Page 1

13

MC

A

U

N

N

A

A+

Y

R

E

V

O

C

I

F

F

I

E

E

N

L

C

C

Y

R

A

Vallox TSK

T

I

N

G

O

F

E

X

Multi 50

T

R

A

C

T

A

I

R

E

H

R

E

T

A

80

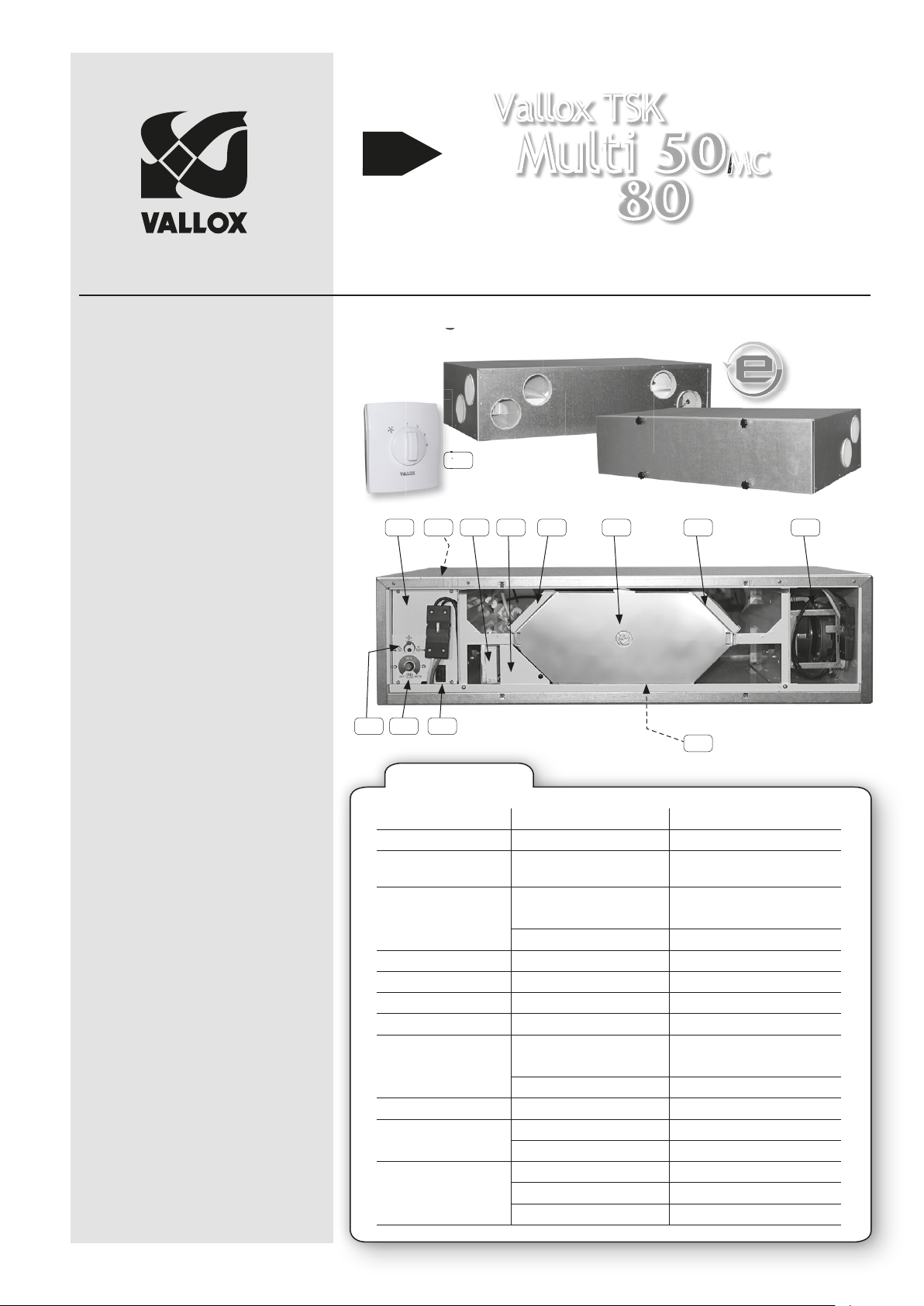

Low-energy ventilation unit

with heat recovery

Models

TSK Multi 50 MC 3603

TSK Multi 80 MC 3602

MC

© Vallox

1.09.399B EN

Updatet

26.1.2015

Valid from:

26.1.2015

1 Supply air fan

2 Extract air fan

3 Post-heating radiator, electric,

900 W (behind supply air heater)

4 Bypass duct heater, electric,

900 W (only TSK Multi 80 MC,

behind HR cell)

5 Heat recovery cell

6 Outdoor air fi lter F7

7 Outdoor air fi lter G4

8 Extract air fi lter G4

9 Automatic summer/winter damper

10 Safety switch

11 Adjustment of relationship between

supply and extract air

12 Adjustment of supply air

temperature and

summer/winter function

13 Speed selector switch (1-4)

(option)

Operating, maintenance and technical instructions

13

1

12 1011

TECHNICAL DATA

Electrical connection 230 V, 50 Hz, = 4.5 A 230 V, 50 Hz, = 8.8 A

Degree of protection

provided by enclosures

Integrated direct-current fan

Extract air 0.043 kW 0.32 A 57 dm

Supply air 0.043 kW 0.32 A 49 dm

Heat recovery Cross-counter fl ow cell, > 80% Cross-counter fl ow cell, > 80%

Heat recovery bypass Automatic Motorised damper

Electric post-heating unit 900 W, 3.9 A max 900 W, 3.9 A

Bypass duct heater - 900 W, 3.9 A

Filters

Supply air G4 + F7 G4 + F7

Extract air G4 G4

Weight 45.0 kg 58.5 kg

Ventilation power adjustment SC controller, 0-10 VDC SC controller, 0-10 VDC

Options SC controller SC controller

9 8 7563

4

VALLOX TSK MULTI 50 MC VALLOX TSK MULTI 80 MC

IP 34 IP 34

3

/s 100 Pa 0.071 kW 0.5 A 93 dm3/s 100 Pa

3

/s 100 Pa 0.071 kW 0.5 A 76 dm3/s 100 Pa

Remote monitoring control 0-10 VDC Remote monitoring control 0-10 VDC

SlimLine PTXP MC cooker hood SlimLine PTXP MC cooker hood

SlimLine PTXPA MC cooker hood SlimLine PTXPA MC cooker hood

2

Page 2

Vallox TSK

MCMC

Multi 50

80

MC

OPERATING INSTRUCTIONS

Fan speed adjustment

The fan speed of a Vallox ventilation unit can be controlled with a control switch (option), with

a separate cooker hood (option) or directly with a 0–11,4 V voltage signal.

Speeds 1, 2, 3 and 4 can be selected at the control switch.

1. Operation during absence. When the dwelling is empty, ventilation can be reduced

temporarily.

2–3. Normal operation. In normal operation, air has to be replaced once every two hours.

4. Boosted operation. Cooking, taking a sauna bath, washing, drying clothes, using

the toilet, having guests or a corresponding situation may cause a need for higher

ventilation than in normal operation.

Adjustment of supply

air temperature

Fireplace switch, fl ush

mounting (option)

Supply and extract

air fl ow adjustment

potentiometer

Four-step control switch

Cooker hood PTXPA-MC

Adjustment of supply air temperature and summer/winter

function

The temperature of air coming to the dwelling can be adjusted between circa +10 °C and

+30 °C. The midpoint of the adjustment range is circa +20 °C. When supply air temperature

adjustment has been turned in the OFF position, post-heating is not active. This means that

summer function is activated for the ventilation unit. The unit has a motorised summer/winter

function. When the summer function is on, the heat recovery cell is bypassed as soon as

outdoor air temperature has risen above +14 °C. When outdoor air temperature goes below

+12 °C, the unit starts to recover heat. When supply air temperature adjustment is in the

AUTO position, automatic function is activated for the unit. In this case, the setpoint for postheating is +17 °C and the heat recovery cell is bypassed automatically according to outdoor

temperatures as indicated above. When the unit bypasses the heat recovery cell, in which

case summer function is activated, post-heating is off.

Fireplace switch function

It is possible to connect a timer-operated switch to the unit. The switch stops the extract air fan

during the time when the fi replace is heated. NOTE! The starting of the extract air fan may

weaken draught in the fi replace! In winter, this situation may disturb the winter function of the

unit. The situation will normalise in a while, after the fi replace function stops.

Winter function of ventilation unit

A threshold value has been set at the factory for the freezing of the heat recovery cell. When

the threshold is exceeded, the ventilation unit starts to melt the heat recovery cell by guiding

outdoor air fl ow to bypass the heat recovery cell.

A normal melting period takes from 15 to 45 minutes depending on the extent of ice on

the heat recovery cell and on the amount of extract air fl ow. The unit has been optimised to

operate on the factory settings in normal operation in dwellings and detached houses. The

winter function parameters can be adjusted for extreme conditions, such as a swimming bath,

but even then it is advisable to contact Vallox Maintenance.

Adjustment of relationship between supply and extract air

This feature may be useful when adjusting air fl ows at the valves during mounting. After the

valves have been adjusted, a user does not need, and must not, touch the adjustment. When

needed, supply or extract air fl ow can be reduced at the potentiometer.

When the potentiometer is approximately halfway, supply and extract air fl ow have not been

reduced. Turning the potentiometer anticlockwise reduces air fl ow on the supply side, and

turning it clockwise reduces air fl ow on the extract side.

Maintenance reminder

The unit reminds of the need for maintenance every six months if an indicator (not standard)

has been connected to the connectors of the fault signal relay. The indicator then blinks at

one-second intervals. The maintenance reminder is reset when the door of the ventilation unit

is opened. See the maintenance instructions for information on the necessary maintenance

activities.

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack

of experience and knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way and understand

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

2

the hazards involved.

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

Page 3

MAINTENANCE INSTRUCTIONS

Troubleshooting

When a fault described in the table appears, the unit indicates of

the fault with a fault signal relay, indicator light and LED on the circuit

board. The number of blinks reveals the fault in question

Led

Problem Repair

blinks

Supply air sensor after the HR cell is faulty Check the sensor and conductors, replace if needed

1

Extract air sensor is faulty Check the sensor and conductors, replace if needed

2

Supply air sensor is faulty Check the sensor and conductors, replace if needed

3

Exhaust air sensor is faulty Check the sensor and conductors, replace if needed

4

Outdoor air sensor is faulty Check the sensor and conductors, replace if needed

5

Supply air fan has stopped Check the wiring of the fan, replace the fan if needed

6

Extract air fan has stopped Check the wiring of the fan, replace the fan if needed

7

EEPROM faulty Replace the circuit board of the unit with a new one

8

Vallox TSK

Multi 50

80

MC

MAINTENANCE

T

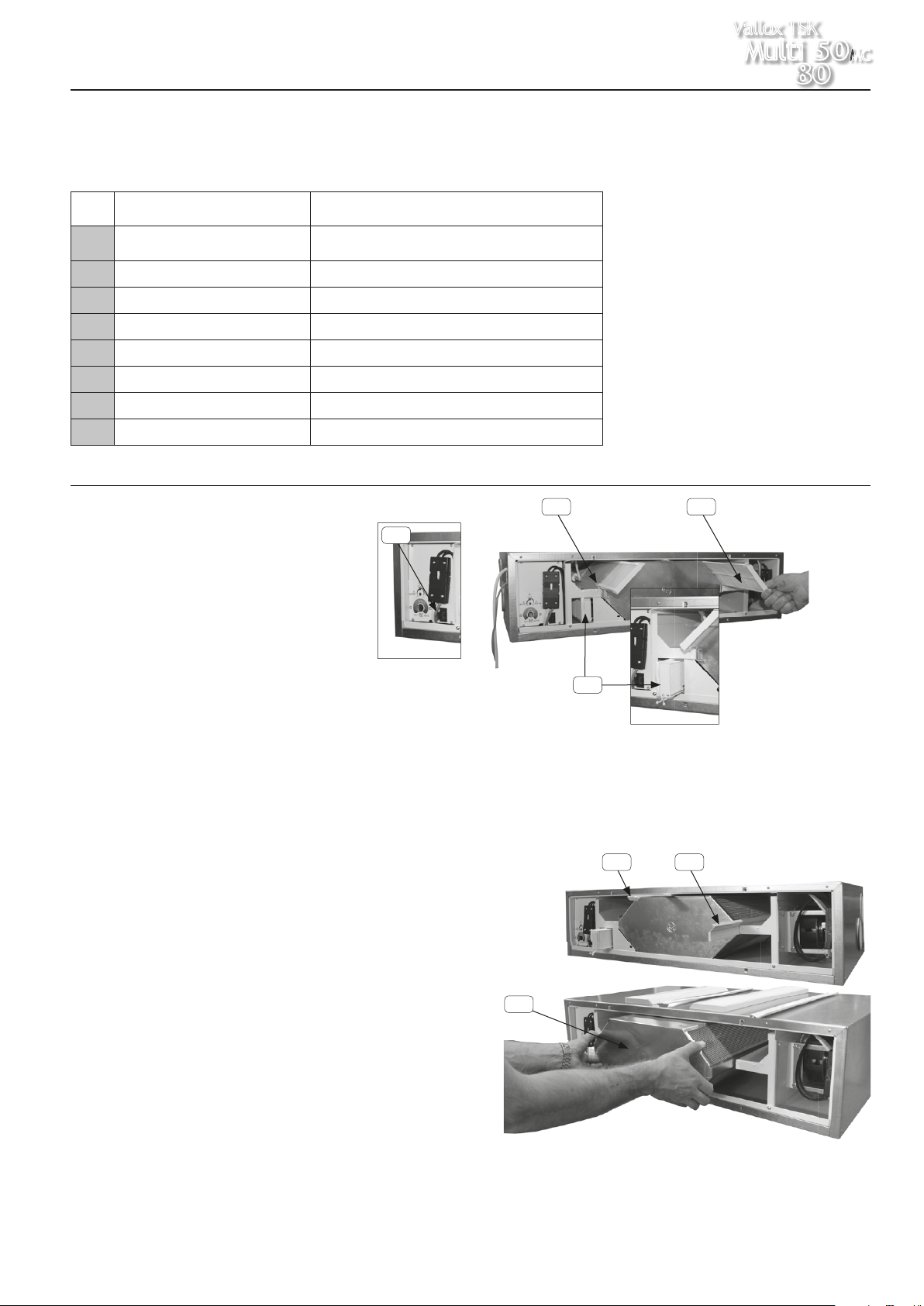

Before starting maintenance

operations

When you open the VALLOX TSK Multi 50/80

MC unit, the safety switch of the door (T) turns

power off from the unit. In spite of that, always

disconnect the plug of the VALLOX TSK Multi

50/80 MC unit before starting maintenance

operations.

Filters

When the maintenance reminder gives an alarm, the cleanliness of

the fi lters must be checked. Outdoor air is fi ltered in the unit with two

kinds of fi lters. A coarse fi lter (A) fi lters off insects, heavy pollen and

other dust. An F7 class fi ne fi lter (B) fi lters off fi ne dust invisible to the

eye. Extract air is fi ltered with a coarse fi lter (C).

By using original Vallox fi lters you ensure good operation of the

ventilation unit and the best fi ltering result. The replacement interval

of fi lters depends on dust content in ambient air. It is recommended to

replace fans in spring and autumn, but at least once a year.

Heat recovery cell

When you replace the fi lters, you are also advised to check the

cleanliness of the heat recovery (HR) cell (D) at about two-year

intervals.

The G4 fi lters and their supports, the sealing ledge (E) above the HR

cell and the side sealing ledge (F) must be pulled off before the cell

can be detached. When the sealing ledge has been removed, the

HR cell can be pulled out of the unit.

Note! The laminas of the HR cell are very thin and get easily

damaged. The correct way to remove the HR cell is to put your

hands behind the HR cell and slowly pull it off. If the HR cell is dirty,

wash it by immersing it in a solution of water with washing-up liquid.

Rinse the HR cell clean with a jet of water. When water has drained

from between the laminas, you can push the HR cell back in place.

Finally, push the sealing ledges and fi lters in place.

C A

B

VALLOX TSK Multi 50/80 MC fi lters and heat recovery cell

The units are available as right- and left-handed models. In a right-handed

(model R) model, outdoor air comes to the unit from the right side of the

centre line, as shown in the instructions. In a left-handed (model L) unit, outdoor comes from the left side of the unit. The fi lters, summer/winter damper

and heating radiator also change places correspondingly.

E F

D

Detaching of HR cell

Pull the coarse fi lters and their frames out of the unit. Also remove the fi ne

fi lter if it has been used. You can then pull out the sealing ledges situated

on top and on the sides of the HR cell. When the sealing ledges have been

removed, the HR cell can be pulled out of the unit. Note! The laminas of the

HR cell are very thin and get easily damaged.

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

3

Page 4

Vallox TSK

Multi 50

80

MC

MAINTENANCE INSTRUCTIONS

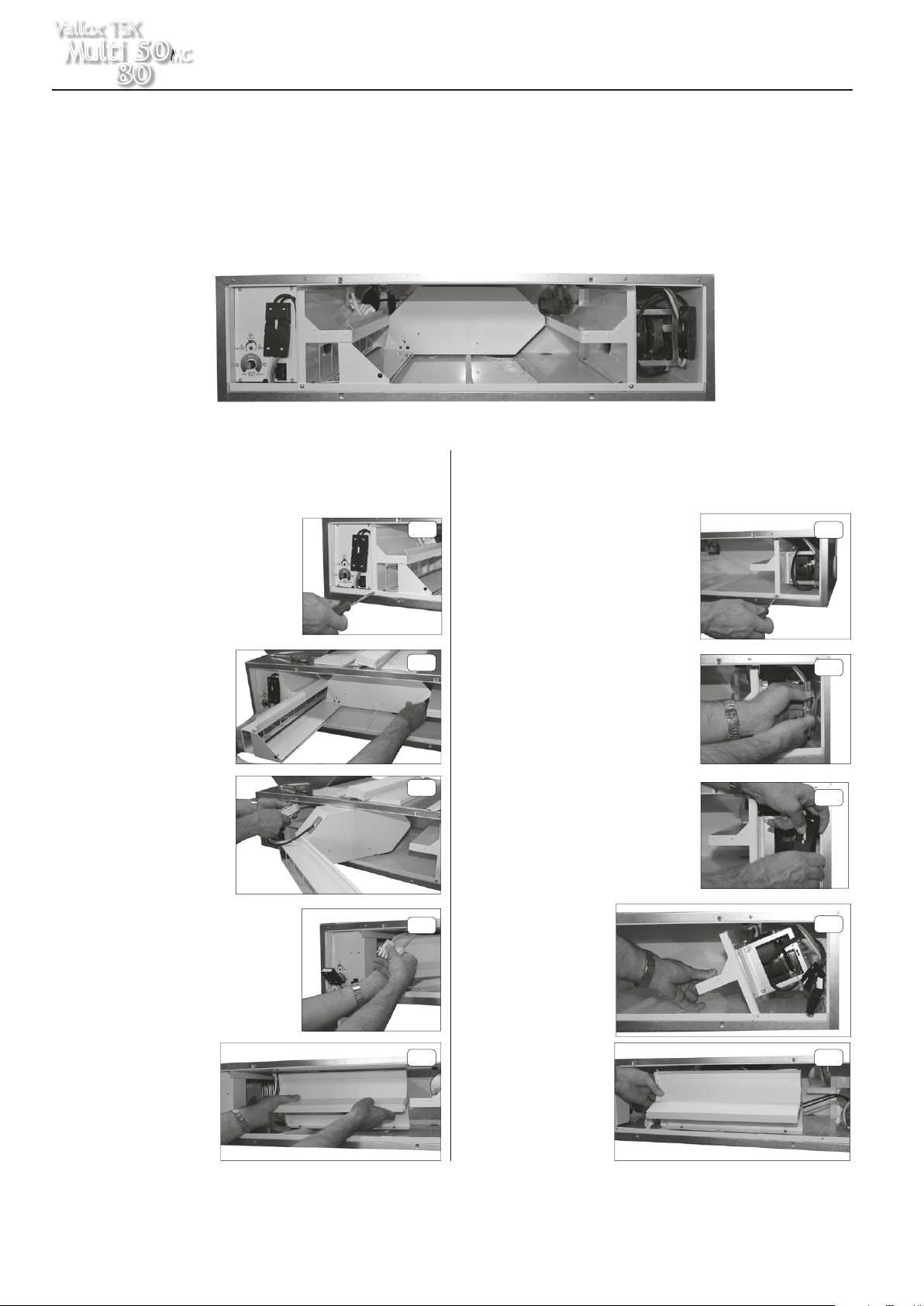

Fans

Check the cleanliness of the fans when carrying out maintenance for

the fi lter and the heat recovery cell. Clean the fans if needed. The

fans can be removed from the unit for cleaning. The fan blades can

be cleaned with compressed air or with a brush. Do not remove or

move the balancing pieces on the fan blade.

Unit with HR cell and fi lters removed

Detaching of supply air fan, right-handed unit

(When detaching the supply air fan of a left-hand unit,

reverse the instructions.)

1

1. Unfasten the fi xing screw of the fan

housing.

Detaching of supply and extract air fan

Before detaching the supply and extract air fans, you have to remove

the fi lters and the heat recovery cell of the unit as described earlier.

The detaching and remounting of the fan housings and bypass duct

must be done carefully according to the following instructions in order

to avoid damage. Because the unit is small in size, there is not much

room for maintenance.

Detaching of extract air fan, right-handed unit

(When detaching the supply air fan of a left-hand unit, reverse the

instructions)

1

1. IUnfasten the fi xing screw

of the fan housing.

2. Pull the bypass duct/fi lter

stand bundle out and turn

it to the right.

3. Unfasten the wire of the

bypass damper motor.

4. Tilt the supply air fan to the right and

take the connectors out of way.

5. Turn the fan by 90° and

pull it out from the unit,

tilting it forwards.

2

2. Detach the connector

bundle from the wall.

3. Detach the connectors from

3

4

5 5

each other.

4. Tilt the fan to the

left and turn by

90°.

5. Pull the fan out,

tilting it forwards.

2

3

4

The mounting of the fan housings is carried out in the opposite order.

4

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

Page 5

MAINTENANCE INSTRUCTIONS

Condensing water

During the heating season, humidity of extract air condenses into

condensing water. Water formation may be abundant in new

buildings or if ventilation is low compared to the humidity build-up

caused by the residents.

Condensing water needs to fl ow out from the ventilation unit without

hindrance. In carrying out maintenance, for instance in autumn

before the beginning of the heating season, make sure that the

condensing water outlet (L) in the bottom tank is not clogged. You

can check it by pouring a little water in the tank. Clean if needed.

Do not let water fl ow into electrical devices. The unit comes with

a condensing outlet (in the fi gure) equipped with an airlock and

an outlet without airlock that takes less space. If you use the outlet

without airlock, you have to mount an airlock somewhere between

the discharge pipes (the accessory bag contains the parts needed).

An airlock guarantees the removal of condensing water and

silencing of any sounds.

Location of condensing water

outlet from side

Vallox TSK

Multi 50

80

Location of condensing water outlet

from behind

MC

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

5

Page 6

Vallox TSK

Multi 50

MC

80

Measuring points

Measuring points after the

connection outlet. Fan curves

indicate the total pressure

available for duct losses.

Supply air

Extract air

TECHNICAL DATA

Performance TSK Multi 50 MC

Air volumes Vallox TSK Multi 50 Supply air (F7 + G4), Extract air (G4)

300

E = Extract air fan

S = Supply air fan

ED and SD are examples of pressure

losses in supply and extract ducts.

SFP (Specifi c Fan Power) recommended value <2.5 (kW m3/s)

Input power (total) (W)

SFP =

Air fl ow (max) (dm

3

/s)

SEEN FROM ABOVE

Left

side

Input power of the unit

Fan control voltage

with SC controller

(V)

Input power of

the unit

(W)

3 11

4 15

5 20

6 26

7 37

8 49

9 65

10 87

11,4 108

Sound

values

Adjustment position

Air fl ow dm3/s

Medium

frequency

of the

octave

band Hz

L

L

11,4 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V 11,4 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V

54,6 50,4 43,9 38,7 31,3 25,1 18,8 13,8 8,1 62,8 56,9 50,3 45,0 37,9 32,1 26,2 19,1 13,7

57,6 57,4 54,1 52,8 50,2 47,3 44,9 40,7 42,3 51,0 50,0 47,6 45,5 43,4 *38,2 *34,0 *31,6 *30,3

63

60,4 59,3 57,3 55,6 53,7 50,0 51,1 47,8 40,5 57,8 57,0 54,5 51,9 49,2 48,0 44,7 44,1 40,4

125

64,0 62,3 61,0 59,9 58,5 55,1 51,2 45,9 34,9 55,3 53,9 52,7 52,1 48,6 47,9 43,5 37,6 28,7

250

66,2 64,3 61,8 60,8 55,2 50,0 45,5 39,5 30,1 51,0 50,2 48,3 49,4 40,8 36,2 30,8 *25,3 *17,6

500

63,2 61,5 59,6 56,6 51, 47,5 42,3 35,5 *24,0 51,1 49,3 46,5 44,1 39,1 36,1 31,6 *25,4 *16,8

1000

58,8 56,9 54,3 51,3 47,4 41,9 34,4 *23,9 *17,8 40,1 38,4 36,8 35,3 29,9 *27,7 *21,3 *13,9 *12,2

2000

53,6 51,4 48,1 43,9 38,0 *29,6 *23,1 *20,6 *18,6 33,0 31,1 29,5 *26,5 *19,9 *18,4 *17,6 *17,6 *17,5

4000

36,5 33,4 *29,6 *26,5 *24,3 *23,3 *23,1 *23,1 *23,2 *23,5 *23,2 *23,1 *23,2 *22,9 *22,9 *22,9 *22,9 *22,9

8000

L

,dB

70,6 68,9 66,8 65,2 62,0 58,1 55,4 50,9 45,2 61,3 60,2 58,1 56,7 53,0 51,5 47,6 45,3 *41,2

W

, dB(A)

WA

67,5 65,6 63,3 61,1 57,0 52,3 47,6 41,5 32,5 54,1 52,7 50,6 49,7 44,5 42,7 38,0 *33,5 *28,9

Sound pressure level coming from the unit through the envelope in the rooms where the unit has been installed

11,4 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V

54,0 / 61,4 49,3 / 55,8 43,9 / 50,1 38,1 / 44,0 31,5 / 37,3 25,1 / 30,9 19,4 / 25,1 13,4 /18,6

, dB (A) 49,2 47,7 45,6 42,9 39,3 35,6 32,1 *27,0 *24,4

pA

250

Right

side

200

150

100

50

Pressure loss in ducts. Total pressure (Pa)

E 3,0 V

S 3,0 V

S 4,0 V

E 4,0 V

S 5,0 V

E 5,0 V

S 6,0 V

E 6,0 V

0

Sound power level in supply air duct (one duct)

ADJUSTMENT POSITION/AIR FLOW dm

by octave band L

, dB

W

3

/s ADJUSTMENT POSITION/AIR FLOW dm3/s

ADJUSTMENT POSITION/AIR FLOWS (supply/extract)

S 9,0 V

E 8,0 V

S 8,0 V

E 7,0 V

S 7,0 V

2

sound absorption)

(10m

S 11,4 V

E 10,0 V

S 10,0 V

E 9,0 V

Volume fl ow rate (dm

E 11,4 V

SFP <2.0 kW/m

3/

s

ED

SFP <1.5 kW/m

W

SD

3/

s

, dB

SFP <1.0 kW/m

3/

s

3

/s)

Sound power level in extract air duct (one duct)

by octave band L

8,0 / 13,1

*The background noise requirements of standard ISO 3741:2010 have not been met

6

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

Page 7

TECHNICAL DATA

Performance TSK Multi 80 MC

Vallox TSK

Multi 50

80

MC

Measuring points

Measuring points after the

connection outlet. Fan curves

indicate the total pressure

available for duct losses.

Supply air

Extract air

SEEN FROM ABOVE

Left

side

Input power of the unit

Fan control voltage

with SC controller

(V)

Input power of

the unit

(W)

3 12

4 17

5 25

6 34

7 47

8 68

9 95

10 125

11,3 165

Right

side

Air volumes Vallox TSK Multi 80 Supply air (F7 + G4), Extract air (G4)

E = Extract air fan

S = Supply air fan

ED and SD are examples of pressure

losses in supply and extract ducts.

SFP (Specifi c Fan Power) recommended value <2.5 (kW m3/s)

Input power (total) (W)

SFP =

Air fl ow (max) (dm

3

/s)

350

300

250

200

S 8,0 V

E 10,0 V

S 10,0 V

E 9,0 V

S 9,0 V

E 8,0 V

S 11,3 V

E 11,3 V

SFP <2.0 kW/m

3/

s

ED

150

100

Pressure loss in ducts. Total pressure (Pa)

50

E 3,0 V

S 3,0 V

E 4,0 V

S 4,0 V

0

E 5,0 V

S 5,0 V

S 6,0 V

E 6,0 V

S 7,0 V

E 7,0 V

SFP <1.0 kW/m

SD

SFP <1.5 kW/m

3/

s

3/

s

0 10 20 30 40 50 60 70 80 90 100 110

Volume fl ow rate (dm

3

/s)

Sound

values

Adjustment position

Air fl ow dm3/s

Medium

frequency

of the

octave

band Hz

L

, dB(A)

WA

, dB (A) 53,5 51,2 49,5 45,9 42,0 37,4 34,4 *28,9 *24,7

L

pA

Sound power level in supply air duct (one duct)

ADJUSTMENT POSITION/AIR FLOW dm

by octave band L

, dB

W

3

/s ADJUSTMENT POSITION/AIR FLOW dm3/s

Sound power level in extract air duct (one duct)

by octave band L

, dB

W

11,3 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V 11,3 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V

83,8 75,2 65,7 57,7 47,9 39,6 31,6 23,1 15,6 101,0 92,2 81,3 71,2 59,3 50,3 43,3 33,1 22,3

60,4 60,4 57,4 56,0 54,3 52,4 55,8 43,3 43,2 55,6 55,0 57,7 54,5 48,5 47,3 48,4 39,8 *38,9

63

64,5 61,9 60,4 58,5 56,9 54,6 52,4 46,1 39,1 60,1 58,3 56,8 53,7 50,9 48,3 48,0 41,6 33,9

125

71,9 72,0 69,5 68,0 60,3 56,6 50,9 46,0 38,3 59,1 58,2 56,9 55,3 50,3 46,9 42,9 36,7 30,3

250

73,0 66,8 63,2 59,9 56,3 51,8 47,4 40,9 33,1 55,2 52,3 48,9 45,9 42,9 37,5 34,3 27,1 *21,8

500

66,0 62,9 59,7 56,5 51,8 47,1 42,5 36,2 *27,9 53,1 49,9 47,5 44,1 40,0 35,7 32,1 *25,5 *19,8

1000

62,0 59,3 56,2 53,0 48,9 43,6 38,3 30,1 *19,7 42,3 39,8 37,0 33,6 29,7 25,8 *22,3 *16,4 *13,9

2000

52,5 49,6 46,1 42,2 37,2 31,5 *25,8 *20,0 *17,9 29,4 *26,7 *23,9 *20,7 *18,8 *18,0 *17,8 *17,7 *18,0

4000

38,5 34,9 30,8 *27,3 *24,4 *23,2 *23,0 *23,0 *22,9 *23,5 *23,2 *23,1 *23,1 *23,0 *23,0 *23,0 *23,0 *23,0

8000

L

,dB

76,6 74,2 71,5 69,6 64,0 60,6 58,8 50,8 45,9 64,4 62,9 62,3 59,6 55,2 52,6 52,0 44,7 *40,7

W

72,2 69,1 66,1 63,2 57,9 53,4 48,8 42,6 *35,0 57,0 54,8 52,7 49,8 45,7 41,6 38,9 *32,7 *28,1

Sound pressure level coming from the unit through the envelope in the rooms where the unit has been installed

2

sound absorption)

(10m

ADJUSTMENT POSITION/AIR FLOWS (supply/extract)

11,3 V 10,0 V 9,0 V 8,0 V 7,0 V 6,0 V 5,0 V 4,0 V 3,0 V

84,0 / 88,1 74,8 / 79,2 66,1 / 70,4 57,0 / 61,7 47,4 / 52,1 39,3 / 43,1 32,3 / 36,8 23,4 / 27,8

*The background noise requirements of standard ISO 3741:2010 have not been met

15,1 / 19,5

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

7

Page 8

Vallox TSK

Multi 50

80

Electrical

connection

MC

S Supply air fan

E Extract air fan

TK Safety switch

R1 Bypass duct heater (80 MC, behind HR cell)

R2 Post-heating radiator

M Damper motor

FS Fireplace switch (option)

OK Voltage switch (in the cooker hood)

VA Light switch (in the cooker hood)

Wiring:

BK black

BN brown

BU blue

GN green

GY grey

E

RD = 7

WT = 8

WT white

YE/GN yellow/green

RD red

YE = 16

BU = 15

BK = 1

BN = 2

YE/GN = 9

BU = 1

BN = 2

YEGN = 9

951153 / 951159:

BN = 7

WT = 8

951150 / 951152

TECHNICAL DATA

951153

951152

YE = 16

GN = 15

R1

130°C

T1

T2

90°C

DIP switch Up Down

1. Post-heating Electric VKL

2. Additional heating Electric MLV

3. Unit type Bypass Supply fan stopped

LINE: Phase voltage

NEUTRAL: Zero voltage

SLI: Phase voltage to safety switch

SNI: Zero voltage to safety switch

SLO: Phase voltage to circuit board from safety switch

SNO: Zero voltage to circuit board from safety switch

SFL: Phase voltage to supply air fan

SFN: Zero voltage to supply air fan

EFL: Phase voltage to extract air fan

EFN: Zero voltage to extract air fan

FSO: Input to fireplace switch

FSI: Fireplace switch output

AHL: Phase voltage to post-heating

AHN: Zero voltage to post-heating

PHL: Phase voltage to additional heater

PHN: Zero voltage to additional heater

BL: Damper motor phase A

BL1: Damper motor phase B

BN: Damper motor zero

E/I: Fault signal relay input

E/O: Fault signal relay output

951154

951155

4

BK

WT

6

7

5

8

4

8. Supply fan PWM

7. Supply fan Tako

6. GND / -

5. Extract fan PWM

4. Extract fan Tako

SLO, BK

SNO. BK

SFL, BN

SFN, BU

EFL, BN

1

2

3

Extract air NTC ”1”

2

3

1

3. GND / -

2. 11.2 Vdc /+

1. Control signal S

EFN, BU

FSO

FSI

1

AHL, BN

Outdoor air NTC “2”

2

Adjustment of freezing level

AHN, BU

PHL, BN

1 = N

3 =

2 = L

M

GNYEWTGNYE

9

Programming

connector

9. GND / -

LINE, BN

NEUTRAL, BU

SLI, BK

SNI, BK

4. Winter function Normal Wet

Supply air to the dwelling NTC ”3”

PHN, BU

PWM level adjustment

Exhaust air NTC ”4”

Supply air from the cell NTC ”5”

345

3 4

1 2

DIP switch

Adjustment of post-heating

Fault signal relay

LED

BL1, 3

BL, 2

BN, 1

E/I

E/O

BK

4

TK

4 x 951107

T1

130°C

S

T2

90°C

R2

951150

951166

+

4

3

2

1

External controller

or cooker hood

8

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

951159

951123

951129

LED

S

3461600

230V 50Hz

7024000

Page 9

MOUNTING INSTRUCTIONS

Vallox TSK

Multi 50

80

MC

Mounting location

VALLOX TSK Multi 50/80 MC has to be

mounted in a place where temperature does

not go below +10 °C. Without protective

enclosure, the unit must be located in a place

with no acoustic disturbance: storeroom,

utility room, suspended ceiling etc.

Important!

The outdoor air duct to the unit and the

exhaust air duct out must be insulated with

closed cell insulation for the whole length.

Dimensions and duct outlets

DIMENSION VALLOX TSK

MULTI 50 mm

A 900 1026

B 547 626

C 236 293

D 100 (female) 125 (female)

E 87 110

F 197 254

G 86 110

H 161 200

I 161 200

J 86 96

K 96 96

L 206 231

M 498 624

VALLOX TSK

MULTI 80 mm

Seen from

the right

G

Fastening

VALLOX TSK Multi 50/80 MC is mounted

normally to a ceiling with four fastening hooks

delivered with the unit. When fastening, take

into account that the unit weighs 45 kg.

Important!

Mount the unit horizontally level to make

sure that the condensing water gathering

in the bottom tank runs into the condensing

outlet.

A

4

H

B

4

1

C

I

Right side

1

4

4

J

K

L

Seen from above

1

1

Seen from behind

Condensing water

The delivery includes a water seal. By

connecting a pipe to the water seal the

water condensing from extract air can be

led to a fl oor drain (not directly to the drain).

The pipe must not rise after the water seal.

For further instructions on the mounting of

the water seal and outlet, see the accessory

bag.

Seen from

the left

ØD

2

Left side

3

2

3

3

2

J

K

L

2

3

Model R:

1. Outdoor air to unit

2. Supply air to rooms

3. Extract air to unit

4. Exhaust air out

I

Model L:

1. Extract air to unit

2. Exhaust air out

3. Outdoor air to unit

4. Supply air to rooms

F

E

DIMENSION VALLOX TSK

MULTI 50 mm

A 431 519

B 91 91

C 16 16

D 548 626

E 530 600

F 236 293

G 935 1060

H 900 1026

VALLOX TSK

MULTI 80 mm

SPACE FOR MAINTENANCE

Plug cord and cord

for SC speed switch

F

E

SPACE FOR MAINTENANCE

B

G

H

ALITOTLOUH

D

A

Water seal

Water outlet

(alternative)

C

43

61

Space required

for mounting

27

47

54

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

9

Page 10

Vallox TSK

Multi 50

MC

80

Exploded view and parts list

VALLOX TSK MULTI MC 50/80

39

40

6

4

5

29

23

27

22

2b

7

20

21

2

19

17

3

18

LIST OF SPARE PARTS

28

1

32

37

35

4

33

36

34

8

13

12

14

15

10

9

41

42

26

16

30

31

11

25

24

38

No. Part Code

1 Body TSK Multi 50 SC BP / 50 MC / 80 SC BP / 80 MC

2 Door assembly (incl. 2b door switch button) (50 MC/SC BP) .............................................................................................3473500

2 Door assembly (incl. 2b door switch button) (80 MC/SC BP) .............................................................................................3483000

3 Heat exchanger, counter-fl ow cell GS1 8/400 (50 MC/SC BP) ..........................................................................................933120

3 Heat exchanger, counter-fl ow cell GS 25/450 (80 MC/SC BP) ..........................................................................................933130

4 Fan assembly (50 MC/SC BP) .....................................................................................................................................3473400

4 Fan assembly (80 MC/SC BP) .....................................................................................................................................3482900

5 Fan motor 43 W (50 MC/SC BP) R3G133-AE07-02EC ....................................................................................................935385

5 Fan motor 71 W (80 MC/SC BP) R3G190-AB07-02 EC ................................................................................................... 935375

6 Fan mounting plate ..................................................................................................................................................... 3335110

7 Fan fastening angle ....................................................................................................................................................1088410

8 Fan housing (metal parts: inlet cone, partition and insulation) (50 MC/SC BP) ....................................... 3463100, 3463200, 3463300

8 Fan housing (metal parts: inlet cone, partition and insulation) (80 MC/SC BP) ....................................... 3387410, 3318210, 3478900

9 Bypass duct assembly (50 MC/SC BP R)........................................................................................................................3432700

9 Bypass duct assembly (50 MC/SC BP L) ........................................................................................................................ 3432701

9 Bypass duct assembly (80 MC/SC BP R)........................................................................................................................3479500

9 Bypass duct assembly (80 MC/SC BP L) ........................................................................................................................ 3479600

10 Body of bypass duct and F7 fi lter support (50 MC/SC BP) ................................................................3433111, 3425310, 3451901

10 Body of bypass duct and F7 fi lter support (80 MC/SC BP) ................................................................3479700, 3479800, 3480100

11 Cell damper (50 MC/SC BP) ......................................................................................................................................3433000

11 Cell damper (80 MC/SC BP) ......................................................................................................................................3480000

12 Bypass duct damper (50 MC/SC BP) ............................................................................................................................ 3432800

12 Bypass duct damper (80 MC/SC BP) ............................................................................................................................ 3479900

13 Damper motor CM230-R (R units) .................................................................................................................................... 930621

13 Damper motor CM230-L (L units) ..................................................................................................................................... 930620

14 Damper motor arm (50 MC/SC BP) .............................................................................................................................. 3383320

14 Damper motor arm (80 MC/SC BP) .............................................................................................................................. 3480300

10

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

Page 11

Vallox TSK

Multi 50

LIST OF SPARE PARTS

No. Part Code

15 Retaining bracket for arm ............................................................................................................................................. 3458100

16 Bottom of connection box (50 MC/SC BP) ..................................................................................................................... 3444800

16 Bottom of connection box (80 MC/SC BP) ..................................................................................................................... 3444810

17 Cover of connection box (50 MC/SC BP) ...................................................................................................................... 3444900

17 Cover of connection box (80 MC/SC BP) ...................................................................................................................... 3444910

18 Ground terminal ........................................................................................................................................................... 950432

19 Cable clamp ............................................................................................................................................................... 952130

20 MC circuit board .........................................................................................................................................................949035

21 MC potentiometer .......................................................................................................................................................951110

22 Safety switch Cherry/ Dong Hai .....................................................................................................................................948370

23 MC potentiometer knob ................................................................................................................................................. 948435

24 HR side sealing ledge (50 MC/SC BP) .......................................................................................................................... 3356300

24 HR side sealing ledge (80 MC/SC BP) .......................................................................................................................... 3352600

25 HR upper sealing ledge (50 MC/SC BP)........................................................................................................................3463400

25 HR upper sealing ledge (80 MC/SC BP)........................................................................................................................3488700

26 G4 fi lter stand 500 mm (supply air) (50 MC/SC BP) ........................................................................................................3356400

26 G4 fi lter stand 580 mm (supply air) (80 MC/SC BP) ........................................................................................................3352700

27 G4 fi lter stand 400 mm (extract air) (50 MC/SC BP) ........................................................................................................3382800

27 G4 fi lter stand 450 mm (extract air) (80 MC/SC BP) ........................................................................................................3368500

28 G4 fi lter (supply air) (50 MC/SC BP) ...............................................................................................................................978036

28 G4 fi lter (supply air) (80 MC/SC BP) .............................................................................................................................3326700

29 G4 fi lter (extract air) (50 MC/SC BP) ..............................................................................................................................978035

29 G4 fi lter (extract air) (80 MC/SC BP) ............................................................................................................................3379700

30 F7 fi lter (50 MC/SC BP) ...............................................................................................................................................978136

30 F7 fi lter (80 MC/SC BP) ...............................................................................................................................................978135

31 F7 fi lter puller (50 MC/SC BP) .....................................................................................................................................3452100

31 F7 fi lter puller (80 MC/SC BP) .....................................................................................................................................3480200

32 Plug (50 MC/SC BP) ....................................................................................................................................................990630

32 Plug (80 MC/SC BP) ....................................................................................................................................................990640

33 Cover plate 100 mm (50 MC/SC BP) ........................................................................................................................... 3363500

33 Cover plate 125 mm (80 MC/SC BP) ........................................................................................................................... 3363600

34 Water seal ................................................................................................................................................................3212200

35 Condensing water outlet .............................................................................................................................................. 3477000

36 Pipe connector cover of water seal ................................................................................................................................3482600

37 Ceiling mounting part (in mounting accessory bag 3361500) ............................................................................................ 3358500

38 Knurled-head screw ......................................................................................................................................................990698

39 Post-heating radiator (R units) ...........................................................................................................................................942210

39 Post-heating radiator (L units) ........................................................................................................................................... 942211

40 Post-heating radiator holder .......................................................................................................................................... 3452000

41 Bypass duct radiator (80 MC R units) ............................................................................................................................... 942210

41 Bypass duct radiator (80 MC L units) ................................................................................................................................942211

42 Front resistor bracket ...................................................................................................................................................3429500

80

MC

© VALLOX • We reserve the right to make changes without prior notice.

What the units include can vary depending on the sales area.

11

Page 12

Vallox TSK

Multi 50

80

MC

12

www.vallox.com

© VALLOX • We reserve the right to make changes without prior notice.

1.09.399bE/26.1.2015/PDF

What the units include can vary depending on the sales area.

Loading...

Loading...