Val-Matic 30 and Larger Butterfly Valve User Manual

Manual No.

BFV- OM2-3

®

Val-Matic

30" and Larger Butterfly Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION ....................................... 1

RECEIVING AND STORAGE .................... 1

DESCRIPTION OF OPERATION .............. 1

VALVE CONSTRUCTION ......................... 2

INSTALLATION ......................................... 3

MAINTENANCE ......................................... 6

TROUBLESHOOTING ............................... 9

DISASSEMBLY ....................................... 10

REASSEMBLY ........................................ 10

PARTS & SERVICE ................................. 12

WARRANTY ............................................ 12

VALVE AND MANUFACTURING CORP.

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

g

VAL-MATIC'S 30" AND LARGER BUTTERFLY VALVE

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

The Series 2000 Butterfly Valve has been designed to

give years of trouble-free operation. This manual will

provide you with the information to properly install and

maintain the valve to ensure a long service life. The

valve is a resilient seated, quarter-turn valve capable of

handling air, water, or other clean fluids. For fluids with

suspended solids, a Model 5800R Eccentric Plug

Valve should be used. The Size, Cold Working

Pressure (CWP), and Model No. are stamped on the

nameplate for reference.

CAUTION: Do not use valve for line testing

at pressures higher than

nameplate rating or leakage and

dama

The "Cold Working Pressure" is the non-shock

pressure rating of the valve at 150

intended for flow in either direction. The “Seat End” is

marked on the nameplate so that access to the seat

can be assured.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. Do not lift valves with slings or chains

around the actuator or through the seat area. Extra

care must be taken when handling electric motor and

cylinder actuated valves.

Valves should remain crated, clean and dry until

installed to prevent weather related damage. For long

term storage greater than six months, indoor storage is

recommended. The valve flange covers must remain

in place, the valve must remain slightly open (3-5

degrees), and the rubber surfaces of the disc should

be coated with a thin film of FDA approved grease

such as Dow Corning # 7. Do not expose the resilient

seat to sunlight or ozone for any extended period.

Electric actuators must be powered if stored outdoors

or in cool areas so that the internal heaters will prevent

condensation in the control unit.

e to valve may occur.

o

F. The valve is

DESCRIPTION OF OPERATION

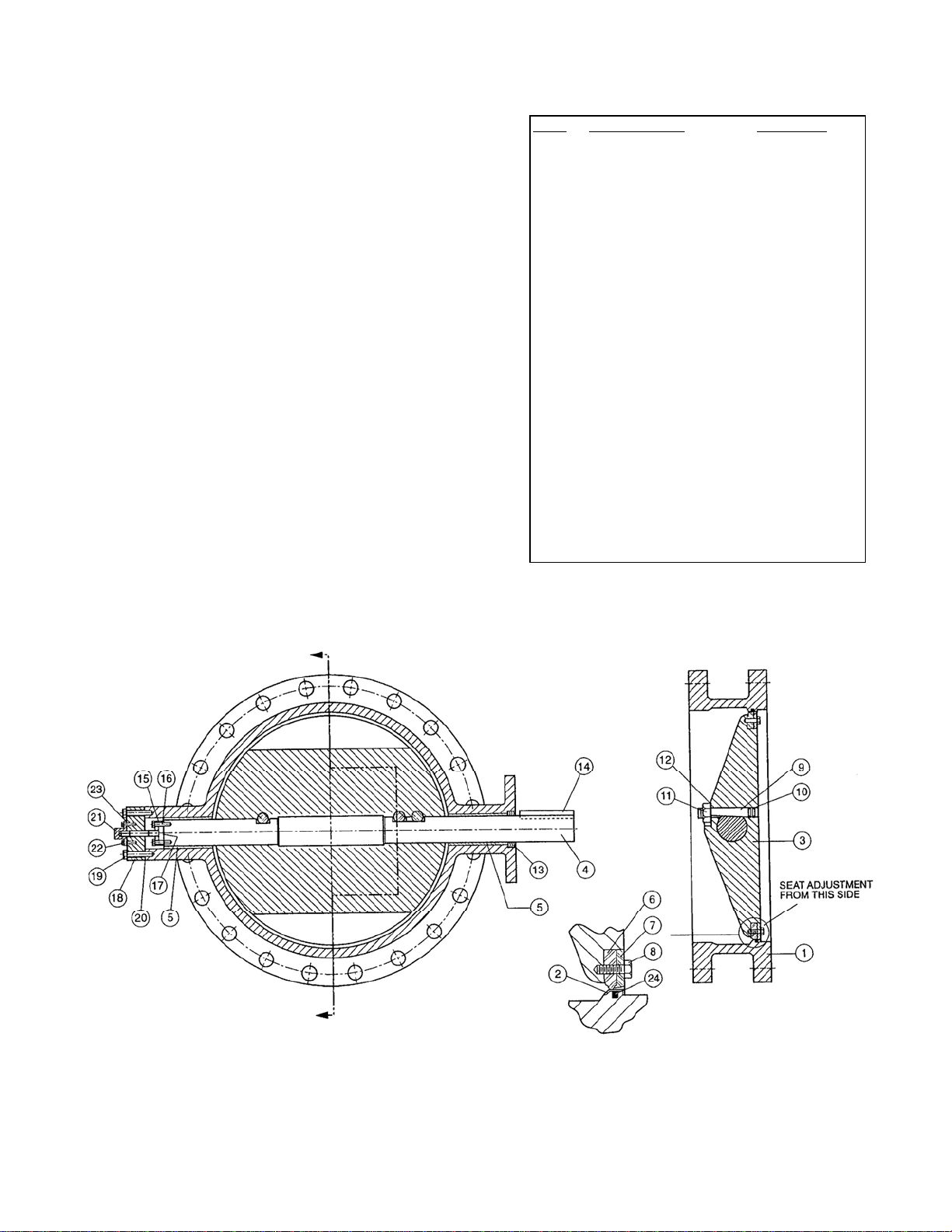

As shown in Figure 1, the valve consists of a body, a

disc, and a shaft that rotates in body bearings. The

resilient seat provides drop-tight shutoff.

FIGURE 1. BUTTERFLY VALVE WITH ACTUATOR

The disc is rigidly attached to the shaft with taper pins.

The actuator rotates the valve shaft and disc through

90 degrees of operation. The disc can rotate through

the seat, but is factory set to stop in the center of the

seat to provide tight shut off. Additional torque on the

actuator when against the closed stop of the actuator

will not provide tighter shut off. The valve seat is easily

adjustable or replaceable should wear or damage

occur over time.

The valve is typically operated with a manually

operated gear actuator. The gear actuator as shown in

Figure 1 requires multi-turn input on a 2" square nut,

handwheel, or chainwheel. The valve can also be

automated with power actuators such as an electric

motor or hydraulic cylinder.

1

VALVE CONSTRUCTION

The standard Series 2000 Butterfly Valve is

constructed of rugged cast iron with a stainless steel

shaft and resilient disc edge. See the specific

Materials List submitted for the order if other than

standard cast iron construction. The details of

construction are illustrated in Figure 2.

The body (1) is available with flanged or mechanical

joint ends for connection to the pipeline. The body is

equipped with a stainless steel seat (2). The 1/4 turn

disc (3) is guided by a stainless steel shaft (4) which

rotates in non-metallic bearings (5) fixed in the body.

Leak-tight closure is made when the resilient seat (6) is

rotated into the stainless steel seat on the "SEAT END"

of the body.

FIGURE 2. STANDARD BUTTERFLY VALVE CONSTRUCTION

ITEM DESCRIPTION MATERIAL

1 Body Gray or Ductile Iron

2 Body Seat Stainless Steel

3 Disc Ductile Iron

4 Shaft Stainless Steel

5 Sleeve Bearing* Teflon/Fiberglass

6 Resilient Seat* Buna-N

7 Seat Retaining Ring Stainless Steel

8 Ret. Ring Screws* Stainless Steel

9 Taper Pin Stainless Steel

10 Taper Pin O-Ring* Buna-N

11 Taper Pin Nut Stainless Steel

12 Taper Pin Washer Stainless Steel

13 Packing* Buna-N

14 Key Carbon Steel

15 Thrust Bearing Cap Ductile Iron

16 Cap Screws Carbon Steel, Plated

17 Thrust Brg. Stud Bronze

18 Thrust Plate Cast Iron

19 Thrust Plate Bolt Carbon Steel. Plated

20 Thrust Plate Gasket Non-Asbestos Fiber

21 Lock Cap Cast Iron

22 Lock Cap Bolts Carbon Steel, Plated

23 Lock Cap Gasket Non-Asbestos Fiber

24 Body O-Ring Buna-N

*Recommended Spare Part

TABLE 1. STANDARD VALVE PARTS LIST

2

INSTALLATION

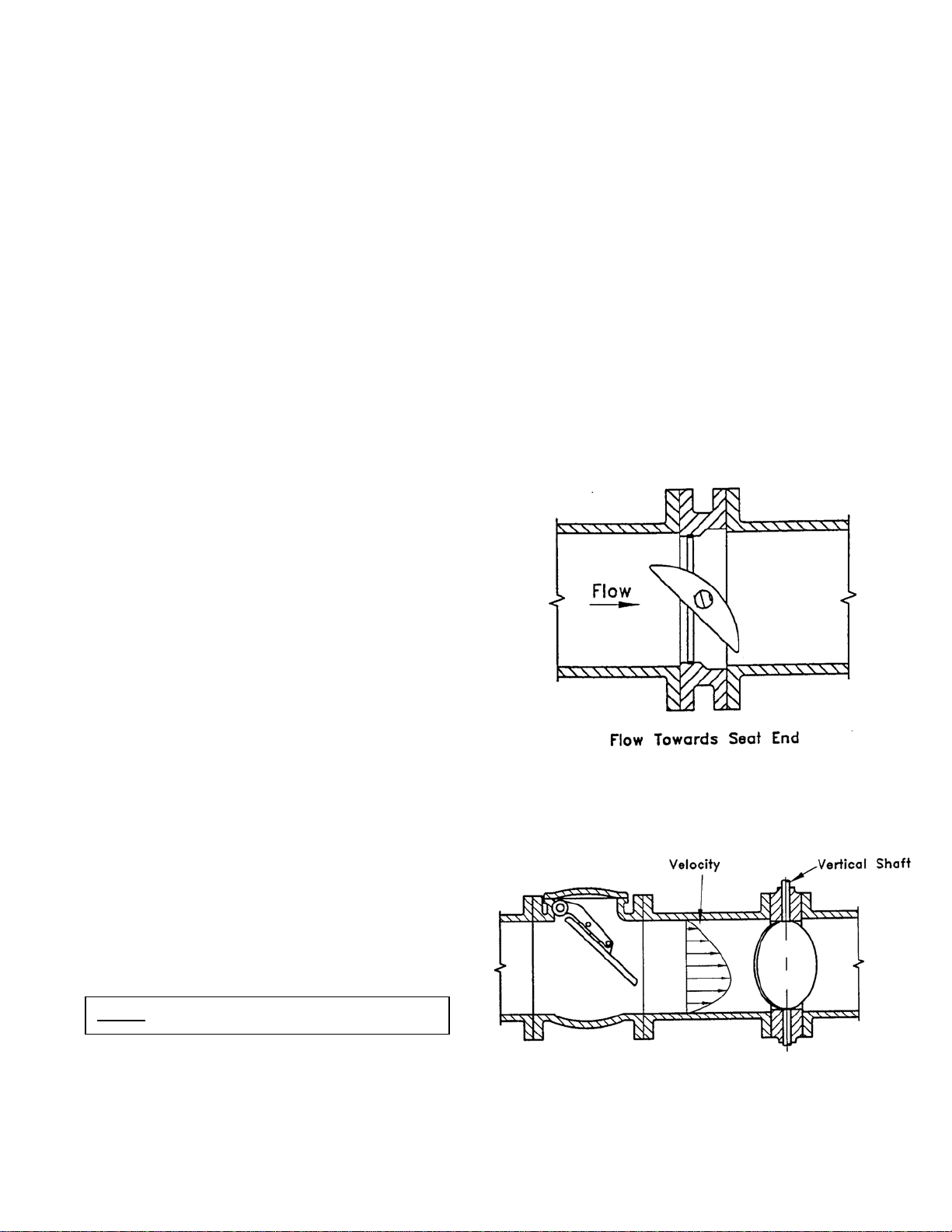

The Val-Matic butterfly Valve is Bi-Directional,

however, when deciding the valve’s installation

orientations, the engineer should consider the seat

position in regards to flow and access. The following

guidelines are intended to assist the engineer. The

“SEAT END” and “SUGGESTED FLOW” are marked

on the valve nameplate, which is mounted on the

flange O.D. The seat end identifies which end the seat

can be adjusted from when the valve is closed. The

flow direction may affect valve torque for large valves.

Some specific piping problems are also shown in the

figures to the right.

GENERAL PIPELINE APPLICATIONS: Orient the

“Seat End” towards the access point (i.e. manway,

pipe coupling, or spool).

WATER SERVICE: The normal flow direction is

towards the seat end of the valve. When the flow

stops, the return pressure will be held by the closed

disc and the seat bolts (8) can be adjusted to provide

tight shut off should the seat be worn or damaged.

The normal flow direction and the words "SEAT END"

are marked on the nameplate.

AIR AND GAS SERVICE: Install valve with pressure

toward the end opposite the “Seat End”. Lubricate

resilient seat with FDA approved silicone grease such

as Dow Corning #7 before installation. Gear actuators

are recommended for gas service applications.

PUMP DISCHARGE SERVICE: On all horizontal pump

discharge applications (Figure 3), the “Seat End”

should be towards the pump. The valve will seal tightly

against return flow allowing seat adjustment if

necessary. The valve shaft should be oriented parallel

to the plane of the pump discharge elbow (i.e. vertical

valve shaft on a vertical discharge elbow). If the

butterfly valve is downstream of a check valve, the

clearance between the two discs must be checked.

The butterfly valve shaft should be oriented as shown

in Figure 4.

BURIED SERVICE: The valve should be installed with

the shaft horizontal and the actuator nut directed

upwards (Figure 4). The valve box or extension pipe

should be installed so that the actuator nut and

extension stem turn freely.

NOTE: Adjust and test valve prior to backfill.

FLANGED ENDS: AWWA Class 150B flanged valves

should be mated to ANSI Class 125# or AWWA C207

flat-faced flanges equipped with resilient gaskets.

When ring gaskets are used, the bolt material shall be

ASTM A307 Grade B or SAE Grade 2 Carbon Steel.

Higher strength bolts may only be used with full-face

gaskets.

Some of the flange holes are tapped near the shaft

ends of the valve as shown on the Sales Drawing.

Special bolt lengths may be needed. An engagement

of at least one bolt diameter is typically used for the

flange bolts used in the tapped flange holes.

AWWA Class 250B flanged valves can be mated with

either ANSI Class 125#, ANSI Class 250# or AWWA

C207 flanges depending on the specified flange

drilling. Class 250B valves can be mated with flatfaced or raised-face flanges with full face or ring

gaskets and with no bolting restrictions.

FIGURE 3. PUMP DISCHARGE

FIGURE 4. UPSTREAM CHECK VALVE

3

Loading...

Loading...