Vallox Vallox 90 MV, Vallox 096 MV, Vallox TSK Multi 50 MV EH, Vallox 90K MV, Vallox TSK Multi 50 MV User Manual

...Page 1

Manual

Model

Vallox TSK Multi 50 MV

Vallox TSK Multi 50 MV EH

Vallox TSK Multi 80 MV

Vallox TSK Multi 80 MV EH

Vallox TSK Multi 80 MV EHX

Vallox 90 MV

Vallox 90K MV

Vallox 096 MV

Vallox 101 MV

Vallox 110 MV

Vallox 145 MV

Vallox 245 MV

Vallox 245 MV VKL

MANUAL

Document

D3768

Valid from

3.2.2015

Updated

9.1.2018

Ventilation units

Page 2

INTRODUCTION 4

Safety 4

Installation 4

Guarantee 4

Intended use 4

Disposal of the ventilation unit 4

Safety signs used in the instructions 5

Dierences between the models 5

Main parts 6

Vallox TSK Multi 50 MV and Vallox TSK Multi 80 MV 6

Vallox 90 MV 7

Vallox 90K MV 8

Vallox 096 MV, Vallox 110 MV, and Vallox 145 MV 9

Vallox 101 MV 10

Vallox 245 MV 11

Ventilation unit control 12

Connecting the ventilation unit to the cloud service 12

Ventilation unit control options 12

Unit software 15

Starting the unit 15

Turning the unit o 15

Starting up and shutting down the unit 15

SETUP WIZARD 16

Basic settings 16

Setup wizard 16

Select the language 16

Set the time 16

Set the 24- or 12-hour clock 16

Set the automatic daylight saving time 16

Set the date 17

Completing the setup 17

Expert settings 18

Lock code and access rights 18

User level 18

Parental controls 18

Basic fan settings 19

Adjusting the supply and extract air flows 19

Expert settings 20

Profile settings 20

At home and Away profiles 20

Boost profile 20

Fireplace profile 21

Finishing the setup 21

Four ventilation unit profiles 22

USING THE UNIT 22

At home 22

Away 22

Boost 22

Fireplace profile 22

Symbols for ventilation profiles 22

Changing the profile 23

Browsing the information of the At home, Away, and Boost

profiles. 23

Viewing the Fireplace profile information 24

Modif ying and saving the profile settings 24

Modif ying profile set tings 24

Timer functions of the Boost and Fireplace profiles 24

Viewing temperature data 25

Viewing temperature statistics 25

Relative humidity of air and carbon dioxide level statistics 26

Viewing the relative humidity of air and carbon dioxide

levels measured by the sensors 26

Filter settings 27

Setting the date the filters were last replaced 27

Setting the Filter replacement reminder interval 27

Filter maintenance reminder 28

Display settings 28

Setting the sleep time 28

Adjusting the display brightness 28

Selecting the user interface language 28

Time and date 29

Setting the time and date 29

Setting the time 29

Selecting the 24- or 12-hour clock 29

Automatic daylight saving time 29

Setting the date 30

Week clock 30

Turning the week clock on 30

Setting and editing the weekly program 31

Turning the Week clock o 31

Removing the week clock settings 31

Example of setting a weekly program 32

Turning the unit o 32

Troubleshooting 33

Condensing water (User) 33

MAINTENANCE 34

Vallox TSK Multi 50 MV ja Vallox TSK Multi 80 MV 34

Before beginning maintenance work 34

Replacing the filters (User) 34

Cleaning the heat recovery cell (User) 35

Cleaning the fans (Installer) 36

Cleaning the supply air fan 36

Cleaning the extract air fan 37

CONTENTS

NOTE

You can register your Vallox MV ventilation unit with the MyVallox Cloud cloud service and sign

in into your MyVallox Cloud account at www.myvallox.com.

INTRODUCTION

Page 3

© Vallox Oy - All rights reserved

CONTENTS

Vallox 90 MV 38

Before beginning maintenance work 38

Replacing the filters (User) 38

Cleaning the heat recovery cell (User) 39

Cleaning the fans (Installer) 40

Vallox 90K MV 41

Before beginning maintenance work 41

Replacing the filters (User) 41

Cleaning the heat recovery cell (User) 41

Cleaning the fans (Installer) 41

Cleaning the grease filter of the cooker hood (User) 41

Replacing the cooker hood lamp (User) 41

Vallox 101 MV 42

Before beginning maintenance work 42

Replacing the filters (User) 42

Cleaning the heat recovery cell (User) 43

Cleaning the fans (Installer) 44

Vallox 096 MV, Vallox 110 MV ja Vallox 145 MV 45

Before beginning maintenance work 45

Replacing the filters (User) 45

Cleaning the heat recovery cell (User) 46

Cleaning the fans (Installer) 47

Cleaning the supply air fan 47

Cleaning the extract air fan 49

Vallox 245 MV 50

Before beginning maintenance work 50

Replacing the filters (User) 50

Cleaning the heat recovery cells (User) 51

Cleaning the fans (Installer) 52

Removing and cleaning the supply and extract air fans 52

Removing the resistor 53

INSTALLATION 54

Installation site 54

Condensing water 54

Vallox TSK Multi 50 MV ja Vallox TSK Multi 80 MV 55

Installation site 55

Dimensions and duct outlets 56

Vallox 90 MV 57

Mounting on the wall 57

Mounting on the ceiling 57

Mounting the ceiling mounting plate 57

Installing the ventilation unit to the ceiling mounting plate 58

Attic floor penetration plate 58

Measuring tubes 58

Dimensioning of and space required for installation of

the Vallox Silent Klick water seal 58

Vallox 90K MV 59

Mounting on the wall 59

Installing the cooker hood 59

Measuring tubes 59

Water seal 59

Vallox 096 MV, Vallox 110 MV, Vallox 145 MV 60

Mounting on the wall 60

Mounting on the ceiling 60

Mounting the ceiling mounting plate 60

Installing the ventilation unit to the ceiling mounting plate 61

Attic floor penetration plate 61

Vallox 101 MV 62

Mounting on the ceiling 62

Mounting the ceiling mounting plate 62

Installing the ventilation unit to the ceiling mounting plate 62

Attic floor penetration plate 63

Mounting on a base ( Vallox 145 MV) 64

Measuring tubes 64

Water seal 65

Dimensioning figure and space required for installation of

the Vallox Silent Klick water seal 65

Space required by the alternative Vallox Silent Klick water seal

installation method (elbow) 65

Vallox 245 MV 66

Mounting on the floor 66

Measuring tubes 66

Installing the water seals 66

TECHNICAL DATA 67

Vallox TSK Multi 50 MV ja Vallox TSK Multi 80 MV 67

Vallox 90 MV ja Vallox 90K MV 71

Vallox 096 MV 73

Vallox 101 MV 74

Vallox 110 MV 76

Vallox 145 MV 78

Vallox 245 MV 80

Vallox 245 MV VKL 83

Internal electrical connection 84

TSK Multi 50 MV ja 80 MV 84

TSK 90 MV 85

Vallox 90K MV 86

Vallox 096 MV ja Vallox 101 MV 87

Vallox 110 MV, Vallox 145 MV, Vallox 245 MV 88

Vallox 245 MV VKL 89

External electrical connection 90

Duct radiator operation chart 91

Operation and sample connection 91

Exploded view and parts list 93

Vallox TSK Multi 50 MV ja Vallox TSK Multi 80 MV 93

Vallox 90 MV 94

Vallox 90K MV 95

Vallox 096 MV 96

Vallox 101 MV 97

Vallox 110 MV 98

Vallox 145 MV 99

Vallox 245 MV 100

User level diagrams 101

Conformity certificates 102

INTRODUCTION

Page 4

4

NOTE

For further information,

go to www.vallox.com

INTRODUCTION

SAFETY

Safe and appropriate handling requires knowledge of the basic

safety regulations, and of the intended use of the ventilation

system. Read this manual before operating the ventilation unit.

Retain the manual for later reference. If you lose the manual, it can

be downloaded from our website.

This user manual contains all the information necessary for safe

operation of the system. All persons who operate and maintain

the ventilation system must follow the instructions provided in this

manual. Furthermore, all local accident prevention regulations must

be observed.

Installation

Installation and setup should be carried out only by qualified

experts. Electrical installations and connections must be carried

out only by an electrician and in compliance with local regulations.

GUARANTEE

The guarantee and liability exclude damage resulting from:

• Inappropriate use of the ventilation system or the control unit

• Incorrect or inappropriate installation, setup or use

• Neglect of instructions concerning transportation, installation,

use, or maintenance

• Structural or electronic modifications or changes made to the

software

INTENDED USE

All Vallox ventilation units have been designed to provide

appropriate and continuous ventilation so as to present no threat to

health and to maintain structures in good condition.

IMPO RTANT

In order to ensure that the indoor air presents no harm to

health and remains optimal also for the structures of the

building, ventilation must be kept on without disruptions. It

is recommended that ventilation be left turned on during long

holidays also. This keeps the indoor air fresh and prevents humidity

from condensing in the ventilation ducts and structures. It also

reduces the risk of moisture damage.

DISPOSAL OF THE VENTILATION UNIT

Do not dispose of electronic devices with household waste. Follow

local laws and regulations on safe and ecological disposal of the

product.

WARNING

The unit is not intended for

use by children under 8 or by

persons with reduced sensory,

physical or mental capabilities,

or whose lack of knowledge

and experience do not ensure

safe operation of the unit.

Such persons can use the

unit under supervision, or by

following the instructions of

someone who is responsible for

their safety.

Page 5

5

© Vallox Oy - All rights reserved

INTRODUCTION

SAFETY SIGNS USED IN THE INSTRUCTIONS

MODELS TYPE

Vallox TSK Multi 50 M V

Vallox TSK Multi 50 M V EH

Vallox TSK Multi 80 MV

Vallox TSK Multi 80 MV EH

Vallox TSK Multi 80 MV EHX

3609-1

3609

3608-1

3608

3609-1

3608-2

(EH = post-heating)

(EHX= post-heating and additional heating)

Vallox 90 MV

Vallox 90 KMV

3527

3528

Vallox 096 MV

Vallox 101 MV

Vallox 110 MV

Vallox 145 MV

3722

3741

3702

3712

Vallox 245 MV

Vallox 245 MV VKL

3732

3732

DANGER

Indicates a hazard that will result in

death or serious injury if not avoided.

WARNING

Indicates a hazard that can result in

death or serious injury if not avoided.

CAUTION

Indicates a hazard that can result

in minor or moderate injury if not

avoided.

IMPO RTANT

Indicates a hazard that can result in

damage to property or loss of data if

not avoided.

DIFFERENCES BETWEEN THE MODELS

• Power

• Size and weight

• Vallox 90 MV, Vallox 90K MV, Vallox 096 MV, and Vallox 101 do not have an additional heater. Vallox 110 MV and

Vallox 145 MV have an additional heater.

• Vallox 245 MV has an electric 1500W post-heating radiator and an electric 1500W additional heating radiator.

Vallox 245 MV VKL has a water circulation post-heating radiator and two electric 1500W additional heating

radiators.

• In Vallox 096 MV, there is a sealing tape at the bottom of the heat recovery cell. In other models, there is a

separate sealing bar under the heat recovery cell.

• Vallox 90K MV has a cooker hood underneath the unit, with a suction hole at the bottom of the unit and in the

insulation.

NOTE

The standard equipment and available accessories vary from country to country.

MOUNTING OPTIONS:

• Vallox 90 MV, Vallox 096 MV, Vallox 101 MV and Vallox 110 MV can be mounted either on the wall, or on the

ceiling by using a mounting plate (optional).

• Vallox 90K MV can only be mounted on the wall.

• Vallox 145 MV can be mounted either on the wall, or on the floor by using a floor rack (optional).

• Vallox 245 MV must always be installed on the floor by using a floor rack.

• Vallox TSK Multi 50 MV and Vallox TSK Multi 80 MV are designed to be mounted above a false ceiling.

UNIT TYPE CODES

NOTE

Indicates essential

information about the

product.

TIP

Provides additional

information about the use of

the product and its benefits.

Page 6

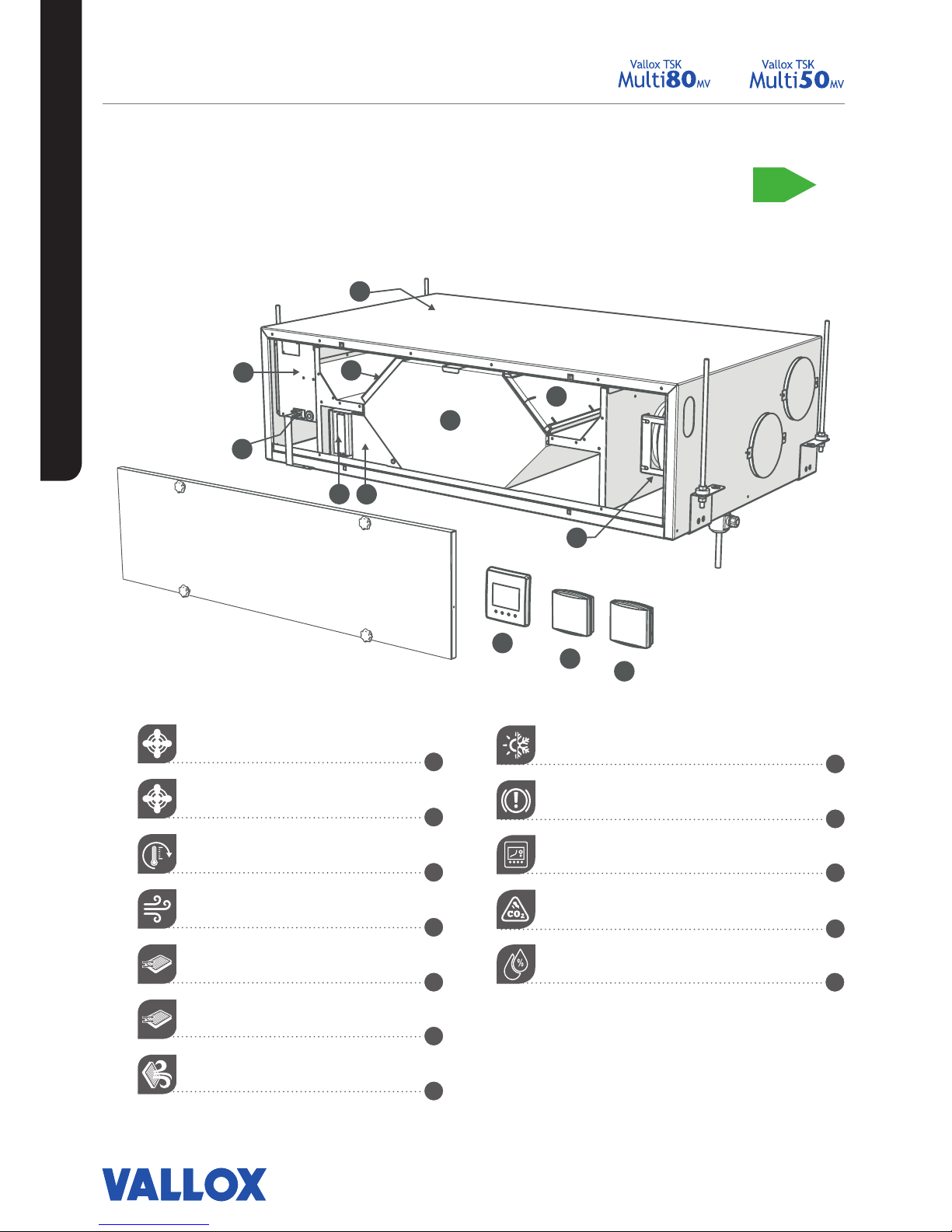

MAIN PARTS

P

O

I

S

T

O

I

L

M

A

N

L

Ä

M

M

Ö

N

T

A

L

T

E

E

N

O

T

O

N

V

U

O

S

I

H

Y

Ö

T

Y

S

U

H

D

E

L

U

O

K

K

A

A+

8

9

10

11

12

1

2

3

4

5

6

7

6

Supply air fan

Extract air fan

Post-heating radiator

Heat recovery cell

Supply air filter F7

Supply air filter G4

Extract air filter G4

R model in the figure

Bypass flap

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

10

11

12

5

8

9

3

1

7

2

6

4

INTRODUCTION

VALLOX TSK MULTI 50 MV AND

VALLOX TSK MULTI 80 MV

Page 7

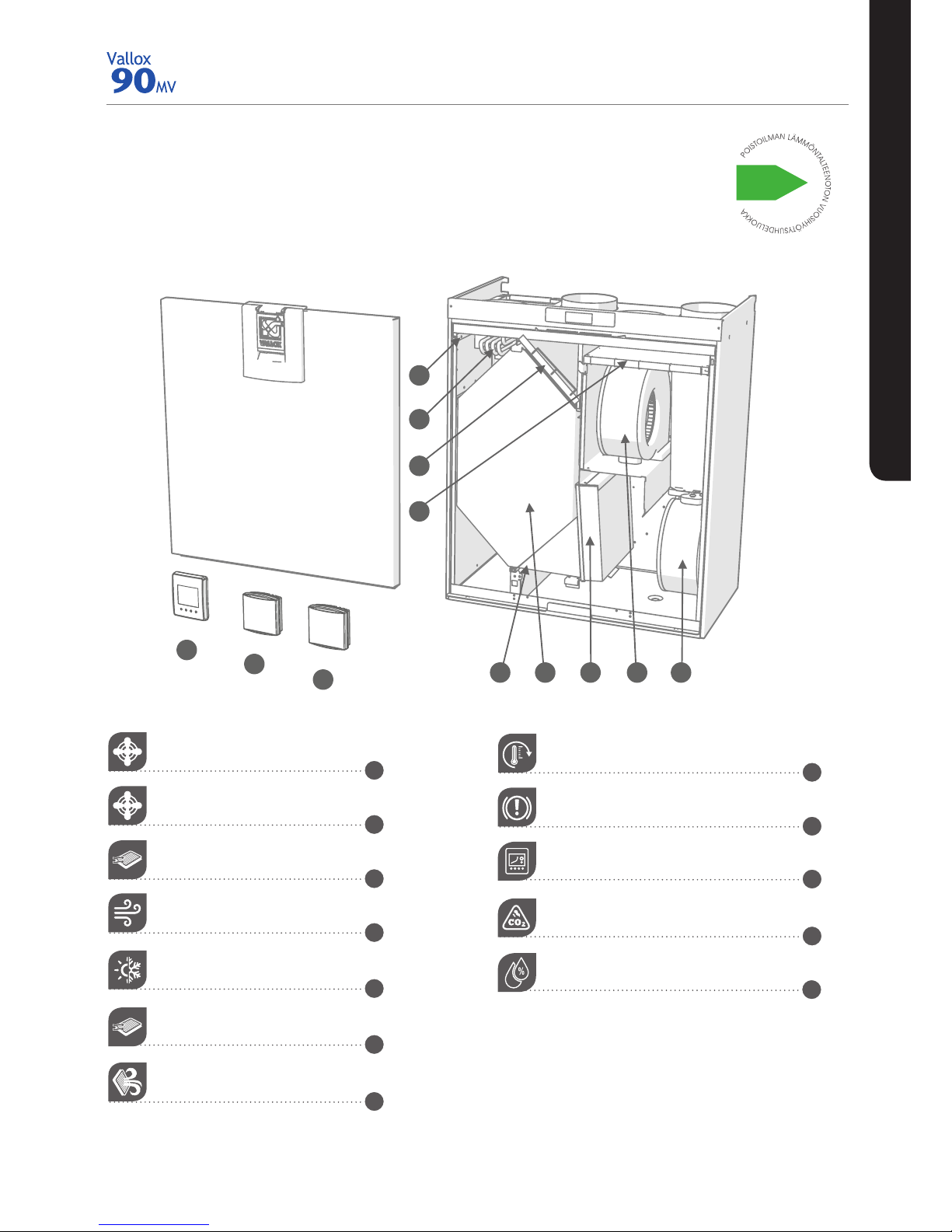

7

© Vallox Oy - All rights reserved

5

10

11

12

8

9

3 1

7

2

6

4

Extract air fan

Supply air fan

Supply air filter F7

Heat recovery cell

Automatic summer/winter damper

Supply air filter G4

Extract air filter G4

Post-heating radiator

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

B

8

9

10

11

12

1

2

3

4

5

6

7

R model in the

figure

MAIN PARTS

INTRODUCTION

VALLOX 90 MV

Page 8

8

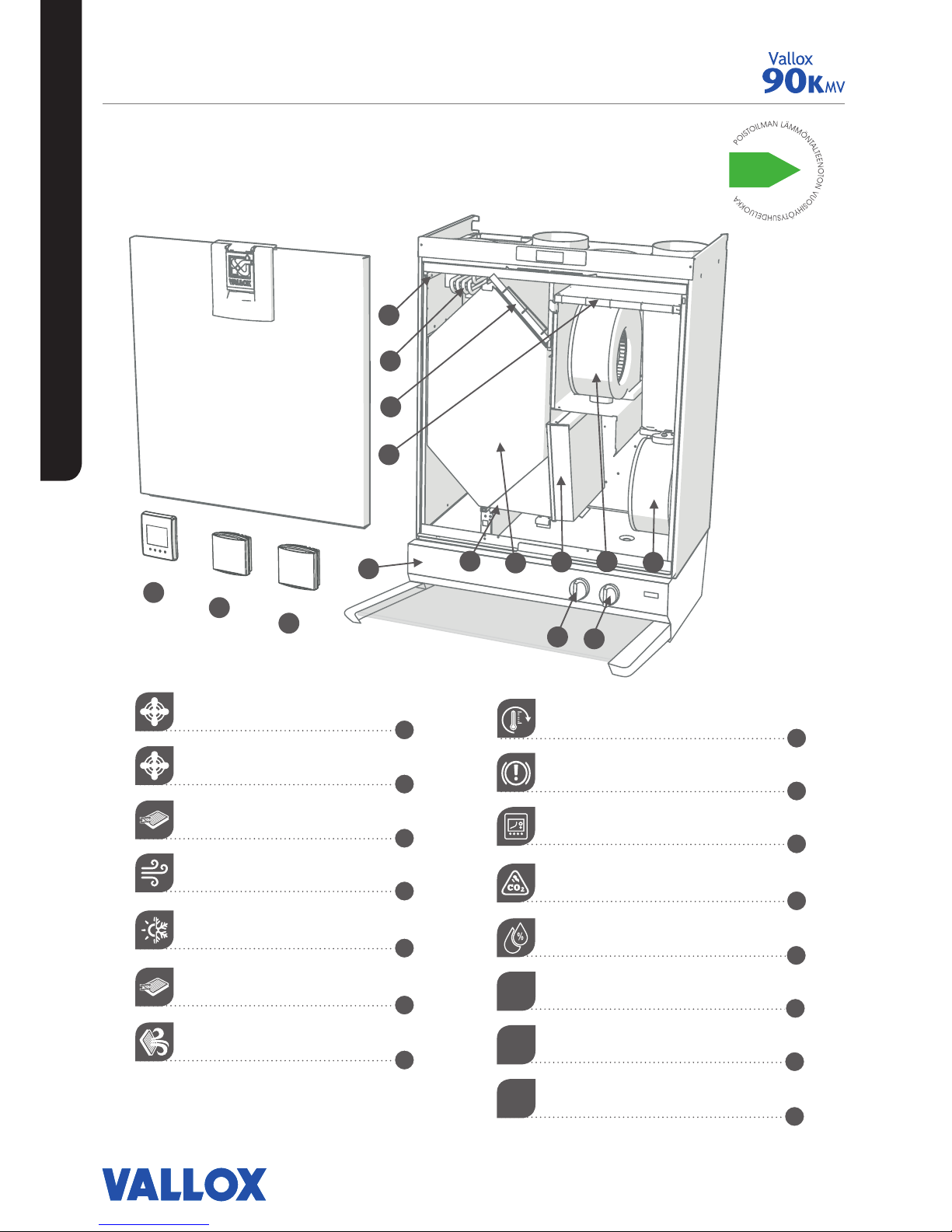

INTRODUCTION

VALLOX 90K MV

Extract air fan

Supply air fan

Supply air filter F7

Heat recovery cell

Automatic summer/winter damper

Supply air filter G4

Extract air filter G4

Post-heating radiator

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

Cooker hood

Cooker hood damper adjustment

Fan speed adjustment

B

MAIN PARTS

5

10

11

12

8

9

3 1

7

2

6

4

13

14

15

8

9

10

11

12

1

2

3

4

5

6

7

13

14

15

R model in the

figure

Page 9

9

© Vallox Oy - All rights reserved

9

© Vallox Oy - All rights reserved

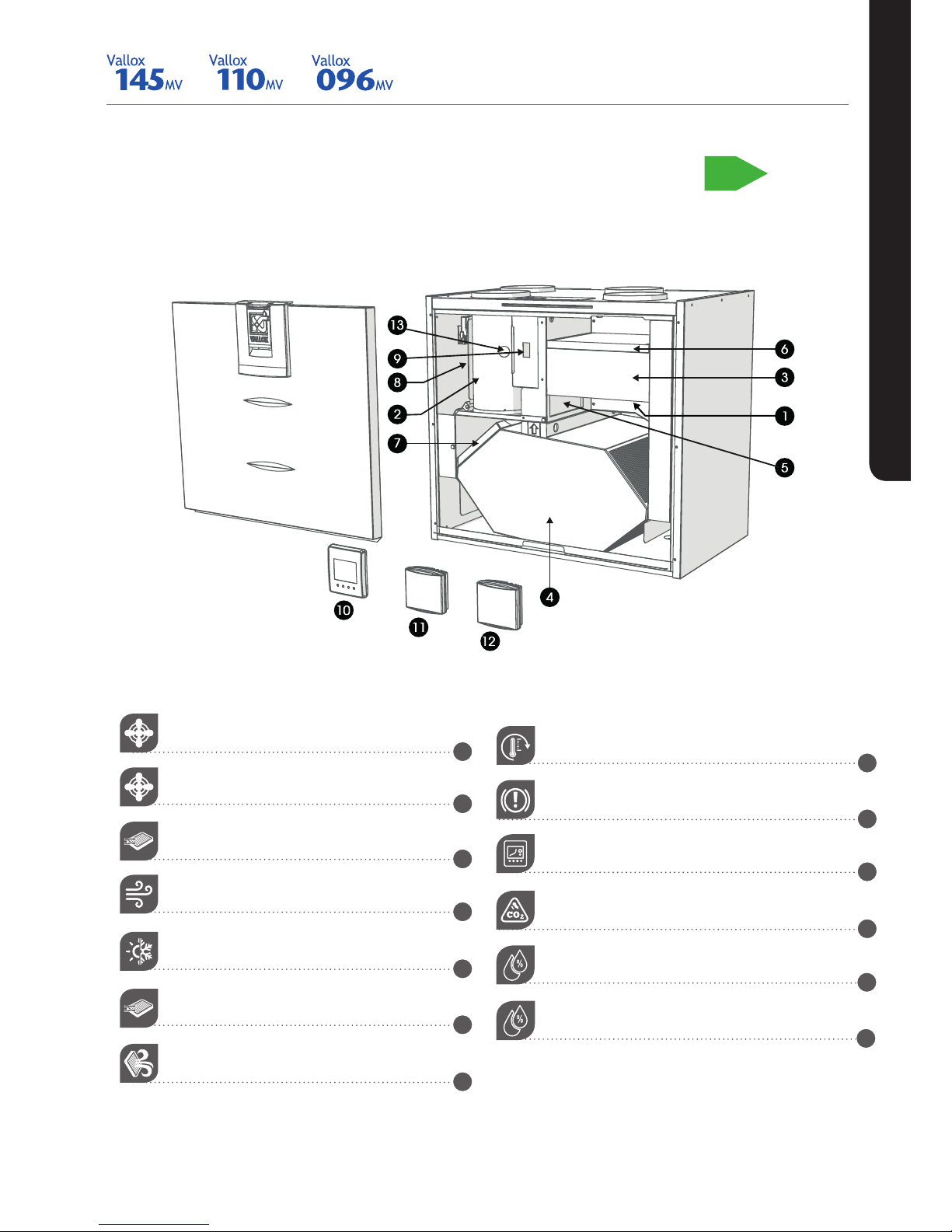

VALLOX 096 MV, VALLOX 110 MV, AND VALLOX 145

MV

R model in the

figure

Extract air fan (behind the protective cover)

Supply air fan (behind the extract air duct)

Supply air filter F7

Heat recovery cell

Bypass flap

Supply air filter G4

Extract air filter G4

P

O

I

S

T

O

I

L

M

A

N

L

Ä

M

M

Ö

N

T

A

L

T

E

E

N

O

T

O

N

V

U

O

S

I

H

Y

Ö

T

Y

S

U

H

D

E

L

U

O

K

K

A

A+

MAIN PARTS

INTRODUCTION

Post-heating radiator (behind the extract air duct)

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

Internal humidity sensor

8

9

10

11

12

1

2

3

4

5

6

7

13

Page 10

10

INTRODUCTION

1

5

3

6

8

9

13

7

2

4

12

11

10

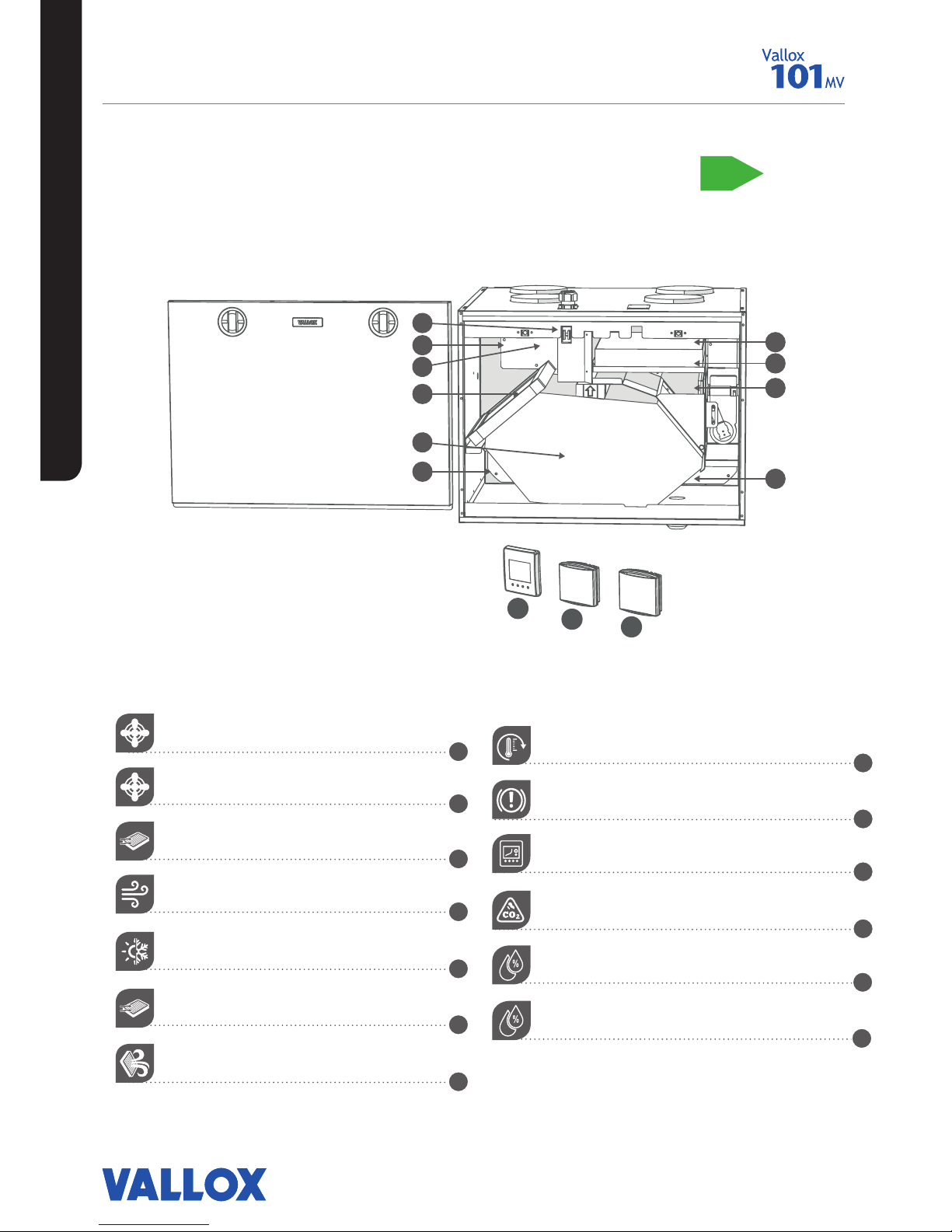

VALLOX 101 MV

R model in the

figure

Extract air fan

Supply air fan

Supply air filter F7

Heat recovery cell

Bypass flap

Supply air filter G4

Extract air filter G4

P

O

I

S

T

O

I

L

M

A

N

L

Ä

M

M

Ö

N

T

A

L

T

E

E

N

O

T

O

N

V

U

O

S

I

H

Y

Ö

T

Y

S

U

H

D

E

L

U

O

K

K

A

A+

MAIN PARTS

Post-heating radiator (in the supply air duct)

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

Internal humidity sensor

8

9

10

11

12

1

2

3

4

5

6

7

13

Page 11

11

© Vallox Oy - All rights reserved

INTRODUCTION

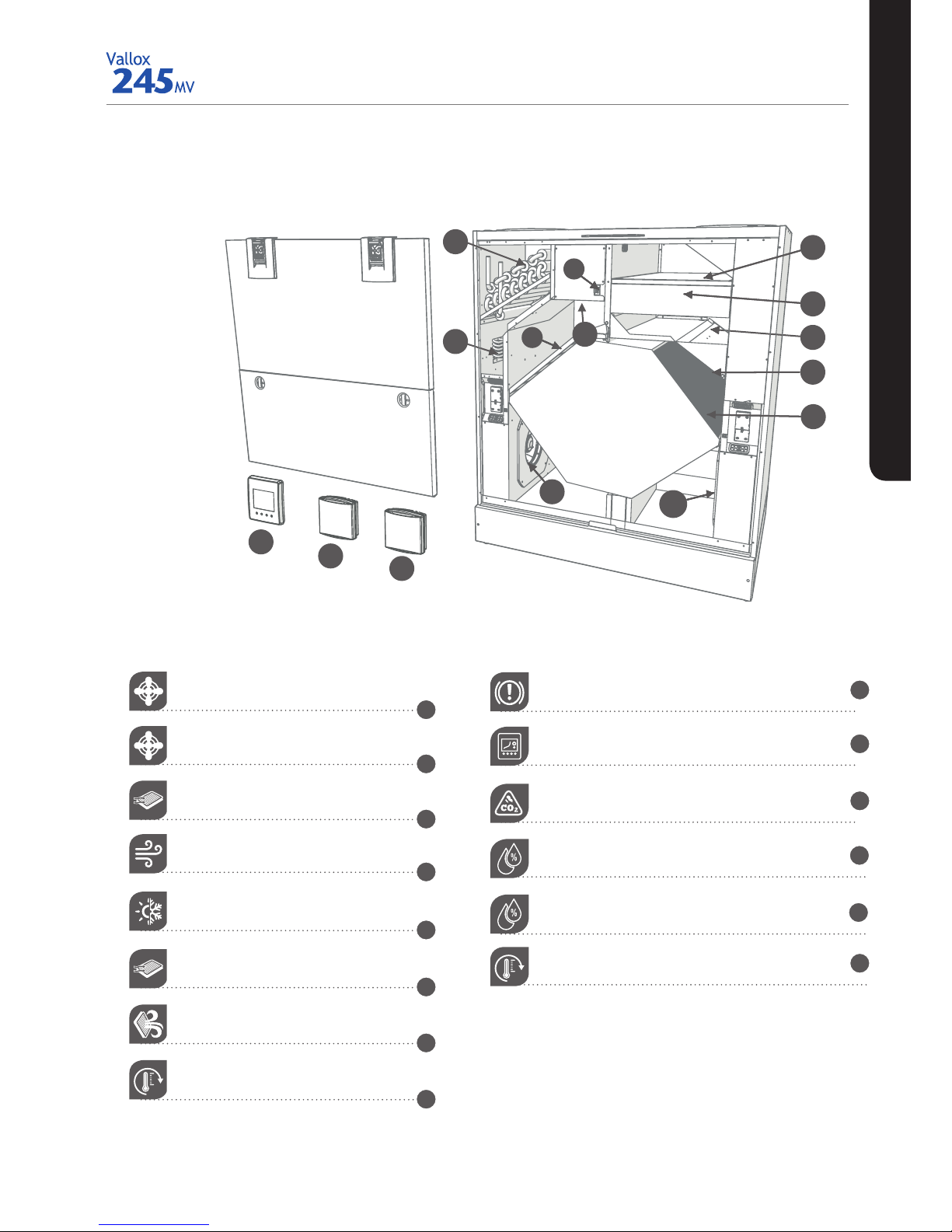

R model in the

figure

Supply air fan

Extract air fan

Supply air filter F7

Heat recovery cell, 2 pcs

Bypass flap

Supply air filter G4

Extract air filter G4

Post-heating radiator

5

1

4

8

7

9

4

3

5

14

1

4

8

7

9

4

3

2

6

13

10

11

12

Safety switch

Control panel

Carbon dioxide sensor

Humidity sensor

Internal humidity sensor (behind the electric box)

Post-heating liquid radiator

8

9

10

11

12

1

2

3

4

5

6

7

13

14

VALLOX 245 MV

Page 12

12

INTRODUCTION

TIP

The MyVallox Control control

panel automatically switches to

the sleep mode when the Sleep

time set in the Display settings

has elapsed. You can wake up

the control panel by pressing

any control panel button.

VENTILATION UNIT CONTROL

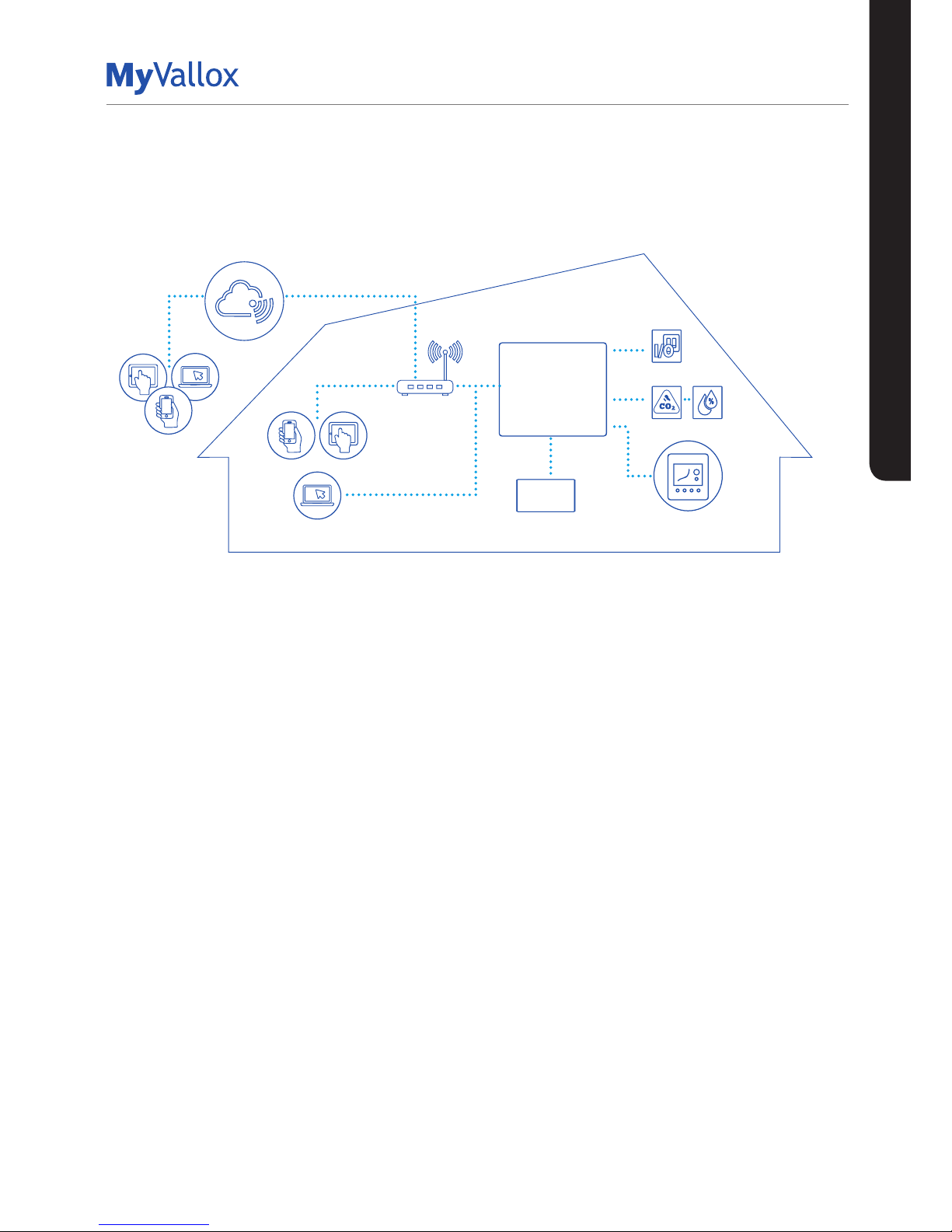

Connecting the ventilation unit to the

cloud service

The ventilation unit can be connected to the MyVallox

Cloud cloud service. The cloud service allows for controlling

ventilation remotely also, using e.g. a smartphone or tablet.

Also the unit software is updated automatically through

the cloud service. To connect to the cloud service, the

ventilation unit must be connected to the Internet via LAN

and registered with the cloud service. At the same time you

create a MyVallox Cloud account for yourself. Read more

about the service at www.myvallox.com.

Ventilation unit control options

Operation of the Vallox ventilation unit can be controlled by

the following means:

• Through the control panel installed in the building

• Through the MyVallox Home local area network

connection and the MyVallox Home/Cloud user interface.

• Through the MyVallox Cloud cloud service and the

MyVallox Home/Cloud user interface.

• Through a remote monitoring service or building

automation that uses voltage signals or Modbus

messages

In addition to the integrated humidity sensor, ventilation

can also be adjusted automatically using the optional

carbon dioxide and humidity sensors. When these are

used, ventilation remains optimal even when the dwelling is

unoccupied.

Each user can use the week clock to adjust the ventilation to

fit their individual lifestyle.

Page 13

13

© Vallox Oy - All rights reserved

INTRODUCTION

SYSTEM DESCRIPTION

Modbus

1

4

2

3

5

6

MyVallox Cloud

Vallox MV

MyVallox Control

1. Internet

2. WLAN

3. Router

4. WLAN/LAN

5. Additional switch

6. Sensors

VENTILATION UNIT CONTROL

Page 14

14

VENTILATION UNIT CONTROL

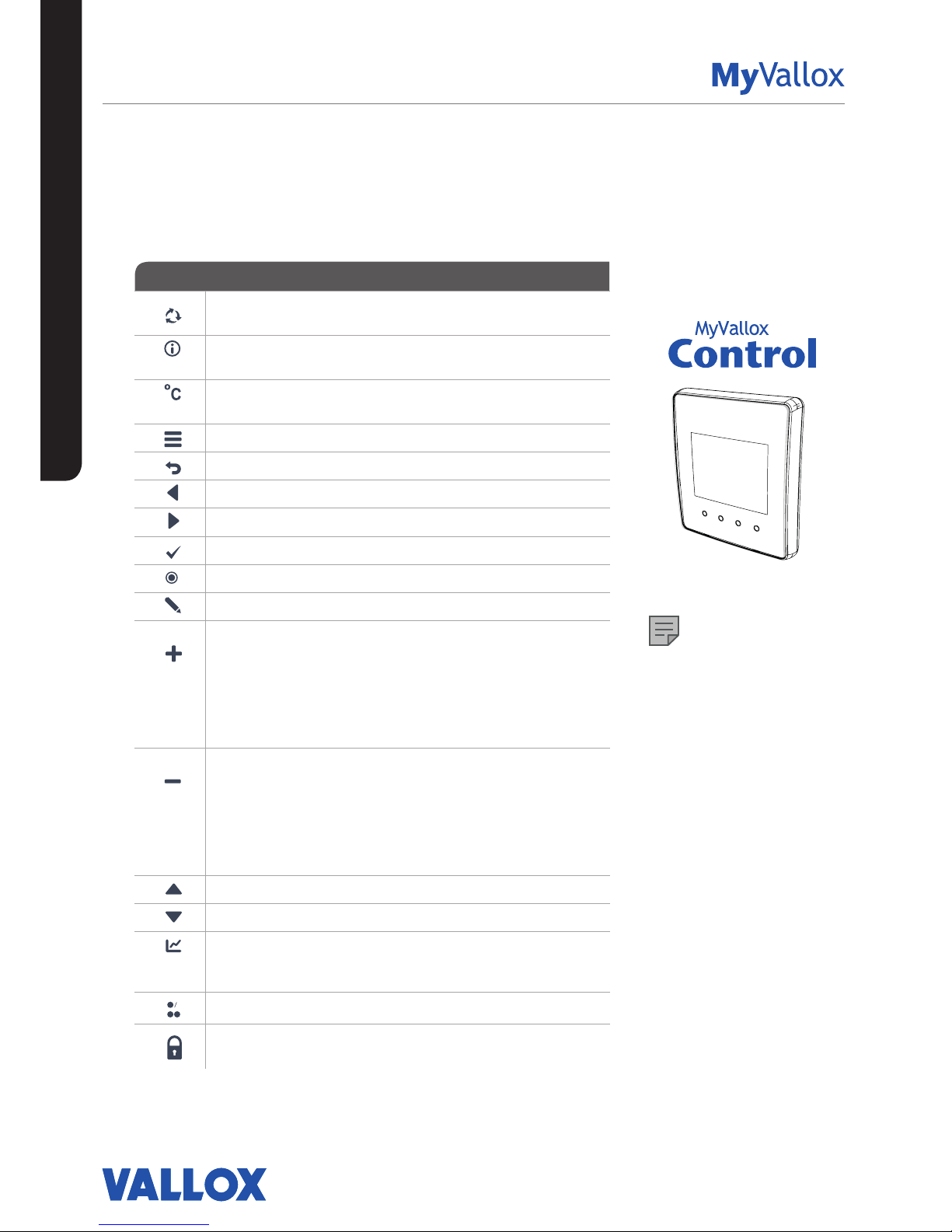

The Change profile button changes the ventilation profile or

the operating status used.

The Profile information button allows you to view the

currently active profile information.

The Temperature button displays temperature and sensor

information.

The Settings button opens the settings.

The Back button takes you backwards in the menu.

The Left arrow button takes you leftward in the menu.

The Right arrow button takes you rightward in the menu.

The OK button accepts the selected option.

The Select button selects an option from the list.

The Edit button allows you to edit settings.

The Plus button allows you to:

• Increase the value of the selected setting.

• Move to the next menu item.

• Move from a one-day view to a week view in the

temperature, relative humidity of air and carbon dioxide

level graphs.

The Minus button allows you to:

• Reduce the value of the selected setting.

• Return to the previous menu item.

• Move from a week view to a one-day view in the

temperature, relative humidity of air and carbon dioxide

level graphs.

The Up arrow button takes you upward in the menu.

The Down arrow button takes you downwards in the menu.

The Statistics button opens the temperature, relative

humidity of air and carbon dioxide level graphs (1 day or 1

week).

These icons indicate the hierarchy level of the settings.

This icon indicates when the feature is turned o at your user

level.

BUTTON DESCRIPTION

NOTE

The MyVallox Control control

panel contains the buttons

described in the following table.

You can press the graphical user

interface buttons by using the

ring-shaped buttons below the

control panel. The control panel

does not have a touch screen.

CONTROL PANEL BUTTONS

INTRODUCTION

Page 15

15

© Vallox Oy - All rights reserved

INTRODUCTION

STARTING UP AND SHUTTING DOWN THE UNIT

Unit software

We recommend that the latest software version be always

used. Check and download the latest version at

http://www.vallox.com or at cloud.vallox.com either before or

immediately after startup.

The current software version of the ventilation unit is shown

on the control panel display when the unit is connected to

the mains or factory settings are restored. Alternatively, the

current software version can be checked from the Diagnostics

display of the Maintenance menu.

Download the software into the unit using the USB Micro-B

port of the control panel.

Starting the unit

If you are starting the ventilation unit for the first time or after

a maintenance procedure, first connect it to the mains. This

will start the unit. During start-up, the diagnostics display

appears for a few seconds. Once the download is complete,

a profile display opens showing the latest saved status of the

unit.

If the ventilation unit was turned o from the control panel

(see Turning the unit o), you can start it by pressing any

control panel button.

Turning the unit o

To turn the ventilation unit o:

1. Select Turn unit o using the arrow buttons.

2. Select OK.

3. Press OK to confirm the selection. The ventilation unit

has now been turned off.

IMPORTANT

It is recommended that the ventilation be kept turned on

without disruptions.

NOTE

The first starting of the unit may

take a while, because of the

software version check.

Page 16

16

SETUP WIZARD

BASIC SETTINGS

SETUP WIZARD

SETUP WIZARD

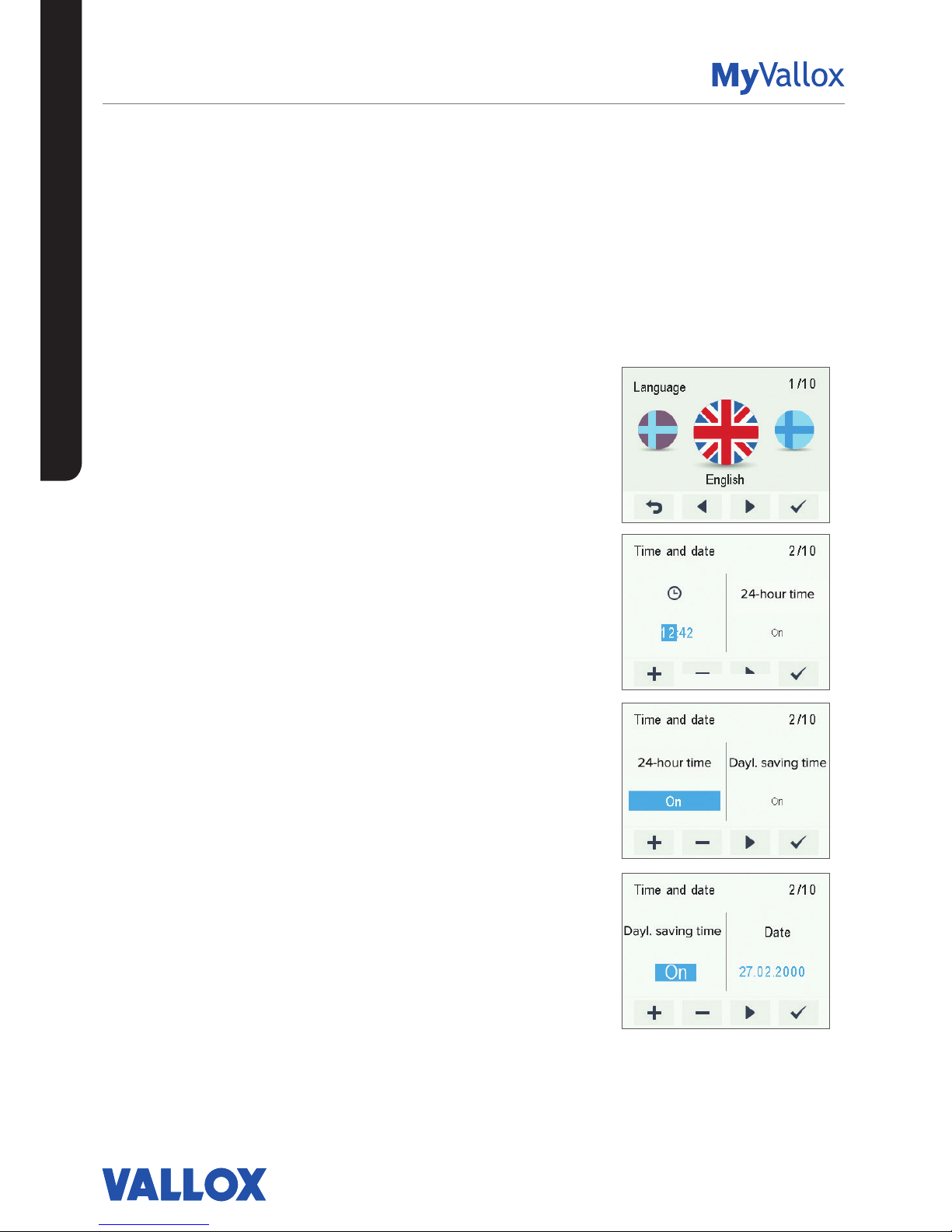

The following settings will be configured during the setup of the

ventilation system:

• user interface language

• time and date

• system administrator lock code

• parental controls, if turned on

• fan settings

• user profile settings, such as the temperature.

The qualified ventilation installer must complete the fan settings in

accordance with the ventilation plan. Do not change these settings.

1. Start the Vallox ventilation unit.

2. When the unit is started for the first time, the language menu

opens on the control panel display. Select OK.

3. The setup wizard is launched.

Select the language

1. Use the arrow buttons to select the language.

2. Select OK.

3. The language has now been set, and the control panel will

move on to the time settings.

Set the time

1. Use the Plus and Minus buttons to set the hours.

2. Select Right arrow.

3. Use the Plus and Minus buttons to set the minutes.

4. The time is now set.

5. Proceed to the next phase by selecting Right arrow.

Set the 24- or 12-hour clock

The 24-hour clock is used by default.

To use the 12-hour clock:

1. Select Minus. The 24-Hour time setting value is changed to O.

2. Proceed to the next phase by selecting Right arrow.

Set the automatic daylight saving time

By default, the automatic daylight saving time is on.

To use the manual daylight saving time setting:

1. Select Minus. The Dayl.saving time setting value is changed to O.

2. The manual daylight saving time setting is now on.

3. Proceed to the next phase by selecting Right arrow.

Page 17

17

© Vallox Oy - All rights reserved

SETUP WIZARD

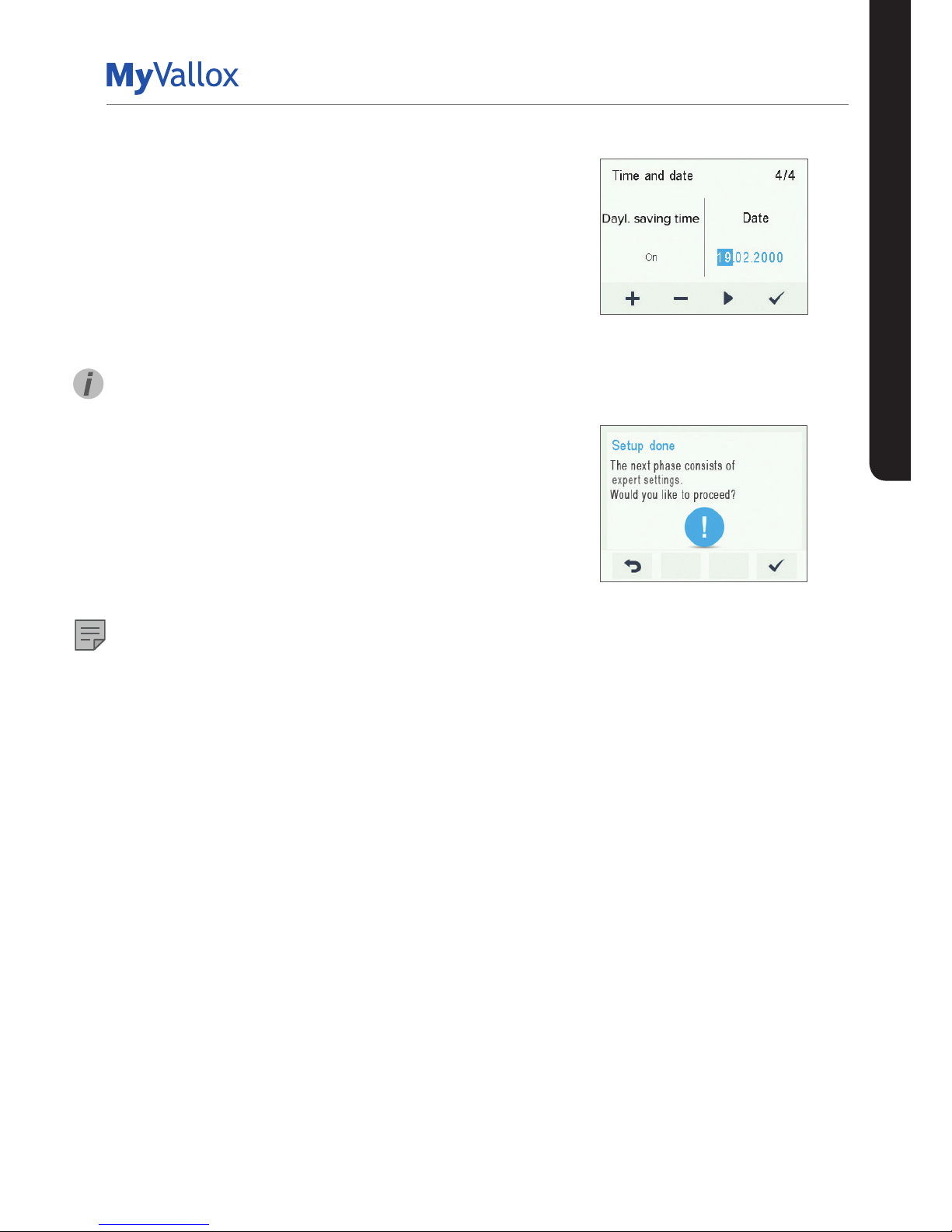

Set the date

1. Use the Plus and Minus buttons to set the date.

2. Select Right arrow.

3. Use the Plus and Minus buttons to set the month.

4. Select Right arrow.

5. Use the Plus and Minus buttons to set the year.

6. Select OK.

7. The date is now set.

TIP

You can browse the Time and date settings by using the

Right arrow button.

Completing the setup

Once you have completed the basic settings for the setup,

select OK to proceed to the expert settings of the ventilation

unit.

Select Back to use the ventilation unit on factory settings

and complete the configuration of the expert settings later.

NOTE

Expert settings are settings that use e.g. airflow

measurement equipment.

BASIC SETTINGS

Page 18

18

EXPERT SETTINGS

Lock code and access rights

NOTE

The default lock code is 0000, i.e. the lock code inquiry is

turned o.

1. Enter the first digit of the lock code using the Up arrow and

Down arrow buttons. Proceed to the next digit by selecting

Right arrow.

2. Set the remaining digits of the lock code in the same way.

3. Select OK.

4. The lock code is now set.

User level

There are three user levels:

• Extensive - At the extensive user level, users can access all

ventilation unit settings.

• Normal - At the normal user level, access to some menus is

restricted.

• Limited - At the limited user level, users have access only to

the basic functions of the ventilation unit.

For more information on user levels, see Chapter “User level

diagrams”.

1. Use the Plus and Minus buttons to set the user level.

2. The user level is now set.

3. Proceed to the next phase by selecting Right arrow.

Parental controls

Parental controls lock the control panel so that no damage

can be done to the ventilation unit by random pressing of the

control panel buttons.

1. By default, the parental controls are turned off. Use the Plus

and Minus buttons to turn the parental controls on.

2. Select OK.

3. The parental controls are now set.

TIP

You can browse the Lock code and access rights settings with

the Right arrow button.

NOTE

The access code of the parental controls cannot be changed.

The access code is always 1001.

Parental controls access code:

1 0 0 1

Enter the new access code

here:

SETUP WIZARD

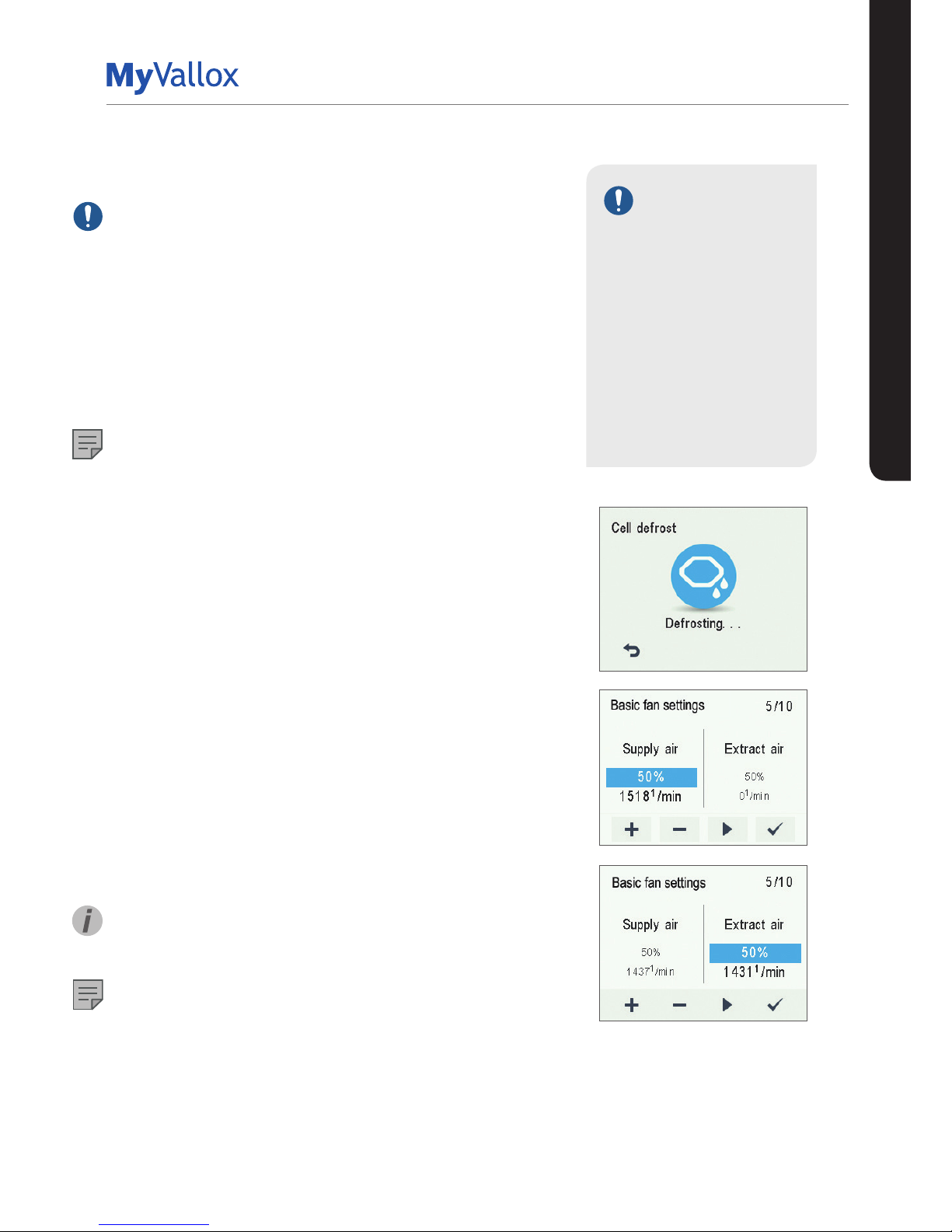

Page 19

19

© Vallox Oy - All rights reserved

SETUP WIZARD

EXPERT SETTINGS

Basic fan settings

IMPORTANT

Adjust the air flows according to the values specified in the

ventilation plan. It is recommended that the air flows be

adjusted without having to choke the air flows at the valves.

This is the most energy-ecient set up.

First, set both values as close to the ideal value as possible

by looking at the supply and extract air fan curves. If the

ratio between the air flows is very high at first, the ventilation

unit may have to carry out extra defrosting cycles in sub-zero

temperatures, thus making adjustment of the air flows more

complicated. Check the air flows by measuring them at the

valves, and fine-tune the percentage values as required.

NOTE

If the outside air is extremely cold (below -10°C on an

aluminium cell or below -3°C on a plastic cell), the ventilation

unit may have to defrost the heat recovery cell. If this

happens, the Defrosting icon will be displayed on the control

panel. The air flows cannot be adjusted during defrosting.

Adjusting the supply and extract air flows

1. Use the Plus and Minus buttons to set the supply air fan

ratio as a percentage of the maximum output ratio. The

fan speed (1/min) will change accordingly.

2. Measure and adjust the supply air flows from the valves.

3. Press the Right arrow button.

4. Use the Plus and Minus buttons to set the extract air fan

ratio as a percentage of the maximum output ratio. The

fan speed (1/min) will change accordingly. Measure and

adjust the extract air flows from the valves.

5. Select OK. Supply and extract air flow settings are now

complete.

6. Record the set percentages in the measurement log.

Do not change the output ratio between the supply and

extract air fans once the settings are complete. The same

ratio is also used in the Away and Boost profiles.

TIP

You can browse the Basic fan settings by using the Right

arrow button.

NOTE

If the use of the ventilation unit has been started before air

flow adjustment, we recommend that the factory settings of

the ventilation unit be restored before adjustment is started

(see “Save and restore settings”). This ensure that the unit

settings are optimal for adjusting the air flows and that any

settings made during the adjustment are saved as setup

settings. Any later changes will be saved as user settings.

Both the setup and user settings can be restored later even

if the settings had been modified later.

IMPORTANT

The supply and extract air

settings have been completed

by a specialist during setup

of the ventilation unit. These

settings should be changed

only when the ventilation

unit is reconfigured, and not

at any other time. Changing

the ventilation settings so

that overpressure is created

can result in damage to the

structures of the building.

Page 20

20

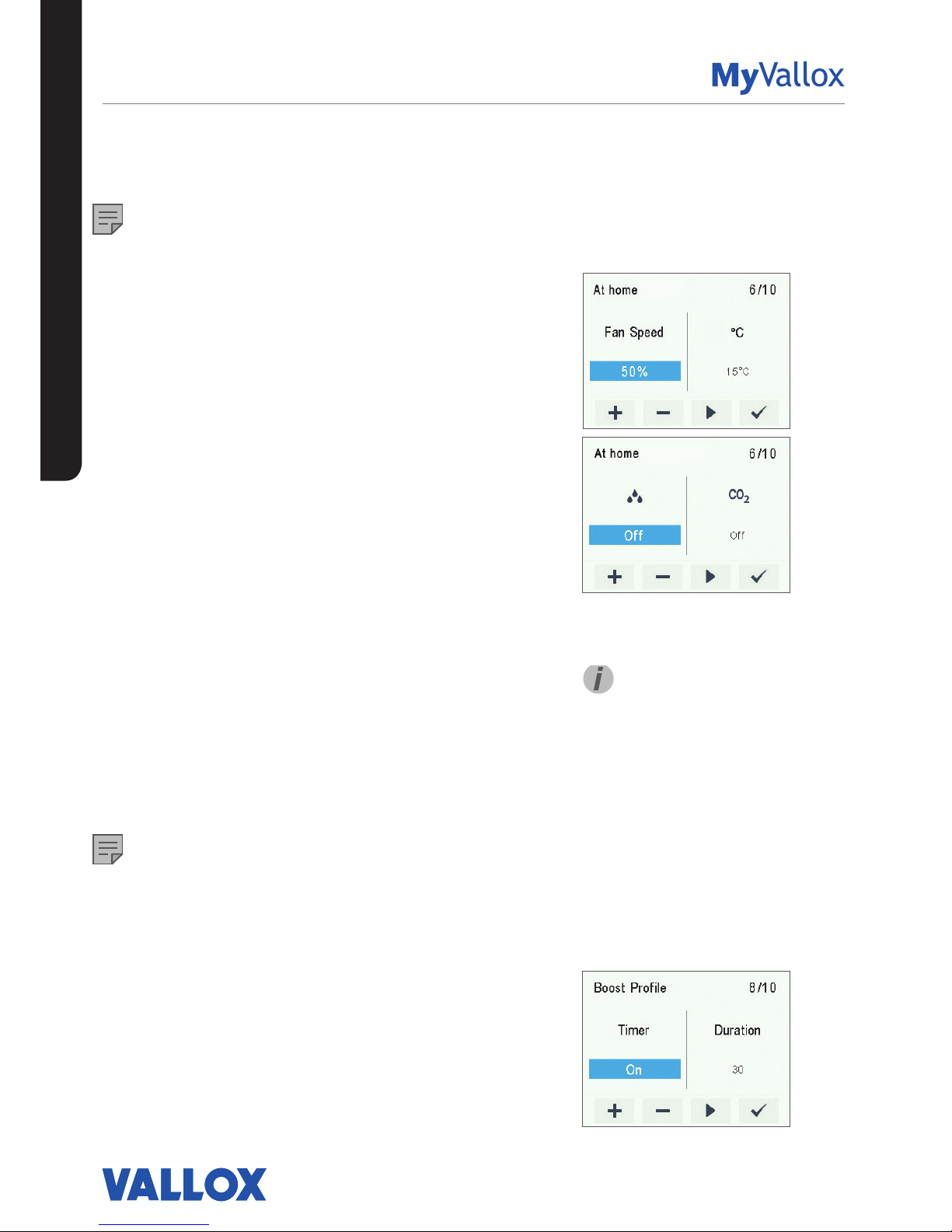

SETUP WIZARD

PROFILE SETTINGS

NOTE

By default, the At home profile uses the higher basic ventilation

fan speed. We recommend that this basic ventilation setting be

used with the At home profile. Once you have set the fan speed

for the At home profile, the fan speed for the Away profile will

by default be set to -30% of the At home profile fan speed.

We recommend that the default fan speed settings be used.

However, the settings can be changed as required.

At home and Away profiles

To set the ventilation settings of the profiles:

1. Use the Plus or Minus buttons to set the profile fan speed

as a percentage of the maximum output ratio.

2. The fan speed is now set for the profile.

3. Proceed to the next phase by selecting Right arrow.

4. Use the Plus or Minus buttons to set the desired supply air

temperature for the profile. You can adjust the temperature

in the range +10°C ... +25°C.

5. The profile supply air temperature is now set.

6. Proceed to the next phase by selecting Right arrow.

7. Use the Plus and Minus buttons to turn the automatic fan

speed control based on relative humidity of air on or off.

8. The automatic fan speed control, based on the relative

humidity of air, is now set.

9. Proceed to the next phase by selecting Right arrow.

10. Use the Plus and Minus buttons to turn the automatic fan

speed control based on carbon dioxide content on or off.

11. The automatic fan speed control, based on the carbon

dioxide level, is now set.

12. Select OK.

13. Proceed to the settings of the next profile by selecting Right

arrow.

NOTE

Once you have set the fan speed for the At home profile, the

fan speed for the Boost profile will by default be set to +30%

of the At home profile fan speed. It is recommended that this

fan speed setting be used for the Boost profile. However, the

setting can be changed as required.

Boost profile

The fan speed, supply air temperature, and the automatic fan

speed control (based on either relative humidity of air or carbon

dioxide level) is set for the Boost profile in the same way as for

the At home and Away profiles. The Boost profile also has a

timer setting.

TIP

You can browse the At home

profile settings with the Right

arrow button.

EXPERT SETTINGS

Page 21

21

© Vallox Oy - All rights reserved

SETUP WIZARD

EXPERT SETTINGS

1. Use the Plus and Minus buttons to turn the profile timer

function on or off. The options are:

• On — When the timer is on, the Boost profile is used only for the

period specified in the timer.

• O — When the timer is off, the Boost profile is used until the

profile is changed, either manually or automatically by the week

clock.

2. Proceed to the next phase by selecting Right arrow.

3. Use the Plus and Minus buttons to set the profile timer duration

in minutes.

4. Select OK.

5. Proceed to the settings of the next profile by selecting Right

arrow.

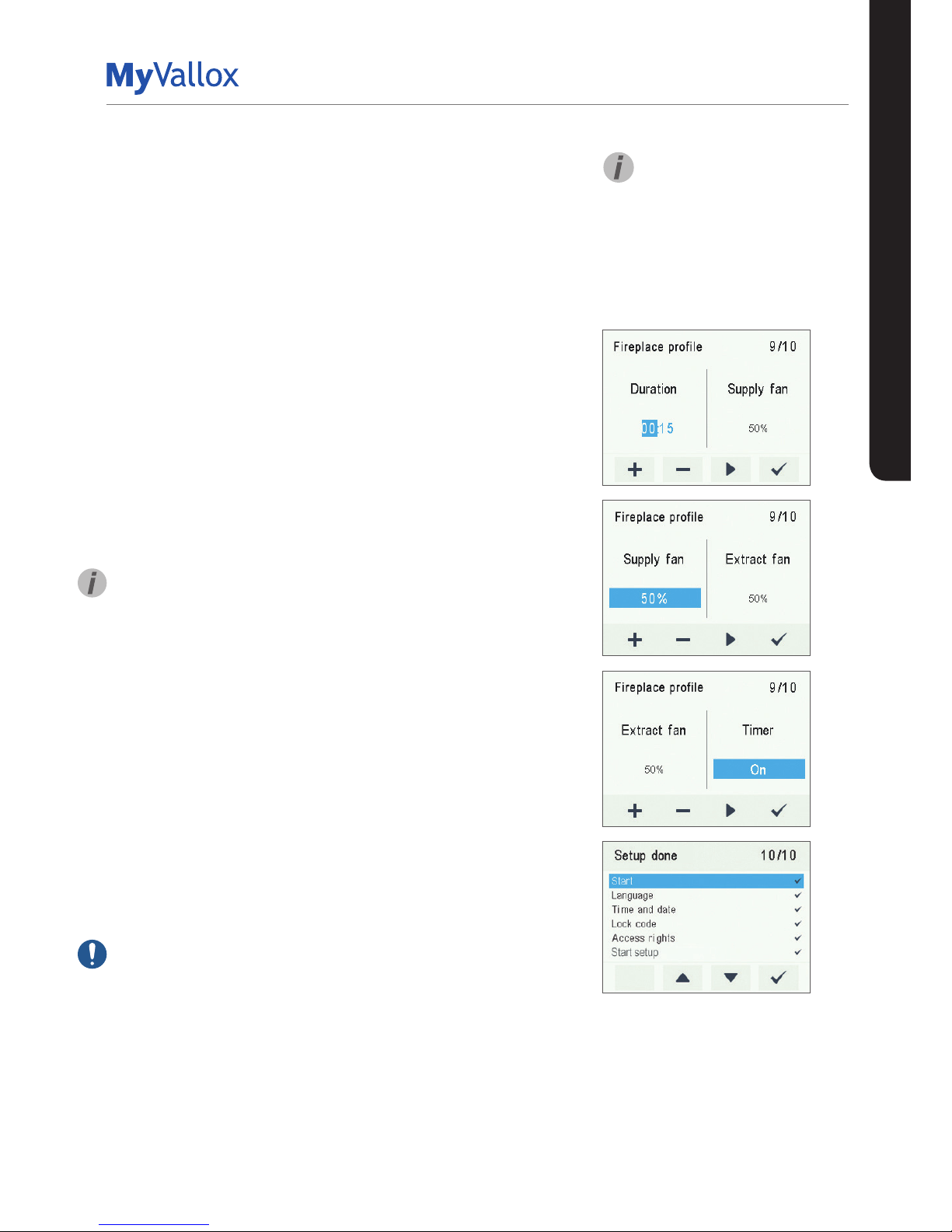

Fireplace profile

1. Use the Plus and Minus buttons to set the Fireplace profile

timer duration in minutes.

2. The Fireplace profile timer duration is now set.

3. Proceed to the next phase by selecting Right arrow.

4. Use the Plus and Minus buttons to set the Fireplace profile’s

supply air fan speed as a percentage of the maximum output

ratio.

TIP

It is recommended that a higher supply air fan speed be used in

the fireplace profile to create overpressure in the ventilation zone.

Reducing the extract air fan speed is not recommended.

5. The supply air fan speed of the Fireplace profile is now set.

6. Proceed to the next phase by selecting Right arrow.

7. Use the Plus and Minus buttons to set the extract air fan speed

of the Fireplace profile as a percentage of the maximum output

ratio.

8. The extract air fan speed of the Fireplace profile is now set.

9. Proceed to the next phase by selecting Right arrow.

10. Use the Plus and Minus buttons to turn the profile timer

function on or off. The options are:

• On — When the timer is on, the Fireplace profile is used only for the

period specified by the timer.

• O — When the timer is off, the Fireplace profile is used until the

profile is changed, either manually or automatically by the Week

clock.

11. The profile timer function is now set.

12. Select OK.

IMPORTANT

Do not turn the timer function o if there is no timer in the external

fireplace switch.

Finishing the setup

Once you have completed all phases of the setup, finish up the

setup as follows:

1. To change any of the set values, use the arrow buttons to

return to the desired line and then press OK.

2. When you are satisfied with the settings, use the arrow buttons

to select Start and then press OK.

TIP

You can browse the settings

of the Boost or the Fireplace

profile by using the Right arrow

button.

Page 22

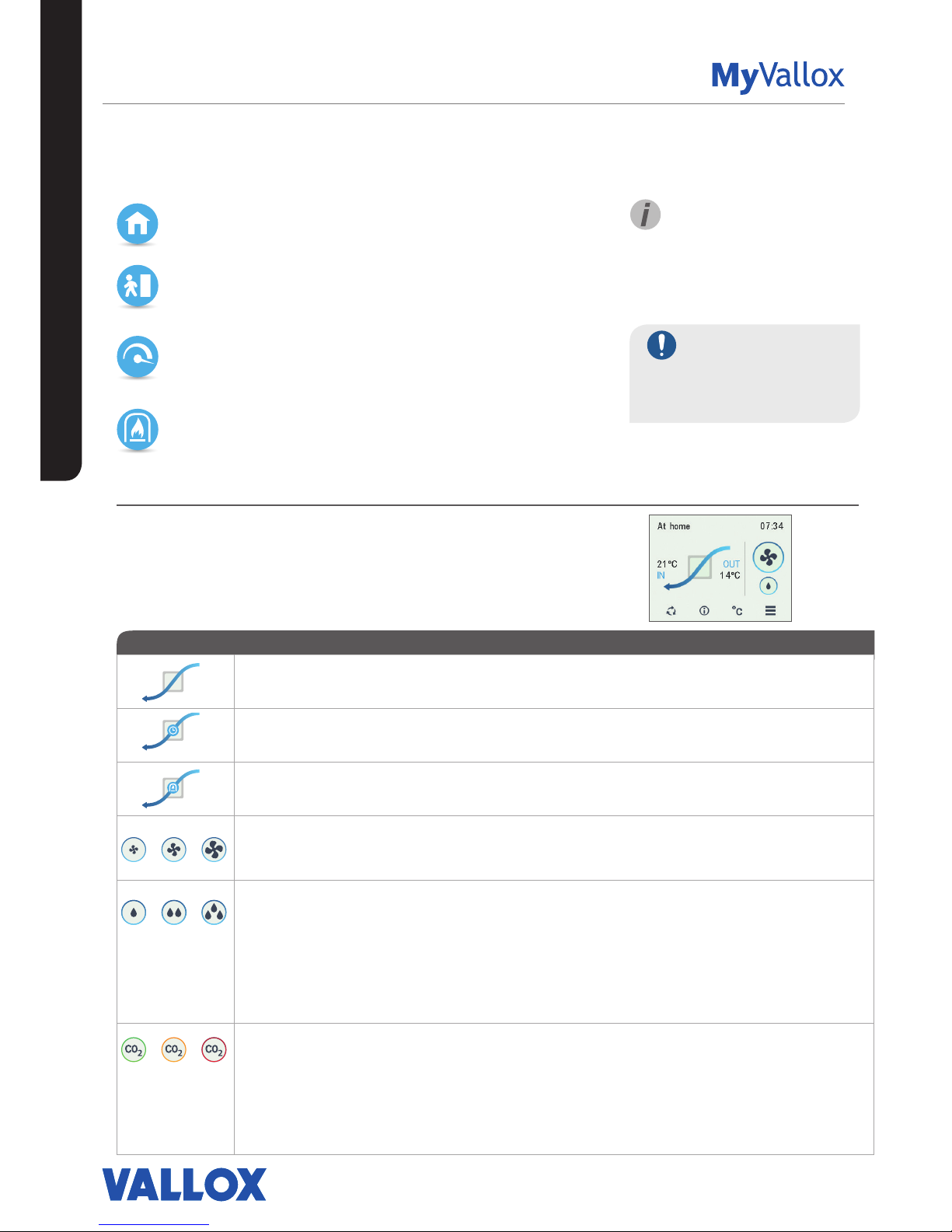

22

USING THE UNIT

FOUR VENTILATION UNIT PROFILES

At home

Use this ventilation profile when the dwelling or the premises

are occupied.

Away

Use this ventilation profile when the dwelling or premises are

unoccupied, e.g. during a trip or other long absence.

Fireplace profile

Use this ventilation profile when, for example, you are making

a fire in the fireplace. This profile is primarily used to create

momentary overpressure in the apartment.

Boost

Use this profile to increase the ventilation rate, e.g. when there

are more people than usual in the dwelling or elsewhere on the

premises.

Symbols for ventilation profiles

The following symbols are used on the main displays of the profiles:

Table 2. Profile symbols

SYMBOL DESCRIPTION

The profile in use is either the At home, Away, or Boost profile. The week clock is turned o.

The profile in use is either the At home, Away, or Boost profile. The week clock is on.

The Fireplace profile is used. The week clock might be turned on.

These symbols indicate the currently active profile. The smallest fan icon indicates that the Away

profile is in use, and the largest fan icon indicates that the Boost profile is being used.

Droplet symbols indicate the relative humidity of air. The symbols are:

• One drop — The humidity sensor has been successfully installed and the relative humidity of

air is normal.

• Two drops — The relative humidity of air is slightly higher than normal. The fan speed will be

automatically increased if automatic adjustment is allowed.

• Three drops — The relative humidity of air is significantly higher than normal. The fan speed

will be automatically increased if automatic adjustment is allowed.

These symbols indicate the carbon dioxide level in the air. The colour codes are:

• Green — The carbon dioxide sensor has been installed and the carbon dioxide level is

normal.

• Orange — The carbon dioxide level is slightly higher than normal. The fan speed will be

automatically increased if automatic adjustment is allowed.

• Red — The carbon dioxide level is significantly higher than normal. The fan speed will be

automatically increased if automatic adjustment is allowed.

IMPORTANT

Prolonged overpressure

can result in damage to the

structures of the building.

USING THE UNIT

TIP

Using the At home, Away, and

Boost profiles according to

need helps to save energy.

VENTILATION PROFILES

Page 23

23

© Vallox Oy - All rights reserved

USING THE UNIT

VENTILATION PROFILES

CHANGING THE PROFILE

1. Press the Change profile button until the desired ventilation

profile icon appears on the display.

2. Wait until the main display of the ventilation profile appears.

3. The ventilation profile has now been changed.

Browsing the information of the At home,

Away, and Boost profiles.

To view the profile settings:

1. Open the main display of the profile you wish to view.

2. Select Profile information.

The following information is shown on the first information

display of the profile:

• Supply air — Indicates the temperature of the air blown into

the building and its set value (in brackets), if the supply air is

warmer than the set value.

• Outdoor air — Indicates the outdoor temperature.

• Fan speed — Indicates the fan speed. If the automatic fan

speed boost is turned on, the set value is shown in brackets

first followed by the actual fan speed.

• Cell status — Indicates the status of the ventilation unit heat

recovery cell. The status options are:

• Heat recovery — The heat recovery cell heats the air streaming

in from outdoors.

• Cooling — The heat recovery cell cools the air streaming in from

outdoors.

• Cell bypass — The inflowing air bypasses the heat recovery cell.

• Defrosting — The heat recovery cell is being defrosted.

3. Proceed to the next phase by selecting Right arrow.

The next information display of the profile shows the following

information:

• Humidity — Indicates the highest relative humidity of air

measured by the sensors.

• Carbon dioxide — Indicates the highest carbon dioxide level

measured by the sensors.

• Replace filters — Indicates the next recommended filter

replacement date.

• Time in operation — Indicates how long the device has been

running.

Page 24

24

USING THE UNIT

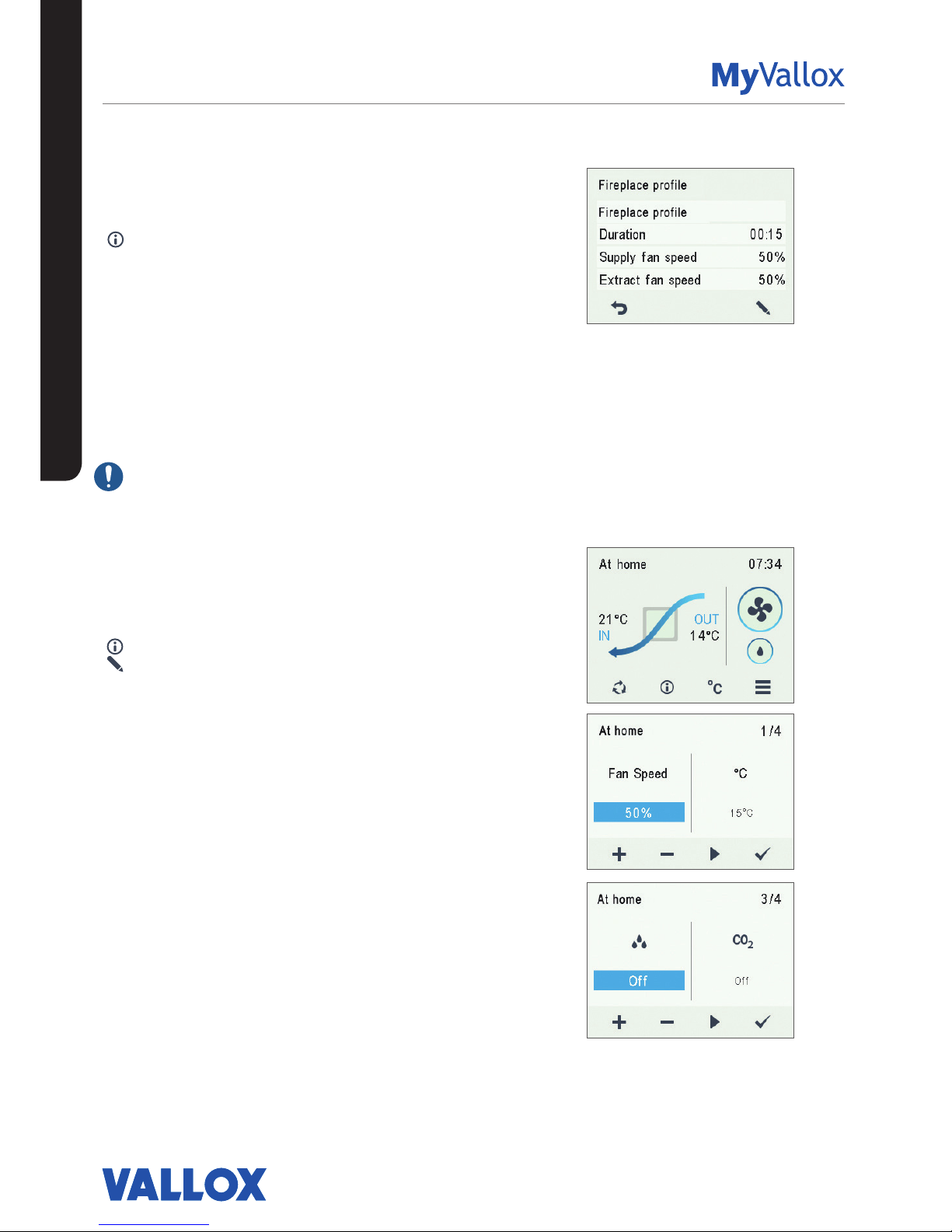

Viewing the Fireplace profile information

1. Open the main display of the Fireplace profile:

2. Select Profile information.

3. The information display shows the following information:

• Duration — Indicates the duration of enhanced

ventilation when the Fireplace profile is activated. The

value is expressed in hours and minutes.

• Supply fan speed — Indicates the percentage of the

supply air fan speed relative to the maximum speed.

• Extract fan speed — Indicates the percentage of the

extract air fan speed relative to the maximum speed.

Modifying and saving the profile settings

IMPORTANT

The unit does not automatically save any settings, not even

those that are currently in use. Unless saved, settings may

be lost during a power cut, for example. To save the settings,

select Expert settings > Save and restore settings.

Modifying profile settings

1. Open the main display of the profile you wish to view.

2. Select Profile information.

3. Select Edit.

4. Make the desired changes as instructed in the section

Setup wizard > Profile settings.

Timer functions of the Boost and Fireplace

profiles

In addition, the timer function can be modified in the Boost

and Fireplace profiles. See Setup wizard -> Profile settings.

VENTILATION PROFILES

Page 25

25

© Vallox Oy - All rights reserved

USING THE UNIT

TEMPERATURES AND SENSORS

Indoor air temperature graph for the

past 24 hours. The outside and supply

air values are shown on a similar display.

You can view the graph for a week or for

a single day.

Indoor air

Outdoor air

Supply air

Exhaust air

1 day

1 week

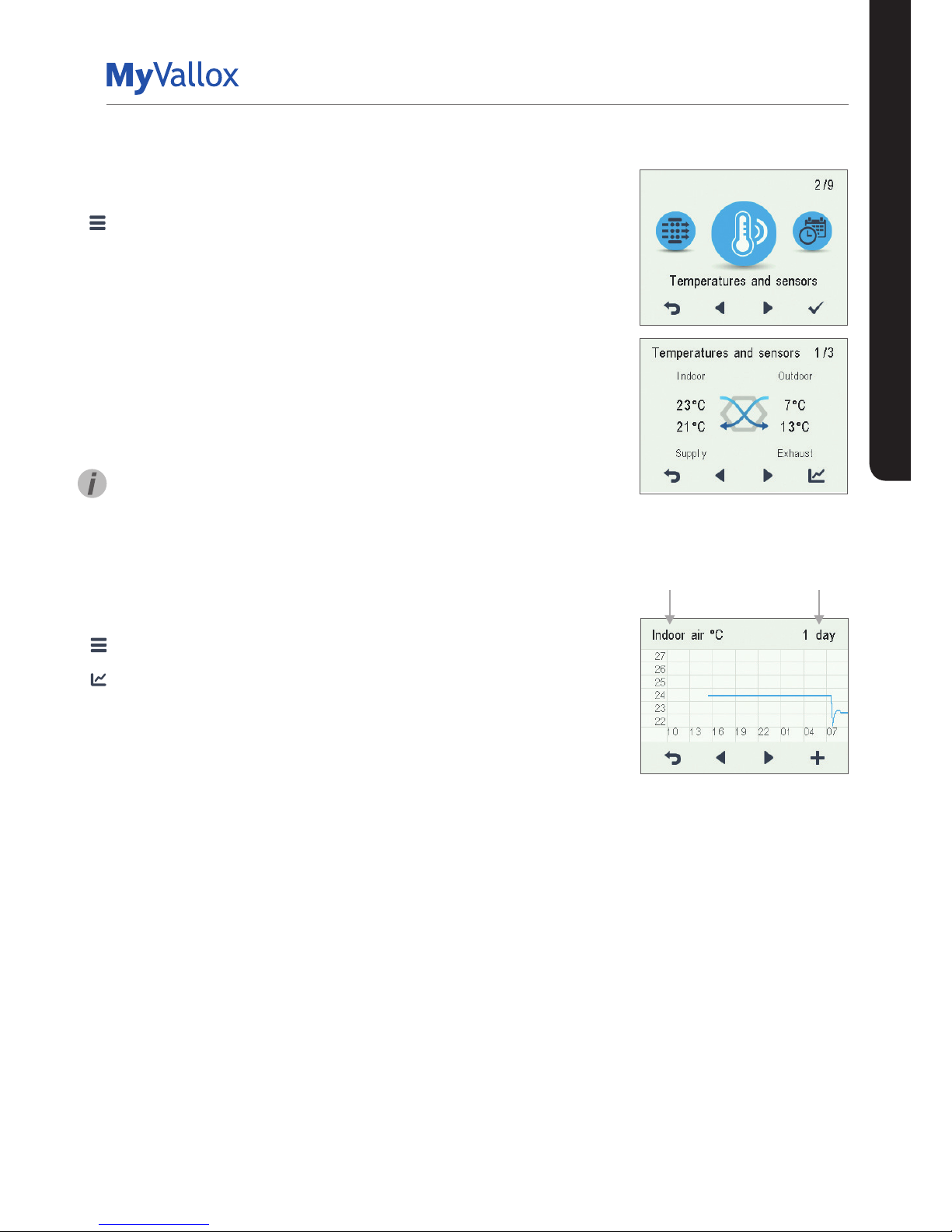

Viewing temperature data

1. Select Settings > Temperatures and sensors.

2. Select OK.

The summary display of temperatures and sensors shows

the following information:

• Indoor — Indicates the temperature of the air flowing into

the unit to be removed from the premises.

• Outdoor — Indicates the temperature of the air flowing

into the unit from outside.

• Supply — Indicates the temperature of the air flowing

into the premises from the unit.

• Exhaust — Indicates the temperature of the exhaust air

flowing outdoors from the unit.

TIP

The temperature and sensor data can also be viewed by

pressing the temperature button on the profile display.

Viewing temperature statistics

1. Select Settings > Temperatures and sensors.

2. Select OK.

3. Select Statistics.

4. A graph appears on the display showing the indoor air

temperature over the past 24 hours.

5. Use the Plus and Minus buttons to alternate between

weekly and daily statistics.

6. Use the arrow buttons to view outdoor air, supply air, and

exhaust air temperature statistics.

7. On each display, use the Plus and Minus buttons to

alternate between weekly and daily statistics.

8. To exit the menu, press the Back button.

Page 26

26

USING THE UNIT

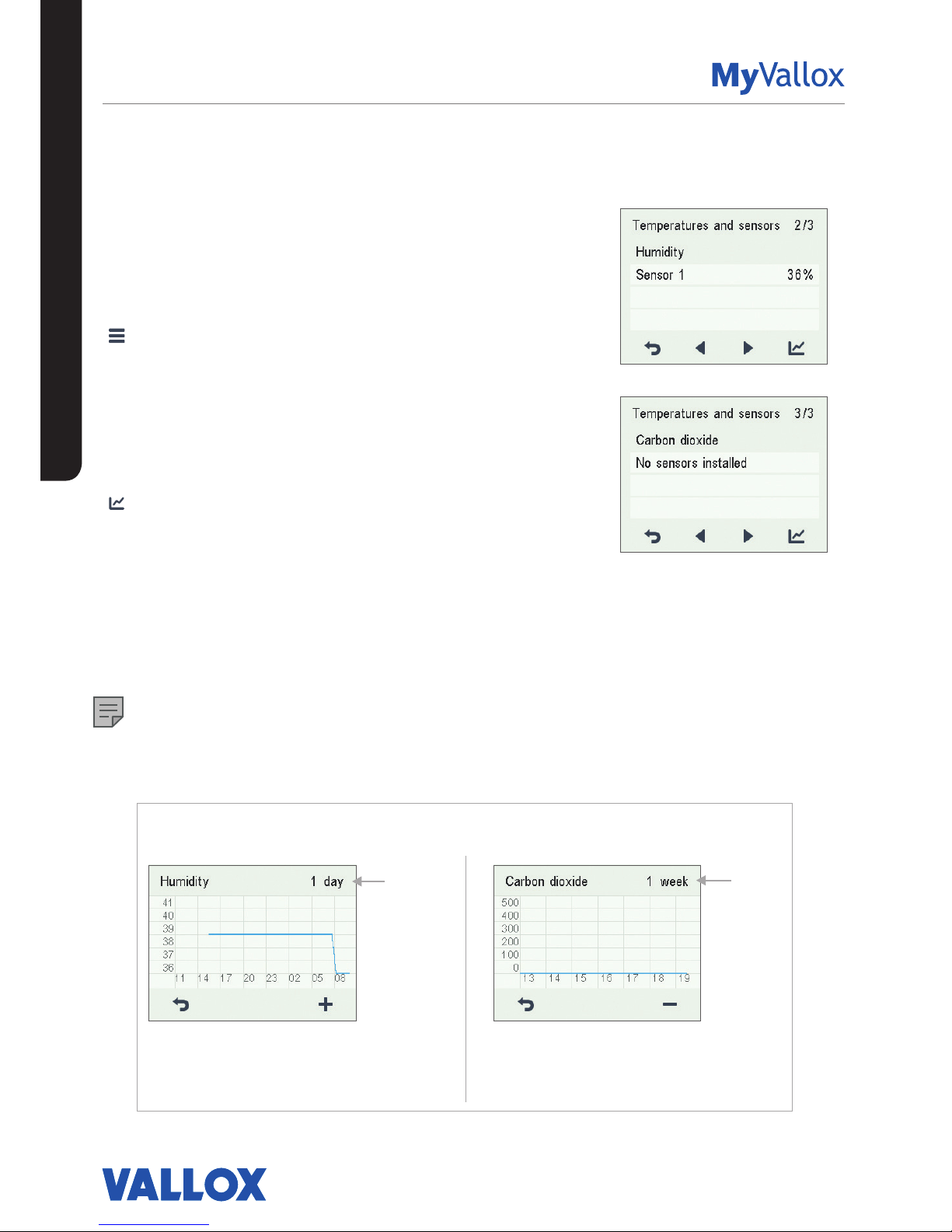

Viewing the relative humidity of air and

carbon dioxide levels measured by the

sensors

To browse levels measured by individual sensors:

1. Select Settings > Temperatures and sensors.

2. Select OK.

3. Use the arrow buttons to switch from the summary

display of Temperatures and sensors to view the relative

humidity of air and carbon dioxide levels measured by

the humidity and carbon dioxide sensors.

To browse statistics for relative humidity of air and carbon

dioxide levels:

1. Select Statistics next to the sensor group you wish to

view.

2. A graph opens on the display showing the relative

humidity of air and carbon dioxide levels recorded over

the past 24 hours by the sensor with the highest values.

3. Use the Plus and Minus buttons to alternate between

weekly and daily statistics.

4. To exit the menu, press the Back button.

NOTE

For more detailed instructions, go to

www.vallox.com

Relative humidity of air statistics for the past 24 hours.

You can view the graph for a week or for a single day.

Carbon dioxide level statistics for the past week. You

can view the graph for a week or for a single day.

1 day

1 week

Relative humidity of air and carbon dioxide level statistics

1 day

1 week

TEMPERATURES AND SENSORS

Page 27

27

© Vallox Oy - All rights reserved

USING THE UNIT

SETTINGS

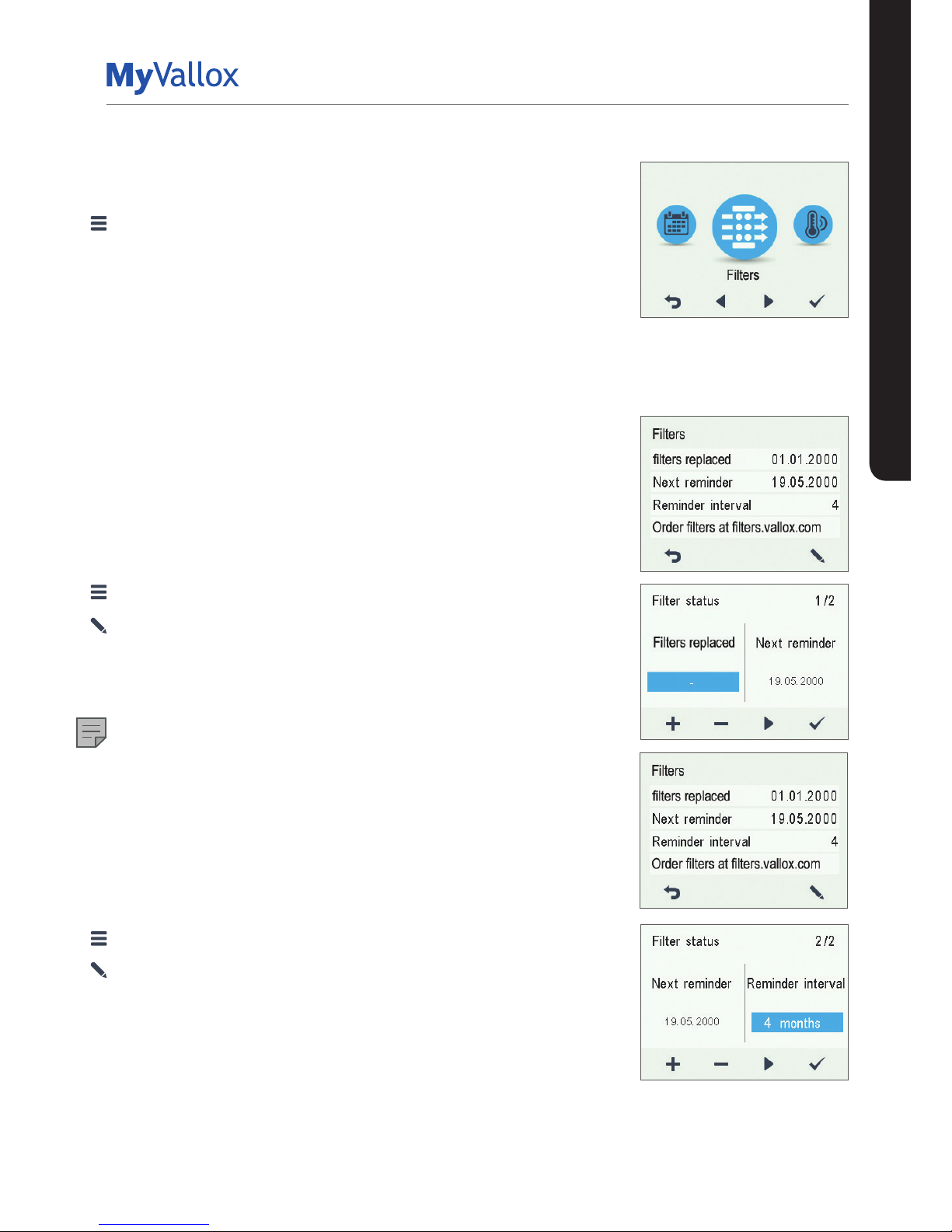

FILTER SETTINGS

1. Select Settings > Filters.

2. Select OK.

3. The summary display of filter replacement shows the

following information:

• Filters replaced — Indicates the date when the filters were

last replaced.

• Next reminder — Indicates the date when a reminder to

replace the filters will next be shown.

• Reminder interval — Indicates the filter replacement interval

in months.

Setting the date the filters were last

replaced

Instructions for replacing the filters are provided in the

Maintenance section.

After replacing the filters, enter the replacement date.

1. Select Settings > Filters.

2. Select OK.

3. Select Edit.

4. Select Plus on the Filter replacement display. The Last

replaced field now reads Today.

5. Select OK.

NOTE

Based on the set reminder interval, the unit will automatically

set the service to provide a reminder to replace the filters at

the due time.

Setting the Filter replacement reminder

interval

1. Select Settings > Filters.

2. Select OK.

3. Select Edit.

4. Select Right arrow.

5. Use the Plus and Minus buttons to set the desired

reminder interval in months in the Reminder interval field.

The interval value can be between 1 and 12 months. The

default setting is 4 months.

6. Select OK.

Page 28

28

USING THE UNIT

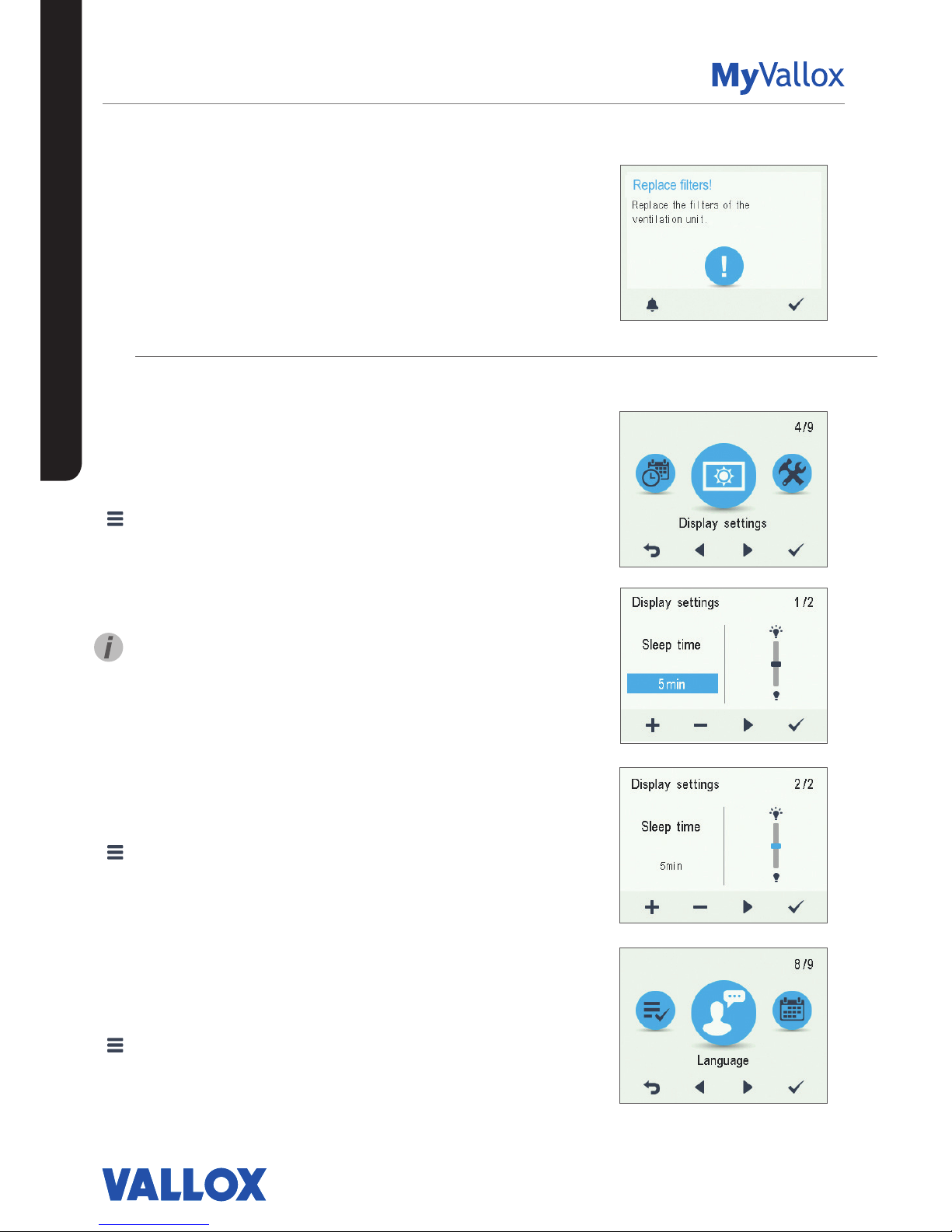

Filter maintenance reminder

The maintenance reminder reminds you of the filter

replacement with a pop-up window.

The message can be acknowledged by selecting OK.

Press the clock button to postpone the reminder for one

week.

DISPLAY SETTINGS

Setting the sleep time

1. Select Settings > Display settings.

2. Select OK.

3. Use the Plus and Minus buttons to set the Sleep time.

4. Select OK.

TIP

The MyVallox Control control panel automatically switches

to the sleep mode when the pre-set Sleep time has elapsed.

To reactivate the MyVallox Control control panel, press any

button.

Adjusting the display brightness

1. Select Settings > Display settings.

2. Select OK.

3. Select Right arrow.

4. Use the Plus and Minus buttons to set the display

brightness.

5. Select OK.

Selecting the user interface language

1. Select Settings > Language.

2. Select OK.

3. Select your language.

4. Select OK.

SETTINGS

Page 29

29

© Vallox Oy - All rights reserved

USING THE UNIT

SETTINGS

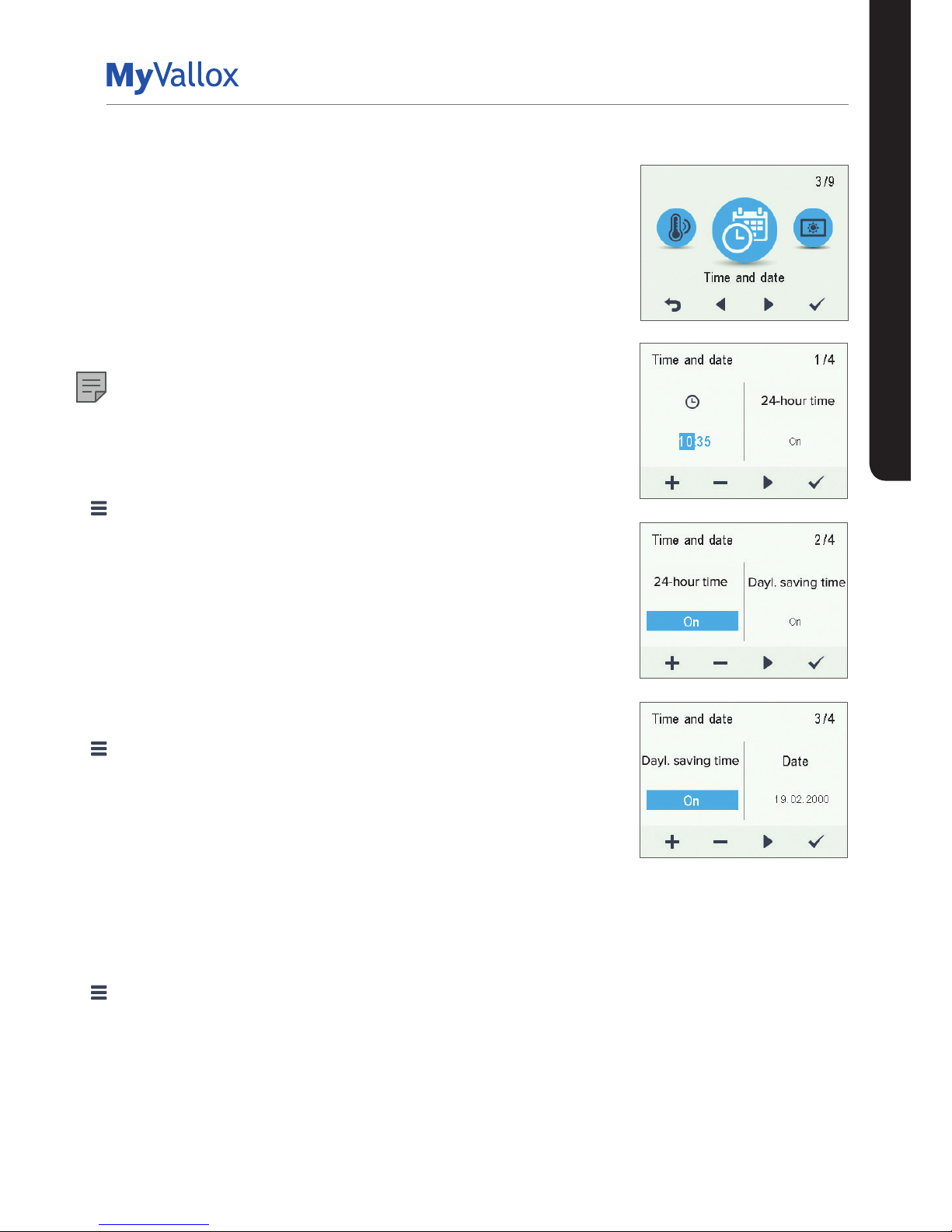

TIME AND DATE

Setting the time and date

The available time settings are:

• Time

• 24- or 12-hour clock

• Automatic daylight saving time

• Date

NOTE

The ventilation unit time will withstand a power cut of a few hours.

Setting the time

1. Select Settings > Time and date.

2. Select OK.

3. Use the Plus and Minus buttons to set the hours.

4. Select Right arrow.

5. Use the Plus and Minus buttons to set the minutes.

6. Select OK.

Selecting the 24- or 12-hour clock

The 24-hour clock is used by default. To use the 12-hour clock:

1. Select Settings > Time and date.

2. Select OK.

3. Select Right arrow until the 2/4 display opens

4. Select Minus. The 24-Hour setting value is changed to O.

5. Select OK.

Automatic daylight saving time

By default, automatic daylight-saving time is turned on. To use the

manual daylight saving time setting:

1. Select Settings > Time and date.

2. Select OK.

3. Select Right arrow until the 3/4 display opens.

4. Select Plus. The Dayl.saving time setting value is changed to O.

5. Select OK.

Page 30

30

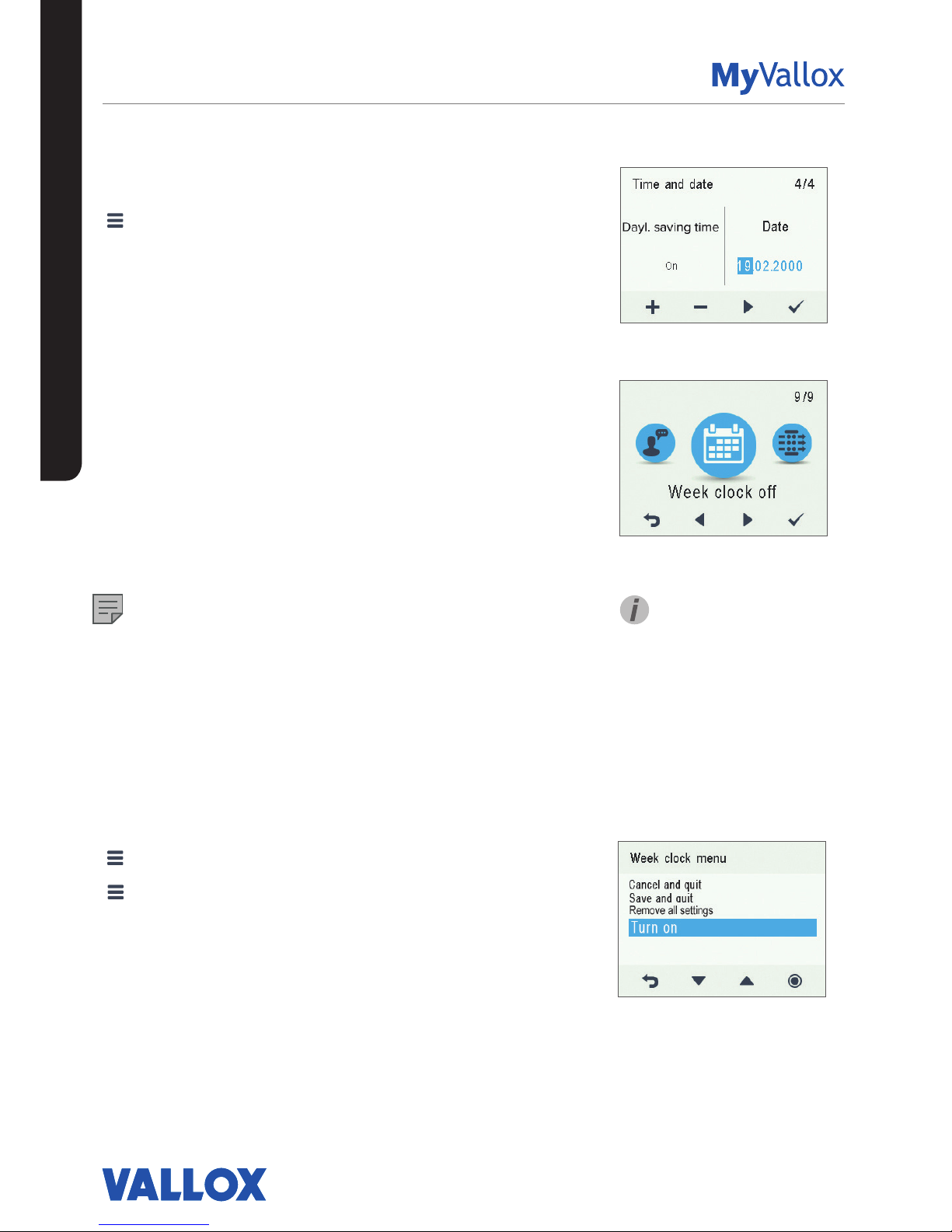

Setting the date

1. Select Settings > Time and date.

2. Select OK.

3. Select Right arrow until the 4/4 display opens.

4. Use the Plus and Minus buttons to set the date.

5. Select Right arrow.

6. Use the Plus and Minus buttons to set the month.

7. Select Right arrow.

8. Use the Plus and Minus buttons to set the year.

9. Select OK.

WEEK CLOCK

The week clock allows you to pre-set a weekly ventilation

program for the ventilation unit. For each hour of the week,

one of the following profiles can be configured:

• At home — The At home profile is used.

• Away — The Away profile is used.

• Boost — The Boost profile is used.

• Blank — Do not change the profile.

NOTE

If you change the profile manually when the week clock is

on, the selected profile will be active until the week clock

switches to the next profile in the program.

If the humidity or carbon dioxide sensors control the

ventilation, they will adjust the fan speed, regardless of

whether the profile has been manually selected or selected

by the week clock.

Turning the week clock on

1. Select Settings > Week clock o.

2. Select OK.

3. Select Settings.

4. Select Turn on.

5. Select Select.

6. The control panel confirms that the week clock is turned

on.

USING THE UNIT

SETTINGS

TIP

You can turn the week clock on

or o by pressing the OK button

on the Week clock display for a

few seconds.

Page 31

31

© Vallox Oy - All rights reserved

USING THE UNIT

SETTINGS

Setting and editing the weekly program

1. Select Settings > Week clock on.

2. Select OK.

3. Use the Right arrow button to select the desired day.

4. Use the Down arrow button to select the desired time.

5. Use the Select button to browse and select the

ventilation profile that will be turned on at the chosen

time. The icons are:

At home profile

Away profile

Boost profile

6. Once you have selected the profiles for the week clock,

select Settings.

7. Select Save and quit, or select Cancel and quit to leave

without saving the week program or the changes made

to it.

8. Once you have saved the week clock program, select

OK on the confirmation display.

Turning the Week clock o

1. Select Settings > Week clock on.

2. Select OK.

3. Select Settings.

4. Select Turn o.

5. Select Select.

6. The control panel will confirm that the week clock is

turned off.

7. The week clock is now turned off. If you have set a

weekly program, it will be saved in the unit.

Removing the week clock settings

To delete the weekly program settings:

1. Select Settings > Week clock on or Week clock o.

2. Select OK.

3. Select Settings.

4. Select Remove all settings.

5. Select OK to accept deletion of the weekly program. The

weekly program has now been deleted.

Page 32

32

Example of setting a weekly program

In this example, the following weekly program has been set:

• Mon-Fri 8-17, Away .

• Mon-Fri 17-07, At home.

• Sat 8-17, At home.

• Sat 18-20, At home with a ventilation boost needed for

cooking, for example.

• Sat 21-Mon 8, At home.

To set the week clock, proceed as follows:

1. Open the week clock.

2. Select Monday, and input the following settings:

• For 08:00, select the Away profile.

• For 17:00, select the At home profile.

3. Then input the corresponding settings for the other

weekdays.

4. Then select Saturday, and input the following settings:

• At 18, select the Boost profile.

• At 21, select the At home profile.

5. Ensure that the Week clock is turned on.

6. The weekly program has now been set.

USING THE UNIT

TURNING THE UNIT OFF

To turn the ventilation unit o:

1. Select Settings> Turn unit o.

2. Select OK.

3. Accept the command by selecting OK.

4. The ventilation unit has now been turned off.

IMPORTANT

In order to ensure that the indoor air presents no harm

to health and remains optimal for the structures of the

building, ventilation must be kept on without disruptions. It is

recommended that ventilation be left turned on during long

holidays also. This keeps the indoor air fresh and prevents

humidity from condensing in the ventilation ducts and

structures. It also reduces the risk of moisture damage.

TIP

To re-start the ventilation unit, press any key.

The figures above show the

aforementioned settings in the

week clock.

SETTINGS

Page 33

33

© Vallox Oy - All rights reserved

USING THE UNIT

TROUBLESHOOTING

NOTE

Error messages are displayed on the control panel and in the

MyVallox Home and MyVallox Cloud services.

CONDENSING WATER USER

In the heating season, the extract air humidity condenses

to water. In new buildings, condensation runo can form

rapidly. Condensed water must be able to freely leave the

unit.

At some time before the heating season begins (e.g. during

autumn maintenance), check that the water seal or the

condensing water outlet in the bottom pool are not clogged.

To check this, pour some water into the pool. Clean as

required.

FA U LT CAUSE MEASURES

Error message:

Extract air fan stopped

The extract air fan has stopped. Make sure that the fan is not running. The fan cabling

and operation must be checked, and if necessary the

fan must be replaced. Contact the service centre.

Error message:

Supply air fan stopped

The supply air fan has stopped. Make sure that the fan is not running. The fan cabling

and operation must be checked, and if necessary the

fan must be replaced. Contact the service centre.

Error message:

Temperature sensor 1/2/3/4/5

The temperature sensor indicated

on the user interface is damaged.

The sensor installation must be checked, and if

required the sensor must be replaced. Contact the

service centre.

Error message:

Bus fault

Problems with the data transfer

bus.

Make sure that the Modbus bus is connected correctly,

and that the devices connected to it are properly

functioning.

The ventilation unit is not

working; the control panel is

not working.

Power input to the unit is lost or the

safety switch catch of the door is

not touching the safety switch.

Check:

• Fuse in the fuse box

• Fuse in the unit

• Press the safety switch all the way down and test if

the unit can be turned on. If the unit can be turned

on, ensure that the safety switch catch is touching

the safety switch.

The ventilation unit is working,

but the control panel is not

working.

Either the control panel 24 VDC

power is lost, there is a problem

with data transmission, or the

control panel is damaged.

Check the cables from the unit to the control panel.

Contact the service centre if necessary.

NOTE

Some condensing water may

have accumulated in the bottom

pool of the unit; this is normal

and requires no corrective

action.

WARNING

Water must at all times be kept

out of the electrical system.

Page 34

MAINTENANCE

34

BEFORE BEGINNING MAINTENANCE WORK

The safety switch (S) automatically turns o the power when the door of the unit is opened.

WARNING

Always disconnect the power plug before starting the ventilation unit maintenance.

MAINTENANCE

There are two unit models, left- (L) and right-handed (R). In the

right handed version, outdoor air blows into the unit from the

right side of the centre line as shown in the instructions. In the

left handed version, outdoor air blows into the unit from the left

side. Also the position of the filters, bypass flap, and heating

radiator is mirrored in the left-handed model.

REPLACING THE FILTERS USER

When the maintenance reminder becomes activated, check

the cleanliness of the filters and replace them if required. The

ventilation unit has three air filters:

• Class G4 coarse filter (A) filters insects, heavy pollen and

other relatively large foreign objects out of the outdoor air.

• Class F7 fine filter (B) filters microscopic pollen and dust

particles out of the supply air.

• Class G4 coarse filter (C) filters the extract air and keeps the

heat recovery cell clean.

To replace the filters:

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Open the door of the unit.

3. Lift the door off.

4. Remove the old filters (A, B, C) and discard them.

5. Install the new filters (A, B, C).

6. Close the door of the unit. Ensure that the safety switch

catch of the door is touching the safety switch, allowing the

unit to be turned on.

7. Plug the ventilation unit back into the mains.

8. The filters have now been successfully replaced.

S

C

A

B

NOTE

Using original Vallox filters

ensures that the ventilation

unit remains in top condition,

giving the best results. The

filter replacement interval

depends on the ambient

dust concentration. It is

recommended that the filters

be replaced every spring and

autumn, or at the very least

once a year.

Page 35

35

© Vallox Oy - All rights reserved

MAINTENANCE

CLEANING THE HEAT RECOVERY CELL

USER

Check that the heat recovery cell (D) is clean roughly once a

year when the filters are being replaced. Clean by washing as

required.

IMPORTANT

Handle the cell carefully! For example, do not lift the cell by the

layers. The cell layers are very thin and easily damaged.

To check the heat recovery cell (HR cell):

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Lift the latch to open the door of the ventilation unit.

3. Lift the door off.

4. Pull the G4 filters (A, C) and filter supports out of the unit.

5. Remove the sealing strip (E) above the HR cell.

6. Remove the side sealing strip (F).

7. Remove the G7 filter (B).

8. Lift and pull the cell (D) out of the unit.

9. If the cell is dirty, clean it by immersing it in warm water, to

which a small amount of a mild detergent has been added.

10. Rinse the cell clean with a water spray. Do not use a highpressure cleaner.

11. When all the water has drained from between the layers,

reassemble the ventilation unit in the reverse order.

12. Close the door. Ensure that the safety switch catch of the

door is touching the safety switch.

13. Plug the ventilation unit back into the mains.

14. The heat recovery cell has now been checked and cleaned.

IMPORTANT

If the unit has an enthalpy cell, it must not be washed. Only

aluminium or plastic cells can be washed.

Page 36

36

MAINTENANCE

CLEANING THE FANS INSTALLER

Check the cleanliness of the fans when servicing the filters

and the heat recovery cell. Clean the fans as required.

You can clean the fan blades with compressed air (wear

protective goggles) or by brushing them gently. Do not

remove or move the fan blade balancing weights.

IMPORTANT

The fans are extremely sensitive to external shocks. It is

recommended that the fans be cleaned in place, i.e. without

attempting to remove them. Remove the fan beds and

the bypass duct carefully in accordance with the below

instructions to prevent damage to the unit. The small size of

the unit restricts the space available for servicing.

IMPORTANT

Handle the fan blades carefully. Do not remove or move the

fan blade balancing weights.

Cleaning the supply air fan

The steps are mirrored for the left handed unit.

To remove and clean the supply air fan:

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Unfasten the four screws to open the door of the unit.

3. Lift the door off.

4. Remove the extract air filter (C), the cell top bracket (E)

and the heat recovery cell (D), as described in sections

“Filters” and “Heat recovery cell”.

5. Remove the mounting screws of the fan bed (2 pcs).

6. Pull the bypass duct/filter stand package out of the unit

and turn to the right.

7. Remove the cable connector (black) of the fan and move

the supply air fan slightly to the right.

8. Remove the post-heating radiator connector. The post

heating radiator connector can be removed once the

supply air fan has been moved slightly to the right.

9. Tilt the supply air fan to the right and push the

connectors out of the way. Turn the fan 90° and tilt it

forward to pull it out of the unit.

10. The fan has now been removed for cleaning.

11. To reassemble the ventilation unit, follow the above

steps in reverse order.

12. Close the door. Ensure that the safety switch catch of the

door is touching the safety switch.

13. Plug the ventilation unit back into the mains.

The fan has now been checked and cleaned.

NOTE

The steps are mirrored for the left

handed unit.

Page 37

37

© Vallox Oy - All rights reserved

MAINTENANCE

Cleaning the extract air fan

To remove and clean the extract air fan:

1. Disconnect the ventilation unit from the mains

electricity supply.

2. Lift the latch to open the door of the ventilation

unit.

3. Lift the door off.

4. Remove the extract air filter (C), the cell top

bracket (E) and the heat recovery cell (D), as

described in sections “Filters” and “Heat recovery

cell”.

5. Remove the fan bed mounting screw (see

removing the supply air fan, Figure 1).

6. Remove the connector package from the wall.

7. Separate the connectors from each other.

8. Tilt the fan to the left and turn 90°.

9. Tilt the fan forward to pull it out of the unit.

10. The fan has now been removed for cleaning.

11. To reassemble the ventilation unit, follow the

above steps in reverse order.

12. Close the door. Ensure that the safety switch catch

of the door is touching the safety switch.

13. Plug the ventilation unit back into the mains.

The fan has now been checked and cleaned.

NOTE

Install the fan beds in a reverse order.

NOTE

The steps are mirrored for the left

handed unit.

Page 38

38

B

C

A

BEFORE BEGINNING

MAINTENANCE WORK

The safety switch (S) automatically turns o the

power when the door of the unit is opened.

WARNING

Always disconnect the power plug before starting

the ventilation unit maintenance.

There are two unit models, left- (L) and righthanded (R). The figure shows the right-handed

model. In the right handed version, outdoor air

blows into the unit from the right side of the centre

line as shown in the instructions. In the left handed

version, outdoor air blows into the unit from the left

side. Also the position of the filters, bypass flap,

and heating radiator is mirrored in the left-handed

model.

REPLACING THE FILTERS

USER

When the maintenance reminder becomes

activated, check the cleanliness of the filters and

replace them if required.

The Vallox ventilation unit has three air filters:

• Class G4 coarse filter filters insects, heavy

pollen and other relatively large foreign objects

out of the outdoor air.

• Class F7 fine filter filters microscopic pollen

and dust particles out of the supply air.

• Class G4 coarse filter filters the extract air and

keeps the heat recovery cell clean.

The filter replacement interval depends on the

ambient dust concentration. It is recommended

that the filters be replaced every spring and

autumn, or at the very least once a year.

To replace the filters:

1. Disconnect the ventilation unit from the mains

electricity supply.

2. Open the upper door of the unit.

3. Remove the old filters (A, B, C) and discard

them.

4. Install the new filters (A, B, C).

5. Close the door of the unit. Ensure that the

safety switch catch of the door is touching the

safety switch, allowing the unit to be turned on.

6. Plug the ventilation unit back into the mains.

7. The filters have now been successfully

replaced.

D

S

B

C

A

E

F

G

TIP

Using original Vallox filters ensures

that the ventilation unit remains in top

condition, giving the best results.

MAINTENANCE

Page 39

39

© Vallox Oy - All rights reserved

MAINTENANCE

CLEANING THE HEAT RECOVERY

CELL USER

Check that the heat recovery cell is clean roughly once a

year, or whenever the filters are being replaced. Clean by

washing as required.

IMPORTANT

If the unit has an enthalpy cell, it must not be washed. Only

aluminium or plastic cells can be washed.

To check and clean the heat recovery cell:

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Lift the latch to open the door of the ventilation unit and

lift the door off.

CAUTION

The door is heavy.

3. Remove the filters (A, B, C).

4. Remove the sealing strip (E) above the cell in the

direction of the arrow.

5. Lift and pull the cell (D) out of the unit.

IMPORTANT

Handle the cell carefully! For example, do not lift the cell by

the layers. The cell layers are very thin and easily damaged.

6. If the cell is dirty, clean it by immersing it in warm water,

to which a small amount of a mild detergent has been

added.

7. Rinse the cell clean with a water spray. Do not use a

high-pressure cleaner.

8. When all the water has drained from between the layers,

reassemble the ventilation unit in the reverse order.

9. Close the door and ensure that the safety switch catch of

the door is engaged.

10. Plug the ventilation unit back into the mains. The heat

recovery cell has now been checked and cleaned.

D

E

D

E

Page 40

40

MAINTENANCE

Removing and cleaning the supply air fan (A)

To clean the supply air fan:

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Lift the latch to open the door of the Vallox ventilation unit.

3. Lift the door off.

CAUTION

The door is heavy.

4. Remove the fine filter (1). To do so, pull the fine filter out of

the unit.

5. The fan has been fastened on the mounting plate with

wing bolts (2). Remove the wing bolts and lift the fan out of

the unit.

6. Disconnect the quick connector (3) of the fan cable.

7. Clean the fan. The fan blades can be cleaned with

compressed air (wear protective goggles) or by brushing

them gently. Do not remove or move the fan blade

balancing weights.

8. To reassemble the ventilation unit, follow the above steps

in reverse order.

9. Close the door. Ensure that the safety switch catch of the

door is touching the safety switch.

10. Plug the ventilation unit back into the mains.

Removing and cleaning the extract air fan (B)

To clean the extract air fan:

1. Disconnect the ventilation unit from the mains electricity

supply.

2. Lift the latch to open the door of the ventilation unit.

3. Lift the door off.

CAUTION

The door is heavy.

4. The fan has been fastened on the mounting plate with

wing bolts. Remove the wing bolts and lower the fan out of

the unit.

5. Disconnect the quick connector of the fan cable.

6. Clean the fan. The fan blades can be cleaned with

compressed air (wear protective goggles) or by brushing

them gently. Do not remove or move the fan blade

balancing weights.

7. To reassemble the ventilation unit, follow the above steps

in reverse order.

8. Close the door. Ensure that the safety switch catch of the

door is touching the safety switch.

9. Plug the ventilation unit back into the mains.

CLEANING THE FANS INSTALLER

Check the cleanliness of the fans when servicing the filters and the heat

recovery cell. Clean the fans as required.

B

A

2

2

1

B

A

3

2 x

IMPORTANT

The fans are extremely

sensitive to external shocks. It

is recommended that the fans

be cleaned in place, i.e. without

attempting to remove them.

Handle the fan blades carefully.

Do not remove or move the fan

blade balancing weights.

Page 41

41

© Vallox Oy - All rights reserved

MAINTENANCE

BEFORE BEGINNING MAINTENANCE

WORK

The safety switch automatically turns o the power when the door

of the unit is opened.

WARNING

Always disconnect the power plug before starting the ventilation

unit maintenance.

There are two unit models, left- (L) and right-handed (R).

REPLACING THE FILTERS USER

See section Vallox 90 MV, Replacing the filters.

CLEANING THE HEAT RECOVERY CELL

USER

See section Vallox 90 MV, Cleaning the heat recovery cell.

CLEANING THE FANS INSTALLER

See section Vallox 90 MV, Cleaning the fans.

CLEANING THE GREASE FILTER OF THE

COOKER HOOD USER

Clean the grease filter of the cooker hood 1-2 times a month.

To clean the grease filter:

1. Open the quick connectors of the bottom plate of the cooker

hood by pressing them.

2. Let the bottom plate move to the down position.

3. Remove the grease filter from its mountings.

4. Clean the grease filter either by washing it with hot water and

hand-washing detergent or in a dishwasher.

REPLACING THE COOKER HOOD LAMP

USER

To replace the cooker hood lamp (type PL 11, 11 W), remove the

protective glass of the lamp (A) by pushing it to the left. Once you

have replaced the lamp, put the protective glass back in its place.

A

1

2

Page 42

42

MAINTENANCE

BEFORE BEGINNING MAINTENANCE WORK

The safety switch (S) automatically turns o the power when the door of the unit is opened.

WARNING

Always disconnect the power plug before starting the ventilation unit maintenance.

There are two unit models, left- (L) and right-handed (R). The figure shows the right-handed model.

REPLACING THE FILTERS USER

When the maintenance reminder becomes activated, check

the cleanliness of the filters and replace them if required.

The Vallox ventilation unit has three air filters:

• Class G4 coarse filter filters insects, heavy pollen and

other relatively large foreign objects out of the outdoor

air.

• Class F7 fine filter filters microscopic pollen and dust

particles out of the supply air.

• Class G4 coarse filter filters the extract air and keeps the

heat recovery cell clean.

The filter replacement interval depends on the ambient dust

concentration. It is recommended that the filters be replaced

every spring and autumn, or at the very least once a year.

NOTE

Using original Vallox filters ensures that the ventilation unit

remains in top condition, giving the best results.

C

B

S

A

Page 43

43

© Vallox Oy - All rights reserved

MAINTENANCE

To replace the filters:

1. Disconnect the ventilation unit from the mains electricity supply.

2. Open door of the Vallox ventilation unit by undoing the finger

screws.

3. Lift the door off.

CAUTION

The door is heavy.

4. Remove the old filters (A, B, C) and discard them.

5. Install the new filters (A, B, C).

6. Close the door of the unit. Ensure that the safety switch catch

of the door is touching the safety switch, allowing the unit to be

turned on.

7. Plug the ventilation unit back into the mains.

The filters have now been successfully replaced.

CLEANING THE HEAT RECOVERY CELL

USER

Check that the heat recovery cell is clean roughly once a year,

or whenever the filters are being replaced. Clean by washing as

required.

To check and clean the heat recovery cell:

1. Disconnect the ventilation unit from the mains electricity supply.

2. Open door of the Vallox ventilation unit by undoing the finger

screws.

3. Lift the door off.

CAUTION

The door is heavy.

4. Remove the sealing strip (E) above the HR cell in the direction of

the arrow.

5. Remove the extract air filter (C).

6. Lift and pull the HR cell (D) out of the unit.

7. If the cell is dirty, clean it by immersing it in warm water, to which

a small amount of a mild detergent has been added.

8. Rinse the cell clean with a water spray. Do not use a highpressure cleaner.

9. When all the water has drained from between the layers,

reassemble the ventilation unit as follows:

10. Ensure that the lower support (F) is in place between the knobs

at the bottom of the unit.

11. Push the heat recovery cell in place.

12. Push the sealing strip (E) in place so that the strip is supported by

the corner bracket (G) at the rear.

13. Install the extract air filter (C) in place.

14. Close the door. Ensure that the safety switch catch of the door is

touching the safety switch.

15. Plug the ventilation unit back into the mains.

The heat recovery cell has now been checked and cleaned.

IMPORTANT

Handle the cell carefully! For

example, do not lift the cell by

the layers. The cell layers are

very thin and easily damaged.

IMPORTANT

If the unit has an enthalpy cell,

it must not be washed. Only

aluminium or plastic cells can

be washed.

D

C

G

E

F

Page 44

44

MAINTENANCE

CLEANING THE FANS INSTALLER