Page 1

miniSVS

Operating Manual

Document Ref:

Date:

This document was prepared by the staff of Valeport Limited, the Company, and is the property of

the Company, which also owns the copyright therein. All rights conferred by the law of the

copyright and by virtue of international copyright conventions are reserved to the Company. This

document must not be copied, reprinted or reproduced in any material form, either wholly or in

part, and the contents of this document, and any method or technique available therefrom, must

not be disclosed to any other person whatsoever without the prior written consent of the

Company.

Valeport Limited

St Peters Quay

Totnes

Devon, TQ9 5EW

United Kingdom

As part of our policy of continuous development, we reserve the right to alter, without prior notice,

all specifications, designs, prices and conditions of supply for all our equipment.

06508141a

09 March 2017

+44 1803 869292

sales@valeport.co.uk

www.valeport.co.uk

Tel:

e mail:

Web:

Page 2

Table of Contents

Page 2Page 2

Table of Contents

..................................................................................................................................... 31. Introduction

..................................................................................................................................... 42. Sensors

.................................................................................................................................... 42.1. Specifications

.................................................................................................................................... 52.2. Physical Characteristics

..................................................................................................................................... 73. Communications

.................................................................................................................................... 73.1. Sampling Modes

.................................................................................................................................... 73.2. Data Formats

.................................................................................................................................... 113.3. Wiring Information

..................................................................................................................................... 184. Operations

.................................................................................................................................... 184.1. Power Up

.................................................................................................................................... 184.2. Stop Command

.................................................................................................................................... 184.3. Command Echoes

.................................................................................................................................... 184.4. Pressure Format Commands

.................................................................................................................................... 184.5. Pressure Tare Commands

.................................................................................................................................... 194.6. Other Commands

..................................................................................................................................... 205. Appendix 1: FAQ’s

Page 3

Introduction

Page 3

© 2017 Valeport Ltd

1. Introduction

The Valeport miniSVS Sound Velocity Sensor has been designed with the objective of

providing high resolution, high accuracy sound velocity data in the most compact

package possible. The basic principle of Valeport’s Sound Velocity technology is “time

of flight”; that is to say, the sound velocity is calculated from the time taken for a single

pulse of sound to travel a known distance.

The miniSVS therefore consists of a single circuit board controlling all sampling, processing

and communications functions, and a sensor comprising a ceramic transducer, a signal

reflector, and spacer rods to control the path length. The two are connected by a single

coaxial cable. A titanium housing may be fitted, which provides waterproof protection

to a depth in excess of 6000m.

Optionally, a strain gauge pressure sensor may be added to the miniSVS, enabling sound

velocity profiles to be obtained. This configuration is used in the SoundBar 2 Digital Bar

Checker, where a 100 dBar range transducer is used, but the miniSVS may be fitted with

a selection of different range transducers up to 6000 dBar. The pressure option also uses

a secondary PCB.

As an alternative option, the miniSVS may be fitted with a PRT temperature sensor.

Note: the miniSVS may have either a pressure or temperature sensor fitted as an

option, but not both

Page 4

miniSVS

Page 4

© 2017 Valeport Ltd

2. Sensors

2.1. Specifications

2.1.1. Power

· Requires 8 – 29V DC input

· miniSVS draws approximately 17mA at 12V DC

· miniSVS with pressure draws approximately 24mA at 12V DC

· miniSVS with temperature draws approximately 20mA at 12V DC

2.1.2. Data Output

Units are fitted with both RS232 and RS485 communications as standard. RS485 is

enabled by grounding a pin in the communications lead (refer to Section 4). Protocol is 8

data bits, 1 stop bit, no parity, no flow control.

Baud rate is factory set to 19200. User may choose between 2400, 4800, 9600, 19200,

38400, 57600 or 115200. (Note that fast data rates may not be possible with low baud

rates).

2.1.3. Signal Frequency

Single sound pulse of 2.5MHz frequency.

2.1.4. Update Rate

Selected by command – Single output or continuous output at one of the following rates:

1Hz, 2Hz, 4Hz, 8Hz ,16Hz, 32 Hz or 60Hz

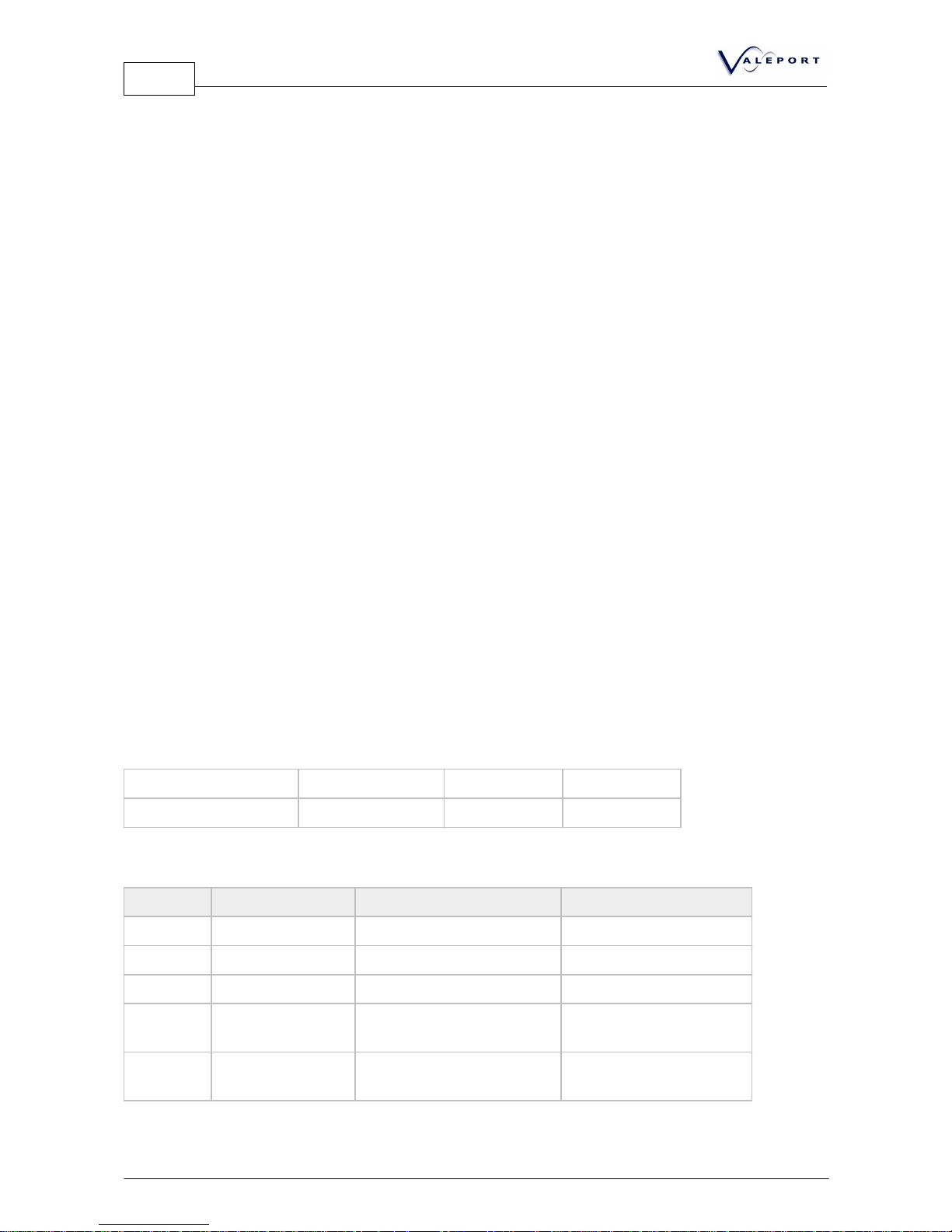

The fastest rate possible is determined by the combination of sensors fitted:

SV only

SV + P

SV + T

Max Data Rate:

60Hz

32Hz

16Hz

2.1.5. Performance

Sensor

Resolution

Range

Overall Accuracy

25mm

0.001m/sec

1375 – 1900m/s

±0.020 m/s

50mm

0.001m/sec

1375 – 1900m/s

±0.019 m/s

100mm

0.001m/sec

1375 – 1900m/s

±0.017 m/s

Pressure

0.01% FS

0 to 100, 500, 1000 or

6000 dBar

±0.05%FS

(over -10°C to 40°C)

Temp.

0.001°C

-5 to +35°C

(others available)

±0.01°C

Page 5

Sensors

Page 5

© 2017 Valeport Ltd

Certain features of the sensor package are designed specifically to enable high quality

data to be delivered:

Carbon Composite Rods:

The carbon composite material used for the sensor spacer rods has been specifically

selected to provide 3 features:

a) Excellent corrosion resistance

b) Very high strength

c) Virtually zero coefficient of thermal expansion

This last point is particularly important; accurate sound velocity measurement relies on

measuring the time taken for a pulse of sound to travel a known distance. The material

selected does not measurably expand over the operating temperatures of the

instrument, ensuring the highest possible accuracy at all times.

Size:

The longer the path length used, the higher the accuracy that can be achieved. It has

been found that a signal stability of ±2mm/sec can be achieved with a sensor path

length of 25mm (overall 50mm path for reflected signal), falling to ±1.7mm/sec for a

100mm path (overall 200mm path for reflected signal).

Digital Sampling Technique:

Enables a timing resolution of 1/100th of a nanosecond, equivalent to about 0.5mm/sec

speed of sound on a 25mm path sensor, or 0.125mm/sec on a 100mm sensor. In practice,

the output is restricted to 1mm/sec resolution.

Linear sensor performance allows easy calibration.

2.2. Physical Characteristics

Main housing

Titanium or Acetal

Main bulkhead

Titanium

Space Rods

Carbon Composite

Reflector Assembly

Titanium

SV Transducer

Ceramic transducer behind polycarbonate window.

Signal cable

3mm co-ax cable, nominal 25cm length. Push fit connector.

Pressure Transducer

Stainless steel diaphragm with acetal protective cover.

Temperature sensor

PRT in titanium housing with polyurethane backing.

Page 6

miniSVS

Page 6

© 2017 Valeport Ltd

2.2.1. Dimensions

Dependent on type supplied. See diagram below

Page 7

Communications

Page 7

© 2017 Valeport Ltd

3. Communications

The miniSVS has 3 different sampling modes, and a selection of data output formats.

Each mode is available with each output format.

3.1. Sampling Modes

· Single [data on request]

· Multiple at defined data rates [free running]

· Multiple as fast as possible [free running]

3.1.1. Sampling Commands

S<enter> Demands a single reading to be taken and data transmitted

M<enter>

Unit free runs at fastest data update rate

M1<enter>

Unit free runs at 1 Hz

M2<enter>

Unit free runs at 2 Hz

M4<enter>

Unit free runs at 4 Hz

M8<enter>

Unit free runs at 8 Hz

M16<enter>

Unit free runs at 16Hz

M32<enter>

Unit free runs at 32Hz

M60<enter>

Unit free runs at 60Hz

3.2. Data Formats

Data output is dependent on the parameters fitted to the miniSVS and the output format

selected.

Pressure data format is dependent on sensor range, and may be any of the following.

Pressure value is in dBar (abs), and leading zeroes are included, so it is a fixed length

string:

PPPP.P (e.g. 1234.5 dBar)

PPP.PP (e.g. 123.45 dBar)

PP.PPP (e.g. 12.345 dBar)

Temperature data format is fixed to a 5 digit string with 3 decimal places. Temperature

value is in °C and leading zeroes are included; it is signed only if negative. Examples:

21.456

02.769

-01.174

In the examples below, pressure data is expressed as {pressure} and the temperature

data is expressed as {temperature}

Page 8

miniSVS

Page 8

© 2017 Valeport Ltd

3.2.1. Valeport Standard Format

#082;off

Sets data format to standard Valeport mode (SV in mm/s)

SV only

<space>1234567<cr><lf>

where 1234567 is the speed of sound in mm/sec[i.e. 1234.567 m/sec]

P + SV

<space>{pressure}<space>1234567<cr><lf>

where 1234567 is the speed of sound in mm/sec[i.e. 1234.567 m/sec]

T + SV

<space>{temperature}<space>1234567<cr><lf>

where 1234567 is the speed of sound in mm/sec [i.e. 1234.567 m/sec]

P + T + SV

<space>{pressure}<space>{temperature}<space>1234567<cr><lf>

where 1234567 is the speed of sound in mm/sec [i.e. 1234.567 m/sec]

3.2.2. Alternative format #2:

#082;2

Sets SV data format to metres per second to 2 decimal places.

SV only

<space>1234.56<cr><lf>

where 1234.56 is the speed of sound in m/s

P + SV

<space>{pressure}<space>1234.56<cr><lf>

where 1234.56 is the speed of sound in m/s

T + SV

<space>{temperature}<space>1234.56<cr><lf>

where 1234.56 is the speed of sound in m/s

P + T + SV

<space>{pressure}<space>{temperature}<space>1234.56<cr><lf>

where 1234.56 is the speed of sound in m/s

3.2.3. Alternative format #3:

#082;3

Sets SV data format to metres per second to 3 decimal places.

SV only

<space>1234.567<cr><lf>

where 1234.567 is the speed of sound in m/s

P + SV

<space>{pressure}<space>1234.567<cr><lf>

where 1234.567 is the speed of sound in m/s

T + SV

<space>{temperature}<space>1234.567<cr><lf>

where 1234.567 is the speed of sound in m/s

P + T + SV

<space>{pressure}<space>{temperature}<space>1234.567<cr><lf>

where 1234.567 is the speed of sound in m/s

Page 9

Communications

Page 9

© 2017 Valeport Ltd

3.2.4. CSV format (SBE CT format)

#082;csv

Sets the miniSVS to output in CSV/SBE CT mimic mode

TTT.TTTT,CC.CCCCC,SSSS.SSSS,VVVVV.VVV <cr><lf>

This format mimics the SBE output format, where:

TTT.TTTT

is temperature value

CC.CCCCC

is conductivity value

SSSS.SSSS

is salinity value

VVVVV.VVV

is sound velocity in m/s

In this format, the miniSVS will substitute zeroes for parameters it cannot measure.

3.2.5. Seabird CTD format

#082;SEABIRD

Sets the miniSVS to output in Seabird CTD mimic mode

TTT.TTTT,CC.CCCCC,PPPPP.PPPP, SSSS.SSSS,VVVVV.VVV <cr><lf>

This format mimics the Seabird CTD output format, where:

TTT.TTTT

is temperature value

CC.CCCCC

is conductivity value

PPPPP.PPPP

is the pressure value

SSSS.SSSS

is salinity value

VVVVV.VVV

is sound velocity in m/s

In this format, the miniSVS will substitute zeroes for parameters it cannot measure.

Leading zeroes are replaced with spaces

Note: this output format is only available from firmware version 0650713B5

3.2.6. AML SVT format

#082;AML_SVT

Sets the miniSVS to AML SVT mimic mode

<space>{temperature}<space><space>1234.567<space><space><cr><lf>

where 1234.56 is the speed of sound in m/s

In this format, the miniSVS will substitute zeroes for parameters it cannot measure.

Page 10

miniSVS

Page 10

© 2017 Valeport Ltd

3.2.7. MVP format

#082;MVP

Sets the miniSVS to MVP mode

<space>pppp.p<space><space>ssss.ss<space><space>tt.ttt<space><cr><lf>

Where

pppp.p denotes pressure/depth

ssss.ss denotes speed of sound

tt.ttt denotes temperature

In this format, the miniSVS will substitute zeroes for parameters it cannot measure.

3.2.8. Sonardyne Format for use with Compatt

#013;on

Sets the unit to Sonardyne format

#013;off

Returns the unit to normal operation

Page 11

Communications

Page 11

© 2017 Valeport Ltd

3.3. Wiring Information

This section contains wiring information for all sensor configurations, and includes the

standard connector types and the most commonly requested alternatives. If your system

is fitted with a connector type not listed here, then the wiring information will be supplied

as an addendum at the back of the manual. Be sure to confirm that you are looking at

the appropriate information.

Wiring colours are correct at the time the manual was printed. However, it is advised that

continuity checks are performed prior to all terminations.

Connections:

Internal

Co-axial connector to sensor (J3)

5 – way FCI (power and comms) (J1)

NB: J2 & J4 are for Valeport calibration and setup purposes – not for use by

customer.

External

Standard is SubConn type MCBH6F (In titanium on titanium housings, in

brass on Acetal housings)

Alternatives may be supplied on request

Wiring Information is in Section 4

3.3.1. OEM Systems

Supplied with a short test lead to enable configuration and testing:

FCI 5 way

connector

Wire

Colour

Function

9 Way D Type

Connector

4mm Banana Plugs

1 (square pin)

Green

Signal / Power GND

5 (Linked to

1,6,8,9)

Black Plug, Green Wire,

connected inside 9 way D

type

2

Yellow

RS232 Tx (Out of sensor)

or RS485A

2

3

Blue

RS232 Rx (Into sensor)

or RS485B

3

4

Red

+V

Red Plug, Red Wire,

connected inside 9 way D

type

5

Link to Pin 1 for RS485.

N/C for RS232

Page 12

miniSVS

Page 12

© 2017 Valeport Ltd

3.3.2. Housed Systems (standard SubConn connector)

Systems are supplied with a short (50cm) lead for splicing or testing

SubConn 6 pin male line

(MCIL6M)

Function

9 Way D

Type

4mm Banana Plugs

Pin

Wire Colour

Pin

Pin

Wire Colour

1

Black

RS232 GND

5 (Link to

1,6,8,9)

2

White

RS232 Tx (Out of

sensor) or RS485A

23Red

RS232 Rx (Into sensor)

or RS485B

34Green

+V

Red Plug

Red, linked to Green

inside D type

5

Orange

Link to Pin 1 for RS485.

N/C for RS232

6 (Link to pin

1 in sensor)

Blue

Power GND

Black Plug

Black, linked to Brown

inside D type

Alternatively systems may be supplied with a test lead connected solely through a 9-way

D-type connector.

SubConn 6 pin male line

(MCIL6M)

Function

9 Way D Type

Pin

Wire Colour

Pin

1

Black

RS232 GND

5 (Link to 6,8,9)

2

White

RS232 Tx (Out of sensor) or

RS485A

2

3

Red

RS232 Rx (Into sensor)

or RS485B

3

4

Green+V7

5

Orange

Link to Pin 1 for RS485

N/C for RS232

6 (Link to pin

1 in sensor)

Blue

Power GND

1

Page 13

Communications

Page 13

© 2017 Valeport Ltd

3.3.3. Housed Systems (Impulse IE55-12-CCP connector,

optional fit only)

Systems are supplied with a free end lead for splicing

View onto

Bulkhead

Connector Pins

Impulse 6 pin male bulkhead

Function

Pin

Wire Colour

1

Green

RS232 Rx (in to sensor)

RS485A

2

Yellow

Power & RS232 Ground

3

Blue

9 – 28V DC input

4

Red

RS232 Tx (out of sensor)

RS485B

5

N/C

6

N/C

NB: RS232 and Power grounds must be linked.

Impulse 6 pin female line

Function

Pin

Wire Colour

1

Yellow

RS232 Rx (in to sensor)

RS485A

2

White

Power & RS232 Ground

3

Red

9 – 28V DC input

4

Brown

RS232 Tx (out of sensor)

RS485B

5

Orange

Link to Pin 2 for RS485.

N/C for RS232

6

Blue

N/C

Screen

N/C

Note: Do not connect screen.

Page 14

miniSVS

Page 14

© 2017 Valeport Ltd

3.3.4. Housed Systems (Impulse MHDG-5-BCR connector,

optional fit only)

Systems are supplied with a free end lead for splicing

Impulse MHDG-5-BCR

Function

Free End

Pin

Wire Colour

Wire

1

Green

RS232 Ground

Screen

2

2

White / Black

RS232 TX (out of sensor)

3

3

White / Red

RS232 RX (in to sensor)

44Red+V55 Black

-V (join to pin 1)

6

Page 15

Communications

Page 15

© 2017 Valeport Ltd

3.3.5. Housed Systems (SubConn OM8F connector, optional

fit only)

SVS Test Cable, 3m Valeport 8-Core Cable.

SubConn 8 pin

male line (OM8F +

OMBB)

Function

9 Way D

Type

4mm Banana Plugs

Pin

Pin

Pin

Wire colour1+V

Red Plug

Red2-V

Black Plug

Black345 6

RS232 RX (In to SVS)

3

7

RS232 TX (Out of SVS)

2

8

RS232 GND

5 (Link to

1,6,8,9)

139-IPS Extension Cable, 10m Valeport 8-Core Cable.

SubConn 8 pin male line

(OM8F + OMBB + DLSB-F)

Function

Subconn 8 pin female line

(OM8M + OMBB + DLSB-M)

Pin

Pin

1+V12-V233445 56

RS232 RX (In to SVS)

6

7

RS232 TX (Out of SVS)

7

8

RS232 GND

8

Page 16

miniSVS

Page 16

© 2017 Valeport Ltd

3.3.6. MVP Housed Systems (SubConn Male Bulkhead

Connector)

miniSVS instruments built to operate with MVP equipment can be operated in RS232 or

RS485 serial comms modes.

In order to operate in RS485 pins 2 to 5 have to be linked. This can be done as a factory

build setting and are designated 'Internal' RS485 configuration or as an optional setting

externally to the instrument.

3.3.6.1. Internal RS485

Pins 2 and 5 are linked inside the instrument.

Systems are supplied with a short (50cm) lead for splicing or testing

SubConn 6 pin

female line

(MCIL6F)

Function

15 Way D

Type

4mm Banana Plugs

Pin

Wire Colour

Pin

Pin

Wire

Colour

2

WHITE

-V

Join BLACK &

WHITE wires in

the hood

Black

4mm

plug

BLACK

3

RED

+V

Join RED &

RED wires in

the hood

Red

4mm

plug

RED

4

GREEN

RS485 A

10,12

1

BLACK

RS485 B

9.11

2

WHITE

RS485 GND

5

Page 17

Communications

Page 17

© 2017 Valeport Ltd

3.3.6.2. External RS485

For RS485 comms pins 2 and 5 need to be connected at some point within the interface

cable.

Systems are supplied with a short (50cm) lead for splicing or testing with no link.

SubConn 6 pin

Female Line

(MCIL6F)

Function

15 Way D

Type

4mm Banana Plugs

Pin

Wire Colour

Pin

Pin

Wire Colour

2

WHITE

-V

Join BLACK &

WHITE wires in

the hood

Black 4mm

plug

BLACK

3

RED

+V

Join RED &

RED wires in

the hood

Red 4mm

plug

RED

4

GREEN

RS232 Rx (into

sensor) or

RS485 A

10,12

1

BLACK

RS232 Tx (out of

sensor) or RS485 B

9.11

2

WHITE

RS232 / RS485 GND

5

5

Orange

RS485 Enable

Link to 5*

*or in the mating SubConn link pin 2 to pin 5

Note: RS485 A/B is not formally specified. If data cannot be read successfully it may be

that the RS485A/B need to be swapped

Page 18

miniSVS

Page 18

© 2017 Valeport Ltd

4. Operations

4.1. Power Up

There are two power up modes. The unit will either immediately begin running in the

previous sample mode, or will immediately send a ‘>’ character, and wait for a

command. There needs to be a delay of at least 500ms before sending the first

command. In both cases, the data format will remain as that previously used.

#092<enter>

Reads start up mode

#091;ON<enter>

Readings at last rate at start up

#091;OFF<enter>

No readings at start up

4.2. Stop Command

The unit can be stopped at any time by sending the ‘#’ character. The unit returns a ‘>’,

and waits for a further command.

4.3. Command Echoes

Each command character is immediately echoed back

<Enter> is echoed back as <cr><lf>

4.4. Pressure Format Commands

#083;0

Turns pressure sensor off and unit reverts to SV only operation mode

#083;1

Sets pressure data format to 1 decimal place

#083;2

Sets pressure data format to 2 decimal places

#083;3

Sets pressure data format to 3 decimal places

#018;0

Sets units to dBar

#018;1

Sets units to Metres

#018;2

Sets units to Feet

#019

Read Pressure Units

4.5. Pressure Tare Commands

#011;on

Turns Tare mode on (i.e. unit subtracts fixed value from pressure data)

#011;off

Turns Tare mode off (i.e. unit outputs pressure as read)

#009;

Unit takes single pressure reading to use as Tare value.

#009;0

Sets Tare value to zero (i.e. removes tare)

#009;

{value}

Input Tare value in units of 0.001dBar (i.e. 9000 = 9dBar)

Page 19

Operations

Page 19

© 2017 Valeport Ltd

4.6. Other Commands

#059;{baud_rate}<cr>

e.g. #059;19200

Sets the units baud rate.

Options are 2400,4800,9600,19200,38400,57600,115200

#031;raw

Sets data output to raw format (time of flight in 100ths of

nanoseconds)

#031;cal

Sets data output to calibrated format (sound velocity in

mm/sec). Unit always starts in cal mode from power on.

#001;nn

Sets RS485 address (01 to 99)

#005;ON or OFF

Turns Address mode ON or OFF

#006

Returns ON or OFF for address mode

#026;{xxxx}

Sets data separator for Valeport mode. Default is

<space>, separator may be up to 4 characters.

Page 20

miniSVS

Page 20

© 2017 Valeport Ltd

5. Appendix 1: FAQ’s

Why is the Data Different From My Old CTD Data?

Quite simply, the Valeport SV sensor is more accurate than anything else that has

previously been available. The CTD formulae (Chen & Millero, Del Grosso etc.) all have

errors in them – they were after all based on observed data taken over 30 years ago

using the best technology available at the time. The Valeport SV sensor simply highlights

those errors. This does raise an interesting point – if it is more important to you that your

data is consistent with old data, rather than accurate in its own right, then you are

possibly better off using a CTD (we would suggest a Valeport CTD, naturally).

How is it so Accurate?

Several reasons. Primarily, we use an advanced digital signal processing technique that

removes virtually all noise from the data, tells us the precise moment that the sound pulse

is both transmitted and received, and allows us to measure the time of flight with a

resolution of 1/100th of a nanosecond (10-11 seconds). Secondly, we have developed a

carbon composite material that doesn’t expand or contract with temperature, so our

“known distance” is a constant. Technically, the material will expand and contract

minutely, but over the operating temperatures of the probe, it is an almost immeasurably

small amount, and any change is included in our overall error budget. Finally, our

calibration method removes virtually all of the error sources associated with other

techniques.

But Don’t you Just Calibrate it Against Chen & Millero?

No we don’t – that would defeat the purpose. While the seawater formulae (Chen &

Millero, Del Grosso etc.) have inherent errors that are accepted as being at best

±0.25m/s, we use a different formula to calibrate the sensor. Del Grosso also published a

formula for speed of sound in pure water (with Mader, 1972), which is much more

accurate. In pure water, the only variable that can affect sound velocity is temperature

(assuming that you are at atmospheric pressure in a laboratory environment), rather than

both temperature and Salinity with the seawater equations. The Del Grosso & Mader

formula therefore has an error of just ±0.015m/s. By calibrating against this rather against

the error-filled seawater equations, we can achieve significantly better performance.

Is a Pure Water Calibration Valid?

Absolutely – the purpose of a calibration is just to compare (and adjust) the sensor output

against a known standard – it doesn’t really matter what that standard is, as long it is

precisely defined. Our standard happens to be pure water because it is the most

accurately defined standard available.

How Often Does a miniSVS Need Calibrating?

The SV sensor itself is remarkable stable. Since the entire timing system is digital, it is not

subject to the drift that analogue components often exhibit over time. The only part of

the system that can drift with time is the timing crystal itself. This is typically less than

±0.005m/s in the first year, and less than ±0.002m/s in subsequent years. We quite

confidently say that the SV sensor should remain within specification for several years.

However, the temperature and pressure sensors (if fitted) do exhibit greater drift with

time. It is our experience that in the majority of cases, performance can be maintained

by recalibrating at 2-yearly intervals. However, we are aware that many operators’ own

QA requirements state annual recalibration, and it is true that most instruments are

returned to us on a yearly basis.

Page 21

Appendix 1: FAQ’s

Page 21

© 2017 Valeport Ltd

What is the Response Time?

Virtually instant – the sound pulse takes a matter of microseconds, and the measurement

is made using just one pulse.

The Sensor Outputs Zero Sometimes – Why?

The sensor outputs zero when it doesn’t record the returning sound pulse within the

expected time frame (a time frame that equates to 1375 – 1900m/s in terms of sound

velocity). The most common occurrence of a zero value is when the sensor is in air, but it

can also happen if the probe has been dropped into a soft bed and is covered in mud

or sediment. This will normally wash off during the up-cast. It can also happen if the

sensor has been deployed for some time without cleaning, and there is significant growth

on the sensor.

Loading...

Loading...