Valmar MULTY P TTi Series, MULTY P 7 TTi, MULTY P 7 TTi+dual, MULTY P 12 TTi Handling, Operating And Maintenance Manual

VALMAR

HANDLING, OPERATING AND

MAINTENANCE GUIDE OF THE APPLIANCES

FOR THE PRODUCTION OF ICE CREAM

Model MULTY P TTi

Ver_MU_TT_001

2

Italian Gelato Concepts Pty Limited

PO Box 2134 Toowong Qld 4066

ABN 48 603 731 424

www.italiangelato.com.au

info@italiangelato.com.au

Mob: +61 (0) 411 089 142

3

TABLE OF CONTENTS

1 INSTRUCTIONS ON HOW TO USE THE GUIDE ...................................... 7

1.1

2 GENERAL FEATURES AND SPECIFICATIONS ....................................... 8

2.1

2.2

2.3

3 TRANSPORTATION AND PLACING OF THE APPLIANCE ................... 12

3.1

3.2

3.3

3.4

4 REQUIREMENTS AND CONDITIONS FOR NORMAL OPERATION OF

THE APPLIANCE ............................................................................................ 14

4.1

4.2

4.3

5 CONNECTING THE APPLIANCE ............................................................ 16

5.1

5.2

5.3

6 OPERATING THE APPLIANCE ............................................................... 18

7 CONTROL BOARD .................................................................................. 19

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

8 PROGRAMS ............................................................................................. 73

9 MENU PROGRAMS.................................................................................. 74

9.1

9.2

10 CHANGING PARAMETERS OF MACHINE ............................................. 87

10.1

10.2

11 PROTECTION OF THE USER AND OF THE MACHINE ......................... 99

11.1

11.2

11.3

11.4

12 USE OF THE APPLIANCE ..................................................................... 100

12.1

12.2

12.3

12.4

12.5

SYMBOLS USED IN THE GUIDE ........................................................ 7

GENERAL FEATURES ........................................................................ 8

IDENTIFICATION OF THE APPLIANCE ........................................... 10

TECHNICAL SPECIFICATIONS ........................................................ 11

INSTRUCTIONS FOR PREVENTING INJURIES .............................. 12

UNLOADING THE APPLIANCE FROM THE LORRY........................ 12

UNPACKING OF THE APPLIANCE ................................................... 13

PLACING THE APPLIANCE ON THE GROUND ............................... 13

ENVIRONMENTAL CONDITIONS ..................................................... 14

WATER SUPPLY REQUIREMENTS ................................................. 14

ELECTRICITY SUPPLY REQUIREMENTS ....................................... 15

INSTRUCTIONS FOR PREVENTION OF INJURIES ........................ 16

CONNECTING THE APPLIANCE TO THE WATER SUPPLY ........... 16

CONNECTING THE APPLIANCE TO THE POWER SUPPLY .......... 17

TOUCH SCREEN (dual inactive home screen) ................................. 19

PUSH-BUTTON PANEL (TREATING – HEATING) ........................... 49

PUSH-BUTTON PANEL (PRODUCTION – COOLING) ..................... 53

FIRST USING OF THE MACHINE ..................................................... 61

LANGUAGE SELECTION .................................................................. 62

DATA DOWNLOAD ........................................................................... 63

UPDATE OF NEW PROGRAM OR NEW DATABASE ...................... 71

WEAR OF THE SCRAPERS ............................................................. 72

MENU PROGRAMS of the HEATING PART ..................................... 74

MENU PROGRAMS of the COOLING PART ..................................... 80

CHANGING PARAMETERS (cooking part) ....................................... 87

CHANGING PARAMETERS (cooling part) ........................................ 93

PROTECTION OF THE USER........................................................... 99

ELECTRICAL OVERLOAD PROTECTION ........................................ 99

THERMIC SAFETY DEVICES ........................................................... 99

PROTECTION OF THE COOLING SYSTEM .................................... 99

INSTRUCTIONS FOR THE PREVENTION OF INJURIES .............. 100

BASIC RULES FOR OPERATING THE APPLIANCE...................... 101

COVER OF THE KETTLE ................................................................ 102

OUTLET VALVE .............................................................................. 102

PROCESSING CYLINDER DOOR .................................................. 103

4

12.6

OUTLET HOLE COVER .................................................................. 103

12.7

TO-DO LIST BEFORE OPERATING THE APPLIANCE .................. 104

13 CLEANING OF THE APPLIANCE .......................................................... 105

13.1

INSTRUCTIONS FOR THE PREVENTION OF INJURIES .............. 105

13.2

CLEANING THE SURFACES OF THE APPLIANCE ....................... 106

13.3

USING THE WATER PIPE FOR CLEANING ................................... 106

13.4

CLEANING OF PARTS THAT COME IN CONTACT WITH THE ICE

CREAM 107

13.5

13.6

DISINFECTION OF THE KETTLE ................................................... 130

DISINFECTION OF THE ICE CREAM PRODUCTION CYLINDER . 131

14 MAINTENANCE OF THE APPLIANCE .................................................. 131

14.1

INSTRUCTIONS FOR PREVENTION OF INJURIES ...................... 131

14.2

PROBLEMS, ERRORS AND TROUBLESHOOTING ...................... 132

14.3

REGULAR MAINTENANCE INSPECTION PLAN............................ 133

14.4

TEST RUN ....................................................................................... 133

14.5

CHECKING THE CONDITION AND WEAR OF THE MIXER

SCRAPERS .................................................................................................... 133

14.6

REPLACING THE MIXER SCRAPERS AND SLIDERS .................. 135

14.7

SETTING THE WATER REGULATION VALVE ............................... 137

14.8

DANGER OF TEMPERATURES BELOW 0 °C ............................... 138

14.9

ORDERING SPARE PARTS ............................................................ 139

5

BASIC STARTING OF THE MACHINE

STARTING OF THE MACHINE (heating at 85°C ):

• With quick key AUTOMATIC

AUTOMATIC - button for the heating of the mixture up to 85°C.

STARTING OF THE MACHINE (ice cream production)

• With quick key ICE CREAM

ICE CREAM - button for the producing of the ice cream in MODE 1.

STARTING OF THE MACHINE (extraction of the ice cream)

• With key EXTRACTION

EXTRACTION - button for the extraction of the ice cream.

For more information read the entrie manual!

6

HOT AREA!

PAY PARTICUAL ATTENTION - HOT MIXTURE!

Duiring the heating operation (hot mixture) or after emptying of it (time 10

minutes) the user:

can only by handle slowly opened or closed the outlet valve!

can turn the handle in clockwise direction (for opening and closing the

outlet pipe)!

can’t apprehended or turn the inox part of the outlet pipe!

The user must take particular attention when slow opening and closing the

outlet pipe (the cover of the batch feeder must be closed) that does’n the hot

mixture burned the hands, face...!

7

1 INSTRUCTIONS ON HOW TO USE THE GUIDE

Since we are in the company VALMAR aware that it is in yours as well as in our

interest that the machine would operate at its best and as cheap as possible we

have prepared this instruction manual, in order to assist you with your machine.

The instruction manual must be stored near the machine, so you will be able to

access it when needed.

Only authorized persons (operators), who know how to operate the appliance,

are allowed to handle and operate it. Operators must read and study the

manual carefully and they must follow the instructions.

The company VALMAR can not be held responsible for any kind of damage or

injuries occurred due to non-consideration of the instruction manual.

Further to these instructions, all applicable environmental legislation and

regulations regarding safety at work must be taken into consideration.

Handling the appliance required carefulness, which is expressed in the manual

with symbols.

1.1 SYMBOLS USED IN THE GUIDE

This symbol represents important content in the manual. You should study the

text accompanied with this symbol carefully. Disregard of instructions and

warning symbols may lead to serious personal injury and damage to the

appliance.

This symbol represents explicit prohibition of specific actions or operations.

When you see this symbol, special attention should be paid to what it refers.

This symbol calls your attention to the importance of the text as regards proper

handling of the appliance, but without danger of personal injury.

This symbol means that the content of the text is of a technical nature and is

related to technical specifications.

This symbol is an instruction to proceed with caution while engaging in a

specific operation referred to in the text.

This symbol means that the action to which it refers may also be carried out by

persons skilled in the operation of the appliance.

8

This symbol is a warning that any action or operation referred to in the text must

be carried out only by authorized servicing personnel.

2 GENERAL FEATURES AND SPECIFICATIONS

2.1 GENERAL FEATURES

The appliance is designed exclusively for the ice cream and other mass

(custard...) production and the processing of fresh ice cream. The

manufacturing company VALMAR cannot be held liable in any way for personal

injuries or damage caused to the appliance in cases when the appliance has

been used for any other purposes than those specified.

The appliance consists of:

main construction

side panels and top cover

mixture producing cylinder with mixer

electrical assembly

hydraulic assembly (water)

cooling assembly

It is forbidden to reassemble, alter or in any way modify the appliance or any

part of the appliance without an express permission of the manufacturer.

This appliance is designed in compliance with the following European

directives:

CEE 2006/42/EC and updates,

CEE 2006/95/EC and updates,

CEE 2004/108/EC and updates,

CEE 89/109 and updates,

CEE 1935/2004 and updates,

CEE 2023/2006 and updates,

CEE 72/2002 and updates.

and following standards:

EN ISO 12100-2:2003+A1:2009

EN 60204:2006+A1:2009

EN ISO 14121-1:2007

EN ISO 13857:2008

EN 61310-1 + EN 61310-2

EN ISO 14159

This appliance is fully compliant with all legal standards for operational safety.

The level of operating noise does not exceed 75 dB (in front of the machine).

Cooling is carried out with the use of ecological gas (see the silver plate on the

back side of the machine) and water condenser with the possibility of mounting

air condenser.

9

With the intention to provide our customers with a well-tested appliance, ready

for normal operation, the initial start-up is always carried out at the factory by

the manufacturer before the product is packed and shipped to our client.

Additional start-up and appliance's adjustments can be made on the client's

premises by technicians authorized by VALMAR.Set the appliance in a suitable

place, block it to ensure stability, and connect to the water and power supplies.

Blocked and connected appliance is ready for operation.

The price of the appliance does not include installation costs and the cost of the

demonstration of its operation.

The warranty does not include replacements or repairs of malfunctions caused

by incorrect connection of the appliance.

The quality and the quantity of the ice cream depend on:

temperature of the cooling water;

temperature of air;

final temperature of the ice cream;

quantity and quality of the ice cream mixture;

desired consistency of ice cream;

increase in the volume of ice cream.

The mixture is poured into the treating cylinder and then pressing AUTOMATIC

key. The mixture is heated up to treating temperature (85°C) and then

maintained at treating temperature until is poured into processing cylinder.

Hot mixture is introduced inside the production cylinder. The production of ice

cream - mass is started by pressing the ICE CREAM key or START key.

The machine cools the mixture (mass, ice cream) until the final density (or up to

the final temperature or the preset time) of ice cream.

DUAL machine can heating and cooling some mixture or cream in production

cylinder by pressing the START key (actual program).

Ice cream, mass is extraced out through the ejection hole into the vessel by

pressing EXTRACTION key.

Operations of the appliance:

Kettle - heating part:

mixing and heating the mixture in the treating cylinder up to the

predetermined temperature (85°C) and then maintenance at the

predetermined temperature (AUTOMATIC HEATING ),

Caution must be taken because the outlet valve and the pipe are

heated because they are exposed at hot mixture. Danger of scalding!

mixing and heating the mixture in the cylinder of preparation up to the

selected temperature trough the selected program (START );

Caution must be taken because the outlet valve and the pipe are

heated because they are exposed at hot mixture. Danger of scalding!

mixing in the mixture treating cylinder (MIXING, CLEANING,

DESINFECTING, TESTING START UP );

Cylinder - cooling part:

mixing and cooling of the ice cream mixture in the production cylinder

in trough the selected program (quick button) ;

mixing and cooling of the cream mixture in the production cylinder in

trough the selected program (START );

mixing and heating or colling of the mixture, cream in the production

cylinder in trought the selected program (START ) - only DUAL

MACHINES;

fast mixing – extraction of the ice cream in the production cylinder

(EXTRACTION );

slow mixing in the production cylinder (MIXING, CLEANING,

DESINFECTING, TESTING START UP ).

The warranty does not include replacements or repairs of malfunctions caused

by incorrect use of the appliance.

2.2 IDENTIFICATION OF THE APPLIANCE

Every appliance has its own identification label, which is fixed on the backside

of the appliance.

The ID label contains the essential technical specifications of the appliance:

1. manufacturer

2. manufacturers address

3. model

4. serial number

5. power supply voltage

6. nominal frequency

7. maximum current

8. cooling gas type

9. cooling gas weight

10. power

11. year of manufacturing

10

MODEL

WATER FLUX

PRODUCTION OF

SINGLE QUANTITY

1

2

3

5

8

6

9

4

7

10

11

The ID label must not be removed or damaged!

2.3 TECHNICAL SPECIFICATIONS

The appliances essential technical specifications:

power supply voltage (see appliance label)

maximum current (see appliance label)

power (see appliance label)

nominal frequency (see appliance label)

water consumption

production capacity

capacity of a cylinder cycle

weight

dimensions

All technical specifications, such as the weight, dimensions and power of the

appliance are not mandatory for the manufacturer and may change.

MULTY P

7 TTi 613 709+241 1401+100 11 17 9/45 2 7

7 TTi+dual

12 TTi 613 709+241 1401+100 15,34

WEIGHT

Kg Leight Depth Height KW * l/ciklus Kg/h Min kg Max kg

613 709+241 1401+100 11,7 17 9/45 2 7

DIMENSION (mm) POWER

cca

21 12/75 3 10

ICE-CREAM

VOLUME/CYCLE

11

Note that 1 liter of ice cream mixture is equivalent to 1,1 kilogram.

*

The water consumption in cylinder depends on:

the incoming water temperature,

the ice cream mixture (type),

the ice cream mixture temperature,

the required final ice cream temperature.

3 TRANSPORTATION AND PLACING OF THE

APPLIANCE

3.1 INSTRUCTIONS FOR PREVENTING INJURIES

Pay due attention to legally required safety measures.

At work wear suitable clothing. Do not wear ties, jeweller’s chains or belts,

which could get caught in the machine.

Do not shift or dislocate the safety switches or protective parts.

Make sure that the lifting device is in good condition and that its load capacity

exceeds the weight of the appliance (refer to the technical specifications data

sheet).

Lift the appliance following the instructions for its use and maintenance. Pay

attention to the handling and handgrip locations. The use of a suitable lifting

device is recommended.

While lifting or moving the appliance do not stand under the machine.

Do not turn the appliance after holding the cables or the water hose has lifted it.

If you have to attend to any work higher up above the appliance, you should use

a suitable ladder and not the appliance for support.

3.2 UNLOADING THE APPLIANCE FROM THE LORRY

Required devices are a hand lift for pallets and a forklift truck with load capacity

of at least 1,200 kg.

Lift the crate containing the appliance using the hydraulic palette lift and move it

as close to the open side of the lorry as possible.

12

Remove the hand lift from underneath and handle the crate with the forklift

truck. Make sure that the weight is focused on the holding points.

Remove the crate from the lorry with the forklift truck in reverse gear as soon as

the crate is moved out of the lorry, and lower the crate to the minimal height of

around 30 cm.

Slowly and carefully place the box containing the appliance in its place. To

move the appliance around on the premises use wheels, which are supplied

with the appliance.

3.3 UNPACKING OF THE APPLIANCE

Upon the delivery check if the crate was not damaged during transportation.

First the appliance is fixed on the pallet with two paking strips and then is

placed the carton box which is fixed to the pallet with two paking strip too.

When the machine is unpacked, make sure that the packaging is disposed in a

suitable manner and in compliance with standards on environmental safety.

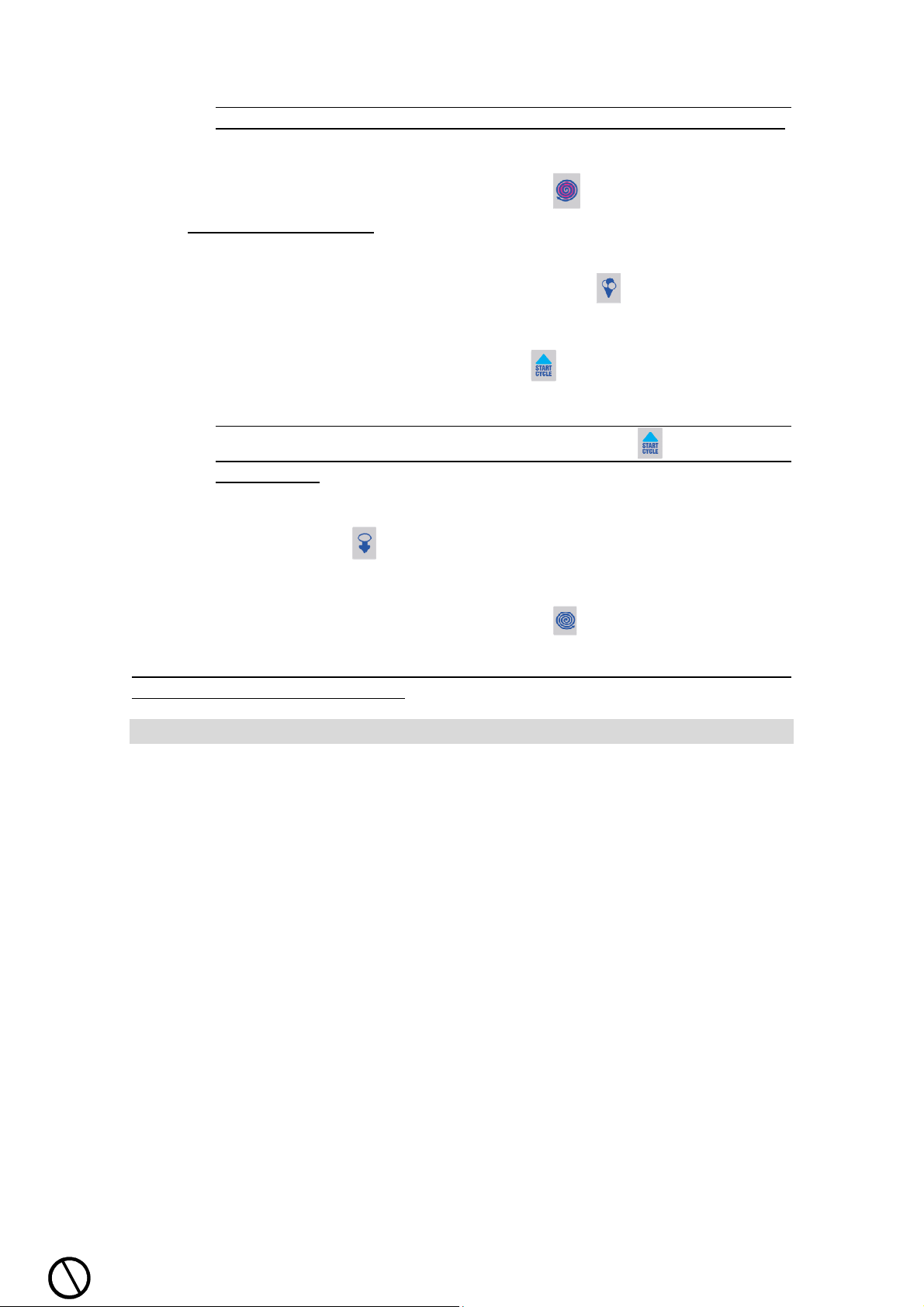

3.4 PLACING THE APPLIANCE ON THE GROUND

Place the machine on a level solid non-combustible surface with an adequate

strength of at least 600 kg per m² for the weight of the machine, and position the

appliance at least 60 cm away from the wall or other objects. Leave enough

space in front of the appliance to ensure comfortable access and work with the

appliance.

13

min.

max.

While placing the appliance in position, block the front wheels (by pressing the

brake), which will ensure that the appliance will not be able to move.

4 REQUIREMENTS AND CONDITIONS FOR

NORMAL OPERATION OF THE APPLIANCE

Before connecting the appliance to electricity supply, the operator must make

sure that environment requirements have been met: the temperature and

humidity of the air must be appropriate and the water supply and electricity

networks comply with all requirements for normal operation of the appliance.

When the characteristics of either the water supply or electricity network fail to

meet the requirements for normal operation, the machine must not be

connected to power supply.

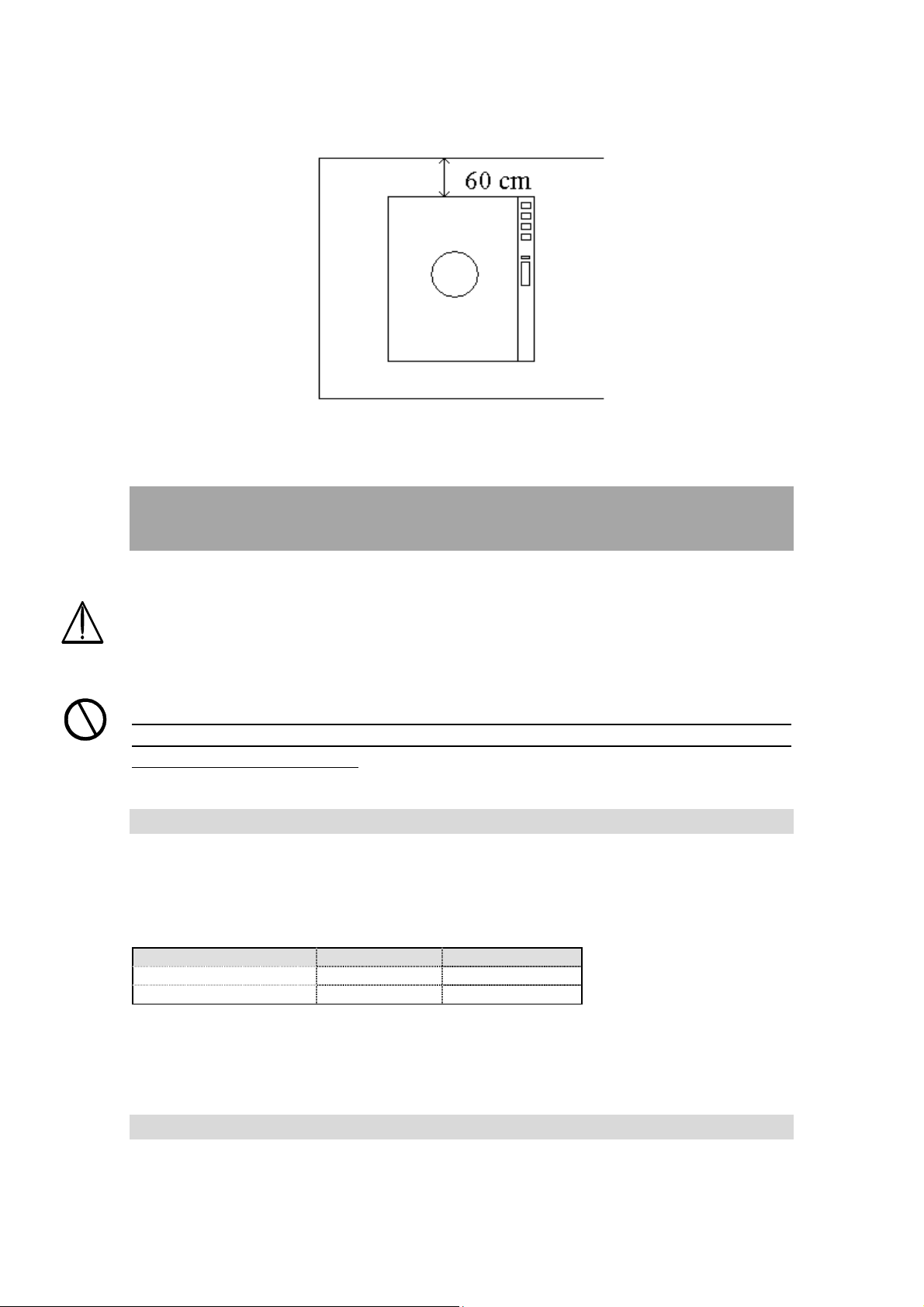

4.1 ENVIRONMENTAL CONDITIONS

Prior to connecting the appliance, the temperature and the humidity of the

environment, in which the appliance will be operated, must be assessed and

checked.

AIR TEMPERATURE 10°C 38°C

AIR HUMIDITY 0% 85%

If room temperature drops under 0 ºC (273K), water must be released from the

condenser.

4.2 WATER SUPPLY REQUIREMENTS

14

Prior to connecting the appliance to the power source, the temperature,

min.

max.

nominal voltage

min. voltage

max. voltage

nominal voltage

min. voltage

max. voltage

nominal voltage

min. vol

tage

max. voltage

nominal voltage

min. voltage

max. voltage

nominal voltage

min. voltage

max. voltage

pressure and water flow from the water supply network must be checked.

Permitted water temperature and water pressure from the water supply network:

WATER TEMPERATURE

WATER PRESSURE 100kPa (1bar) 800kPa (8bar)

WATER FLOW 400 l/h /

5°C 30°C

Water supply must be checked for all conditions that are required for alimentary

use.

Low water pressure causes the cooling system to function improperly. The

cooling gas does not condense, thus causing the compressor to overload. In

such cases, the safety pressure valve kicks in and switches off the compressor.

The results of mixture treating and ice cream production when the water

pressure is too low are not as good as when the water pressure is normal.

The maximum presence of chlorides in water is 120 ppm. Exchangers are not

suitable for the use of salt water.

4.3 ELECTRICITY SUPPLY REQUIREMENTS

Prior to connecting the appliance to the power source, the voltage and the

maximum power current allowed in the network must be checked and the

appliance must be protected externally with FUSES and the MAIN SWITCH.

Permitted voltage of three-phase appliances (400/50/3):

400V 380V (400V–5%) 420V (400V+5%)

Permitted voltage of three-phase appliances (230/50/3):

230V 220V (230V–5%) 240V (230V+5%)

Permitted voltage of one-phase appliances (230/50/1):

230V 220V (230V–5%) 240V (230V+5%)

Permitted voltage of one-phase appliances (208-220/60/3):

208-220V 208V 220V

Permitted voltage of one-phase appliances (208-220/60/1):

208-220V 208V 220V

The diameter of each phase conductor must be of an appropriate dimension

(corresponding to the power of the fuses).

15

The MAIN SWITCH must be installed in the immediate vicinity of the appliance,

model

max. current

fuse type

where it must be easily visible, accessible to the operator and appropriately

marked.

Magnetothermic differential FUSES (slot ≥ 3 mm) of appropriate dimensions

must be installed between the electricity network and the MAIN SWITCH.

MULTY P 5 TTi (one-phase) 230V/50-60Hz/1ph 32 A SLOW

MULTY P 7 TTi (one-phase) 230V/50-60Hz/1ph 32 A SLOW

MULTY P 7 TTI (three-phase) 400V/50-60Hz/3ph 25 A SLOW

MULTY P 12 TTi (three-phase) 400V/50-60Hz/3ph 32 A SLOW

MULTY P 12 TTi (three-phase) 230V/50-60Hz/3ph 50 A SLOW

The position of the MAIN SWITCH with the FUSES in the power circuit scheme

of the appliance:

5 CONNECTING THE APPLIANCE

5.1 INSTRUCTIONS FOR PREVENTION OF INJURIES

When the characteristics of either the water supply or electricity network fail to

meet the requirements for normal operation, the machine must not be

connected to the power supply.

It is forbidden to connect the appliance to the power source when the floor

around the appliance is wet.

It is forbidden to connect the appliance to the power source if any of the side

panels and the cover is missing.

5.2 CONNECTING THE APPLIANCE TO THE WATER SUPPLY

The water supply regulation valve is connected to the WATER SUPPLY PORT.

The water outlet pipe is connected to the WATER OUTLET PORT and to the

outlet pipe leading to the drain. All these terminals have a diameter of 3/4" and

are located on the backside of the machine.

To connect the appliance to the water supply (water supply port) and the outlet

to the drain (water outlet port), use pipes capable of withstanding 1MPa and

measuring at least ½” in diameter (make sure upon the delivery that the pipes

are supplied with the appliance).

16

WATTER SUPPLY PORT

(condenser)

WATER OUTLET PORT

(condenser)

WATTER SUPPLY PORT (pipe – drinkable water)

If the appliance is meant to be used in areas with two separate water supplies,

two separate water connectors are built in it, one for each: a DRINKING

WATER SUPPLY PORT and a COOLING WATER SUPPLY PORT

(condenser).

The valve belonging to the cooling water supply must not be connected to the

DRINKING WATER SUPPLY PORT.

The valve belonging to the drinking water supply may be connected to the

COOLING WATER SUPPLY PORT and/or to the DRINKING WATER SUPPLY

PORT.

The valve should be opened after the appliance has been connected to the

water supply system.

5.3 CONNECTING THE APPLIANCE TO THE POWER SUPPLY

Only appropriately trained technicians are allowed to connect the appliance to

the electrical current. They must follow installation instructions and observe the

occupational safety regulations applying in the country in which the appliance is

being installed. They must read the instructions carefully and above all

thoroughly familiarize themselves with the sections on REQUIREMENTS AND

CONDITIONS FOR NORMAL OPERATION OF THE APPLIANCE and the

machine’s electrical circuit scheme.

Before connecting the appliance, all attachments that might have become loose

during transportation must be checked. Attachments that may have become

loose or disconnected must be screwed back on and tightened.

Connecting instructions for three-vein cable (one-phase appliances – 230/50/1

or 208-220/60/1):

phase type colour

L1 208-220 or 230 V ~ brown

N 208-220 or 230 V ~ blue

PE ground yellow-green

Connecting instructions for four-vein cable (three-phase appliances – 230/50/3

or 208-220/60/3):

phase type colour

L1 208-220 or 230 V ~ black

L2 208-220 or 230 V ~ brown

L3 208-220 or 230 V ~ grey

17

PE ground yellow-green

Connecting instructions for five-vein cable (three-phase appliances – 400/50/3):

phase type color

L1 400 V ~ black

L2 400 V ~ brown

L3 400 V ~ grey

N neutral blue

PE ground yellow-green

A test start-up of the appliance is carried out by an appropriately trained

electrician who has also connected the machine so as to make sure that it is

properly connected (see the section on MAINTENANCE).

If the machine has been connected correctly, the mixer in the mixture-treating

cylinder will rotate anti - clockwise.

Should the mixers rotate in the wrong direction, it is necessary to change the

connecting position of any of the two phases.

Production cylinder mixer, installed in appliances with built-in inverter, will rotate

in the correct direction regardless of the connecting position of either of the

phases so it is necesary check the direction of the mixer in the cooking cylinder.

The mixer must rotate in clockwise direction.

Should the mixers rotate in the wrong direction, it is necessary to change the

connecting position of any of the two phases.

After connecting the appliance to the electricity network, appropriately trained

electrician must also control the power consumption. The current must not

exceed the maximum allowed on the identification plate or sticker (see the

section GENERAL FEATURES AND SPECIFICATIONS).

6 OPERATING THE APPLIANCE

The user operates the appliance standing in front of appliance. This position

allows user to handle the control panel, the safety switch and the water flow

regulation valve (shower).

The appliance must be always under users control during operation.

18

CONTROL

BOARD

WATER PIPE

(DRINKABLE WATER)

EMERGENCY STOP SWITCH

WATER VALVE

The control panel is used to:

• display the status or the operation phase;

• perform the settings;

• to show messages and errors.

The emergency stop switch is used to safely and securely switch of the

electronics. The electronics is switched off by pressing down the switch-off key

in the normal position and then depressing it. The switch will normally remain

down and must be pulled back up by hand to return to its normal position.

The shower is used for cleaning of the appliance.

7 CONTROL BOARD

Control panel is composed from mixture treating – heating control panel and

cooling cream processing control.

7.1 TOUCH SCREEN (dual inactive home screen)

19

7.1.1 TOUCH SCREEN OF THE KETTLE

3

4

7.1.1.1 TOUCH SCREEN (dual inactive home screen left - kettle part)

1

2

DESCRIPTION:

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

1

information on any errors and give warnings on

operations. This message refers to upper – kettle part of

the machine.

Press the left part of display

2

(kettle) to enter in the single

inactive home screen.

7.1.1.2 Inactive (kettle) home screen:

1

2

20

DESCRIPTION:

6 9

11

10

1

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on

operations.

2

POSITION OF THE MACHINE (standby).

3

Use this button to enter in the

SETTING MENU

4

QUICK PROGRMS KEYS.

7.1.1.3 Setting menu screen:

1

2

3

4

5

8

7

21

DESCRIPTION:

1

Use this function to enter the

PROGRAM MENU

2

Use this function to enter

MACHINE PARAMETERS

3

Use this function to enter

LANGUAGE SELECTION

4

Function to be used only by

Valmar technicians

Use this function to enter in

PASSWORD screen.

5

Digit password to

LOCK/UNLOCK the activities of

the machine.

Use this function to enter the

electronic info sheet and check

6

electronic sheet data: number,

latest update, software version,

etc.

Use this function to enter, check

and change settings such as

7

date, time, units of

measurement

(Celsius/Fahrenheit,

liters/gallons) or water quantity

8

Press the BACK button to return

to the previous screen

22

Press the HOME button to

1

4

2

3

5

6

7

8

9

10

11

12

9

return to the dual inactive home

screen.

For technician - net connection.

10

By correct code you can access

to connection between touch

screen and computer, TV…

Use this function to enter in

PASSWORD screen. Digit

11

password to RESET factory

settings (cancel all changes). All

saved values will be cleared.

7.1.1.4 Info menu screen:

DESCRIPTION:

1

2

3

4

5

6

Type of the machine.

Number of the data base.

The date of the last update.

Serial number of the electronic.

IP number.

MAC address (media access control address)

23

7

6

11 14 15

8

9

10

11

12

7.1.1.5 Setting screen:

Number of the software.

Version – number of the firmware (relay board).

Total hours of the working.

Total hours of the standbay.

Press BACK to return to the previous screen.

Press HOME to return to the main screen.

3

1

2

4

5

16

DESCRIPTION:

1

2

3

4

5

13

Year setting.

Time setting.

Month setting.

Minutes setting.

Day setting.

12

10

7

8

9

6

Liter/Gallon setting.

24

7

8

9

10

11

12

13

14

15

Beep volume setting.

Button volume setting.

Press BACK to return to the previous page.

Press HOME to return to the dual inactive home screen.

Water flow calibration (only sweety machine).

Celsius/Fahrenheit temperature setting.

Save new settings.

DOWN BUTTON decreased the actual value.

ACTUAL VALUES.

16

In the SETTINGS screen you can set the following parameters:

1. DATE: year month day ;

2. TIME: hours minutes ;

3. WATER UNIT OF MEASUREMENT: liters or gallons

4. TEMPERATURE UNIT OF MEASUREMENT: (celsius or

fahrenheit);

5. BEEP VOLUME ;

6. BUTTON VOLUME: .

DESCRIPTION:

UP BUTTON increased the actual value.

Press the button. Set the current year

on the display by using the

arrows. Confirm with the button.

Factory default – central European time

zone.

25

Press the button. Set the current month

on the display by using the

arrows. Confirm with the button.

Factory default – central European time

zone

Press the button. Set the current day

on the display by using the arrows.

Confirm with the button.

Factory default – central European time

zone.

Press to activate the hour button. Set

the hour on the display by using

the arrows. Confirm with the

button.

Factory default (AUT.) – central European

time zone with automatic adjustment of the

winter and summer time.

Two possibilities normal or AUT.

Press to activate the minutes button.

Set the minutes on the display by using

the arrows. Confirm with the

button.

Factory default – central European time

zone.

Press the button. Select liters or

gallons as unit of measurement by using the

arrows. Confirm with the button.

Factory default – liters.

26

2

9

Press the button. Select Celsius or

Fahrenheit as unit of measurement by using

the arrows. Confirm with the

button.

Factory default – Celsius.

Press the button. Adjust the volume

of the signal by using the arrows.

Confirm with the button.

Factory default – value 100.

Press the button. Adjust the volume

of the button by using the arrows.

Confirm with the button.

Factory default – value 70.

Program menu screen:

1

13

12

11

10

DESCRIPTION:

1

3

4

5

6

7

8

ICE CREAM PROGRAM MENU

Select the MILK button to enter the list of programs for milk

ice cream.

27

2

3

4

5

6

7

SORBET, SLUSH, FRUIT SAUCE AND TOPPING

PROGRAM MENU

Select the FRUIT button to enter the list of programs for

fruit sorbets, slush and sugar syrups.

PROGRAM MENU FOR CHOCOLATE ICE CREAM AND

OTHER CHOCOLATE PRODUCTS

Select the CHOCO button to enter the list of programs for

chocolate ice cream, toppings, sauces, ganache, creams,

etc..

PROGRAM MENU FOR CHOCOLATE ICE CREAM AND

OTHER CHOCOLATE PRODUCTS

Select the CHOCO button to enter the list of programs for

chocolate ice cream, toppings, sauces, ganache, creams,

etc..

CUSTOMIZED PROGRAM MENU FOR ICE CREAM,

SORBETS, PASTRY AND GASTRONOMY PRODUCTS

Select the CUSTOM button to enter the list of customizable

programs.

FOOD AND GASTRONOMY PROGRAM MENU

Select the GASTRO button to enter the list of food

programs such as soups, minestrone, polenta, risotto,

sauces, béchamel sauce, stew, etc..

PROGRAM NAME

8

9

10

11

12

....

13

FACTORY MENU

Select the FACTORY PROGRAMS button to enter the list

of programs for special functions such as variegated ice

cream extractions, mixing, etc.

Press BACK to return to the previous screen.

Press HOME to return to the dual inactive home screen.

PROGRAM NUMBER.

LAST used or NEW selected program.

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

28

7.1.1.6 Program list screen:

7

10

11

DESCRIPTION:

1

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

2

Program name and number.

1

2

3

4

5

9

8

6

3

4

5

6

7

8

Selected program. When pressed, the button changes color

and becomes black.

Button UP to scroll the program list.

Button DOWN to scroll the program list.

NOT ACTIVE Press the button to enter the step settings

screen. NOT ACTIVE To be used only by Valmar

technicians.

Press here to have a short program

description.

Press OK to confirm the selected program.

29

4

9

Press CHANGE to set the program and link it with one of the

four hot start buttons on the push-button panel and on the

main display.

10

Press BACK to return to the previous screen.

11

7.1.1.7 Program list tekst screen:

Press HOME to return to the dual inactive home screen..

1

2

1

2

...

3

4

2

3

Program description text

Cursor UP and DOWN.

Use the arrows to scroll the text

Press BACK to return to the previous screen

Press HOME to return to the dual inactive home screen.

Press the program info button to have a description of the selected program and

information on how to use it.

30

7.1.1.8 Active program screen:

2

1

11

DESCRIPTION:

1

PLUS button. Select this button to

enter in additional display.

10

4 3

5

6

9

8

7

2

3

4

5

6

7

8

PROGRAM NUMBER.

SET button.

Select this button to enter in

programs parameters of current

step.

PROGRAM NAME.

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

Press BACK to return to the previous screen.

BUTTON SNAIL decreased the actual speed. If the button is

grey the decreasing is not allowed.

MIXER SPEED DISPLAY.

31

9

1

6

BUTTON ROCKET increased the actual speed. If the button

is grey the increasing is not possible.

10

PRODUCTION MODE DISPLAY.

11

TIME DISPLAY.

If the operator not operating (push) on active program screen the

machine after a few seconds change it with the active single home screen:

For returned on active program screen click anywhere on the single active

home screen.

7.1.1.9 Additional active programs screen:

8

7

2

5

4

3

32

DESCRIPTION

1

2

3

4

5

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

PROGRAM NUMBER.

PROGRAM NAME.

Press the button to enter the

parameters screen (only for

Valmar technicians).

Press BACK to return to the previous screen.

6

Press HOME to return to the dual inactive home screen..

10

Press info to have a short program

description.

11

STEP NUMBER.

7.1.1.10 Active program parameters screen:

1

2

7

3

4

DESCRIPTION:

6

5

33

1

2

3

4

5

6

7

In programs (heating) when you change the value you change the value in

active step. When the actual step is finished the machine alerts us with an

audile signal and the new note of the steep is show on TUTOR MESSAGE.

7.1.2 TOUCH SCREEN OF THE CYLINDER

7.1.2.1 TOUCH SCREEN (dual inactive home screen right - cylinder part)

1

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

UP BUTTON increased the actual value. If the button is grey

the increasing is not allowed.

TEMPERATURE DISPLAY – actual values.

CONFIREM BUTTON confirmed the selected value. If the

button is grey the confirmation is not allowed.

DOWN BUTTON decreased the actual value. If the button is

grey the decreasing is not allowed.

Press BACK to return to the previous screen

TIME DISPLAY – actual values.

2

DESCRIPTION:

1

4

34

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on

operations. This message refers to upper – kettle part of

the machine.

Press the right part of display

(cylinder) to enter in the single

inactive home screen.

7.1.2.2 Inactive home screen:

6 9

11

10

3

4

1

DESCRIPTION:

TUTOR MESSAGES help users giving them instructions

1

and information about the processing. They also provide

information on any errors and give warnings on

operations.

2

2

POSITION OF THE MACHINE (standby).

3

Use this button to enter in the

SETTINGS MENU

4

QUICK PROGRMS KEYS.

7.1.2.3 Settings menu screen:

1

2

3

4

8

7

35

5

DESCRIPTION:

1

2

3

4

Use this function to enter the

PROGRAM MENU

Use this function to enter

MACHINE PARAMETERS

Use this function to enter

LANGUAGE SELECTION

Function to be used only by

Valmar technicians

Use this function to enter in

PASSWORD screen.

5

6

7

Digit password to

LOCK/UNLOCK the activities of

the machine.

Use this function to enter the

electronic info sheet and check

electronic sheet data: number,

latest update, software version,

etc.

Use this function to enter, check

and change settings such as

date, time, units of

measurement

(Celsius/Fahrenheit,

liters/gallons) or water quantity

8

36

Press the BACK button to return

to the previous screen

Press the HOME button to

1

4

2

3

5

6

7

8

9

10

11 12

9

return to the dual inactive home

screen.

For technician - net connection.

10

By correct code you can access

to connection between touch

screen and computer, TV…

Use this function to enter in

PASSWORD screen. Digit

11

password to RESET factory

settings (cancel all changes). All

saved values will be cleared.

7.1.2.4 Info menu screen:

DESCRIPTION:

1

2

3

4

5

6

7

8

Type of the machine.

Number of the data base.

The date of the last update.

Serial number of the electronic.

IP number.

MAC address (media access control address)

Number of the software.

Version – number of the firmware (relay board).

37

6

11 14 15

9

10

11

12

7.1.2.5 Setting screen:

Total hours of the working.

Total hours of the standbay.

Press BACK to return to the previous screen.

Press HOME to return to the main screen.

3

1

5

2

4

16

DESCRIPTION:

1

2

3

4

5

13

Year setting.

Time setting.

Month setting.

Minutes setting.

Day setting.

12

10

7

8

9

6

Liter/Gallon setting.

7

Beep volume setting.

8

Button volume setting.

38

9

10

11

12

13

14

15

16

In the SETTINGS screen you can set the following parameters:

Press BACK to return to the previous page.

Press HOME to return to the dual inactive home screen.

Water flow calibration (only sweety machine).

Celsius/Fahrenheit temperature setting.

Save new settings.

DOWN BUTTON decreased the actual value.

ACTUAL VALUES.

UP BUTTON increased the actual value.

1. DATE: year month day ;

2. TIME: hours minutes ;

3. WATER UNIT OF MEASUREMENT: liters or gallons

4. TEMPERATURE UNIT OF MEASUREMENT: (celsius or

fahrenheit);

5. BEEP VOLUME ;

6. BUTTON VOLUME: .

DESCRIPTION:

Press the button. Set the current year

on the display by using the

arrows. Confirm with the button.

Factory default – central European time

zone.

Press the button. Set the current month

on the display by using the

arrows. Confirm with the button.

Factory default – central European time

zone

39

Press the button. Set the current day

on the display by using the arrows.

Confirm with the button.

Factory default – central European time

zone.

Press to activate the hour button. Set

the hour on the display by using

the arrows. Confirm with the

button.

Factory default (AUT.) – central European

time zone with automatic adjustment of the

winter and summer time.

Two possibilities normal or AUT.

Press to activate the minutes button.

Set the minutes on the display by using

the arrows. Confirm with the

button.

Factory default – central European time

zone.

Press the button. Select liters or

gallons as unit of measurement by using the

arrows. Confirm with the button.

Factory default – liters.

Press the button. Select Celsius or

Fahrenheit as unit of measurement by using

the arrows. Confirm with the

button.

Factory default – Celsius.

40

2

9

7.1.2.6 Program menu screen:

1

13

Press the button. Adjust the volume

of the signal by using the arrows.

Confirm with the button.

Factory default – value 100.

Press the button. Adjust the volume

of the button by using the arrows.

Confirm with the button.

Factory default – value 70.

3

4

5

6

12

11

10

DESCRIPTION:

1

2

3

7

8

ICE CREAM PROGRAM MENU

Select the MILK button to enter the list of programs for milk

ice cream.

SORBET, SLUSH, FRUIT SAUCE AND TOPPING

PROGRAM MENU

Select the FRUIT button to enter the list of programs for

fruit sorbets, slush and sugar syrups.

PROGRAM MENU FOR CHOCOLATE ICE CREAM AND

OTHER CHOCOLATE PRODUCTS

Select the CHOCO button to enter the list of programs for

chocolate ice cream, toppings, sauces, ganache, creams,

etc..

41

4

5

6

7

8

9

PROGRAM MENU FOR CHOCOLATE ICE CREAM AND

OTHER CHOCOLATE PRODUCTS

Select the CHOCO button to enter the list of programs for

chocolate ice cream, toppings, sauces, ganache, creams,

etc..

CUSTOMIZED PROGRAM MENU FOR ICE CREAM,

SORBETS, PASTRY AND GASTRONOMY PRODUCTS

Select the CUSTOM button to enter the list of customizable

programs and programs for ice cream production in mode

2, mode 3 and mode 4.

FOOD AND GASTRONOMY PROGRAM MENU

Select the GASTRO button to enter the list of food

programs such as soups, minestrone, polenta, risotto,

sauces, béchamel sauce, stew, etc..

PROGRAM NAME

FACTORY MENU

Select the FACTORY PROGRAMS button to enter the list

of programs for special functions such as variegated ice

cream extractions, variable speed ice cream extraction,

mixing, etc.

Press BACK to return to the previous screen.

10

11

12

....

13

Press HOME to return to the dual inactive home screen.

PROGRAM NUMBER.

LAST used or NEW selected program.

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

42

7.1.2.7 Program list screen:

7

10

11

DESCRIPTION:

1

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

2

Program name and number.

1

2

3

4

5

9

8

6

3

4

5

6

7

8

Selected program. When pressed, the button changes color

and becomes black.

Button UP to scroll the program list ist.

Button DOWN to scroll the program list.

NOT ACTIVE Press the button to enter the step settings

screen. NOT ACTIVE To be used only by Valmar

technicians.

Press here to have a short program

description.

Press OK to confirm the selected program.

43

9

4

Press CHANGE to set the program and link it with one of the

four hot start buttons on the push-button panel and on the

main display.

10

Press BACK to return to the previous screen.

11

Press HOME to return to the dual inactive home screen.

7.1.2.8 Program list tekst screen:

1

2

1

2

...

3

4

2

3

Program description text

Cursor UP and DOWN.

Use the arrows to scroll the text

Press BACK to return to the previous screen

Press HOME to return to the dual inactive home screen.

Press the program info button to have a description of the selected program and

information on how to use it.

44

7.1.2.9 Active program screen:

2

1

3

4

5

13

DESCRIPTION:

1

2

3

6

7

12

11

10

9

8

SECOND DEDICATED button.

Select this button to activate the alternative extraction

arising from actual program (not alyaws present).

PROGRAM NUMBER.

SET button.

Select this button to enter in

programs parameters of current

step.

4

PROGRAM NAME.

5

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

6

FIRST DEDICATED button.

Select this button to activate the alternative extraction

arising from actual program (not alyaws present).

7

Press BACK to return to the previous screen.

8

BUTTON SNAIL decreased the actual speed. If the button is

grey the decreasing is not allowed.

45

9

10

11

12

13

MIXER SPEED DISPLAY.

BUTTON ROCKET increased the actual speed. If the button

is grey the increasing is not allowed.

DISPLAY – production mode of ice cream.

DISPLAY –cooling at temperature

DISPLAY – maintenance time

TIME DISPLAY.

PLUS button. Select this button to

enter in additional display.

If the operator not operating on active program screen the

machine after a few seconds change it with the active single home screen:

For returned on active program screen click anywhere on the single active

home screen.

7.1.2.10 Active program parameters screen:

1

2

8

3

4

7

6

5

46

DESCRIPTION:

1

7 5

1

2

3

4

5

6

7

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

UP BUTTON increased the actual value. If the button is grey

the increasing is not allowed.

ACTUAL VALUES.

CONFIREM BUTTON confirmed the selected value. If the

button is grey the confirmation is not allowed.

DOWN BUTTON decreased the actual value. If the button is

grey the decreasing is not allowed.

CONFIREM BUTTON confirmed the selected value. If the

button is grey the confirmation is not allowed.

Press BACK to return to the previous screen

8

At all programs in which is produced ice cream when you change the value you

change the value in all following steps.

In other programs (heating, cooling) when you change the value you change the

value in active step. When the actual step is finished the machine alerts us with

an audile signal and the new note of the steep is show on TUTOR MESSAGE.

7.1.2.11 Additional active programs screen:

9

TIME DISPLAY.

2

3

8

47

6

4

DESCRIPTION

1

2

3

4

5

TUTOR MESSAGES help users giving them instructions

and information about the processing. They also provide

information on any errors and give warnings on operations.

PROGRAM NUMBER.

PROGRAM NAME.

Press the button to enter the

parameters screen (only for

Valmar technicians).

SET button.

Select this button to enter in

programs parameters of current

step.

6

7

8

9

Press BACK to return to the previous screen.

Press HOME to return to the dual inactive home screen.

Press info to have a short program

description.

STEP NUMBER.

48

7.2 PUSH-BUTTON PANEL (TREATING – HEATING)

7.2.1 KEYS (kettle - heating part)

7.2.1.1 key START

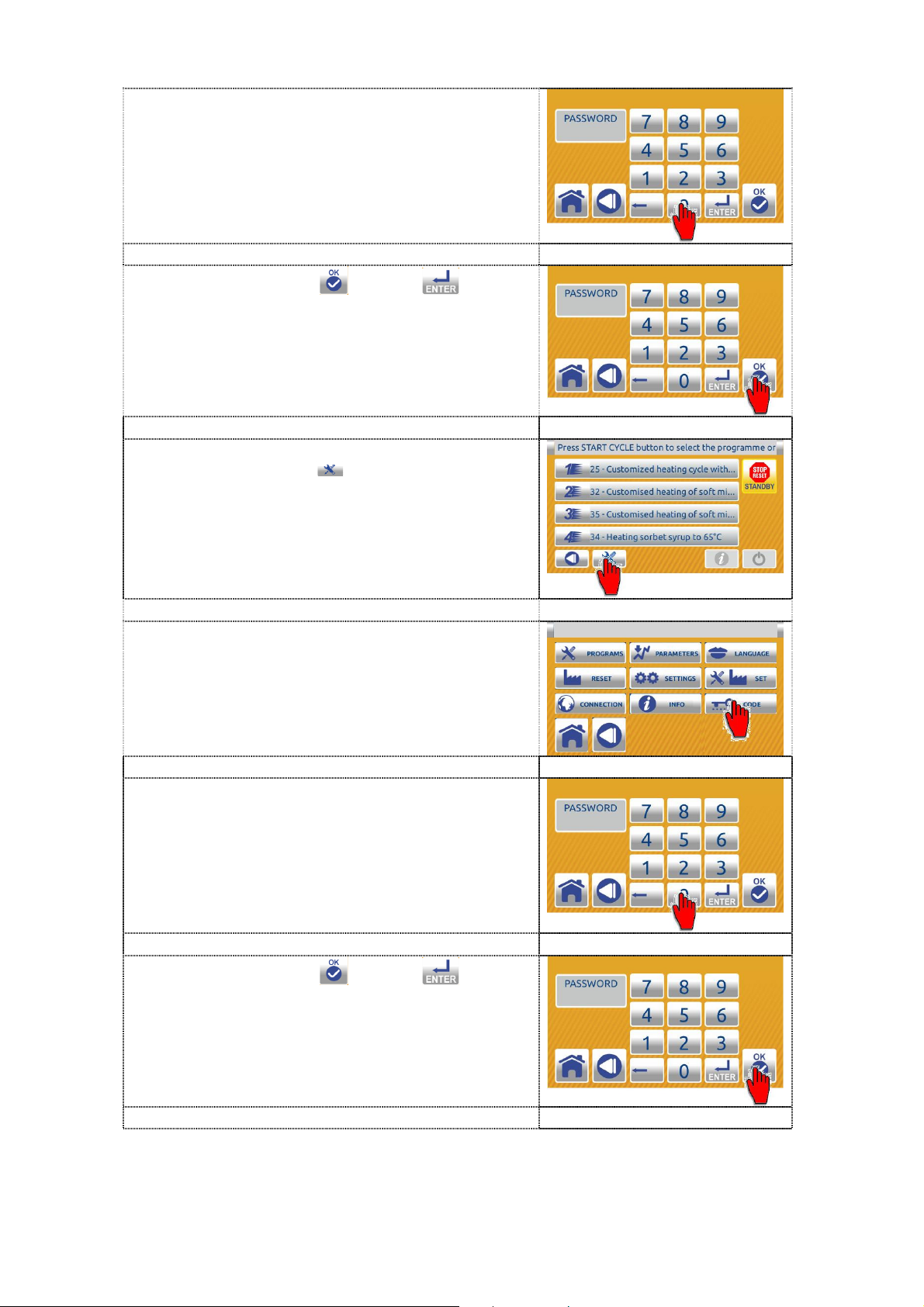

7.2.1.1.1 START with the START CYCLE BUTTON on the PUSH-BUTTON PANEL

The START CYCLE button is always set to one of the menu programs

(except when first using the machine).

1. Press the button to display the set NEW

program or the LAST program used.

2. Press START CYCLE again to start the

program (NEW or LAST).

3. Program screen.

All menu programs you can started with the START CYCLE button .

The end of the cycle is notified by a beep and a light signal (if any). A message

is displayed to take out the mixture.

The machine will continue mixing the mixture without heating until extraction,

i.e. until the end of the maximum time limit.

7.2.1.1.2 START with the START CYCLE BUTTON from the MENU

1. Press the button to display the set NEW

program or the LAST program used.

49

2. Select one of the icons representing the

various menus to enter the list of available

programs.

3. Use the UP / DOWN arrows to scroll

the list of available programs.

Select the desired program by pressing the

relevant button (e.g. 29). When pressed,

the button changes color and becomes

black.

4. Press the button with the name of the

program. The button becomes black (active

button).

5. Press the button to start the machine.

The front display interacts with users giving

them instructions and information about the

processing. The end of the cycle is notified

by a beep and a light signal (if any). A

message is displayed to take out the

mixture. The machine will continue mixing

the mixture without heating until extraction,

i.e. until the end of the maximum time limit.

7.2.1.2 key COOLING in the combinate programs – from the MENU

Some programs (combined) have posibility in heating cycle to set and use the

cooling programs too.

The COOLING button activates the connection with he lower part of the

machine (batch freezer).

The function is active only when the batch freezer is on STAND BY STOP

(machine off). The button is visible only in programs combined with a cooling

system.

In all programs in which after heating phase we want to cooling down the mass

(above 0°C, except production of ice cream) the temperature of production

cylinder must be equal as temperature of ambient (not frozen). In different case

the program of cooling will not be fully implemented.

50

1. Press the button

machine to the set program (cooling).

2. Press the button to start the set

program (cooling).

7.2.1.3 key MIXING

The MIXING button activates the mixing into the kettle. The heating cycle

will be stopped automaically.

In inverter machine the set speed of the mixing is speed 5 which you can

change(+- 2 speeds).

to connect the

For increase mixer speed press button and for decrease mixer speed press

button .

1. Press the button to start a low

continuos mixing.

2. The machine starts with speed 5 for 1200

seconds.

7.2.1.4 key HALF-KETTLE HEATING

When you have less than half mixture in kettle you must press - turn on the

HALF-KETTLE HEATING button !

All scrapers which are not fully covered with mixture must be removed from the

kettle mixture.

51

The HALF-KETTLE HEATING button

activates the heating only with heater

which is positionated in the lower part of the kettle. The button can be

switched on during the heating cycle and is active only during the running

program. The function cannot be stored.

Press the button to start a half heating

(lower) of the kettle.

3. On the display show picture. If you

again press the button the picture

disappear so mean that the machine

working with both heaters.

7.2.1.5 key HEATING AT 85°C

The HEATING button is pre-set to the program ice cream mixture heating at

85°C.

1. Press the button to start pre-set

program 26.

2. The machine will start mixing and heating

the mixture up to 85°C. The front display

interacts with users giving them instructions

and information about the processing. The

end of the cycle is notified by a beep and a

light signal (if any). A message is displayed

to take out the mixture. The machine will

continue mixing the mixture without heating

until extraction, i.e. until the end of the

maximum time limit.

7.2.1.6 key STOP / RESET

The STOP button stops all active function, operation, program of the

machine indifferently in which phase the machine is. The HOME screen is

displayed.

52

7.3 PUSH-BUTTON PANEL (PRODUCTION – COOLING)

7.3.1 KEYS (cylinder – cooling part)

7.3.1.1 key START

7.3.1.1.1 START with the START CYCLE BUTTON on the PUSH-BUTTON PANEL

The START CYCLE button is always set to one of the menu programs

(except when first using the machine).

1. Press the button to display the set NEW

program or the LAST program used.

2. Press START CYCLE again to start the

program (NEW or LAST).

3. Program screen.

All menu programs are started with the START CYCLE button .

The end of the cycle is notified by a beep and a light signal (if any). A message

is displayed to take out the ice cream. Should the operator not take out the ice

cream after the notice, the machine will keep ice cream consistency

automatically until extraction, i.e. until the end of the maximum time limit.

In all DUAL machines you can with START CYCLE button set to one of the

menu programs (heating or cooling).

53

7.3.1.1.2 START with the START CYCLE BUTTON from the MENU

1. Press the button to display the set NEW

program or the LAST program used.

2. Select one of the icons representing the

various menus to enter the list of available

programs.

3. Use the UP / DOWN arrows to scroll

the list of available programs.

Select the desired program by pressing the

relevant button (e.g. 03). When pressed,

the button changes color and becomes

black.

4. Press the button with the name of the

program. The button becomes black (active

button).

5. Press the button to start the machine.

The end of the cycle is notified by a beep

and a light signal (if any). A message is

displayed to take out the ice cream. The

machine will keep ice cream consistency

automatically until extraction, i.e. until the

end of the maximum time limit.

7.3.1.2 Key CONTINUOUS MIXING

The CONTINUOUS MIXING button activated the low mixing. This low mixing

you can use for:

1. mix mixtures in the cylinder,

2. rinse the cylinder,

3. wash the cylinder at the end of production.

54

Press the

button to start a low continuos

mixing.

1. The machine starts with speed 5 for 480

seconds.

With STOP button you can stop mixing – extraction (in any phase).

7.3.1.3 Key STANDARD EXTRACTION (normal speed)

The STANDARD EXTRACTION button activated the automatic variable

speed mixing. Mixer speed will gradually increase until full ice cream extraction.

1. Press the button to start automatic

variable speed mixing.

2. The machine starts with speed 7 for 15

seconds.

3. Then machine start mixing with speed 8 for

30 seconds.

4. At last the machine start mixing with speed

8 for 3 minutes.

With STOP button you can stop mixing – extraction (in any phase).

55

7.3.1.4 Key STANDARD EXTRACTION (low speed) - from the MENU

The STANDARD EXTRACTION button activated the automatic variable

speed mixing. Mixer speed will gradually increase until full ice cream extraction.

1. In running program press the button to

start automatic variable speed mixing.

2. The machine starts with speed 5 for 10

seconds.

3. Then machine start mixing with speed 6 for

10 seconds.

4. Then machine start mixing with speed 7 for

15 seconds.

5. At last the machine start mixing with speed

8 for 200 seconds.

With STOP button you can stop extraction (in any phase).

7.3.1.5 START with the EXTRACTION FOR MAXIMUM QUANTITY OF VARIEGATED ICE

CREAM BUTTON from the MENU

56

The EXTRACTION FOR MAXIMUM QUANTITY of VARIEGATED ICE CREAM

button activated the mixing which will gradually increase until full ice cream

extraction. The program consists of 11 steps alternating mixer speed, from 6/7/8

(quick) to 2 (slow).

1. In running program press the button to

start extractionwith alternating mixing

speed.

2. The machine starts with speed 5. For

continue press START CYCLE button.

3. Now the machine works with speed 2. For

continue press START CYCLE button.

4. Now the machine works with speed 6. For

continue press START CYCLE button.

5. Now the machine works with speed 2. For

continue press START CYCLE button.

6. Now the machine works with speed 7. For

continue press START CYCLE button.

57

7. Now the machine works with speed 2. For

continue press START CYCLE

8. Now the machine works with speed 8. For

continue press START CYCLE button.

9. Now the machine works with speed 2. For

continue press START CYCLE button.

10. Now the machine works with speed 8. For

button.

continue press START CYCLE button.

11. Now the machine works with speed 2. For

continue press START CYCLE button.

12. At last the machine works with speed 8.

With STOP button you can stop mixing – extraction (in any phase).

58

7.3.1.6 START with the EXTRACTION OF CREAM AND OTHER THICK PRODUCT

BUTTON from the MENU

The EXTRACTION OF CREAM AND OTHER THICK PRODUCT button

activated a low speed extraction for creams, thick products and products

requiring low speed extraction.

1. In running program press the button to

start low mixing speed.

2. The machine starts mixing with speed 1 for

10 minutes.

In the most programs the machine offer different modes of the extraction!

So for exemple you can use these modes of extraction:

1. In running program you can use

modes.

7.3.1.7 FREEZING BUTTON from the MENU

The FREEZING button activated a cooling (compressor) for 10 seconds.

59

1. In running extraction step press the button

to start cooling.

2. The machine starts compressor for 10

seconds. On the thouch screen (cylinder –

right side) in tutor message show caption

Ur-FORCE_COMPRESSOR (switching of

the cooling for 10 seconds)…

After 10 seconds the machine

automatically switches off the compressor.

For the anticipated switches off the

compressor press again the freezing

buton.

If the FREEZENG button is grey the colling is not allowed.

With STOP button you can stop extraction (in any phase).

7.3.1.8 Key START

The ICE CREAM button activates mixing and cooling of the ice cream

mixture in the production cylinder in trough the selected program 01 - MODE1

(ICE CREAM ) pressing this key the user activates the selected program.

3. Press the button to start pre-set

program 01.

4. The machine prodiucing ice cream in

MODE 1(ice cream temperature and

density check).

During production you can change value of

MODE 1 (see chapter “PROGRAM

MODIFICATIONS AND SETTINGS”).

Production ends when set values are

reached. The end of the cycle is notified by

a beep and a light signal (if any). A

message is displayed to take out the ice

cream. The machine will keep ice cream

consistency automatically until extraction,

i.e. until the end of the maximum time limit.

60

7.3.1.9 Key STOP / RESET

The STOP button stops all active function, operation, program of the

machine indifferently in which phase the machine is.

The dual inactive HOME screen is displayed.

7.4 FIRST USING OF THE MACHINE

At the first using is necessary to select the language. If the language is not

selected machine after 30 seconds chooses English language.

1. Wait for the software to upload.

2. After Valmar screens, the LANGUAGE

SELECTION screen is automatically

displayed.

3. Select the desired language. If it is not on

the screen, press the button to enter

language selection screen 2.

4. To return to language selection screen 1

press the button

5. Press the button corresponding to the

desired language. The notice - confirm

screen is displayed.

61

6. First carefully read the text and then press

the confirm button

language chosen. The dual inactive home

screen is displayed.

7. The machine is ready for use with

instructions in the selected language.

7.5 LANGUAGE SELECTION

The machine provides instructions in the user’s language for easier use.

Language can be changed after first using the machine. In this case we will

change Italian in English language.

1. Press the left (cooking) or right (cooling) part

on the dual inactive HOME page to enter in

the single inactive home screen.

to confirm the

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

3. Press the LANGUAGE button to

enter the LANGUAGE screen.

4. Press the button corresponding to the

desired language. The notice - confirm

screen is displayed.

62

5. First carefully read the text and then press

the confirm button

to confirm the

language chosen. The dual inactive home

screen is displayed.

6. The machine is ready for use with

instructions in the selected language.

7.6 DATA DOWNLOAD

7.6.1 DATA DOWNLOAD with a USB key (cooking part)

7.6.1.1 Data download for analisis – protected files (sending to VALMAR GLOBAL!)

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

3. Press the PARAMETERS button to

enter the PARAMETERS screen.

4. Insert the USB key into the relevant USB

port.

63

5. Press USB button

to enter in the

PASSWORD screen.

6. Enter the password - user code 333333.

7. Press the confirem or enter button

to lock the access to operation on the

machine.

8. On the message bar appears message

DOWNLOAD.

9. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key and send data to

VALMAR GLOBAL company.

7.6.1.2 Data download of the ERRORS

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

64

2. On the single inactive home screen press

the TOOLS button

menu.

3. Press the PARAMETERS button to

enter the PARAMETERS screen.

4. Insert the USB key into the relevant USB

port.

to enter in SETTING

5. Press ERROR button to enter in the ERROR

screen.

6. Use the UP / DOWN arrows to scroll

the errors to see the informations-details of

the selected error.

7. Press USB button to download errors

into the USB key.

65

8. On the message bar appears message

DOWNLOAD.

9. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key.

Data from USB key (file type: xml) you can

open on computer with xml viewer (Excel,

Libre Ofice Calc, Browser, text editor...).

7.6.1.3 OPTION (surcharge) - download data of the machine, cycle (customer)

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

3. Press the PARAMETERS button to

enter the PARAMETERS screen.

4. Insert the USB key into the relevant USB

port.

66

5. Press “HCCP” button

to enter in

“HCCP” screen.

6. Press USB button to download “HCCP”

data into the USB key.

7. On the message bar appears message

DOWNLOAD.

8. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key.

Data from USB key (file type: xml) you can

open on computer with xml viewer (Excel,

Libre Ofice Calc, Browser, text editor...)

7.6.2 DATA DOWNLOAD with a USB key (cooling part)

7.6.2.1 Data download for analisis – protected files (sending to VALMAR GLOBAL!)

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

67

3. Press the PARAMETERS button

to

enter the PARAMETERS screen.

4. Insert the USB key into the relevant USB

port.

5. Press USB button to enter in the

PASSWORD screen.

6. Enter the password - user code 333333.

7. Press the confirem or enter button

to lock the access to operation on the

machine.

8. On the message bar appears message

DOWNLOAD.

9. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key and send data to

VALMAR GLOBAL company.

68

7.6.2.2 Data download of the ERRORS

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

3. Press the PARAMETERS button to

enter the PARAMETERS screen.

4. Insert the USB key into the relevant USB

port.

5. Press ERROR button to enter in the ERROR

screen.

6. Use the UP / DOWN arrows to scroll

the errors to see the informations-details of

the selected error.

69

7. Press USB button

to download errors

into the USB key.

8. On the message bar appears message

DOWNLOAD.

9. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key.

Data from USB key (file type: xml) you can

open on computer with xml viewer (Excel,

Libre Ofice Calc, Browser, text editor...)

7.6.2.3 OPTION (surcharge) - download data of the machine, cycle (customer)

1. Press the right part (colling) on the dual

inactive HOME screen to enter in the single

inactive home screen.

2. On the single inactive home screen press

the TOOLS button to enter in SETTING

menu.

3. Press the PARAMETERS button to

enter the PARAMETERS screen.

70

4. Insert the USB key into the relevant USB

port.

5. Press “HCCP” button to enter in

“HCCP” screen.

6. Press USB button to download “HCCP”

data into the USB key.

7. On the message bar appears message

DOWNLOAD.

10. When the download is complete appears on

the message bar message DOWNLOAD

OK. Pull out the USB key.

Data from USB key (file type: xml) you can

open on computer with xml viewer (Excel,

Libre Ofice Calc, Browser, text editor...)

7.7 UPDATE OF NEW PROGRAM OR NEW DATABASE

The program is updated only when the machine is OFF!

1. Make sure the machine is OFF before starting.

This can you do if you pres red button (safety

switch). Then Insert the USB key in which you

have a new program or a new database. The

USB socket is situated in right top corner of the

back side of the machine (if you look from back

side).

2. Pull out the red button (safety switch) to switch

ON the machine.

71

3. New data is uploaded automatically. After

upload, the uploaded program and software

version and the date of the last update are

displayed. Automatic switch to the type and

model screen. The screen shows the machine

type and model. Then the notice - confirm

screen is displayed

4. Press the confirm button OK to confirm the

upload. Check if everything is updated (info

menu screen). If this message not show the

uploading does not completely concluded.

8. Then the LANGUAGE SELECTION screen is

automatically displayed. Press the button

corresponding to the desired language. The

notice - confirm screen is displayed.

5. First carefully read the text and then press the

confirm button to confirm the language

chosen. The dual inactive home screen is

displayed.

6. The machine is ready for use with instructions in

the selected language.

Press the BACK button to return to the previous screen. Press the HOME

button to cancel the operation and return to the dual inactive home screen.

7.8 WEAR OF THE SCRAPERS

When the machine reaches a certain number of hours show on display the

lower message.

Press the confirem button to progress in home screen. The message

appears at every start of the machine. Press the reset

button

to permanently delete the message.This you can do only where you changed all

the scrapers and all the sliders!

72

For all damage on the machine or to a person which derived from

inconsediration of this message the company Valmar Global is not responsible!

It is necessary to keep record on the working hours of the mixer scrapers (see

the chapter 14.5 and write hours down to appendix A)!

8 PROGRAMS