Val-Matic 2-12 in.Wafer Style Dual Disc Check Valve User Manual

Manual No.

DDCV-OM3-0

2-12 in. (DN 50-300 mm) Wafer Style

â

Dual Disc

Check Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION.................................... 1

RECEIVING AND STORAGE ................ 1

DESCRIPTION OF OPERATION........... 1

INSTALLATION ..................................... 2

VALVE CONSTRUCTION...................... 3

MAINTENANCE..................................... 4

TROUBLESHOOTING...........................4

DISASSEMBLY...................................... 4

REASSEMBLY....................................... 4

PARTS AND SERVICE.......................... 5

WARRANTY .......................................... 5

®

VAL-MATIC® VALVE AND MANUFACTURING CORP.

905 RIVERSIDE DR. ELMHURST, IL. 60126

TEL. 630 / 941-7600 FAX. 630 / 941-8042

2-12 in. (DN 50-300 mm) WAFER STYLE DUAL DISCâ CHECK

VALVE OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

This manual will provide you with the information to

properly install and maintain the valve to ensure a

long service life. The Series 8800W Dual Disc

Check Valve is ruggedly constructed with bronze

discs and stainless steel trim to give years of trouble

free operation. The valve should be installed in

horizontal or vertical flow up pipes carrying clean

water. The valves can be equipped with special

springs for operation in blower air service (Series

8900W).

The Dual Disc

fully to provide flow in the forward direction and

close rapidly upon flow reversal. The valves are

used to prevent reverse flow through pumps or

piping systems. The size, cold working pressure,

model number, and year of manufacture are

stamped on the nameplate for reference.

This valve is not intended for fluids containing

suspended solids such as wastewater. For

wastewater and other high turbidity applications, use

Val-Matic Series 500 Swing-Flex

The valve is also not intended for hazardous fluids.

CAUTION: This valve is not intended for

â

Check Valve is designed to open

®

Check Valves.

fluids containing suspended

solids or hazardous fluids.

RECEIVING AND STORAGE

Inspect valves upon receipt for damage in shipment.

Unload all valves carefully to the ground without

dropping. When lifting, the valve should be secured

by the body and never lifted by the bronze or

stainless steel trim. Lifting eyebolts are provided on

NPS 10-12 (DN 250-300) valves.

The valves should remain boxed, clean and dry until

installed to prevent weather related damage. For

long term storage greater than six months, the

rubber surfaces of the seat (when provided) should

be coated with a thin film of FDA approved grease

such as Lubriko #CW-606. Do not expose rubber

seat to sunlight or ozone for any extended period.

â

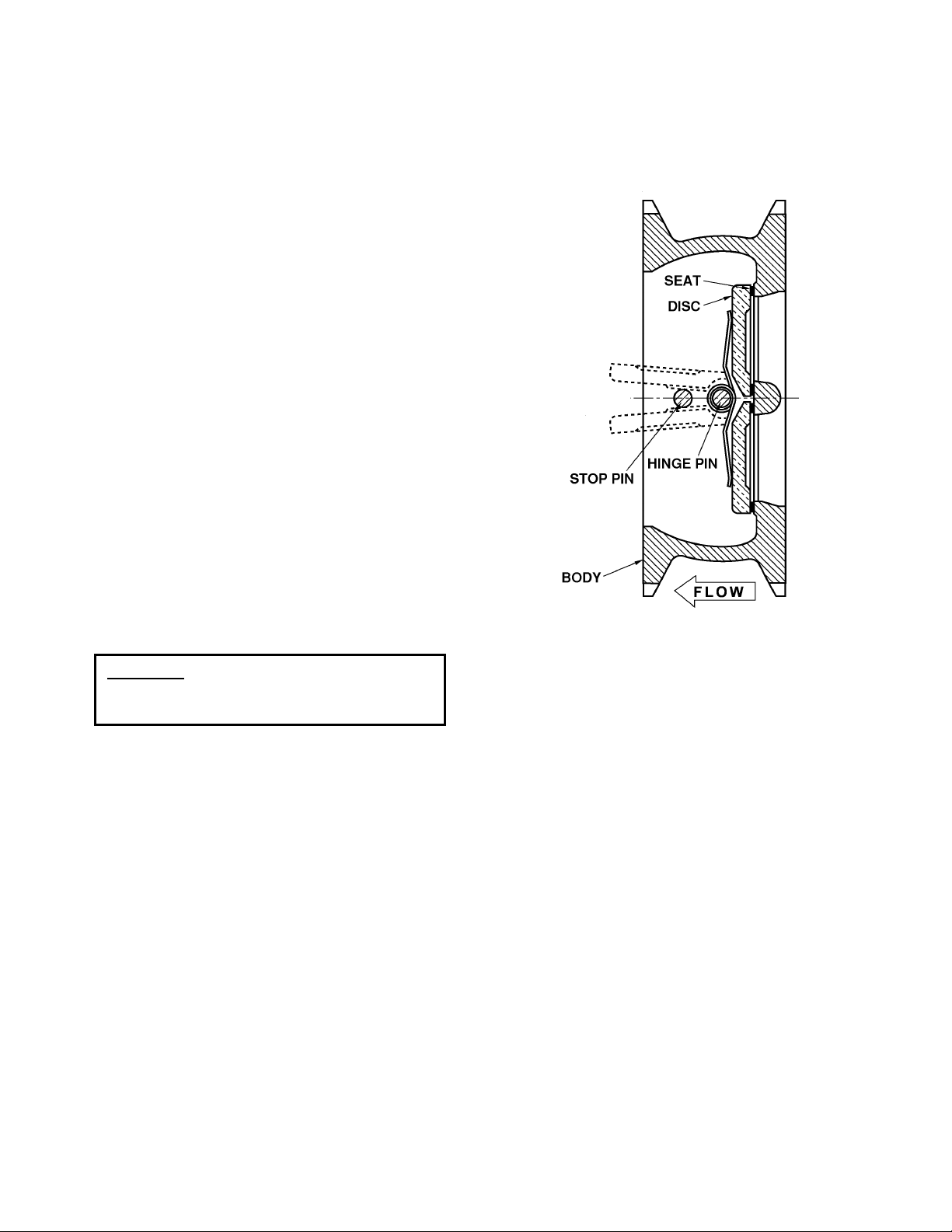

FIGURE 1. DUAL DISC

â

CHECK VALVE

DESCRIPTION OF OPERATION

â

The Dual Disc

reverse flow automatically. On pump start-up, the

flow of water enters the valve from the seat end

(right side in Figure 1) and forces the two discs open

until they strike the disc stop pin. On pump shutdown, the torsion spring closes the disc before a

flow reversal takes place.

The valve body is supplied with compact wafer ends

as shown in Figure 1 for installation between mating

flanges.

The only moving parts in the valve are the discs and

spring. The discs and spring are guided in the body

with a hinge pin and a full open disc stop pin. The

pins are restrained in the body by stabilization

spheres to prevent vibration. The valve also has a

resilient seat for drop tight shut off.

Check Valve is designed to prevent

1

Loading...

Loading...