Val-Matic Rubber-Seated Ball Valve User Manual

Manual No.

BV-OM1-3

®

Val-Matic

Rubber-Seated Ball Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION ....................................... 2

RECEIVING AND STORAGE .................... 2

DESCRIPTION OF OPERATION .............. 2

VALVE CONSTRUCTION ......................... 3

INSTALLATION REQUIREMENTS ........... 4

MAINTENANCE ......................................... 8

TROUBLESHOOTING ............................. 10

DISASSEMBLY ....................................... 10

REASSEMBLY ........................................ 11

PARTS & SERVICE ................................. 12

WARRANTY ............................................ 12

VALVE AND MANUFACTURING CORP.

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

y

VAL-MATIC'S 4"-48" SERIES 4000 BALL VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

The Series 4000 Ball Valve has been designed to

provide long trouble-free operation. This manual will

provide you with the information to properly install and

maintain the valve to ensure a long service life. The

valve is a resilient seated, quarter-turn valve capable of

handling water and wastewater. The Size, Cold

Working Pressure (CWP), and Model No. are stamped

on the nameplate for reference.

CAUTION: Do not use valve for line test ing at

pressures higher than nameplate

rating or leakage and damage to

valve ma

The "Cold Working Pressure" is the non-shock

pressure rating of the valve at 150

discharge service, the valve is intended for flow toward

the seat end of the valve. The “Seat End” is marked

on the nameplate for single-seated valves. This allows

seat adjustment while the valve is holding system

pressure. Double seated valves can be installed with

flow and pressure in either direction.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. Do not lift valves with slings or chains

around the actuator or through the seat area. Lift valve

with straps or hooks in the lifting eyes integrally cast on

the body flanges. Extra care must be taken when

handling electric motor and cylinder actuated valves.

Valves should remain crated, clean and dry until

installed to prevent weather related damage. The valve

is shipped slightly open to maintain the resilient seat in

the un-loaded condition.

For long-term storage greater than six months, indoor

storage is recommended. The valve flange covers

must remain in place, the valve must remain slightly

open (3-5 degrees), and the rubber surfaces of the ball

should be coated with a thin film of FDA approved

grease such as Dow Corning # 7. Do not expose the

resilient seat to sunlight or ozone for any extended

period.

occur.

o

F. On pump

DESCRIPTION OF OPERATION

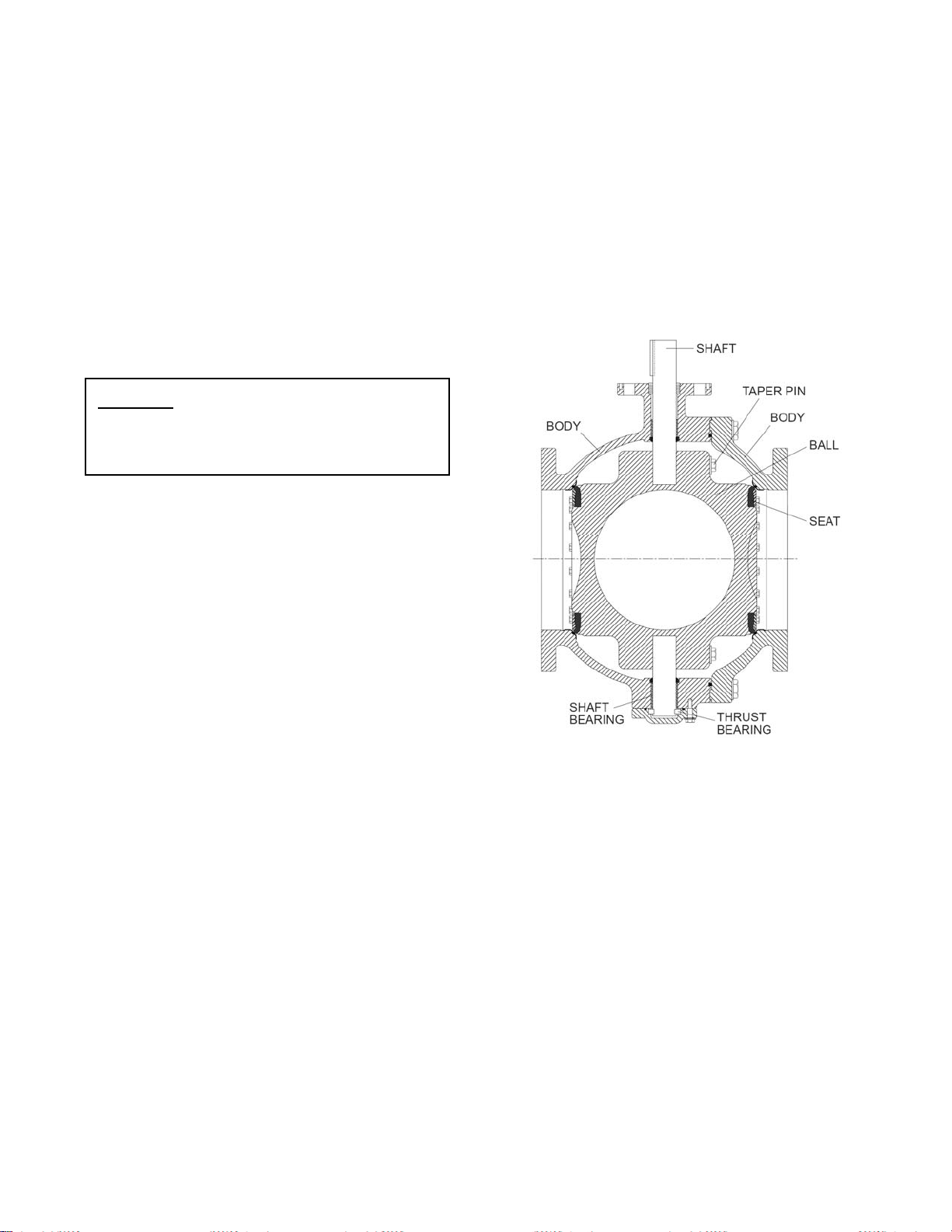

As shown in Figure 1, the valve consists of a two-piece

body, cast ball, and shafts that rotate in shaft bearings.

The ball is centered in the body with a thrust bearing

assembly. The resilient seats provide drop-tight

shutoff.

FIGURE 1. RESILIENT-SEATED BALL VALVE

The ball is rigidly attached to the shaft with taper pins.

The actuator rotates the valve shaft and ball through

90 degrees of operation. The ball can rotate through

the seat, but is factory set to stop in the center of the

seat to provide tight shut off. Additional torque on the

actuator when against the closed stop of the actuator

will not provide tighter shut off. The valve seat is easily

adjustable or replaceable should wear or damage

occur over time.

The valve is operated with a traveling nut manual

actuator; see Figure 3, which requires multi-turn input

on a handwheel or nut. The valve can also be

automated with power actuators such as an electric

motor or hydraulic cylinder.

2

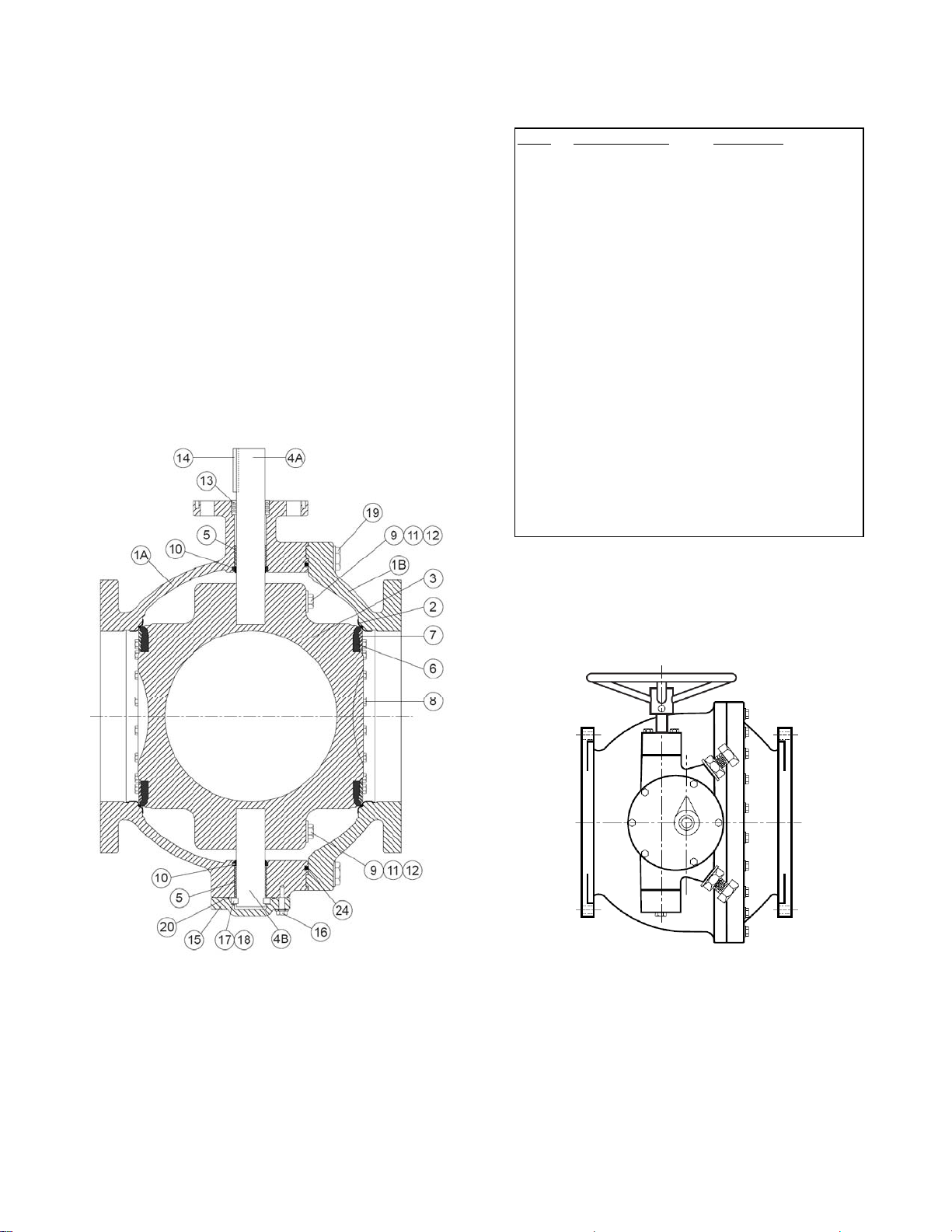

VALVE CONSTRUCTION

The standard Series 4000 Ball Valve is constructed of

rugged cast iron with stainless steel shafts and resilient

seat. See the specific Materials List submitted for the

order if other than standard cast iron construction. The

details of construction are illustrated in Figure 2.

The body (1) is available with Class 150# or Class

300# flanged ends for connection to the pipeline. The

body is equipped with a stainless steel seat (2). The

1/4 turn ball (3) is guided by a stainless steel shaft (4)

which rotates in non-metallic bearings (5) fixed in the

body. Leak-tight closure is made when the resilient

seat (6) located on the ball. If the valve is labeled as a

“Single” seat valve, the seat will be on the right end

and this is the end that is installed toward the pump.

ITEM DESCRIPTION MATERIAL

1 Body Gray or Ductile Iron

2 Body Seat Stainless Steel

3 Ball Gray or Ductile Iron

4 Shaft Stainless Steel

5 Sleeve Bearing* Teflon/Fiberglass

6 Resilient Seat* Resilient

7 Seat Retaining Ring Stainless Steel

8 Ret. Ring Screws* Stainless Steel

9 Taper Pin Stainless Steel

10 Grit Seal * Molythane

11 Taper Pin Bolt Stainless Steel

12 Taper Pin Washer Stainless Steel

13 Packing* Buna-N

14 Key Carbon Steel

15 Thrust Bearing Cap Ductile Iron

16 Cap Screws Carbon Steel, Plated

17 Thrust Brg. Shims Brass

18 Thrust Bearing Bronze

19 Body Bolts Carbon Steel, Plated

20 Cap O-ring Resilient

24 Body O-ring Resilient

*Recommended Spare Part

TABLE 1. STANDARD VALVE PARTS LIST

FIGURE 2. BALL VALVE PARTS LIST

FIGURE 3. VALVE WITH MANUAL ACTUATOR

3

INSTALLATION REQUIREMENTS

Ball valves are a significant component of any water

pumping system or wastewater system. Valve failure

caused by faulty installation, improper operation, or

maintenance in these systems could result in damage,

down time, and costly repairs. In buried or

underground installations, problems or malfunctions

can result in extensive, costly excavation to correct or

eliminate the problem. Many problems with ball valves

can be traced to improper installation, operation, or

maintenance procedures.

OPERATING PARAMETERS: The valve nameplate

lists the maximum pressures and flow rates within

which the valve is intended to operate. If the system

parameters exceed these values, contact the factory

for assistance.

VALVE TYPE: The nameplate will indicate whether

the valve is a “Single” or “Double” seated valve. Flow

direction as discussed below, is important for single

seat valves.

SHAFT ORIENTATION: It is common to install the

valve with the shaft horizontal. This places the

actuator on the side of the pipeline providing good

access to the handwheel, nut, or cylinder actuator

controls. However, the standard valve is designed to

be installed with the shaft in any orientation.

BURIED SERVICE: The valve should be installed with

the shaft horizontal and the actuator nut directed

upwards. The valve box or extension pipe should be

installed so that the actuator nut and extension stem

turn freely.

NOTE: Adjust and test valve prior to backfill.

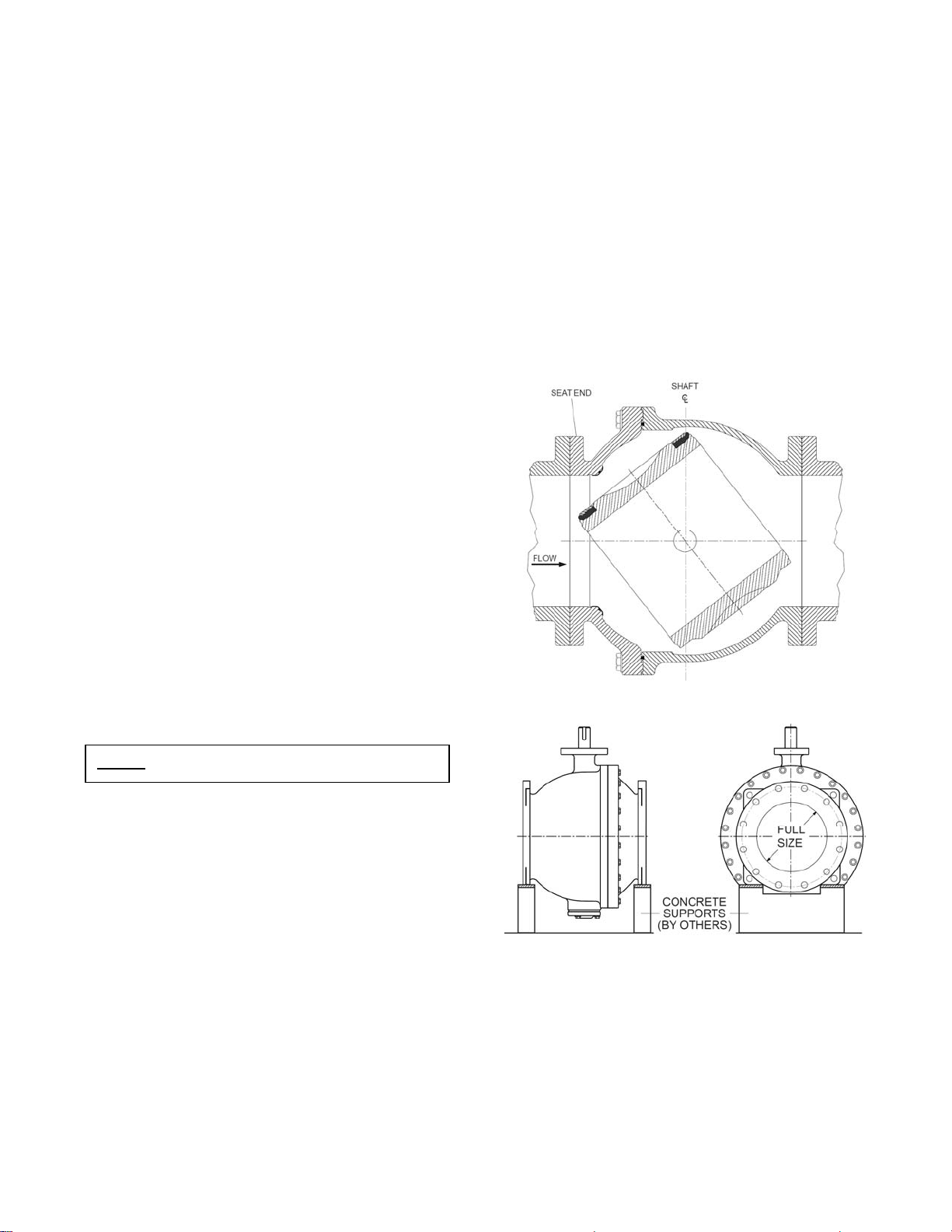

SEAT ORIENTATION FOR PIPELINE SERVICE: If

the valve is furnished with a single seat, the normal

flow direction is towards the seat end of the valve.

When the flow stops, the return pressure will be held

by the closed ball and the seat bolts (8) can be

adjusted to provide tight shut off should the seat be

worn or damaged. The nameplate is located on the

seat end valve flange. If the valve is furnished with

double seats, flow direction is not important.

SEAT ORIENTATION FOR PUMP DISCHARGE

SERVICE: On all horizontal pump discharge

applications (Figure 4), the seat end should be towards

the pump to allow seat adjustment with system

pressure against the ball (Figure 4). If the valve is

furnished with double seats, flow direction is not

important.

VALVE SUPPORT: The valve is designed with

integrally cast pads for lifting and supporting the weight

of the valve on a suitable hanger, support, or concrete

pier. The support system should be designed to

support the weight of the valve and not the axial motion

of the piping system, see Figure 5.

FLANGED ENDS: AWWA Class 150 flanged valves

should be mated to ANSI Class 125# flat-faced flanges

equipped with resilient gaskets. When ring gaskets are

used, the bolt material shall be ASTM A307 Grade B or

SAE Grade 2 Carbon Steel. Higher strength bolts may

only be used with full-face gaskets.

FIGURE 4. Flow Direction for Pump Discharge

FIGURE 5. Support Valve Weight

FIELD TESTING

When rubber-seated ball valves are used to isolate

sections of a line for testing, it is important to realize

that these valves are designed or factory adjusted to

hold rated pressure only. If single seated, they hold

pressure in one direction only. Also, test pressures

above valve rated pressure may cause leakage past

the rubber seat and damage to the valve. In order to

4

Loading...

Loading...