Val-Matic 2-42 Flanged Vacuum Breaker User Manual

2”- 42” Flanged Vacuum Breaker

Operation, Maintenance and

Installation Manual

INTRODUCTION.................................... 1

RECEIVING AND STORAGE................. 1

DESCRIPTION OF OPERATION...........1

INSTALLATION......................................2

DRAWING SS-1381............................... 3

VALVE CONSTRUCTION...................... 5

MAINTENANCE ..................................... 5

TROUBLESHOOTING ........................... 6

DISASSEMBLY...................................... 6

REASSEMBLY....................................... 6

PARTS AND SERVICE.......................... 6

WARRANTY...........................................7

®

Manual No.

VB-OM1-1

VAL-MATIC® VALVE AND MANUFACTURING CORP.

905 RIVERSIDE DR. ELMHURST, IL. 60126

TEL. 630 / 941-7600 FAX. 630 / 941-8042

2 to 42 in. FLANGED VACUUM BREAKER

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install and maintain the vacuum breaker to

ensure a long service life. The vacuum breaker is

ruggedly constructed with bronze or stainless steel

trim to give years of trouble free operation. The

valve should be installed at high points along

horizontal pipelines or over tanks.

The Vacuum Breaker is designed to open fully and

allow air to re-enter the pipeline or system during

critical vacuum conditions in the pipe or tank caused

by power failure or rapid draining of the piping

system. The vacuum breaker will not allow air to

escape from the pipeline. An optional air release

valve can be piped to the side of the valve to release

trapped air during pipeline operation.

The size, cold working pressure, and model number

are stamped on the nameplate for reference. This

valve is not intended for fluids containing suspended

solids such as wastewater. For wastewater and

other high turbidity applications, use Val-Matic

Series 1800VBS Vacuum Breakers for Wastewater

Service.

CAUTION: This valve is not intended for

fluids containing suspended

solids or hazardous fluids.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. When lifting, the valve should be secured

by the body and never lifted by the bronze or

stainless steel trim.

The valves should remain crated, clean and dry until

installed to prevent weather related damage. For

long-term storage greater than six months, the

rubber surfaces of the seat should not be exposed to

sunlight or ozone for any extended period.

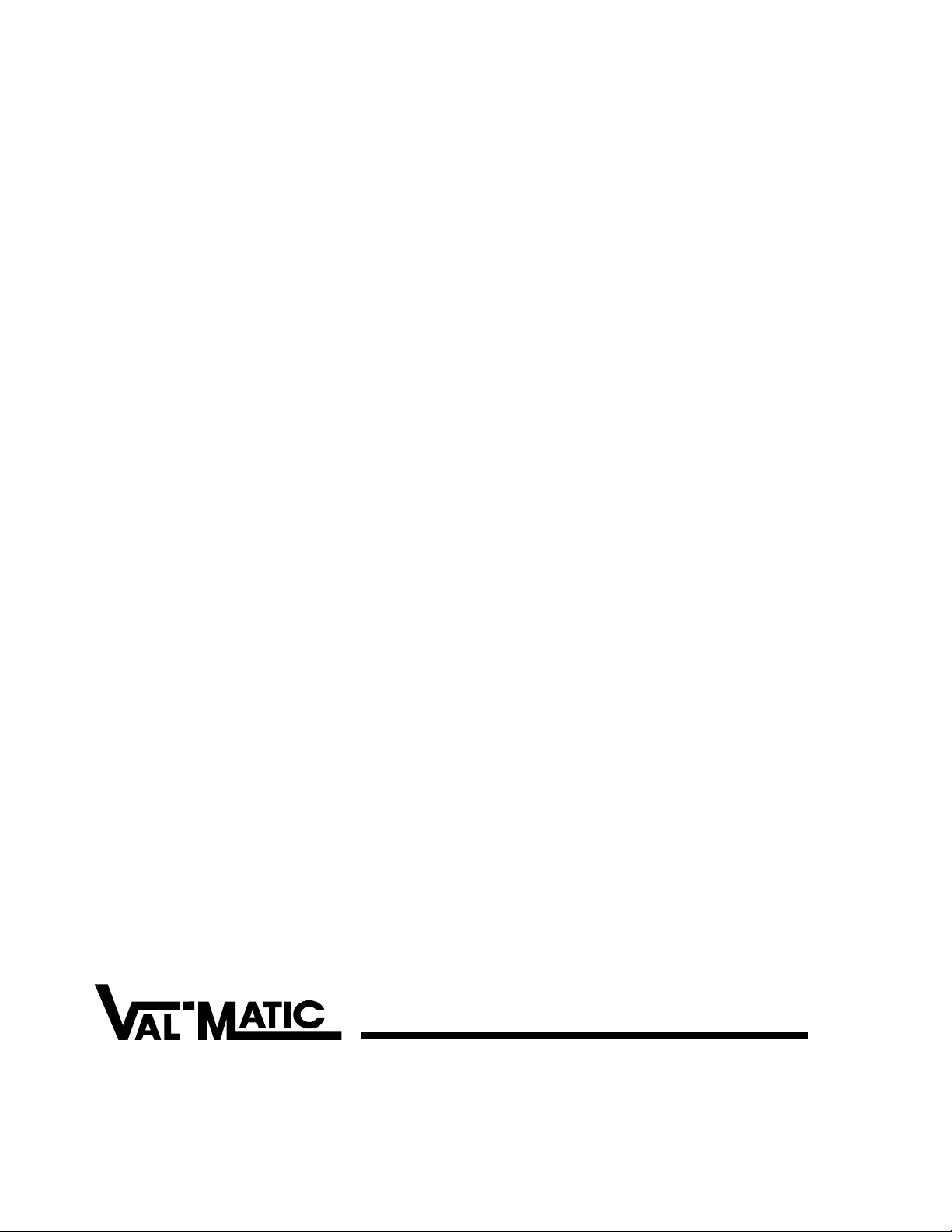

FIGURE 1. VACUUM BREAKER

DESCRIPTION OF OPERATION

The vacuum breaker is designed to prevent vacuum

conditions from occurring in pipes or tanks. After a

power failure or rapid draining of the system, a

vacuum condition often occurs in a pipe or tank.

The pressure difference between the inside vacuum

and outside air will cause a downward force on the

disc. At vacuum pressures greater than -0.25 psig,

the disc will compress the spring and move

downward allowing free flow of outside air into the

pipe or tank to eliminate the vacuum. When positive

pressure is restored in the pipe or tank, the valve will

automatically close and seal tightly. Optional valves

can be piped to the vacuum breaker to vent trapped

air in the pipeline if needed.

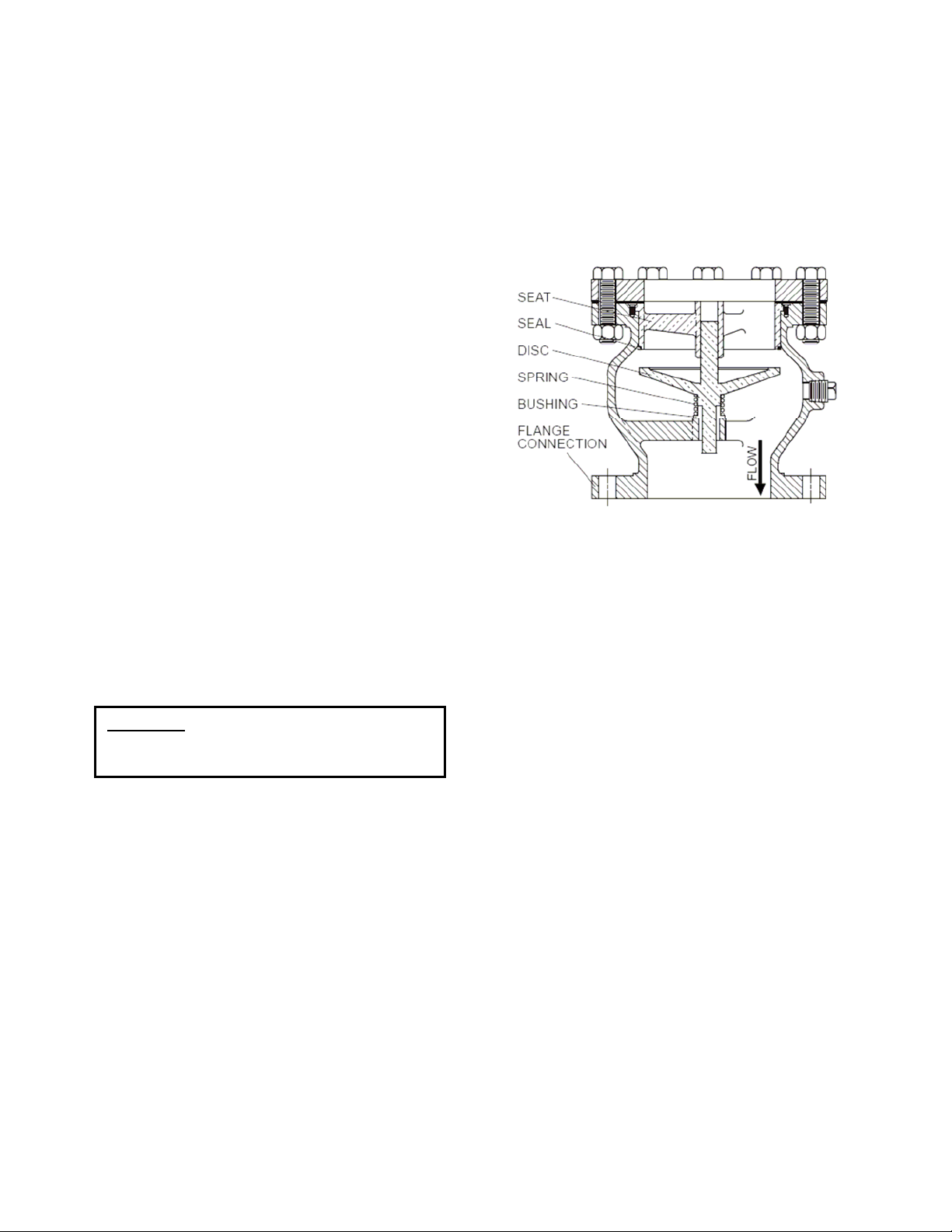

The valve may be supplied with either an optional

hooded outlet (not shown) or a flange for connection

to external piping or vent piping as shown in Figure

2. A flanged outlet is used when the valve vault is

subject to flooding or the vault cannot supply

sufficient air to the pipeline.

The only moving parts in the valve are the disc and

spring. The body bushing controls the movement of

the plug and assures that the plug contacts the seat

evenly. The valve has a resilient seal for drop tight

service.

1

FIGURE 2. VACUUM BREAKER WITH

OPTIONAL FLANGE

INSTALLATION

The installation of the valve is important for its

proper operation. The seat end must be oriented

upward. The valve should be installed on top of

horizontal lines or tanks and equipped with an

isolation valve. If installed in a vault, adequate

ventilation is needed to supply air to the vacuum

breaker.

The valve should be installed to a standard flat-face

flange per ANSI B16.5 or AWWA C207.

When used with an outlet flange, special flange

requirements are given in Drawing SS-1381 on page

3. The mating flange inside diameter must overlap

the valve seat to provide proper seat retention.

Outlet piping and companion flange are required to

retain the seat and disc. Remove the ring flange

and 2 bolts supplied with the vacuum breaker, and

replace with external, full-size flanged piping.

WARNING: Vacuum Breakers with Flanged

When mating the check valve with butterfly isolation

valves, the clearance between the butterfly disc and

the fully open check valve stem must be checked.

Outlets must have outlet piping

installed or damage may occur.

The location of the stem is also shown on the

vacuum breaker submittal drawings. 10 inch and

smaller vacuum breakers have sufficient clearance

for most butterfly valves. However, on 12 inch and

larger valves, the shaft extends beyond the flange

face and may interfere with the operation of adjacent

valves. A short run of pipe or spacer may be

needed between the vacuum breaker and the

isolation valve.

FLANGED ENDS: The flange should be mated with

flat-faced pipe flanges equipped with resilient

gaskets. When ring gaskets are used, the bolt

material shall be ASTM A307 Grade B or SAE

Grade 2 Carbon Steel. Higher strength bolts should

only be used with full-face gaskets.

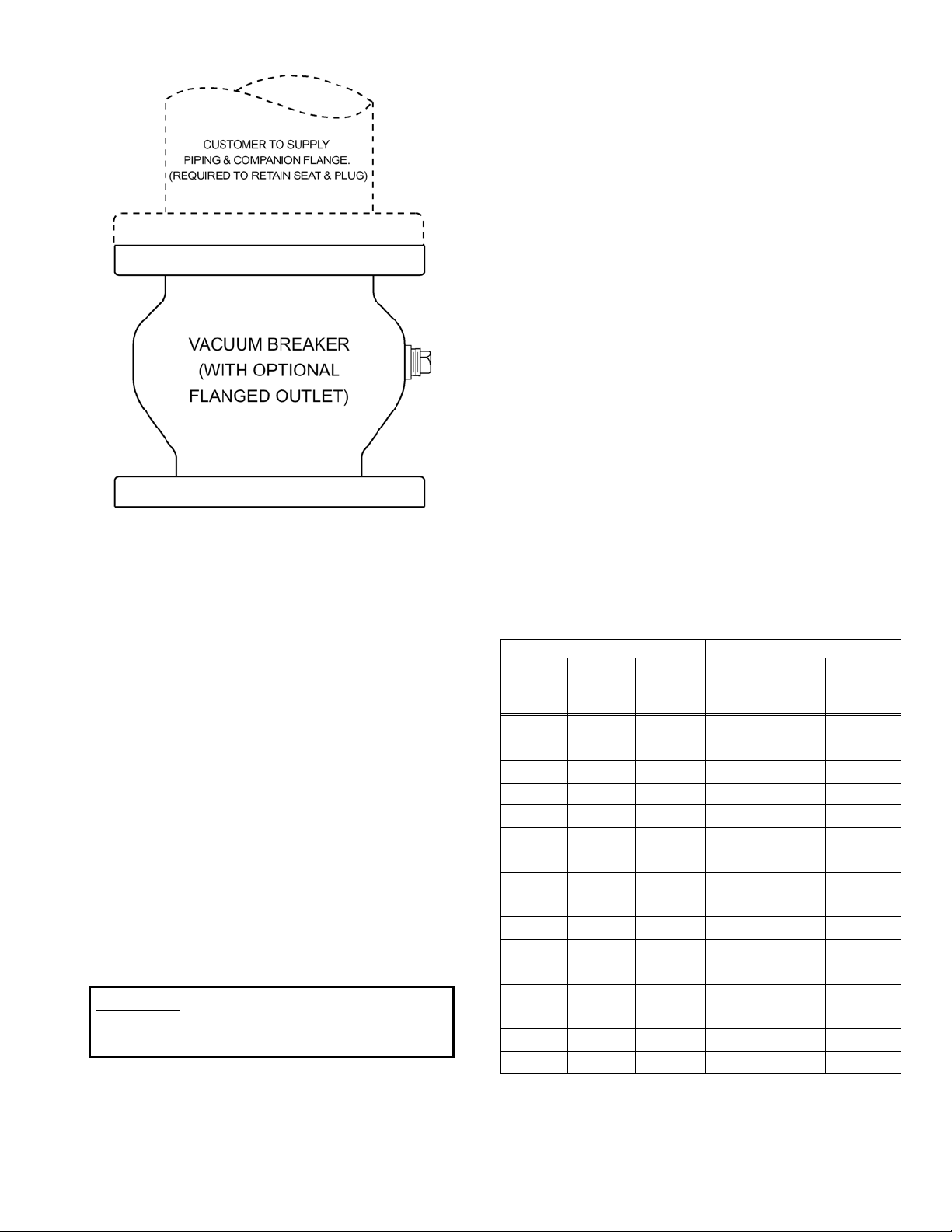

INSTALLATION: Lower valve over mating flange

using slings or chains around the valve body.

Lubricate the flange bolts and insert them around

the flange. Lightly turn bolts until gaps are

eliminated. The tightening of the bolts should then

be done in graduated steps using the cross-over

tightening method. Recommended lubricated

torques for use with resilient gaskets (75 durometer)

are given in Table 1.

If leakage occurs, allow gaskets to absorb fluid and

check torque and leakage after 24 hours. Do not

exceed bolt rating or crush gasket more than 50 per

cent of its thickness.

125# FLANGE DATA 250# FLANGE DATA

Valve

Size

(in)

2.5 5/8

3 5/8

4 5/8

5 3/4

6 3/4

8 3/4

10 7/8

12 7/8

14 1

16 1

18 1 1/8

20 1 1/8

24 1 1/4

30 1 1/4

36 1 1/2

42 1 1/2

Bolt

Dia.

(in)

Bolt

Torque

(ft-lbs)

25-75

25-75

30-90

30-90

30-90

40-120

45-150

65-200

80-250

90-300

100-350

120-450

150-500

180-600

250-750

300-900

Valve

Size

(in)

Bolt

Dia.

(in)

2.5 3/4

3 3/4

4 3/4

5 3/4

6 3/4

8 7/8

10 1

12 1 1/8

14 1 1/8

16 1 1/4

18 1 1/4

20 1 1/4

24 1 1/2

30 1 3/4

36 2

42 2

Bolt

Torque

(ft-lbs)

25-75

35-75

50-150

70-150

70-150

90-200

110-300

160-450

140-450

180-600

190-600

220-600

350-900

500-1500

700-2000

800-2500

TABLE 1. FLANGE BOLT TORQUES

2

Loading...

Loading...