Page 1

UV-SVP

Operating Manual

Document Ref:

Date:

This document was prepared by the staff of Valeport Limited, the Company, and is the property of the

Company, which also owns the copyright therein. All rights conferred by the law of the copyright and by virtue

of international copyright conventions are reserved to the Company. This document must not be copied,

reprinted or reproduced in any material form, either wholly or in part, and the contents of this document, and

any method or technique available therefrom, must not be disclosed to any other person whatsoever without

the prior written consent of the Company.

Valeport Limited

St Peters Quay

Totnes

Devon, TQ9 5EW

United Kingdom

As part of our policy of continuous development, we reserve the right to alter, without prior notice, all

specifications, designs, prices and conditions of supply for all our equipment.

06508142b

28 September 2018

+44 1803 869292

sales@valeport.co.uk | support@valport.co.uk

www.valeport.co.uk

Tel:

e mail:

Web:

Page 2

Table of Contents

© 2018 Valeport Ltd

Page 2

Table of Contents

..................................................................................................................................... 31. EU Declaration of Conformity - CE Marking

..................................................................................................................................... 52. Introduction

..................................................................................................................................... 63. Specifications

..................................................................................................................................... 94. Data Requests

..................................................................................................................................... 115. Output Format

..................................................................................................................................... 126. Dimensions

..................................................................................................................................... 137. Wiring Information

Page 3

© 2018 Valeport Ltd

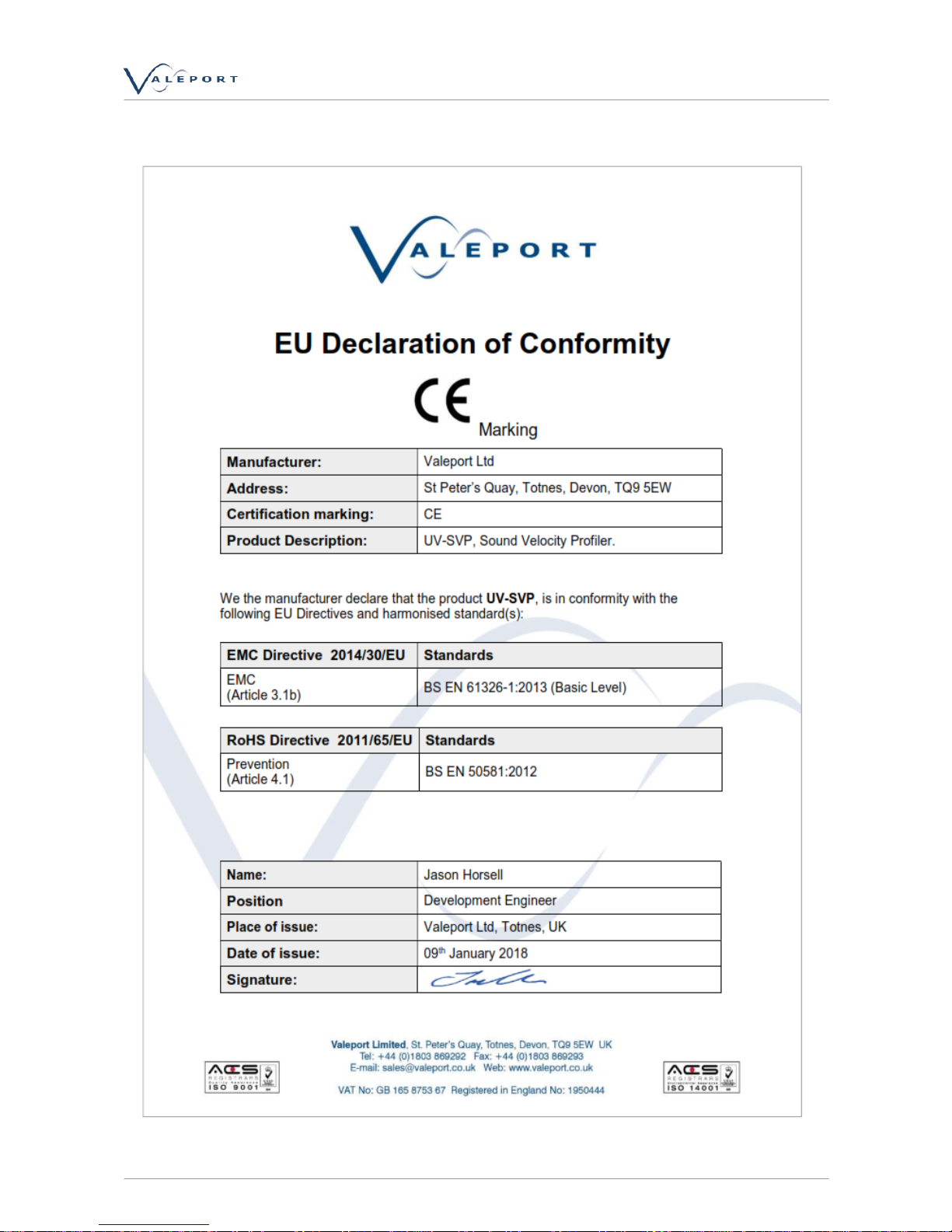

EU Declaration of Conformity - CE Marking

Page 3

1. EU Declaration of Conformity - CE Marking

Page 4

© 2018 Valeport Ltd

06508142b - UV-SVP

Page 4

Please note: Any changes or modifications to the product or accessories supplied, that are not

authorised by Valeport Ltd, could void the CE compliance of the product and negate your authority

to operate it. This product has demonstrated CE compliance under conditions that include the use of

shielded cables. It is important that you use shielded cables compliant with the product’s

conformance, to protect from potential damage and reduce the possibility of interference to other

electronic devices.

Page 5

© 2018 Valeport Ltd

Introduction

Page 5

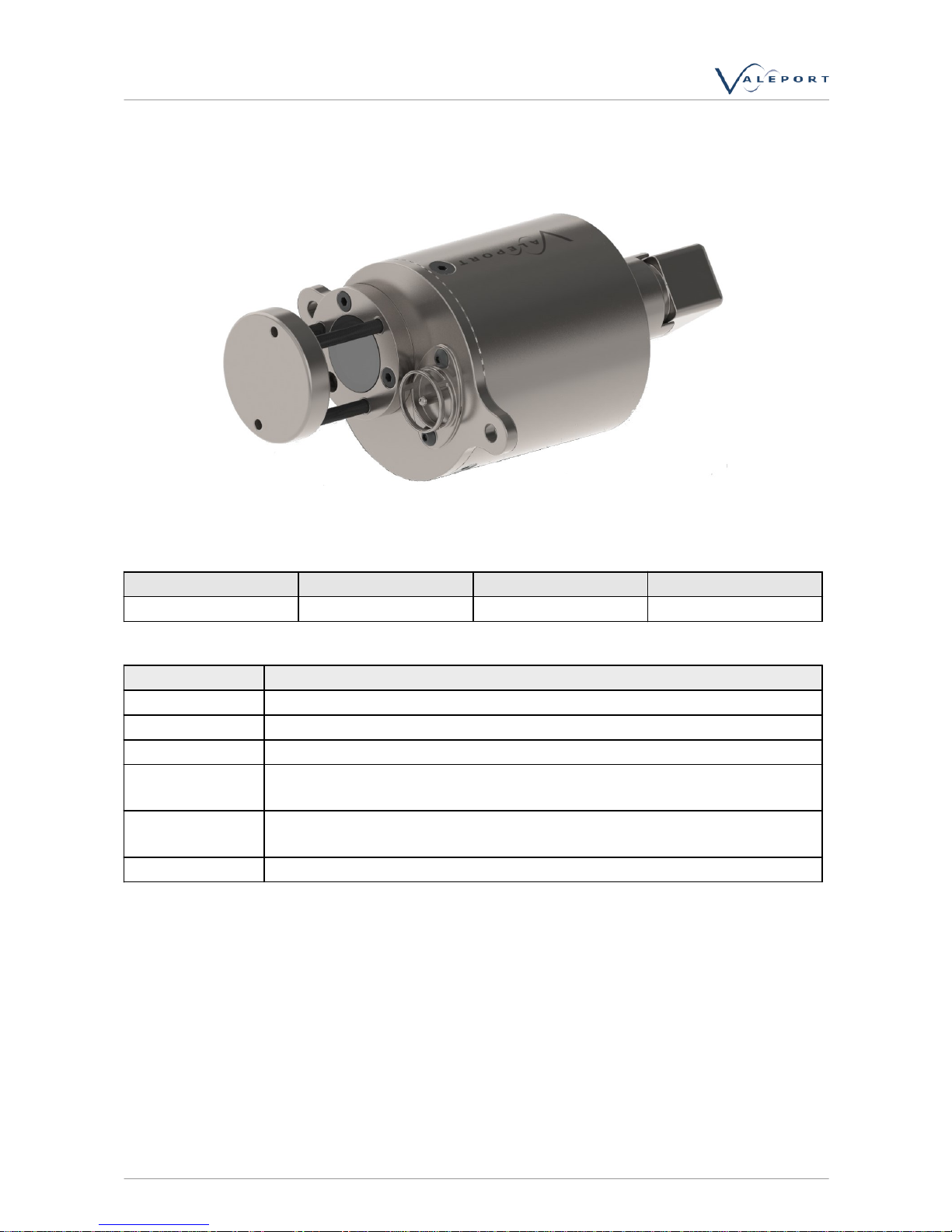

2. Introduction

This manual covers the basic specifications, deployment and maintenance procedures for the UVSVP. The instrument can be controlled by sending commands directly, using a suitable terminal

emulation program such as Valeport Terminal or HyperTerminal.

The instrument is based on Valeport’s existing “mini” sensor range and has been designed to be

simple to use and maintain, as well as being small and lightweight for easy handling and

deployment.

Page 6

© 2018 Valeport Ltd

06508142b - UV-SVP

Page 6

3. Specifications

Dimensions:

Housing Ø

Mounting bulkhead Ø

Overall length

Weight in Air

63mm

90mm

139mm

0.726 Kg

Materials:

Part

Material

Main housing

Titanium

Sensor bulkhead

Titanium

Connector

Titanium SubConn MCBH6F Right Angle

Sound Velocity

Sensor

Carbon Composite legs, Titanium Body, Ceramic Transducer behind

polycarbonate window

Temperature

sensor

Titanium

Pressure sensor

Hastelloy

Power:

External 9 – 28v DC input

0.36W (30mA @12v)

Page 7

© 2018 Valeport Ltd

Specifications

Page 7

Connection:

Standard is SubConn type MCBH6F titanium

Alternatives may be supplied on request

Wiring Information is in Section 4

Output:

Units are fitted with both RS232 and half-duplex RS485 communications as standard, selected by pin

choice on the output connector. Protocol is 8 data bits, 1 stop bit, no parity, and no flow control.

Baud rate is factory set to 19200. User may choose between 2400, 4800, 9600, 19200, 38400, 57600,

115200. (Note that fast data rates may not be possible with low baud rates). Continuous output at 1,

2, 4 or 8Hz

Performance:

Sensor

Sound Velocity

Range

1375 – 1900m/s

Accuracy

±0.02m/s

Resolution

0.001m/s

Frequency

2.5 MHz

Pressure

Range

10, 20, 30, 50, 100, 200 or 300Bar

Accuracy

±0.01% range

Resolution

0.001% range

Temperature

Range

-5 to +35°C

Accuracy

±0.01°C

Resolution

0.001°C

Certain features of the sensors used in the “mini” range are designed specifically to enable high

quality data to be delivered:

Carbon Composite Rods:

The carbon composite material used for the sensor spacer rods has been specifically selected to

provide 3 features:

a) Excellent corrosion resistance

b) Very high strength

c) Virtually zero coefficient of thermal expansion

This last point is particularly important; accurate sound velocity measurement relies on measuring

the time taken for a pulse of sound to travel a known distance. The material selected does not

measurably expand over the operating temperatures of the instrument, ensuring the highest possible

accuracy at all times.

Digital Sampling Technique:

Page 8

© 2018 Valeport Ltd

06508142b - UV-SVP

Page 8

Enables a timing resolution of 1/100th of a nanosecond, equivalent to about 0.5mm/sec speed of

sound on a 25mm path sensor, or 0.125mm/sec on a 100mm sensor. In practice, the output is

restricted to 1mm/sec resolution.

Linear sensor performance allows easy calibration.

Page 9

© 2018 Valeport Ltd

Data Requests

Page 9

4. Data Requests

The instrument responds to a series of text commands that are detailed below for those users who

wish to interface the UV-SVP to other systems.

This list is not comprehensive, but will allow the standard functions of the instrument to be accessed.

For more detailed information, please contact Valeport Ltd.

Notes

·

All commands must be confirmed using “Carriage Return” or “Enter” on the keyboard, with the

exception of the “Stop” command (#).

·

All commands are echoed back by the instrument as they are typed

Code

Followed By

Operation

#

Interrupts instrument when running

M

rate<CR>

Performs continuous measurement at set rate.

M1 = 1 Hz

M2 = 2 Hz

M4 = 4 Hz

M8 = 8 Hz

S

<CR>

Returns a single reading

#001

;address<CR>

Sets the 485 address

#002

<CR>

Returns the address

#004

<CR>

Read header info

#005

;ON<CR> or ;OFF<CR>

Turns ON or OFF address mode

#006

<CR>

Returns ON or OFF for address mode

#009

;<CR> or ;VALUE<CR>

Sets the tare value in systems with pressure fitted.

;<CR> = Makes device take a reading to use as

tare. ;VALUE<CR> = User entered value in units as set by

#018 command.

#010

<CR>

Returns the tare value

#011

;ON<CR> or ;OFF<CR>

Turns Tare function ON/OFF

#012

<CR>

Reads Tare mode

#018

;Pressure units<CR>

Set to either

0 – dBar

1 – Metres

2 – Feet

#019

<CR>

Read pressure units

#026

;valeport_separator<CR>

Sets the Valeport output string separator (1 char)

#027

<CR>

Returns the Valeport output string separator

#028

<CR>

Set the unit into run mode

#029

<CR>

Read run mode

#032

<CR>

Returns the software version number.

Page 10

© 2018 Valeport Ltd

06508142b - UV-SVP

Page 10

Code

Followed By

Operation

#034

<CR>

Returns the units serial number

#039

;ModeValue<CR>

Set mode without putting unit into run mode

Where

M1 = 1 Hz continuous output

M2 = 2 Hz continuous output

M4 = 4 Hz continuous output

M8 = 8 Hz continuous output

M16 = 16 Hz continuous output

#040

<CR>

Read operating mode.

#042

;ON or OFF

Enable/disable leading separator

#043

<CR>

Read leading separator (on or off)

#044

;ON or OFF

Enable/disable trailing separator

#045

<CR>

Read trailing separator (on or off)

#059

;baud_rate<CR>

Sets the units baud rate

2400,4800,9600,19200,38400;57600;115200

#083

;0 or 1 or 2 or 3

Setup the pressure output format

Where

0=not fitted, 1=PPPP.P, 2=PPP.PP, 3=PP.PPP

#084

<CR>

Returns the set pressure range

#091

;ON<CR> or ;OFF<CR>

Sets startup mode.

OFF=No readings at startup,

ON=Readings at last rate at startup

#102

;ON or OFF<CR>

Sets 485 mode

#103

<CR>

Sends 485 mode

Page 11

© 2018 Valeport Ltd

Output Format

Page 11

5. Output Format

Real time data follows the format described below.

Use #091 to control whether the instrument starts sampling as soon as power is applied or waits a for

command.

10.351 21.488 1506.739

·

The data separator is a space (this may be altered if required)

·

Leading and trailing spaces are enabled. (this can be altered if required)

·

Data is presented in the order:

- Pressure

- Temperature

- Sound Velocity

·

Pressure data format is dependent on sensor range, and may be any of the following. Leading

zeroes are included, so it is a fixed length string:

- PPPP.P (e.g. 0123.4 dBar)

- PPP.PP (e.g. 012.34 dBar)

- PP.PPP (e.g. 12.345 dBar)

·

The temperature data is given to 3 decimal places. Value is in °C and leading zeroes are included;

signed if negative:

- 21.456

- 02.769

- -01.174

·

Sound Velocity is given in m/s, as a fixed length string with 3 decimal places. In air, the sensor

reads 0000.000

Page 12

© 2018 Valeport Ltd

06508142b - UV-SVP

Page 12

6. Dimensions

Page 13

© 2018 Valeport Ltd

Wiring Information

Page 13

7. Wiring Information

Wiring colours are correct at the time the manual was printed. However, it is advised that continuity

checks are performed prior to all terminations.

Systems are supplied with a short (50cm) lead for splicing or testing

Subconn 6 pin male line (MCIL6M)

9 Way D Type

4mm Banana Plugs

Pin

Function

Pin

Pin

1

RS232 GND

5 (Link to 1,6,8,9)

2

RS232 Tx (Out of sensor) or RS485A

2

3

RS232 Rx (Into sensor) or RS485B

3

4+VRed Plug

5

Link to Pin 1 for RS485. N/C for RS232

6

Power GND

Black Plug

Loading...

Loading...