Val-Matic 50 Series Air Release Valve User Manual

Air Release Valve

Series 38, 45, 50

(Compound Lever Type)

Operation, Maintenance and

Installation Manual

Manual No.

ARCL-OM1-1

INTRODUCTION ....................................... 1

RECEIVING AND STORAGE.................... 1

DESCRIPTION OF OPERATION.............. 1

INSTALLATION......................................... 2

VALVE CONSTRUCTION......................... 2

MAINTENANCE ........................................ 3

TROUBLESHOOTING .............................. 3

DISASSEMBLY......................................... 3

REASSEMBLY.......................................... 4

PARTS & SERVICE .................................. 4

WARRANTY.............................................. 5

VALVE AND MANUFACTURING CORP.

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

VAL-MATIC'S AIR RELEASE VALVE

(Compound Lever Type)

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information

to properly install and maintain the valve to

ensure a long service life. The Air Release

Valve has been designed with stainless steel

trim to give years of trouble-free operation. The

Air Release Valve is typically mounted at the

high points in a piping system to automatically

remove pockets of air as they accumulate. The

valve can also be used to slowly release air in

tanks and pump casings.

Note: This valve is not intended for fluids

containing suspended solids such as

wastewater. For wastewater and other high

turbidity applications, use Val-Matic Series 48A

& 49A Sewage Air Release Valves.

CAUTION: This valve is not intended

for fuel service or fluids

containing suspended

solids.

The valve is a float-operated, resilient-seated

valve designed to handle clean fluids. The

Maximum Working Pressure and Model No. are

stamped on the nameplate for reference.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in

shipment. Handle all valves carefully without

dropping. Valves should remain boxed, clean

and dry until installed to prevent weather related

damage. For long term storage greater than six

months, the valve must remain in the box and

stored indoors. Do not expose valve to sunlight

or ozone for any extended period.

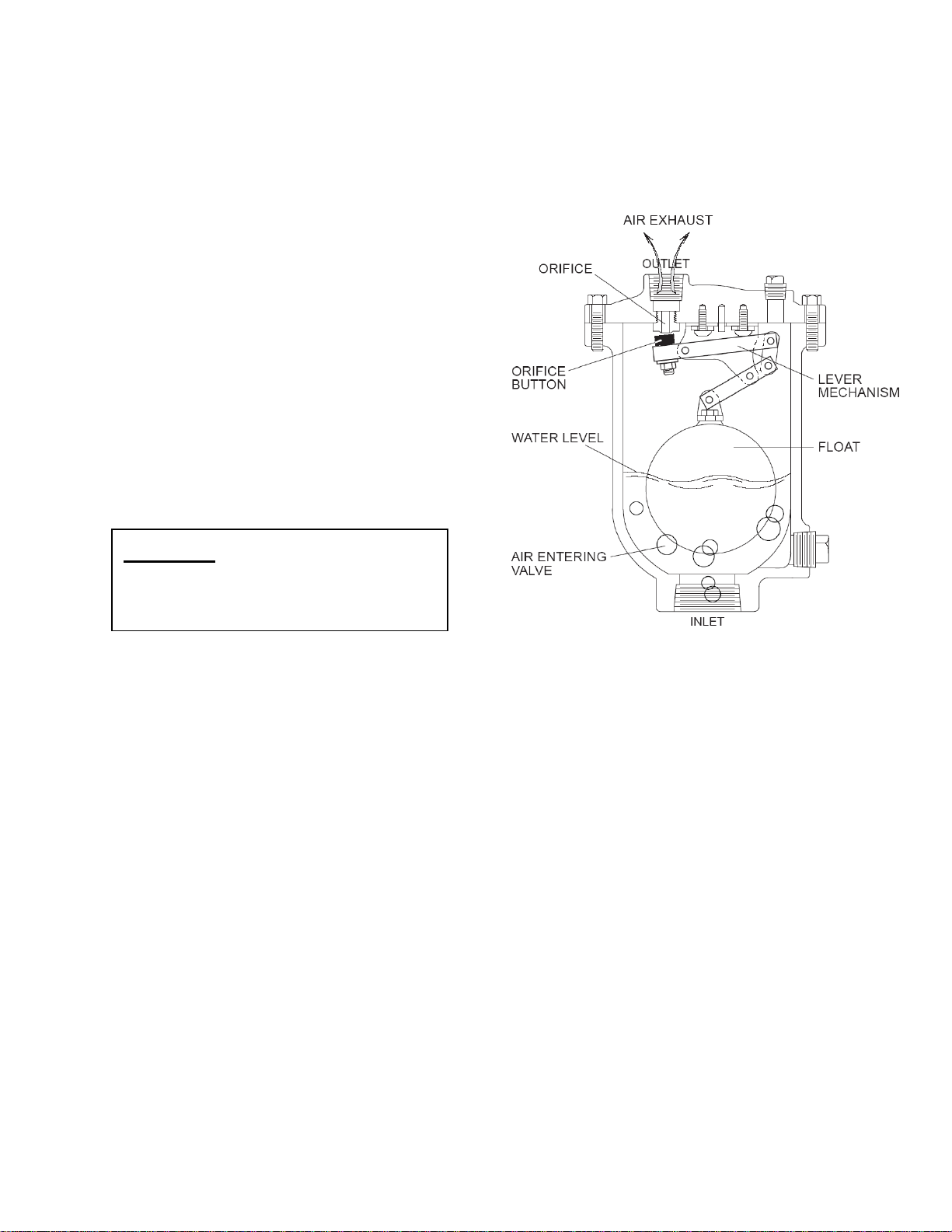

DESCRIPTION OF OPERATION

The Air Release Valve is designed to

automatically remove air pockets at the high

points in a piping system. The valve, as

shipped, is a normally open valve and will slowly

vent air through the top orifice. As fluid enters

the valve, the float will rise, closing the orifice.

As air accumulates in the piping system and

enters the valve, the float drops allowing the

venting orifice to open.

FIGURE 1. Compound Lever AIR RELEASE

VALVE

The lever mechanism provides mechanical

advantage for the float. During system

operation, the pipeline pressure exerts a strong

upward force on the sealing component, the

orifice button. The lever mechanism magnifies

the weight of the float so that the orifice will open

under high pipeline pressures. Additional ports

are provided for flushing, testing and draining

purposes.

1

Loading...

Loading...