Manual No.

CCPV-OM2-3

®

Val-Matic

Cam-Centric® Plug Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION ........................................ 2

RECEIVING AND STORAGE .................... 2

DESCRIPTION OF OPERATION ............... 2

VALVE CONSTRUCTION .......................... 3

INSTALLATION .......................................... 4

MAINTENANCE ......................................... 7

TROUBLESHOOTING ............................... 9

DISASSEMBLY .......................................... 9

REASSEMBLY ......................................... 10

PARTS & SERVICE ................................. 11

WARRANTY ............................................. 11

VALVE AND MANUFACTURING CORP.

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

VAL-MATIC'S CAM-CENTRIC PLUG VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

The Cam-Centric

give years of trouble-free operation. This manual will

provide you with the information to properly install and

maintain the valve to ensure a long service life. The

valve is an eccentric, resilient seated, quarter-turn plug

valve capable of handling many types of fluids

including fluids with suspended solids. The Size,

Cold Working Pressure (CWP), Actuator Rating, and

Model No. are stamped on the nameplate for

reference.

CAUTION: Do not use valve for line testing at

pressures higher than nameplate rating or

leakage and damage to valve may occur.

The "Cold Working Pressure" is the non-shock

pressure rating of the valve at 150

intended as a block valve for line testing above the

valve rating. The “Actuator Rating” is the pressure that

was used to size the actuator for operating conditions

and may be less than the “Cold Working Pressure”.

Because the valve is eccentric, the valve may have a

different actuator rating for reverse and direct pressure.

If the valve is operated at pressures higher than the

actuator ratings, the valve may be difficult to operate or

leak.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. Do not lift valves with slings or chains

around the actuator or through the seat area.

Valves should remain crated, clean and dry until

installed to prevent weather-related damage. For long

term storage greater than six months, the valve must

remain open and the rubber surfaces of the plug

coated with a thin film of FDA approved grease such

as Dow Corning # 7. Do not expose plug to sunlight or

ozone for any extended period.

DESCRIPTION OF OPERATION

As shown in Figure 2, the valve consists of a body and

quarter-turn plug that is offset from the seat centerline.

Plug Valve has been designed to

o

F. The valve is not

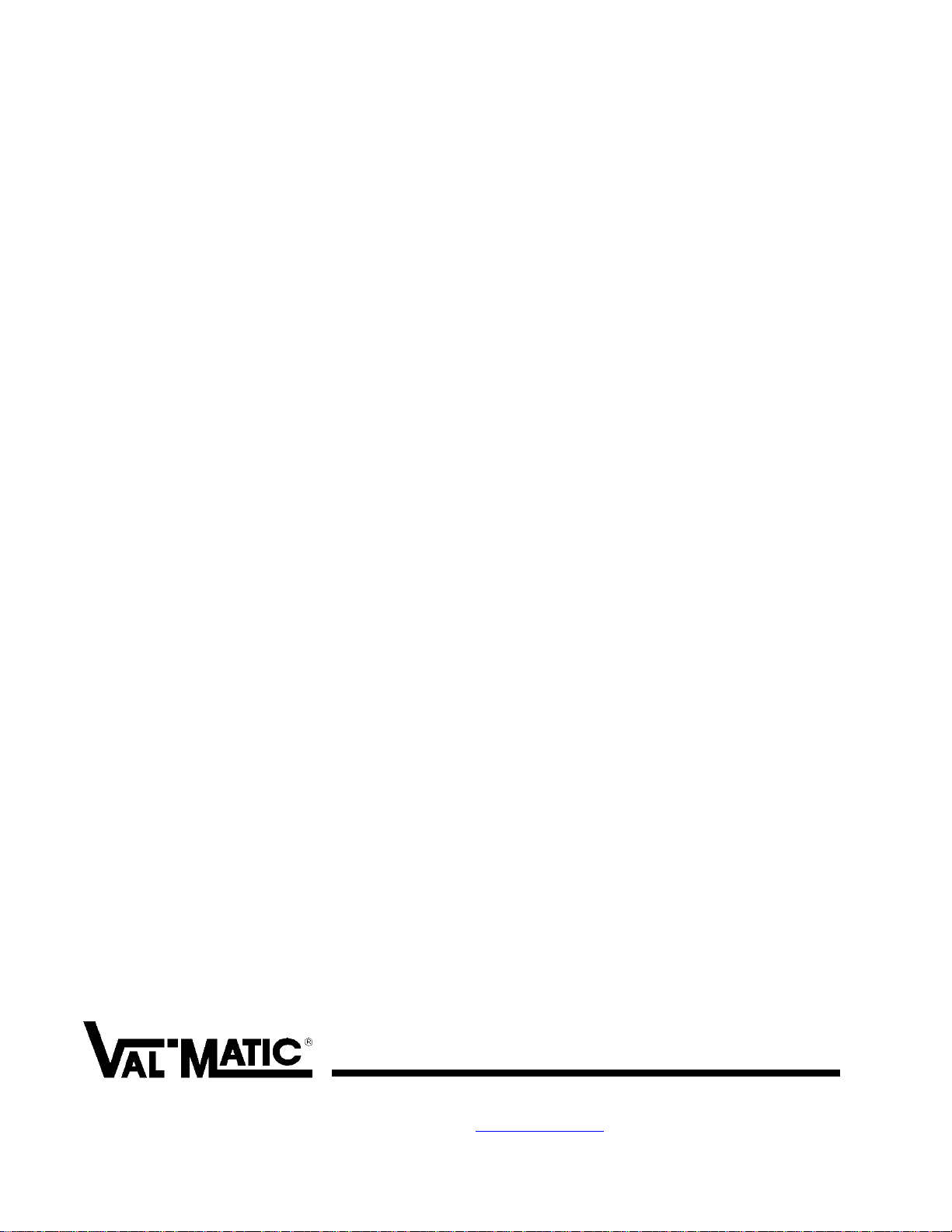

FIGURE 1. PLUG VALVE WITH GEAR ACTUATOR

The eccentric offset causes the plug to lift and rotate

off the seat simultaneously to reduce seat friction and

wear during operation. Direct Pressure pushes the

plug into the seat and Reverse Pressure pushes the

plug away from the seat. The valve can be operated

with a direct nut, lever, or gear actuator. The gear

actuator as shown in Figure 1 requires multi-turn input

on a 2” square nut, handwheel, or chainwheel. The

valve can also be automated with power actuators

such as an electric motor or hydraulic cylinder.

FIGURE 2. PLUG VALVE TERMS

2

VALVE CONSTRUCTION

The standard Cam-Centric

®

Plug Valve is constructed

of rugged cast iron with a welded nickel seat and

permanently lubricated bearings. See the specific

Materials List submitted for the order if other than

standard cast iron construction. The details of

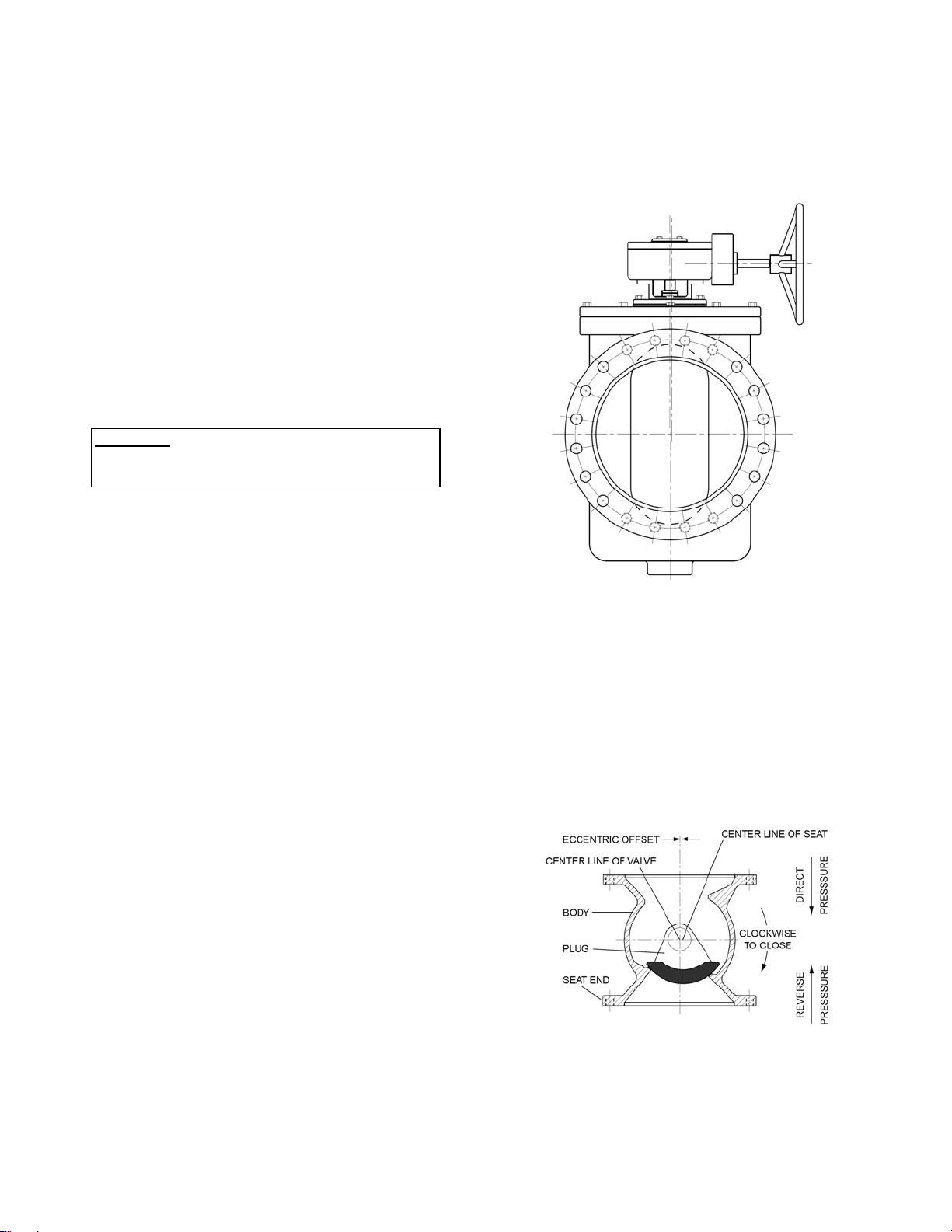

construction are illustrated in Figure 3.

The body (1) is available with flanged or mechanical

joint ends for connection to the pipeline. The valve is

designed to be serviced in-line by removing the cast

cover (2). The quarter-turn plug (3) is guided by sleeve

bearings (6) located in the cover and lower boss in the

body. Grit-Guard seals (21) are located at the bottom

of the bearings (6) to prevent abrasive material from

wearing the bearing. Leak-tight closure is made when

the rubber-coated plug (3) is rotated into the nickel

seat on the “SEAT END” of the body.

ITEM DESCRIPTION MATERIAL

1 Body Cast Iron with Overlay

2 Cover Cast Iron

3 Plug* Cast Iron with

6 Bearings* 316 Stainless Steel

7 V-Type Packing* Buna-N

8 Cover Seal* Buna-N

15 Cover Bolt Alloy Steel, Gr 5

18 Packing Follower Cast Iron

19 Follower Bolt Alloy Steel, Gr. 5

21 Grit-Guard* Buna-N

22 Thrust Bearing* Teflon

23 Thrust Bearing* 316 Stainless Steel

24 Key Carbon Steel

29 Shims 304 Stainless Steel

*RECOMMENDED SPARE PART

Welded Nickel Seat

Resilient Facing

TABLE 1. STANDARD PLUG VALVE PARTS LIST

FIGURE 3. STANDARD PLUG VALVE CONSTRUCTION

3

INSTALLATION

The installation of the valve is important for its proper

operation. The valve is capable of flow in either

direction but the maximum operating pressure can vary

with the location of the seat end. The words “SEAT

END” are marked on the valve flange. Actuators are

available for pressures up to the full rating in both

direct and reverse pressure orientations. Actuator

ratings will be indicated on the nameplate. Higher

operating pressures may require adjustment of the

closed position stop or a larger actuator; consult the

factory.

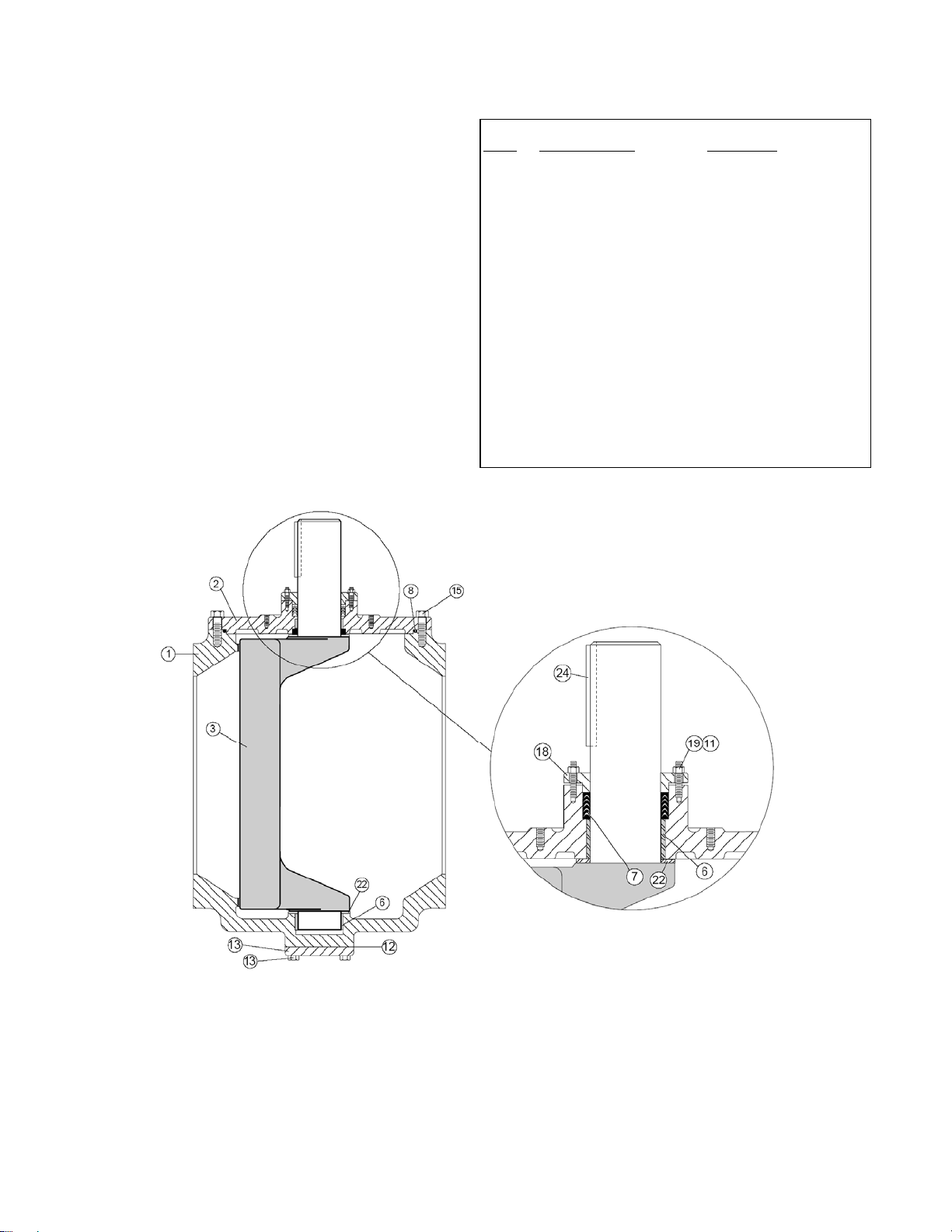

SUSPENDED SOLIDS SERVICE: For fluids

containing suspended solids, special orientations are

needed to prevent debris from collecting in the valve.

For horizontal installations (Figure 4), the valve should

be installed with the flow entering the seat end of the

valve and the shaft in a horizontal position with the

plug up when open. For vertical installations (Figure

5), the valve must be installed with the seat end up

regardless of flow direction.

CLEAN SERVICE: For both horizontal and vertical

installations, install in the direct pressure orientation

(pressure opposite the seat end).

AIR AND GAS SERVICE: Install valve in the direct

pressure orientation (pressure opposite the seat end).

Lubricate plug face with FDA approved silicone grease

such as Dow Corning #7 before installation. Gear

actuators are required for gas service applications.

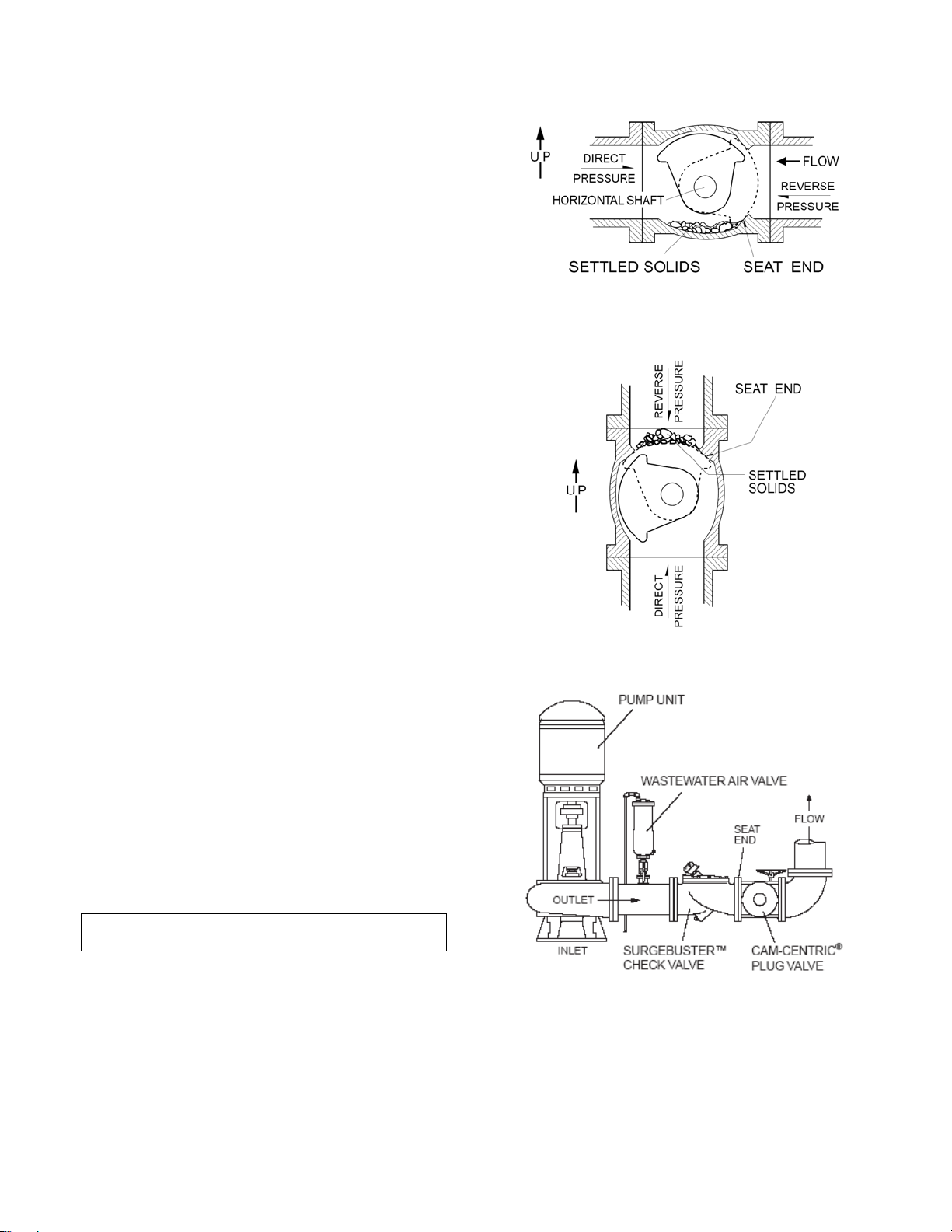

PUMP DISCHARGE SERVICE: On all horizontal

pump discharge applications (Figure 6), the seat end

should be towards the pump.

BURIED SERVICE: Gear actuators are recommended

for buried valves to hold the valve in position and

provide multi-turn closure to prevent water hammer.

The valve should be installed with the shaft horizontal

and the actuator nut directed upwards. The valve box

or extension pipe should be installed so that the

actuator nut and extension stem turn freely.

NOTE: Adjust and test valve prior to backfill.

FIGURE 4. HORIZONTAL PIPE WITH SOLIDS

FIGURE 5. VERTICAL PIPE WITH SOLIDS

FIGURE 6. PUMP DISCHARGE SERVICE

4

FLANGED ENDS: Flanged valves should be mated

with flat-faced pipe flanges equipped with resilient

gaskets. When ring gaskets are used, the bolt material

should be ASTM A307 Grade B of SAE Grade 2

Carbon Steel. Higher strength bolts may only be used

with full-face gaskets.

The valve and adjacent piping must be supported and

aligned to prevent cantilevered stress on the valve.

Lower valve into line using slings or chains around the

valve body. Lubricate the flange bolts or studs and

insert them around the flange. Lightly turn bolts until

gaps are eliminated.

The torquing of the bolts should then be done in

graduated steps using the cross-over tightening

method. Recommended lubricated torques for use

with resilient gaskets (75 durometer) are given in Table

2. If leakage occurs, allow gaskets to absorb fluid and

check torque and leakage after 24 hours. Do not

exceed bolt rating or crush gasket more than 50

percent of its thickness.

VALVE BOLT RECOM MAX

SIZE DIA TORQUE TORQUE

(in) (in) (ft-lbs) (ft-lbs)

MECHANICAL JOINT ENDS: Clean ends of mating

pipe and valve sockets with soapy water (Figure 7).

3 5/8 25 90

4 5/8 30 90

6 3/4 30 150

8 3/4 40 150

10 7/8 45 205

12 7/8 65 205

14 1 80 300

16 1 90 300

18 1 1/8 100 425

20 1 1/8 120 425

24 1 1/4 150 600

30 1 1/4 175 600

36 1 1/2 175 1000

42 1 1/2 200 1000

48 1 1/2 250 1000

TABLE 2. FLANGE BOLT TORQUES

CAUTION: The use of raised-face flanges

or excessive bolt torque may

damage valve flanges.

Place lubricated gasket and retainer gland over pipe

end prior to installing valve. Install valve socket over

pipe. Press gland and gasket toward valve until gasket

is evenly set into valve socket.

FIGURE 7. MECHANICAL JOINT INSTALLATION

Insert T-bolts in valve flange and hand tighten nuts.

Torque nuts in four graduated steps using the crossover tightening method without exceeding the torque

listed in Table 3. Maintain an equal gap between the

gland and the face of the valve at all points around the

socket.

If a tight connection is not achieved, then the joint

should be disassembled, thoroughly cleaned, and

reassembled. Over-tightening may cause damage to

the valve or gland.

VALVE T-BOLT RECOM MAX

SIZE DIA TORQUE TORQUE

(in) (in) (ft-lbs) (ft-lbs)

3 5/8 45 60

4 3/4 75 90

6 3/4 75 90

8 3/4 75 90

10 3/4 75 90

12 3/4 75 90

14 3/4 75 90

16 3/4 75 90

18 3/4 75 90

20 3/4 75 90

24 3/4 75 90

30 1 100 120

36 1 100 120

42 1-1/4 75 150

48 1-1/4 75 150

TABLE 3. MECHANICAL JOINT NUT TORQUES

5

DIRECT NUT OPERATED VALVES: 8” and smaller

valves may be equipped with a top-mounted nut for

direct quarter-turn operation. The nut is 2” square to fit

most valve wrenches and is mounted directly to the

valve plug. To open the valve, slowly rotate the nut 90

degrees in the counter-clockwise (CCW) direction. The

closed position is adjusted with a set screw and lock

nut, see Figure 8. The open position can be adjusted

by moving the bolt along the curved slot.

FIGURE 8. DIRECT NUT ADJUSTMENTS

DIRECT NUT FRICTION ADJUSTMENT: As shown

in Figure 9, valves with direct nut actuators have a

flanged packing follower (18) above the packing (7)

to hold the valve in the open or closed position. If the

valve is difficult to operate or does not maintain its

set position, adjust the clamp bolt (17) to provide

sufficient friction to hold the valve in position. IF the

valve is equipped with a hand lever, the setting

should allow the valve to be operated with about 80

pounds of force on the end of the pipe handle.

FIGURE 9. FRICTION ADJUSTMENT

LEVER OPERATED VALVES: A wrench head and

lever (Figure 10) are available for use over the 2” nut

for direct quarter-turn operation. Various lever lengths

are available for specific direct and reverse pressure

conditions as shown in Table 4.

VALVE DIRECT PRES. REVERSE PRES.

SIZE 100 psi 175 psi 50 psi 175 psi

2 1/2 22 22 22 22

3 22 22 22 22

4 22 22 22 22

6 44 * 44 *

8 44 * 44 *

*Worm gear recommended due to operating torque

The wrench head is placed over the nut and can be

secured with the set screw provided. To open the

valve, rotate the lever 90 degrees in the CCW

direction. The closed position is adjustable with a set

screw and lock nut mounted below the nut, see Figure

8.

CAUTION: Open and close the valve slowly to

GEAR OPERATED VALVES: 4” and larger plug

valves are available with a multi-turn manual gear

actuator. The gear unit has a self-locking worm gear

which multiplies the turning force on the handwheel or

nut so that the valve can be operated with ease. A

clamp-on chainwheel kit can also be used for

installations high above the floor. An indicator on the

top of the actuator housing indicates the position of the

valve plug. The handwheel or nut must be rotated

through 12-80 turns (depending on model) to open or

close the plug valve. The direction of rotation to open

the valve is indicated on the 2” square actuator nut.

WRENCH LENGTH, (Inches)

TABLE 4. APPLICATION OF LEVERS

FIGURE 10. HANDLEVER

prevent water hammer.

6

GEAR ACTUATOR ADJUSTMENT: The standard

gear actuator is provided with factory-set open and

closed position stops. If the valve does not shut off

tight, the stop bolt can be adjusted allowing the plug to

rotate further into the seat. Loosen the locknut, and

turn the closed stop bolt CCW 1 turn at a time (Figure

11). If the valve continues to leak after all of the

adjustment is taken verify the orientation of the valve

during installation. If a tight shut-off can not be

achieved, a larger gear actuator may be required for

the system operating pressure; consult the factory.

CAUTION: Adjust closed stop bolt for tight

FIGURE 11: GEAR ACTUATOR ADJUSTMENT

shut-off only. Over adjustment

may cause high operating torques

and damage to the plug.

MAINTENANCE

The Cam Centric

lubrication or maintenance other than regular

exercising and occasional inspection of the plug. The

exercising is achieved by fully opening and closing the

valve to verify smooth operation. If operation is

difficult, it may be necessary to flush sediment from the

valve by opening and closing the valve several times

under flowing conditions.

CAUTION: Open and close the valve slowly to

The recommended interval for exercising is every six

months or annually if the valve is regularly operated.

Over the life of the valve, inspection and some regular

adjustments may be needed as given below.

®

Plug Valve requires no scheduled

prevent water hammer.

CLOSED POSITION ADJUSTMENT: The standard

valve is factory-set to seal at the “Actuator Pressure

Ratings” shown on the nameplate for direct and

reverse pressure directions (see Figure 2). Higher

pressure applications may require adjustment of the

closed position stop or a larger actuator; consult the

factory.

If the valve is found to leak in the closed position due

to wear, the plug can be adjusted by loosening the

closed position stop on the actuator and rotating the

plug further into the seat. Because of the eccentric

action of the valve, further rotation will provide

additional interference between the rubber plug surface

and the body seat. Valves that have been in service

for several years may require inspection of the plug for

damage or wear. See the Disassembly Instructions of

this manual.

PACKING ADJUSTMENT: V-type packing is pressure

sensitive and therefore self-adjusting in nature. Over

tightening will destroy both the pressure sensitive

nature of the packing as well as its sealing capabilities.

The packing configuration used in Cam-Centric Plug

Valves follows the guidelines and recommendations of

V-packing manufacturers.

Additional adjustment can be achieved by removing

one or more shims found under the packing follower

(18). If a leak develops, remove one shim (29) from

the underside of the follower (18). An equal number of

shims must be removed from both the left and right

hand sides. Re-tighten the follower bolts (19) and

check for leakage. If the leakage continues, remove

additional shims or replace the packing.

FIGURE 12. PACKING ASSEMBLY

7

PACKING REPLACEMENT: To replace the packing

(7), it is recommended that the line be drained and the

actuator removed. The valve can remain in the line. Te

replace the packing, first open the valve and drain the

line. Close the valve to hold it in position. For power

actuators, turn off and lock out electrical and hydraulic

supplies before proceeding.

CAUTION: Drain line and close valve before

removing actuator or valve may

rotate suddenly. Take precautions

against exposure to toxic or

hazardous fluids in the line.

Remove the small round cover on actuator to expose

shaft and key. Remove actuator mounting bolts and lift

actuator from valve taking care not to lose square key.

See Figure 12 and remove gland bolts (19) and lift

follower (18) from the valve shaft. Remove old packing

(7) with packing hook. Lubricate new packing with

FDA grease and set in place one ring at a time taking

care not to bend over the lips of the packing rings.

Reinstall follower with 2 shims (29) per bolt (3 shims

for 12” and larger valves). With valve in the closed

position, place the actuator over valve and reinsert key

(24). Finally, reinstall cover on actuator indicating

“Closed”.

CAUTION: If packing assembly contains

clamp style follower as shown in

Figure 8, do not lubricate shaft or

sleeve.

PACKING REPLACEMENT WITH ACTUATOR: The

above procedure with removal of the actuator will result

in the most reliable shaft seal. But if the actuator can

not be removed, the following alternate procedure can

be followed. To prevent the possibility of leakage

during this procedure, open valve and drain the line.

CAUTION: Take precautions against

exposure to toxic or hazardous

fluids in the line.

Referring to Figure 12, remove follower bolts (19) and

side follower (18) up to actuator. Remove packing

adapters and rings (7) with packing hook. Cut rings

with knife to remove. New packing rings should be cut

at a 45 degree slope to allow insertion around the shaft

and provide some overlap. Install rings one at a time

with the tips down toward the valve. Stagger all joints

180 degrees around the shaft. Pull down follower (18)

and reinsert bolts (19) with 2 shims (29) under follower

(18). V-packing is pressure assisted and only requires

light compression.

GEAR ACTUATOR MAINTENANCE: A typical gear

actuator is shown in Figure 13 and consists of a worm

(3) mounted on an input shaft (9). The worm engages

a worm wheel (2). When the worm is turned, it drives

the wheel through 90 of rotation. The rotation of the

valve plug is displayed by the top indicator (5). The

open and closed positions of the segment gear are

controlled by an end position stop bolts (20). The

stops can be adjusted by loosening the lock nut (21)

and rotating the bolts. The gears are lubricated with

EP2 grease in a cast iron housing (1). Other parts are

listed in Table 5.

The gear box is factory lubricated and sealed. No

regular maintenance is required. If difficult operation is

observed, the cover (4) can be removed and the unit

inspected for wear. All moving parts should be coated

with grease. The grease should have an even and

smooth consistency. If needed, coat all moving parts

with an lithium-based EP-2 grease such as Shell

Alvania #2 or equal. Buried units should be packed

90% with grease.

FIGURE 13. GEAR ACTUATOR CONSTRUCTION

8

ITEM DESCRIPTION MATERIAL

1 Housing Cast Iron

2 Wormwheel Ductile Iron

3 Worm Steel

4 Cover Cast Iron

5 Indicator Cast Iron

6 O-Ring Buna-N

7 Roller Bearing Steel

8 Shaft Bearing Bronze

9 Shaft Steel

10 Gasket Fiber

11 Handwheel Steel or Iron

12 Operating Nut Iron

13 Chainwheel Iron

14 Cover Bolt Steel

15 Indicator Bolt Steel

16 Pipe Plug Steel

17 Pin Steel

18 Spirol Pin Steel

19 Spring Pin Steel

20 Screw Steel

21 Jam Nut Steel

22 Plug Steel

23 U-Cup Seal Buna-N

TABLE 5. GEAR ACTUATOR PARTS LIST

TROUBLESHOOTING

Several problems and solutions are presented below to

assist you in troubleshooting the valve assembly in an

efficient manner.

• Leakage at Valve Shaft: Adjust or replace packing.

• Leakage at Flanges: Tighten flange bolts, replace

gasket.

• Valve Leaks when Closed: Pressure should be in the

direction of pushing the plug into the seat. Adjust

plug position by rotating the handwheel. Inspect plug

for damage and replace.

• Hard to Open: Flush debris from valve. Check

interior of valve for grit buildup or debris. On buried

valves, check alignment of operating stem.

• Leaking Oil: Tighten actuator cover bolts. If leak

persists, remove actuator cover, inspect grease, and

replace actuator gasket.

• Noisy Operation: Flow noise is normal. Loud flow

noise similar to hammering may be cavitation from

dropping high pressures across valve; review

application of valve. For gear actuator noise, inspect

grease; add new grease if there are uncoated

moving parts or grease has broken down into oil.

DISASSEMBLY

Disassembly may be required to inspect the plug for

wear or remove debris and deposits from the valve.

Work on the valve should be performed by a skilled

mechanic with proper tools and a power hoist for large

valves. The valve can be disassembled without

removing the valve from the pipeline. Refer to Figure

14 for valve construction and parts.

WARNING: Open valve and drain line before

1. Open valve and drain the pipeline. Close valve

until plug just touches the seat. Remove the small

cover on the actuator to expose the shaft key.

2. Remove the actuator mounting bolts and lift

actuator from valve taking care not to lose key

(24).

3. Remove cover bolts (15). Matchmark cover (2)

and body. Screw eye-bolts into actuator mounting

holes and use hoist to lift cover (2) and plug

assembly from valve. Use caution to prevent plug

from dropping while lifting cover. To remove plug

(3) from valve, use sling around top portion of

plug.

4. Inspection of the bearings (6) is done by

measuring diameter of shaft and inside diameter of

bearing. Check for a normal running clearance of

.005". Bearings are permanently lubricated.

5. Thrust bearing assembly (23) and packing gland

(18) can be removed by removing all of the hex

nuts (12).

removing cover bolts or pressure

may be released causing injury.

Place plug in lowest position

before removing actuator or plug

may rotate suddenly and jam or

damage plug surface.

9

REASSEMBLY

All parts must be cleaned and gasket surfaces should

be cleaned with a stiff wire brush in the direction of the

serrations or machine marks. Worn parts, gaskets and

seals should be replaced during reassembly.

FIGURE 14. PLUG VALVE PARTS

1. Press new bearings (6) into cover and body with

round, flat bar 1/4" below inside surfaces of body

(1) and cover (2).

2. Install cover seal (8) over cover lip.

3. Apply thin film of FDA silicone grease such as

Dow Corning #7 to plug rubber surface. Place

stainless steel thrust bearing (23) over lower end

of plug, Teflon bearing (22) over the upper end.

Install grit seals (21) over the shafts of the plug.

4. Carefully place plug into the body (1) and insert

lower plug shaft into bottom bearing (6). Plug (3)

should be in the open position. Install cover (2)

over plug shaft and into recess in body. Align

match marks between body and cover (2). Torque

cover bolts (15) per Table 6 in 3-4 increments

using the cross-over tightening method.

SIZE TORQUE (FT-LBS)

1/2"-13 45 - 75

5/8"-11 100 - 150

3/4"-10 150 - 250

7/8"-9 200 - 350

1"-8 300 - 500

1 1/8"-7 450 - 700

1 1/4"-7 650 - 1000

1 1/2"-6 750 - 1100

TABLE 6. TIGHTENING TORQUES

5. Lubricate ID and OD of packing set with FDA

grease and install in packing bore one ring at a

time taking care to keep lips pointing down toward

plug. Reinstall follower, gland bolts, and 2 shims

per bolt.

NOTE: If valve has friction assembly with direct

nut actuator, follow Friction Adjustment procedure

on page 6.

6. Insert key (24) into shaft and place actuator over

valve. Reinstall actuator mounting bolts and

torque per Table 6. Install cover on actuator.

7. Apply power to actuator and cycle valve. Apply

pressure to valve and check for cover and shaft

leakage. Tighten bolts as necessary. Adjust

packing if necessary.

8. If valve does not shut off tight, adjust the closed

position stop as described on page 6 under

“Closed Position Adjustment.”

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the valve

Size, Series No, and Serial No. located on the valve

nameplate and contact:

Val-Matic Valve and Mfg. Corp.

905 Riverside Drive

Elmhurst, IL 60126

PH: 630/941-7600

FAX: 630/941-8042

A sales representative will quote prices for parts or

arrange for service as needed.

All products are warranted to be free of defects in material and workmanship for a period of one year from the date of shipment,

subject to the limitations below.

If the purchaser believes a product is defective, the purchaser shall: (a) Notify the manufacturer, state the alleged defect and

request permission to return the product; (b) if permission is given, return the product with transportation prepaid. If the product

is accepted for return and found to be defective, the manufacturer will, at his discretion, either repair or replace the product,

f.o.b. factory, within 60 days of receipt, or refund the purchase price. Other than to repair, replace or refund as described

above, purchaser agrees that manufacturer shall not be liable for any loss, costs, expenses or damages of any kind arising out

of the product, its use, installation or replacement, labeling, instructions, information or technical data of any kind, description of

product use, sample or model, warnings or lack of any of the foregoing. NO OTHER WARRANTIES, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY, ARE MADE OR AUTHORIZED. NO AFFIRMATION OF FACT, PROMISE, DESCRIPTION OF

PRODUCT OF USE OR SAMPLE OR MODEL SHALL CREATE ANY WARRANTY FROM MANUFACTURER, UNLESS

SIGNED BY THE PRESIDENT OF THE MANUFACTURER. These products are not manufactured, sold or intended for

personal, family or household purposes.

LIMITED WARRANTY

VALVE AND MANUFACTURING CORP.

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

Loading...

Loading...