve's disc.

There is a “Start-Up Observation Record” form at

the end of this manual that may be useful during

start-up operations and recording the “Final, As

Left” set-up configuration.

LEVER AND WEIGHT ADJUSTMENTS

Moving the weight in towards the hinge pin centerline will increase the disc's closing time and

moving the weight out away from the pivot shaft

center-line will decrease the disc's closing time.

Note that the position of the weights can also

affect how far the valve's disc opens under low or

moderate flow conditions.

LEVER AND SPRING ADJUSTMENTS

Moving the spring connection in towards the hinge

pin center-line will increase the disc's closing time

and moving the spring connection out away from

the pivot shaft center-line will decrease the disc's

closing time. Note that the position of the spring

connection can also affect how far the valve's disc

opens under low or moderate flow conditions.

Increasing the spring tension will decrease the

disc's closing time and decreasing the spring

tension will increase the disc's closing time.

AIR CUSHION FLOW CONTROL VALVE

ADJUSTMENTS

There are two speed control valves externally

mounted on the air cushion cylinder ports. To

increase the cushioning effect (increase closure

time) the upper (cylinder rod end) speed control

should be full open and the lower (cylinder cap

end) speed control is used to control the

cushioning effect. Turning the lower external

speed control valve's adjustment knob of the side

mounted air cushion clockwise will increase the

cushioning effect and increase the valve's closing

time and turning the lower external speed control

valve's adjustment knob counter-clockwise will

decrease the cushioning effect and decrease the

valve's disc closing time. If the lower speed

control valve is fully opened and a reduction in the

closure time is desired, the upper (cylinder rod

end) speed control valve should be fully closed

while the swing check valve is in the full closed

position. This will add a pressure boost to the

initial portion of the closing stroke.

Page 5 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INITIAL SETTINGS

1. Before starting pump and placing valve into

service, care must be taken to insure that the

pump's intake structure is free of foreign

objects such as lumber, tools, rocks, etc.,

which can damage the swing check valve.

2. If equipped with a side mounted air cushion,

the upper (cylinder rod end) external speed

control valve of the side mounted air cushion

will be factory set in the full closed position

and the lower (cylinder cap end) external

speed control valve of the side mounted air

cushion will be factory set in a full open

position. These settings provide a pressure

boost to the initial portion of the closing stroke.

3. If equipped with a weight and lever, connect

the weight as far as possible from the centerline of the hinge pin and bolt to hold the weight

secure.

4. If equipped with a spring assembly, connect

the spring as far as possible from the centerline of the hinge pin and the tension of the

spring should be adjusted with the bolt to hold

the spring secure.

CAUTION

These initial settings provide the fastest

check valve closure.

The closure time should be selected,

tested, set, and determined by the user or

his designee who is expert in the installed

piping system as the system’s response to

the valve’s closure can vary greatly and the

system induced transient pressure can

cause severe damage to the valve and

other piping system components.

TROUBLESHOOTING

Several problems and solutions are presented

below to assist you in troubleshooting the valve

assembly in an efficient manner.

Leakage at Hinge Pin: Adjust or replace

packing.

Leakage at Cover or Flanges: Tighten cover or

flange bolts, replace cover seal or flange

gasket.

Valve Leaks When Closed: Inspect disc

rubber seat for damage or debris. Clean or

replace as needed. Inspect body stainless

steel seating surface for damage or debris.

Clean, polish, or replace as needed.

Valve Does Not Open: Check for obstruction

in valve or pipeline; see disassembly

procedure. Operating pressure may be less

than cracking pressure. If less than 0.5 psig,

review application with factory.

DISASSEMBLY

The valve can be disassembled without removing

it from the pipeline. The valve may also be

removed from the pipeline. All work on the valve

should be performed by a skilled mechanic with

proper tools and a power hoist for larger valves.

Disassembly may be required to inspect the disc

for wear or the valve for debris or deposits.

Refer to Figure 2 for parts identification. Always

relieve pressure and drain pipeline before working

on the valve.

WARNING

The pipeline must be relieved of all

pressure and drained before removing the

valve or the valve cover or pressure may be

released causing bodily harm.

SPRING REMOVAL

1. For safety, wrap, restrain and tie the spring

(50) with rags, slings, or rope in case of a

sudden release.

2. Carefully remove nut (57) and spring bolt (52).

Note: The spring bolt (52) may be match

marked to assure re-assembly to the same

tension setting.

3. Remove Spring (50).

4. Remove Lever (51).

5. Remove Key (54).

6. Remove spring bracket (53), bolts (55) and

washers (56).

WEIGHT AND LEVER REMOVAL

1. Support or prepare to lift weight (31).

Carefully remove nut (35), washer (36), and

bolt (34).

2. Remove weight (31). Note: Mark or record

the weight (31) location on the lever arm (30).

3. Remove bolt (33) and lever (30).

4. Remove Key (32).

5. Remove weight and lever and cylinder bracket

(40), bolts (46) and washers (47).

Page 6 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

AIR CUSHION REMOVAL

1. Support or prepare to lift cylinder (42).

Carefully remove clevis pins (43 and 44).

2. Remove cylinder (42).

3. Remove bolt (46) and lever (45).

4. Remove Key (32).

5. Remove weight and lever and cylinder bracket

(40), bolts (46) and washers (47).

VALVE DISASSEMBLY

1. Remove the cover bolts, nuts, and washers

(24, 28, & 29) on the top cover.

2. Pry cover (2) loose and lift off valve body.

Valves 14” and larger have 3 tapped holes in

cover for lifting eyes. See Table 2 for lifting

eye bolt sizes.

3. If desired, remove stop bolt (60), washer (61)

and nut (62). The stop bolt (60) should be

match marked to assure re-installation to the

same extension length.

4. Sling and support yoke arm (4) and disc (3)

slightly off the seat (23)

5. Remove bolts (20), washers (19) and o-ring

(22) from blind hinge cover (18-2).

6. Remove bolts (20) and washers (19) from

through hinge cover (18-1).

7. Remove packing (16) and packing shim (15).

8. Push hinge pin from keyed end out of blind

end side until retaining ring (21) can be

removed. Remove retaining ring (21).

9. Continue to push hinge pin out until blind end

bushing (14) moves out and can be removed.

Remove bushing (14).

10. Push hinge pin back into the blind end until the

bushing (14) on the keyed and of the hinge pin

is moved enough to remove. Remove bushing

(14).

11. Slide the supported yoke arm (4) and disc (3)

back and forth on the hinge pin until the key

(6) can be removed from between the yoke

arm (4) and the body (1). Note: Take care not

to damage the disc seat (8) or the body seat

(11) while moving yoke arm (4) and disc (3).

Remove key (6)

12. Remove hinge pin (5) from keyed end.

13. Lift the supported yoke arm (4) and disc (3)

and place on a clean floor or pallet.

14. If desired, disassemble yoke arm (4), retaining

rings (25), disc pins (24), and disc (3).

15. Remove seat retaining bolts (10), washer (9),

seat retaining segments (7) and rubber seat

(8).

16. Remove body seat (11). In 12” and smaller

valves, the seat (11) is screwed into the body

and must be threaded into place. In 14” and

large the seat (11) is held into the body with

set screws (12). Remove he body seat (11),

set screws (12), and o-ring (23).

17. Clean and inspect parts. Replace worn parts

as necessary and lubricate parts with FDA

grease such as Lubriko #CW-606.

Page 7 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

SWING CHECK VALVE

PARTS CONSTRUCTION

FOR VALVE DIMENSIONS AND WEIGHTS

SEE THE SUBMITTAL DRA W INGS

19 20

21

14

6

14

15

16

17

18-1

5

2

26

7

9 10

4

24

3

11

12

1

18-2

19 20

292827

8

25

23

22

NOTE:

1.) VALVES CONFORM TO AWW A C508,

LATEST E DITION (2" T H RU 24")

2.) SEE TABLE 2 FOR STANDARD

MATERIALS OF CONSTRUCTION OR

SUBMITTAL DRAW ING FOR SPECIAL

CONSTRUCTION

13

FLOW

13

WITH LEVER

& AIR CUSHION

6160

62

WITH LEVER

32

46

33

& WEIGHT

42

54

& SPRING

44

45

30

FLOW

51

55 56

53

FLOW

43

3635

SPEED CONTROL

VALVE

(TYP.)

50

52

57

3134

40

45 46

FIGURE 2. SWING CHECK VALVE PARTS CONSTRUCTION

Page 8 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

TABLE 3. PARTS AND MATERIALS OF CONSTRUCTION

PART NO.

1 Body Ductile Iron (2” To 24”), Cast Iron (30” To 48”)

2 Cover Ductile Iron (2” To 24”), Cast Iron (30” To 48”)

3 Disc Ductile Iron

4 Arm Ductile Iron

5 Hinge Pin Stainless Steel

6 Hinge Key Stainless Steel

7 Seat Retaining Segment Ductile Iron

8

9 Flat Washer Stainless Steel

10 Hex Hd. Cap Screw Stainless Steel

11 Seat Stainless Steel

12 Set Screw Stainless Steel

13 Pipe Plug Steel

14 Bushing Aluminum Bronze

15

16

17 Packing (Pop) Shim Stainless Steel

18-1 Hinge Cover - Thru Ductile Iron

18-2 Hinge Cover - Blind Ductile Iron

19 Flat Washer Plated Steel

20 Hex Hd. Cap Screw Plated Steel

21 Retaining Ring Stainless Steel

22

23

24 Disc Pin Stainless Steel

25 External Retaining Ring Stainless Steel

26

27 Flat Washer Plated Steel

28 Hex Hd. Bolt Plated Steel

29 Hex Nut Plated Steel

30 Weight Lever Ductile Iron

31 Weight Ductile Iron

32 Key Steel

33 Bolt Plated Steel

34 Bolt Plated Steel

35 Nut Plated Steel

36 Washer Plated Steel

40 Cylinder Bracket Steel

42 Cylinder Steel

43 Cylinder Pin Plated Steel

44 Clevis Pin Plated Steel

45 Cylinder Lever Ductile Iron

46 Bolt Plated Steel

47 Washer Plated Steel

50 Spring Plated Alloy Steel

51 Spring Lever Ductile Iron

60 Stop Bolt Stainless Steel With Buna N

61 Flat Washer Stainless Steel

62 Hex Nut Stainless Steel

PART NAME MATERIAL

Rubber Seat Buna-N

V-Packing Shim Nylon

V-Packing Buna-N

O-Ring Buna-N

O-Ring Buna-N

O-Ring Buna-N

= Recommended Spare Part

Page 9 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

RE-ASSEMBLY

All work on the valve should be performed by a

skilled mechanic with proper tools and a power

hoist for larger valves.

VALVE RE-ASSEMBLY

1. Lubricate body seat o-ring (23) and body seat

(11) with an FDA grease such as Lubriko

#CW-606. Install body seat o-ring (23) and

body seat (11). In 12” and smaller valves, the

seat (11) is screwed into the body. In 14” and

large the seat (11) is held into the body with

set screws (12). Remove he body seat (11),

set screws (12), and o-ring (23)

2. Install rubber seat (8), seat retaining segments

(7), washers (9), and seat retaining bolts (10)

onto disc. Torque bolts to values listed in

Table 4 below. Note: Take caution to protect

the rubber seat from damage during the

remainder of the assemble process.

Table 4. Seat Retaining Bolt Torque

Valve Size Bolt Size Torque (ft-lbs)

2” to 4” M5 5

6” to 20” M8 10

24” to 48” M10 20

3. Assemble yoke arm (4), retaining rings (25),

disc pins (24), and disc (3).

4. Sling and support yoke arm (4) and disc (3).

5. Lift and hang the supported yoke arm (4) and

disc (3) and place into body (1) with yoke

hinge boss nestled in the hinge pin recess

area.

6. Install hinge pin (5) and yoke key (6) from

keyed end engaging the key into the keyway

of the yoke (4). Note: The hinge pin may be

installed with the key oriented toward either

side of the valve. The keyed end of hinge pin

(5) must be oriented to the side where the

spring assembly, lever & weight assembly,

and /or air cushion assembly is to be mounted.

7. Install bushings (14) from both ends of hinge

pin (5).

8. Push hinge out the non-keyed end of the

hinge pin until the retaining ring (21) can be

installed and install the retaining ring.

9. Push hinge (5) back into the body until

retaining ring (21) is seating at the back of the

bushing (14). Install bolts, (20) washers (19)

and o-ring (22) with blind hinge cover (18-2).

10. Install packing (16) and packing shim (15).

11. Install bolts (20) and washers (19) with

through hinge cover (18-1).

12. Install stop bolt (60), washer (61) and nut (62).

Set at desired extension length.

13. Lubricate cove o-ring (26) and grove on top of

body (1) with an FDA grease such as Lubriko

#CW-606. Install o-ring (26) on top of body

(1). Place cover (2) on top of body in the

correct orientation with the flow arrow pointing

away from the hinge pin.

14. Install cover bolts (28), washers (27), and nuts

(29). Torque bolts and nuts to the values

listed in Table 5 below in several graduated

steps using the cross-over bolt tightening

method.

Table 5. Cover Bolt Torque

Valve Size Bolt Size Torque (ft-lbs)

2” to 2 ½” M10 50

3” to 4” M12 75

6” to 18” M20 250

20” to 36” M24 500

42” to 48” M30 750

15. Install pipe plugs (13) are not installed into

body (1) and Cover (2) if not already installed.

Note: Vent, drain and/or air release valves

may also be installed into these ports in lieu of

the pipe plugs furnished.

16. If desire, pressure test the body for packing

and cover leaks. Adjust or replace as

necessary.

17. Install spring assembly, lever and weight

assembly and/or air cushion assembly.

SPRING RE-ASSEMBLY

1. For safety, wrap, restrain and tie the spring

(50) with rags, slings, or rope in case of a

sudden release.

2. Install spring bracket (53), bolts (55) and

washers (56).

3. Install Key (54).

4. Install Lever (51).

5. Install Spring (50).

6. Carefully Install nut (57) and spring bolt

(52). Set nut (57) and spring bolt (52)to the

desired tension setting

WEIGHT AND LEVER RE-ASSEMBLY

1. Install weight and lever and cylinder bracket

(40), bolts (46) and washers (47).

2. Install key (32).

3. Install lever (30). Note: Lever has multiple

Page 10 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

keyways for installing at various

orientations.

4. Install weight (31) at the desired location.

5. Install nut (35), washer (36), and bolt (34)

on lever (30).

AIR CUSHION RE-ASSEMBLY

1. Install weight and lever and cylinder bracket

(40), bolts (46) and washers (47).

2. Install Key (32).

3. Install bolt (46) and lever (45).

4. Install cylinder (42) with clevis pins (43 and

44).

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the

valve Model No. and Working Pressure located on

the valve nameplate and contact:

Val-Matic Valve and Mfg. Corp.

905 Riverside Drive

Elmhurst, IL 60126

Phone: (630) 941-7600

Fax: (630) 941-8042

A sales representative will quote prices for parts or

arrange for service as needed.

Page 11 of 13

VAL-MATIC'S SWING CHECK VALVE

OPERATION, MAINTENANCE AND INSTALLATION

START-UP OBSERVATION RECORD

Site or Facility

Valve Description

[Size, Location, Tag, &/or EIN]

Equipped Configuration

Weight

Position

On

Lever

RUN

No.

C/L

Hinge

To

C/L

Weight

Bolt

Hole

Inches

Control

Position

Flow

Turns

Open

Lever & Weight Side Mounted Air Cushion

Lever & Spring Other

Spring

Position

On

Lever

C/L

Hinge

To

C/L

Spring

Bolt

Hole

Inches

Extension

Spring

Adjuster

Bolt

Inches

Below

Bracket

Closed

Lever

Arm

Angle

Degrees

From

Level

Open

Arm

Angle

Degrees

From

Level

Results,

Notes

& Comments

1

2

3

4

5

FINAL

AS

LEFT

Data Recorded By: Date:

Page 12 of 13

A

c

h

r

e

a

u

o

N

A

A

N

d

E

n

e

v

.

c

e

h

t

T

R

A

E

M

N

c

u

e

r

o

O

U

Y

p

E

P

T

w

e

e

c

c

b

I

N

C

A

R

e

v

3

A

n

(

a

f

d

s

c

o

M

N

P

E

c

V

S

V

6

h

)

s

a

n

A

O

o

T

m

x

o

m

,

f

p

k

r

O

f

N

0

a

o

c

r

g

o

O

N

R

ll produ

date of s

If the pu

alleged d

transport

at his dis

purchase

manufact

product, i

descripti

WARRA

FITNESS

FFIRM

SHALL C

THE MA

househol

OP

ts are warra

ipment, subj

chaser belie

fect and req

tion prepaid

retion, eith

price. Ot

rer shall no

ts use, instal

n of produc

TIES, WRI

FOR A PA

TION OF F

REATE ANY

UFACTUR

purposes.

VAL-

RATIO

ted to be fre

ct to the limi

es a produ

uest permiss

If the prod

r repair or r

er than to

t be liable f

lation or repl

use, samp

TEN OR

TICULAR P

CT, PROMI

WARRANT

R. These

ATIC'S

, MAINT

LIMI

e of defects i

tations belo

t is defectiv

ion to return

ct is accept

place the pr

epair, repla

r any loss,

acement, la

le or model,

RAL, EXPR

RPOSE AN

SE, DESCR

FROM MA

roducts are

SWING

NANCE

ED WARR

n material a

.

, the purcha

the product;

d for return

duct, f.o.b.

e or refun

osts, expen

eling, instru

warnings

ESS OR I

D MERCHA

PTION OF

UFACTUR

not manufa

HECK

AND IN

NTY

d workmans

ser shall: (a

(b) if permis

nd found to

factory, withi

as describ

ses or dam

tions, inform

r lack of a

PLIED, INC

TABILITY,

RODUCT

R, UNLESS

tured, sold

ALVE

TALLA

ip for a peri

Notify the

ion is given,

be defective

n 60 days o

ed above,

ges of any

ation or tech

y of the fo

LUDING TH

RE MADE

F USE OR

SIGNED BY

r intended

ION

d of one ye

anufacturer,

return the pr

the manufa

receipt, or

urchaser a

ind arising

nical data of

egoing. N

E WARRA

R AUTHOR

SAMPLE O

THE PRESI

or personal,

r from the

state the

duct with

turer will,

efund the

rees that

ut of the

any kind,

OTHER

TIES OF

IZED. NO

MODEL

DENT OF

family or

VAL-M

age 13 of 1

905

Phon

www.

ATIC® VAL

iverside D

(630) 941-7

almatic.com

E AND MAN

r. ● El

00 ● Fa

UFACTURI

hurst, IL 6

(630) 941-8

G CORP.

0126

42

Loading...

Loading...