www.valex.com

Specification Number SP-9217

Valex High Purity Ball Valve

SECTION DESCRIPTION PAGE

1.0 Scope .........................................................................................................................................2

2.0 Reference Documents ...............................................................................................................2

3.0 Material Characteristics ............................................................................................................2

4.0 Operating Data ..........................................................................................................................3

5.0 Final Process .............................................................................................................................4

6.0 Testing and Inspection ..............................................................................................................4

7.0 Packaging ..................................................................................................................................4

8.0 Marking and Documentation ....................................................................................................5

9.0 Supplementary Features ............................................................................................................5

10.0 Ordering Part Number System .................................................................................................6

11.0 Revision Log .............................................................................................................................8

This document is presented by Valex Corp. for general information purposes and may be reproduced in part or

total. In total, the document reflects the specification requirements met or exceeded by Valex products sold under

the name "Valex High Purity Ball Valve".

SP-9217 Rev. X, Page 1 of 8

1.0 Scope:

Configuration: Ball valve.

Sizes: 1/4” o.d. to 6” o.d. (6.4mm o.d. to 152.4mm o.d.)

JIS 15A to 100A pipe (21.7mm o.d. to 114.3mm o.d.)

2.0 Reference Documents:

General Note: All specification references shall be taken as the latest editions, including appendices,

addenda, errata, and revisions.

ASTM A351/A351M, Standard Specification for Castings, Austenitic, Austenitic-Ferritic

(Duplex), for Pressure Containing Parts.

ASTM A479/A479M, Standard Specification for Stainless Steel Bars and Shapes for Use in

Boilers and Other Pressure Vessels

ANSI/ASME Specifications: ANSI/ASME B46.1, Surface Texture.

Crane Technical Paper: TP-410 Flow of Fluids

CGA Specifications: CGA G-4.1, Cleaning Equipment for Oxygen Service.

ANSI/ASQC Standard: ANSI/ASQC Z1.4-1993 Sampling Procedures and Tables for Inspection by Attributes

3.0 Material Characteristics:

ASTM Reference: Body Housing: ASTM A351-CF8M.

End-Cap Flanges: ASTM A351-CF3M.

Ball: ASTM A351-CF3M or A479 316/316L

Materials of Construction: Wetted Path: CF3M / 316 stainless / 316L stainless.

Non-Wetted: CF8M, 300-series stainless steel, vinyl (handle sleeve), tamper-evident

ink (on bolt threads).

Standard seats/seals: Reinforced Teflon (RTFE) seats, virgin Teflon (PTFE) seals.

Other seat/seal materials are available.

Internal Surface Roughness

Wetted Path: 25 micro-inch maximum.

Assembled Length Tolerance: Per brochure ± .25” (± 6.35mm)

Lubricant: None

SP-9217 Rev. X, Page 2 of 8

Valve Size

Ball Orifice

Connection Orifice

Cv1

(Inches)

(Inches)

1/4" X .035"

0.402

0.180

2.9

3/8” X .035”

0.402

0.305

9.0

1/2” X.049"

0.402

0.402

16.3

3/4" X.065"

0.620

0.620

41.2

1" X.065"

0.870

0.870

84.9

1-1/2" X.065"

1.370

1.370

223.3

2" X.065"

1.870

1.870

432.3

2-1/2" X.065"

2.370

2.370

714.4

3" X.065"

2.870

2.870

1071.2

4" X.083"

3.834

3.834

1975.3

6" X.109"

5.782

5.782

4697.8

JIS 15A (5S)

0.870

0.724

57.4

JIS 20A (5S)

1.370

0.941

100.4

JIS 25A (5S)

1.370

1.209

171.1

JIS 32A (5S)

1.870

1.551

290.7

JIS 40A (5S)

1.870

1.783

391.0

JIS 50A (5S)

2.370

2.252

641.1

JIS 65A (5S)

2.870

2.839

1046.5

JIS 80A (5S)

3.834

3.343

1478.4

JIS 100A (5S)

4.335

4.335

2559.3

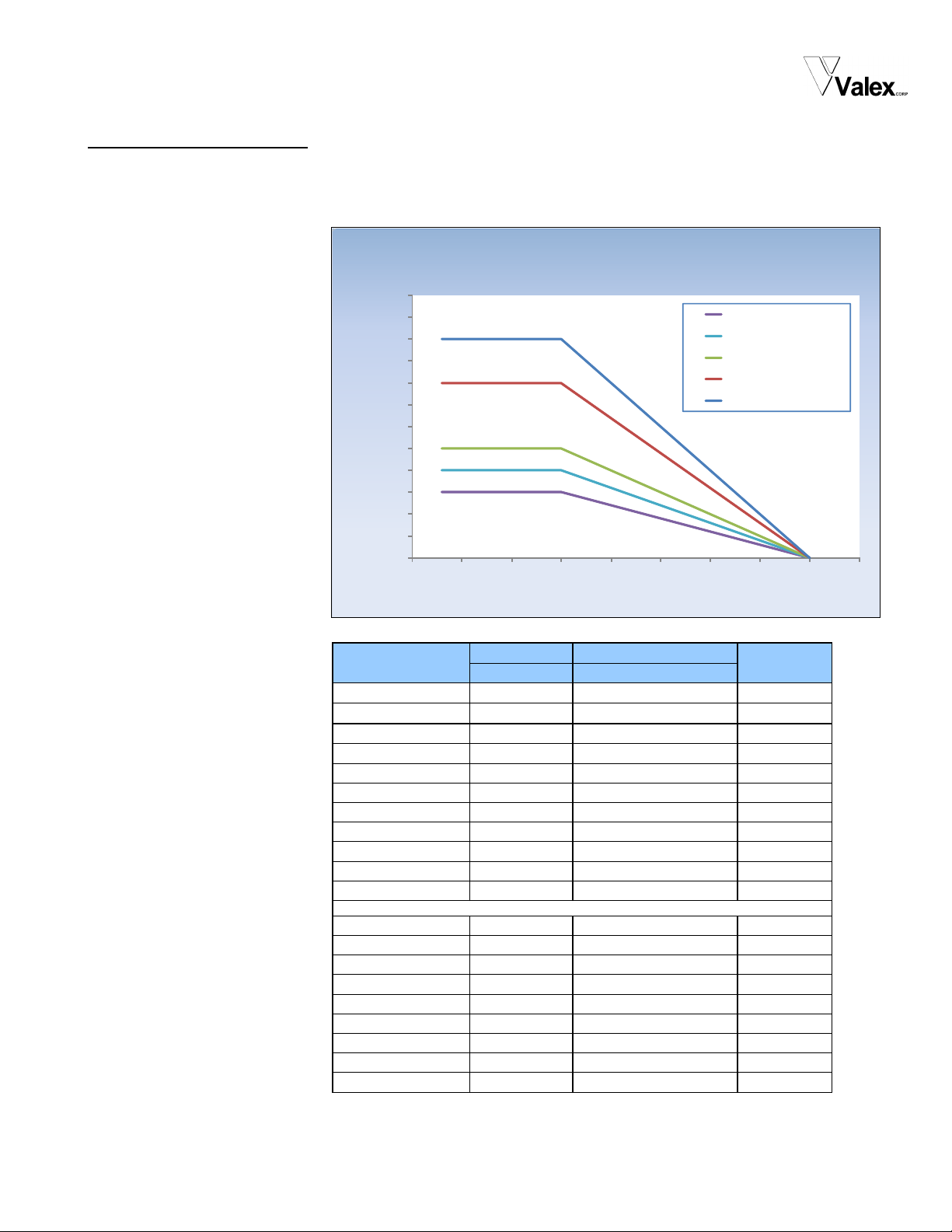

1/4" - 1" 1-1/2" - 2" 2-1/2" - 4" 4.5" 6"

15A 20A - 40A 50A - 80A 100A

-20 1000 800 500 400 300

0 1000 800 500 400 300

100 1000 800 500 400 300

350 0 0 0 0 0

Temp (F)

Pressure (PSIG)

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

-50 0 50 100 150 200 250 300 350 400

Maximum Working Pressure

(PTFE Seats / Seals )

6"

100A

2-1/2" - 4" (50A - 80A)

1-1/2" - 2" (20A - 40A)

1/4" - 1" (15A)

Temperature (°F)

Pressure (PSIG)

4.0 Operating Data:

Temperature Range: -20°F to 350°F as dictated by standard seat/seal materials. Seat/seal materials other

Maximum Working Pressure:

Flow Coefficient Data:

than standard may affect the working temperature range.

1) Flow coefficient data calculated using methods described in Crane Technical Paper TP-410.

SP-9217 Rev. X, Page 3 of 8

Loading...

Loading...