Val-Matic 3 Way Plug Valve User Manual

e

V

W

n

a

U

P

C

A

N

E

&

N

M

P

a

o

O

C

A

N

E

c

g

a

O

V

A

v

6

F

6

a

V

1

2

al-

ati

®

Manu

CCP

l No.

-OM3-1

Op

3–

ratio

Inst

INTROD

RECEIVI

DESCRI

VALVE

INSTALL

MAINTE

TROUBL

DISASS

REASSE

PARTS

WARRA

ay

, M

llati

CTION ....

NG AND S

TION OF

ONSTRU

TION ......

ANCE .....

ESHOOTI

MBLY ......

MBLY .......

SERVIC

TY...........

lu

inten

n M

.................

TORAGE .

PERATI

TION .......

.................

.................

G ............

.................

.................

................

.................

Val

ance

nual

.................

.................

N .............

.................

.................

.................

.................

.................

.................

.................

.................

ve

and

.. 2

.. 2

.. 2

.. 3

.. 4

.. 5

.. 7

.. 7

.. 8

.. 8

.. 9

ALVE

905 Ri

Phone (

www.val

ND MANU

erside Dr.

30) 941-760

matic.com

ACTURING

● Elmh

0 ● Fax (

CORP.

urst, IL 60

30) 941-804

26

2

C

p

TypaTvmsA

n

T

pin

p

R

Uda Vinlo

mps

s

D

A

a

b

p

T

n

rra

a

D

h

O

P

C

P

u

w

o

n

r

W

n

t

G

s

a

o

c

d

p

r

w

w

o

T

d

a

s

a

a

s

v

n

v

VA

O

a

r

r

n

d

W

e

s

v

w

O

p

v

o

a

h

t

h

m

7

P

e

p

h

u

c

t

g

n

e

c

T

A

i

s

r

g

e

t

s

a

e

e

o

a

t

x

o

N

s

e

d

j

a

p

e

s

t

t

r

3

N

e

g

g

d

,

e

k

s

e

t

s

r

e

e

e

o

y

e

e

t

d

-

g

t

n

P

A

e

t

g

c

t

p

a

V

N

t

h

e

r

u

A

L

w

l

n

e

e

n

u

P

T

N

o

d

p

t

o

E

I

NTRODU

he 3-Way

ears of tro

rovide you

nd maintain

he valve is

alve with th

any types

olids. The

ctuator Rati

ameplate fo

AUTION:

ressures

l

eakage and

he "Cold

ressure rati

tended for

lug into the t

ECEIVIN

I

nspect valve

nload all v

ropping. D

round the a

ERATI

TION

lug Valve h

ble-free ope

ith the info

the valve to

a 360 deg

ree seats a

f fluids inclu

Size, Cold

g, and Mod

reference.

o not use

igher tha

damage to

orking Pre

g of the val

ight shutoff

hree seats.

AND ST

upon recei

lves careful

not lift val

tuator or thr

L-MA

N, M

s been des

ration. Thi

mation to p

ensure a lon

ee, resilient

d is capabl

ing fluids wi

orking Pre

l No. are st

alve for li

nameplat

alve may o

sure" is th

e at 150oF.

ith pressur

RAGE

t for damag

ly to the gr

es with slin

ugh the seat

IC'S

INTE

gned to giv

manual wil

operly instal

service life

seated plu

of handlin

h suspende

sure (CWP)

mped on th

e testing a

rating o

cur.

e non-shoc

The valve i

pushing th

in shipment

und withou

gs or chain

area.

-WAY

ANCE

l

l

.

.

ass

posi

The

the

dire

the

the

for

tight

LUG

AND I

n

externally a

mbly is loca

ion the heig

valve is op

ear actuato

tion through

op of the act

lug face.

djustable ind

shutoff.

ALVE

STAL

djustable t

ed in the va

t of the plug

rated by tur

. The valv

a full 360 d

uator cover i

djustable ro

ication of the

ATIO

o-way thrus

ve bonnet t

in the valve.

ing the han

can be turn

grees. The

dicates the l

nd head bol

exact seat l

t bearing

precisely

wheel of

ed in any

ointer on

ocation of

s provide

cation for

alves shoul

stalled to

ng term sto

ust remain

lug coated

uch as Do

unlight or oz

ESCRIP

s shown in

nd a tapere

ody. Three

lug can seal

he seat is

i

terference

ubber plug

ing type seal

nd low oper

t the full r

(

pressure pu

remain cr

revent weat

age greater

open and t

ith a thin fil

Corning #

ne for any e

ION OF O

Figure 1, th

plug that

nickel seats

off any of t

tapered to

nd tight sh

ealing surfa

ng surfaces

ting torque.

ting in the

hing the plu

ted, clean

er-related d

han six mon

e rubber su

of FDA app

. Do not e

xtended peri

ERATIO

valve consi

ivots 360 d

are provide

e three pipe

provide ad

toff service.

e also cont

o provide su

The valve s

direct pres

into the sea

nd dry unti

amage. Fo

hs, the valv

rfaces of th

roved greas

pose plug t

d.

ts of a bod

grees in th

so that th

connections

ustable sea

The molde

ins raised o

erior sealin

als drop-tigh

ure directio

).

.

l

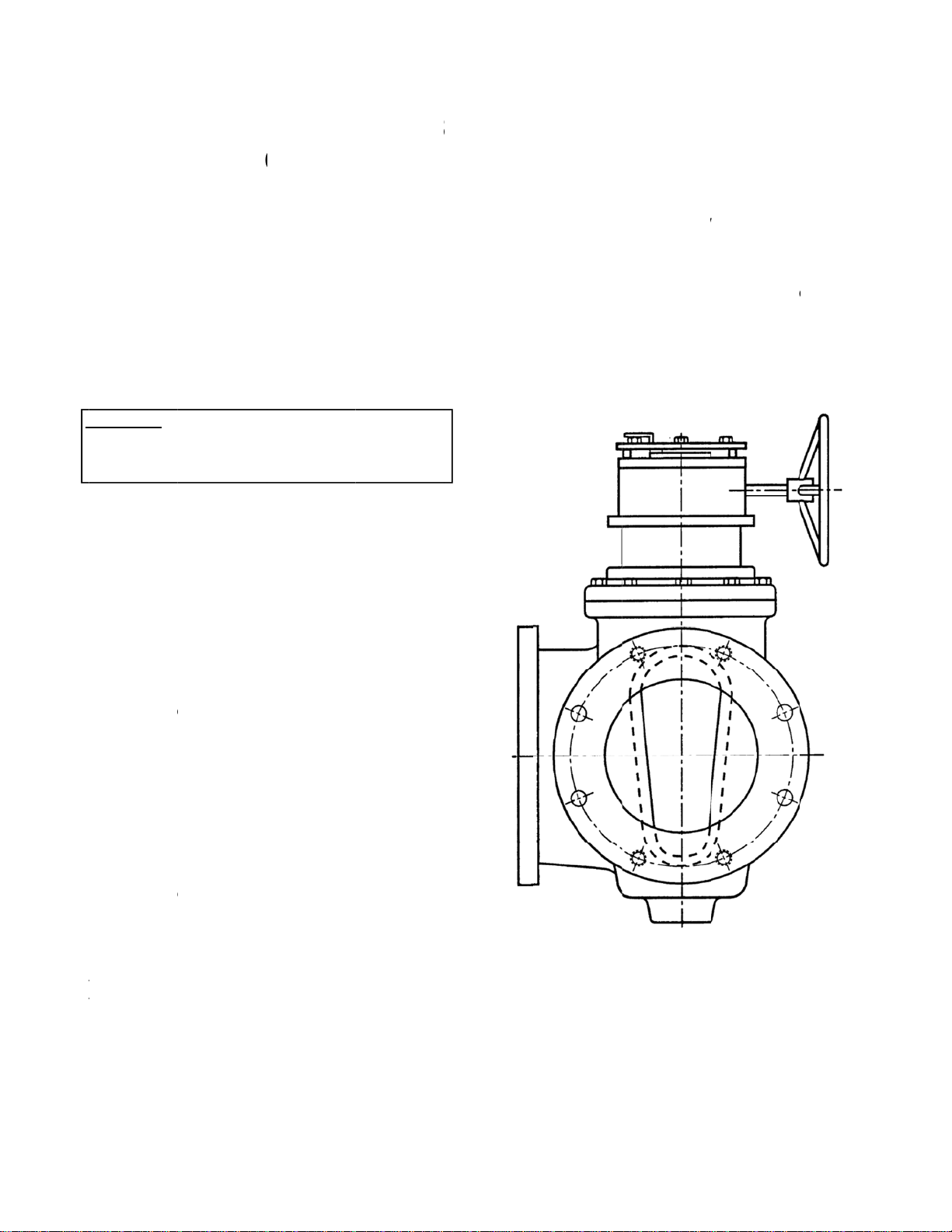

FIGURE

1. 3-WAY

ACTUA

LUG VALV

OR

WITH

V

Tcnssiril T

fotoTsba

mcr

F

ALVE C

O

a

g

t

F

n

d

n

o

m

a

n

S

T

e

t

e

e

e

e

a

n

t

k

P

g

w

t

M

s

n

c

v

1

v

e

E

s

d

s

t

t

e

s

d

y

r

d

e

t

s

C

B

C

r

n

p

r

N

r

g

n

G

o

s

C

N

D

G

R

w

e

w

s

G

s

T

he standa

onstructed o

ickel seat

teel bearin

ubmitted for

on construc

lustrated in

he body (1)

or connectio

o be service

he plug (3)

leeve beari

oss in the b

t the bottom

aterial fro

losure is m

otated into o

NSTRUC

rd Cam-C

rugged cas

nd perman

s. See th

the order if

ion. The d

igure 2.

is available

to the pipeli

in-line by r

has integral

gs (6) locat

dy. Grit-Gu

of the beari

wearing

de when the

e of the nic

ION

ntric® Plu

ductile iron

ntly lubrica

specific

other than

etails of co

with 3-Way

ne. The valv

moving the

shafts and

d in the co

rd® seals (2

gs (6) to pre

he bearing.

rubber coat

el seats.

Valve i

ith a welde

ed stainles

aterials Lis

tandard cas

struction ar

flanged end

e is designe

ast cover (2)

is guided b

er and lowe

) are locate

ent abrasiv

Leak-tigh

d plug (3) i

.

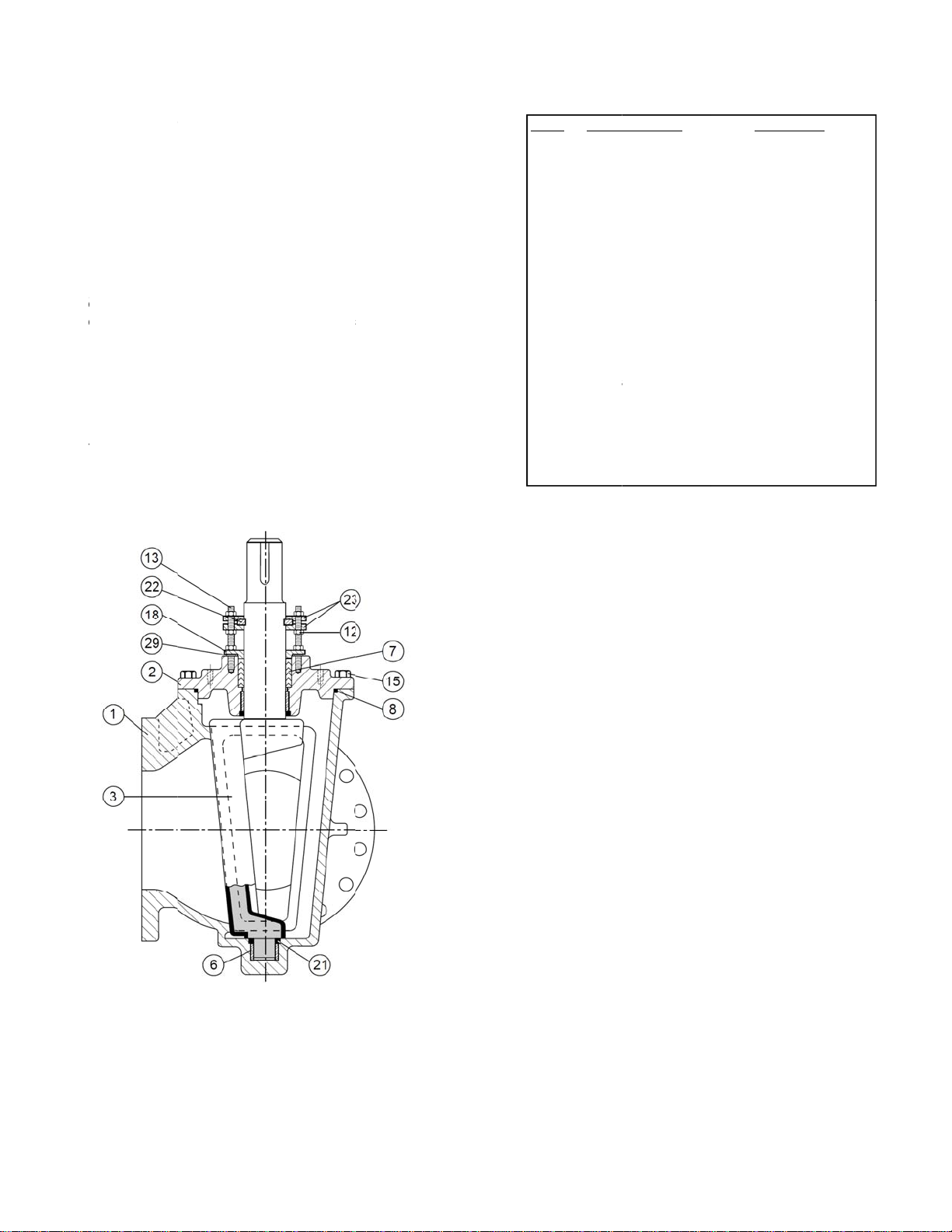

I

TEM DES

1 Body

2 Cove

3 Plug*

6 Beari

7 V-Ty

8 Cove

12 Hex

13 Stud*

15 Cove

17 Sprin

18 Packi

21 Grit22 Thrus

23 Supp

24 Key

29 Shim

RIPTION

gs*

e Packing*

Seal*

ut*

Bolt

Pin*

g Follower

uard®*

t Bearing*

rt Plate*

*

*RE

OMMENDE

MATE

Ductile Iron

Welded Nick

Ductile Iron

Ductile Iron

Resilient Fac

316 Stainles

Buna-N

Buna-N

Steel

Steel

Alloy Steel,

Carbon Steel

Cast Iron

Buna-N

Bronze

Carbon Steel

Carbon Steel

304 Stainles

SPARE PAR

IAL

ith Overlay

l Seat

ith

ing

Steel

r 5

Steel

TA

LE 1. STA

DARD PLU

VALVE PA

RTS LIST

IGURE 2.

TANDARD

LUG VALV

CONSTRU

TION

Loading...

Loading...