1-16 in. FloodSafe® Inflow Preventer

Operation, Maintenance and

Installation Manual

INTRODUCTION .................................... 1

RECEIVING AND STORAGE ................ 1

DESCRIPTION OF OPERATION ........... 1

INSTALLATION ...................................... 2

CONSTRUCTION .................................. 2

MAINTENANCE ..................................... 3

TROUBLESHOOTING ........................... 3

DISASSEMBLY ...................................... 3

REASSEMBLY ....................................... 3

FIELD TESTING ..................................... 4

TEST REPORT ...................................... 5

PARTS AND SERVICE .......................... 6

WARRANTY ........................................... 6

Manual No.

FS-OM1-3

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

®

VALVE AND MANUFACTURING CORP.

1-16 in. FloodSafe® Inflow Preventer

OPERATION, MAINTENANCE AND INSTALLATION

INTRODUCTION

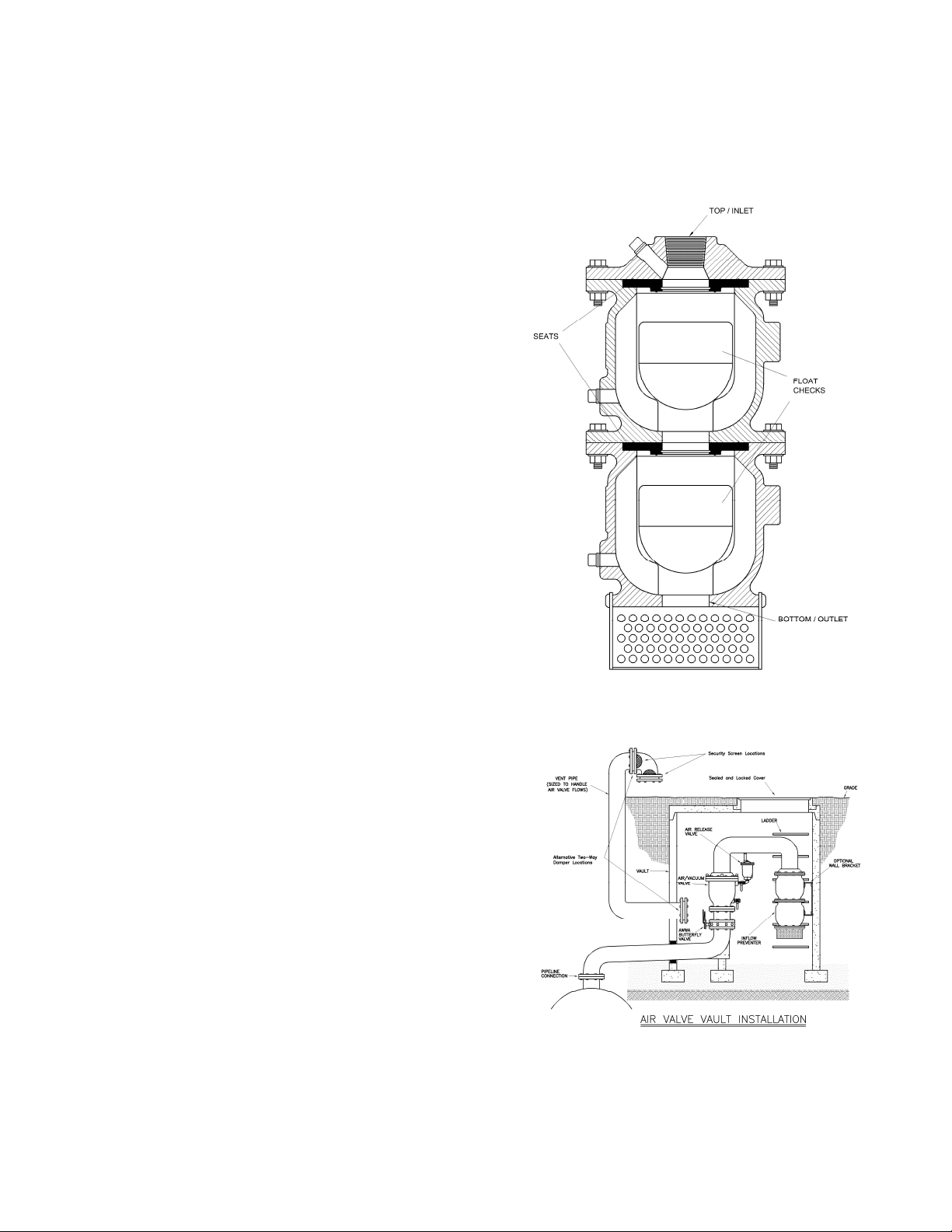

This manual will provide you with the information to

properly install, maintain and ensure a long service

life for the FloodSafe

FloodSafe

release or air/vacuum valve to prevent cross

contamination of the potable water system due to

flooding and malicious tampering as described in

ASSE Standard 1063. The FloodSafe

with two float checks that are open during normal

pipeline operation to allow full airflow in both

directions. The float check(s) will rise and seal when

the surrounding atmosphere is filled with water.

®

is to be installed on the outlet of an air

RECEIVING AND STORAGE

Inspect the FloodSafe

shipment. Unload all devices carefully to the ground

without dropping. Remove all blocking material

inside of the metal basket.

The devices should remain boxed, clean and dry

until installed to prevent weather related damage.

For long term storage greater than six months, the

rubber seat should be coated with a thin film of FDA

approved grease such as Lubriko #CW-606. Do not

expose rubber seat to sunlight or ozone for any

extended period.

DESCRIPTION OF OPERATION

The FloodSafe

lower chamber and upper, redundant chamber. Both

chambers contain identical float checks that are

open during normal pipeline operation and allow full

airflow in both directions. If flooding occurs the

lower float check will rise, preventing floodwater from

reaching the outlet of the air valve and subsequently

the pipeline. If the lower float check fails the upper,

redundant float check will close preventing

floodwater from reaching the air valve. The basket

screen prevents debris from interfering with the

operation of the FloodSafe

®

inflow preventer is designed with a

®

inflow preventer. The

®

is designed

®

upon receipt for damage in

®

.

Figure 1. FloodSafe

Figure 2. Typical Installation

®

Inflow Preventer

1

INSTALLATION

Remove the packing from the top and bottom of

the FloodSafe

during shipping. Install the basket per step 6 in

the REASSEMBLY section on page 3. The

installation of the FloodSafe

proper operation. The FloodSafe

installed plumb in the vertical position with the

basket facing downward. Thread or bolt the

FloodSafe

standard connection practices. The bolting for 6"

and larger devices conforms to ANSI B16.1 for class

125# flanges. An optional mounting bracket (80)

may be used to mount the device to wall supports.

Flanged connections should only be mated with flatfaced pipe flanges equipped with full-face or ring

type resilient gaskets. The bolts should be tightened

in gradual steps using the crossover method.

Recommended torque values are given in Table 1.

The use of excessive bolt torque may damage

the device.

®

that is used to protect the floats

®

is important for its

®

to the outlet of an air valve using

CAUTION:

®

should be

Table 1. Flange Bolt Torques

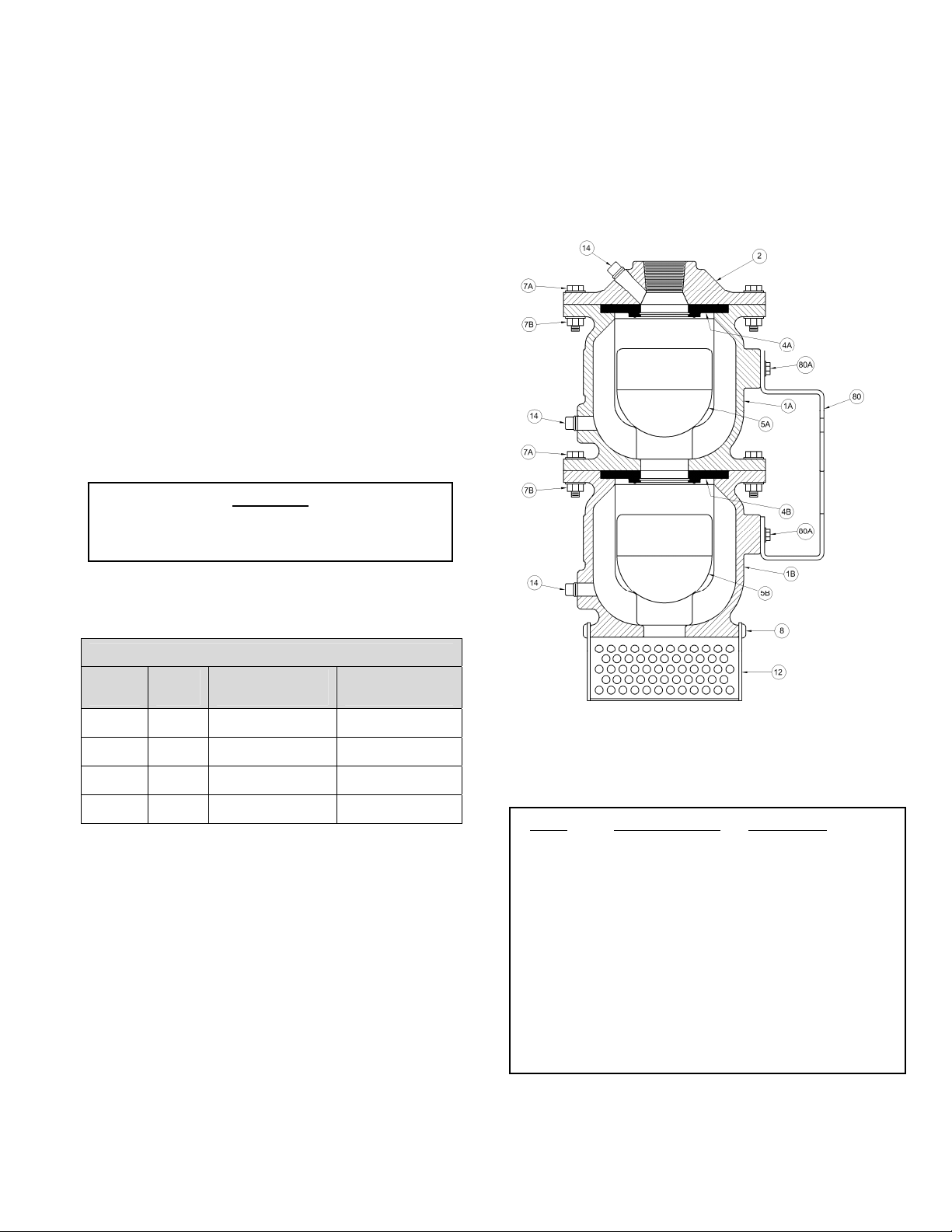

FLOODSAFE® CONSTRUCTION

The standard FloodSafe

®

is constructed of ductile

iron. Stainless steel type 316 float checks are the

only moving elements and seal against a low

hardness resilient seat. The general details of

construction are illustrated in Figure 3 and identified

in Table 2.

Mounting Flange Bolts (ANSI B16.1 Class 125)

Device

Size

Bolt

Size

Recommended

Torque (ft-lbs)

Maximum

Torque (ft-lbs)

6 3/4" 30 150

8 3/4" 40 150

12 7/8” 45 200

16 1” 90 300

Figure 3. FloodSafe

®

Components

ITEM DESCRIPTION MATERIAL

1A, 1B Chamber Ductile Iron

2 Cover Ductile Iron

4A, 4B Seat Resilient

5A, 5B Float Check T316 Stainless Steel

7A, 7B Bolts, Nuts T316 Stainless Steel

8 Basket Retainer T316 Stainless Steel

12 Basket T304 Stainless Steel

14 Pipe Plug Carbon Steel

80* Mounting Bracket Carbon Steel

80A* Mounting Bolt T316 Stainless Steel

* Optional

Table 2. FloodSafe Parts List

2

MAINTENANCE

The FloodSafe

maintenance.

INSPECTION: The FloodSafe

debris by following the disassembly and reassembly

instructions. The seat may be checked for cracks or

tears. The float check may be inspected for

indentations or deep scratches on the top sealing

portion.

®

requires no scheduled lubrication or

®

may be checked for

TROUBLESHOOTING

Several problems and solutions are presented below

to assist you in troubleshooting the FloodSafe

efficient manner.

Air valve water discharge: It is normal for air

valves to discharge some water before closing.

Continuous leakage requires maintenance of

the adjacent air valve.

Leaks during field test: Clean and inspect the

resilient seats and the float checks.

®

in an

DISASSEMBLY

WARNING:

Close the isolation valve underneath the

adjacent air valve. Failure to close the isolation

valve may allow discharge of air into the

FloodSafe

Note: If the FloodSafe is connected to the optional

mounting bracket (80), the FloodSafe™ will need to

be removed from the bracket.

1. Remove the basket (12).

a) On sizes with side taps, use an allen wrench

b) On sizes without the side taps, use an open-

2. Remove the lower chamber (1B) by removing

the bolts (7A) and nuts (7B) joining the two

chamber halves.

The FloodSafe® chambers may be heavy.

Support the chambers when removing the

bolts in order to prevent bodily injury.

®

and cause bodily injury.

to loosen the screws holding the basket to

the lower chamber (1B). Rotate the basket

counterclockwise and pull the basket down

and away from the chamber.

end wrench to remove the bolts holding the

basket to the lower chamber flange.

CAUTION:

3. Remove the seat (4) by pulling it upward and out

of the chamber. Tilt the chamber to remove the

float check (5).

4. The upper chamber is removed in the same

manner as the lower chamber. Remove the

bolts joining the chamber and cover using care

to support the chamber. The seat and float

check can be removed in the same manner as

before.

REASSEMBLY

All parts must be clean. Worn or damaged parts

should be replaced during reassembly.

1. Install the float check (5A) into the chamber

(1A).

2. Insert the seat (4A) with the raised circular

surface facing down into the chamber (1A).

3. Connect the upper chamber (1A) to the cover (2)

with the bolts (7A) and nuts (7B) using the cross

over method. One washer is installed under the

head of the bolt and one underneath the nut.

4. Install the float check and seat into the lower

chamber per steps 1 and 2.

5. Connect the lower chamber (1B) to the upper

chamber (1A) by using the bolts (7A) and (7B).

One washer is installed under the head of the

bolt and one underneath the nut.

6. Install the basket (12) to the lower chamber (1B).

a) On sizes with the side taps, start the socket

head cap screws into the lower chamber

flange. Install the basket by pushing upward

and turning clockwise. Tighten the socket

head cap screws to secure the basket.

b) On sizes without the side bolts, install the

bolts through the bottom flange and into the

tapped holes on the basket screen. One

washer is used underneath the head of the

bolt.

3

FIELD TESTING THE FLOODSAFE

The FloodSafe® inflow preventer should be tested

after installation, and periodically thereafter as

recommended by the local authority having

jurisdiction, but at least annually.

For field testing, a testing kit available from the

manufacturer is required consisting of test cocks and

a test pipe that can be used for multiple installations.

ISOLATE DEVICE

1. Close the isolation valve under the adjacent air

valve with which the FloodSafe

2. Remove the three pipe plugs on the side of the

FloodSafe

with the test kit.

3. Remove the basket screen by loosening the

screws and twisting the screen. Clean the

basket if needed.

4. Block the bottom port with the expandable plug

provided in the kit. Open the three test cocks A,

B, and C.

®

and install the test cocks provided

Figure 4: Field Test Piping

®

is connected.

TEST LOWER CHAMBER

5. Connect the test pipe to test cock A in the lower

chamber as shown in Figure 4. A quickdisconnect coupling is provided to facilitate the

assembly.

6. Fill the clear test pipe and lower chamber with

clean water by pouring water into the test pipe

and maintain the water level above the

“Minimum Test Level” for 5 minutes while

observing test cock B for leakage. The water

level in the tube may drop due to leakage in the

fittings, bottom plug, or as air escapes between

the float and the seat (acceptable). The device

shall be rejected and repaired if water is

observed from test cock B during the 5 minute

test period.

TEST UPPER CHAMBER

7. Close test cock A. Move the test pipe up to the

upper chamber test cock B. A quick-disconnect

fitting under the clear pipe will aid in its removal.

8. Fill the clear test pipe and upper chamber with

clean water by pouring water into the test tube

and maintain the water level above the

“Minimum Test Level” for 5 minutes while

observing test cock C for leakage. The device

shall be rejected and repaired if water is

observed from test cock C during the 5 minute

test period.

9. If one of the initial tests fail and repairs are

made, a “Final Test” shall be conducted and

recorded. Repairs typically consist of removing

the chamber bolts and cleaning the float and

cleaning or replacing the rubber seat.

RETURN TO SERVICE

10. When the tests are complete, open test cock A

and drain the water and remove the test piping

and bottom plug. The test cocks may be left in

the device, but all three must to be closed.

11. Re-assemble the basket screen to the lower

chamber. Tighten the screen bolts.

12. IMPORTANT: Open the isolation valve underneath

the air valve that was closed in step 1.

4

FloodSafe® Inflow Preventer

TEST AND MAINTENANCE REPORT

OWNER: _________________________________________________________________________________

ADDRESS: ________________________________________________________________________________

LOCATION OF ASSEMBLY: __________________________________________________________________

MANUFACTURER: _________________________ MODEL NO: ____________________________________

YEAR OF MANUFACTURE: _______________________ SIZE: ____________________________________

PROCEDURE: See “FIELD TESTING THE FLOODSAFE” in the Instruction Manual.

1. Isolation Valve

Under Air Valve

□ leaked or

□ closed off tight

Record any maintenance

performed:

Inflow Preventer Basket

□ removed and cleaned

Bottom Plug

□ installed

NOTE: All repairs and final tests should be completed within five (5) working days.

COMMENTS: _______________________________________________________________________________

___________________________________________________________________________________________

I hereby certify that this data is accurate and reflects the proper maintenance of the assembly.

TESTER: _____________________________ CERT No. __________________ DATE: __________________

TIME: ___________________

THIS ASSEMBLY: □ Passed □ Failed

2. Inflow Preventer Test

Lower Chamber

□ test cocks OK or

□ test cocks replaced

□ open test cocks

□ Connect test pipe assembly

to test cock A.

□ Fill lower chamber and test

pipe with clean water.

Initial

Tests:

Repairs:

Final

Tests

(when

needed):

IMPORTANT:

□ Maintain water level above

“Minimum Test Level”

□ Observe test cock B for

leakage for 5 minutes.

Any sign of leakage from test

cock is cause for rejection.

□ Pass □ Fail

Record maintenance

performed:

If initial test failed, repeat 5

minute test. Any sign of

leakage from test cock B is

cause for rejection.

□ Pass □ Fail

□ After testing, reopen the isolation valve under the air valve.

3. Inflow Preventer Test

Upper Chamber

□ test cock OK or

□ test cock replaced

□ Connect test pipe assembly

to test cock B.

□ Fill upper chamber and test

pipe with clean water.

□ Maintain water level above

“Minimum Test Level”

□ Observe test cock C for

leakage for 5 minutes.

Any sign of leakage from test

cock is cause for rejection.

□ Pass □ Fail

Record maintenance

performed:

If initial test failed, repeat 5

minute test. Any sign of

leakage from test cock C is

cause for rejection.

□ Pass □ Fail

5

PARTS AND SERVICE

Parts and service are available from your local

representative or the factory. Make note of the

Valve Size and Model Number located on the valve

nameplate and contact:

Val-Matic Valve and Manufacturing Corp.

905 Riverside Drive

Elmhurst, IL 60126

Phone: (630) 941-7600

Fax: (630) 941-8042

www.valmatic.com

A sales representative will quote prices for parts or

arrange for service as needed.

LIMITED WARRANTY

All products are warranted to be free of defects in material and workmanship for a period of one year from the date

of shipment, subject to the limitations below.

If the purchaser believes a product is defective, the purchaser shall: (a) Notify the manufacturer, state the alleged

defect and request permission to return the product; (b) if permission is given, return the product with

transportation prepaid. If the product is accepted for return and found to be defective, the manufacturer will, at his

discretion, either repair or replace the product, f.o.b. factory, within 60 days of receipt, or refund the purchase

price. Other than to repair, replace or refund as described above, purchaser agrees that manufacturer shall not be

liable for any loss, costs, expenses or damages of any kind arising out of the product, its use, installation or

replacement, labeling, instructions, information or technical data of any kind, description of product use, sample or

model, warnings or lack of any of the foregoing. NO OTHER WARRANTIES, WRITTEN OR ORAL, EXPRESS

OR IMPLIED, INCLUDING THE WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND

MERCHANTABILITY, ARE MADE OR AUTHORIZED. NO AFFIRMATION OF FACT, PROMISE, DESCRIPTION

OF PRODUCT OF USE OR SAMPLE OR MODEL SHALL CREATE ANY WARRANTY FROM MANUFACTURER,

UNLESS SIGNED BY THE PRESIDENT OF THE MANUFACTURER. These products are not manufactured, sold

or intended for personal, family or household purposes.

®

VAL-MATIC

905 Riverside Dr. ● Elmhurst, IL 60126

Phone (630) 941-7600 ● Fax (630) 941-8042

www.valmatic.com

6

VALVE AND MANUFACTURING CORP.

Loading...

Loading...