Page 1

miniIPS Operating Manual

Operating Manual

Document Ref:

Date:

This document was prepared by the staff of Valeport Limited, the Company, and is the property of the

Company, which also owns the copyright therein. All rights conferred by the law of the copyright and by

virtue of international copyright conventions are reserved to the Company. This document must not be

copied, reprinted or reproduced in any material form, either wholly or in part, and the contents of this

document, and any method or technique available therefrom, must not be disclosed to any other person

whatsoever without the prior written consent of the Company.

Valeport Limited

St Peters Quay

Totnes

Devon, TQ9 5EW

United Kingdom

As part of our policy of continuous development, we reserve the right to alter, without prior notice, all

specifications, designs, prices and conditions of supply for all our equipment.

0760824b

August 2019

Tel:

e mail:

Web:

+44 1803 869292

sales@valeport.co.uk | support@valport.co.uk

www.valeport.co.uk

Page 2

Table of Contents

Table of Contents

..................................................................................................................................... 31. EU Declaration of Conformity - CE Marking

..................................................................................................................................... 42. Introduction

..................................................................................................................................... 53. Sensors

..................................................................................................................................... 64. Physical Characteristics

.................................................................................................................................... 64.1. Materials

.................................................................................................................................... 64.2. Dimensions

..................................................................................................................................... 75. Communications

.................................................................................................................................... 75.1. Welcome Message

.................................................................................................................................... 75.2. Data Requests and Output Formats

5.2.1 Start / Stop

5.2.2 Communications Setup

5.2.3 Sampling Pattern

5.2.4 Pressure Tare

5.2.5 Data Output Formats

5.2.6 Information #Codes

5.2.7 Calibration

.................................................................................................................................... 7

.................................................................................................................................... 8

.................................................................................................................................... 8

.................................................................................................................................... 10

.................................................................................................................................... 11

.................................................................................................................................... 13

.................................................................................................................................... 13

..................................................................................................................................... 146. Electrical

.................................................................................................................................... 146.1. Wiring Information

..................................................................................................................................... 157. Software

..................................................................................................................................... 168. Care & Maintenance

..................................................................................................................................... 179. Ordering and Part Numbers

© 2019 Valeport Ltd

Page 2

Page 3

EU Declaration of Conformity - CE Marking

Any changes or modifications to the product or accessories supplied, that are not authorised by Valeport

Ltd, could void the CE compliance of the product and negate your authority to operate it. This product has

demonstrated CE compliance under conditions that include the use of shielded cables. It is important that

you use shielded cables compliant with the product’s conformance, to protect from potential damage and

reduce the possibility of interference to other electronic devices

1. EU Declaration of Conformity - CE Marking

Page 3

© 2019 Valeport Ltd

Page 4

0760824b - miniIPS Operating Manual

2. Introduction

The Valeport miniIPS “Intelligent Pressure Sensor” is designed to measure water pressure and provide a real time

output of that data. Suitable for use in a variety of subsea applications (ROV’s, construction, monitoring,

positioning), one of the key development drivers was to provide a cost effective alternative to the use of resonant

quartz pressure sensors. Using the very latest technology in temperature compensated piezo-resistive transducers,

the miniIPS offers several advantages over resonant quartz sensors, with similar performance.

· No external diaphragms, oil reservoir or oil-filled tubes

· Easy to clean – no salt build up

· Titanium construction

· Pressure ranges from 10 to 600Bar (approx 100m to 6000m water)

· Long term calibration stability

· May be recalibrated by customers using standard Class A deadweight tester (requires optional adapter)

· RS232 or addressable RS485 data output

· Choice of calibrated data formats

· Choice of sampling modes

© 2019 Valeport Ltd

Page 4

Page 5

3. Sensors

Type:

Strain Gauge

Range:

5, 10, 30, 50, 100, 300 or 600 Bar (factory fit option)

Resolution:

0.001% of full range

Accuracy:

±0.01% or full range

Response Time:

1 milliseconds

Pressure

The miniIPS is fitted with the following sensors:

· A high accuracy (0.01%), temperature compensated piezo-resistive pressure transducer

Sensors

Page 5

© 2019 Valeport Ltd

Page 6

0760824b - miniIPS Operating Manual

Housing & Bulkhead:

Titanium

Sensor Cap:

Acetal

Transducer Diaphragm

Stainless Steel

Connector:

Standard is SubConn type MCBH6F (titanium)

Alternatives may be supplied on request

Weight:

<1kg (in air)

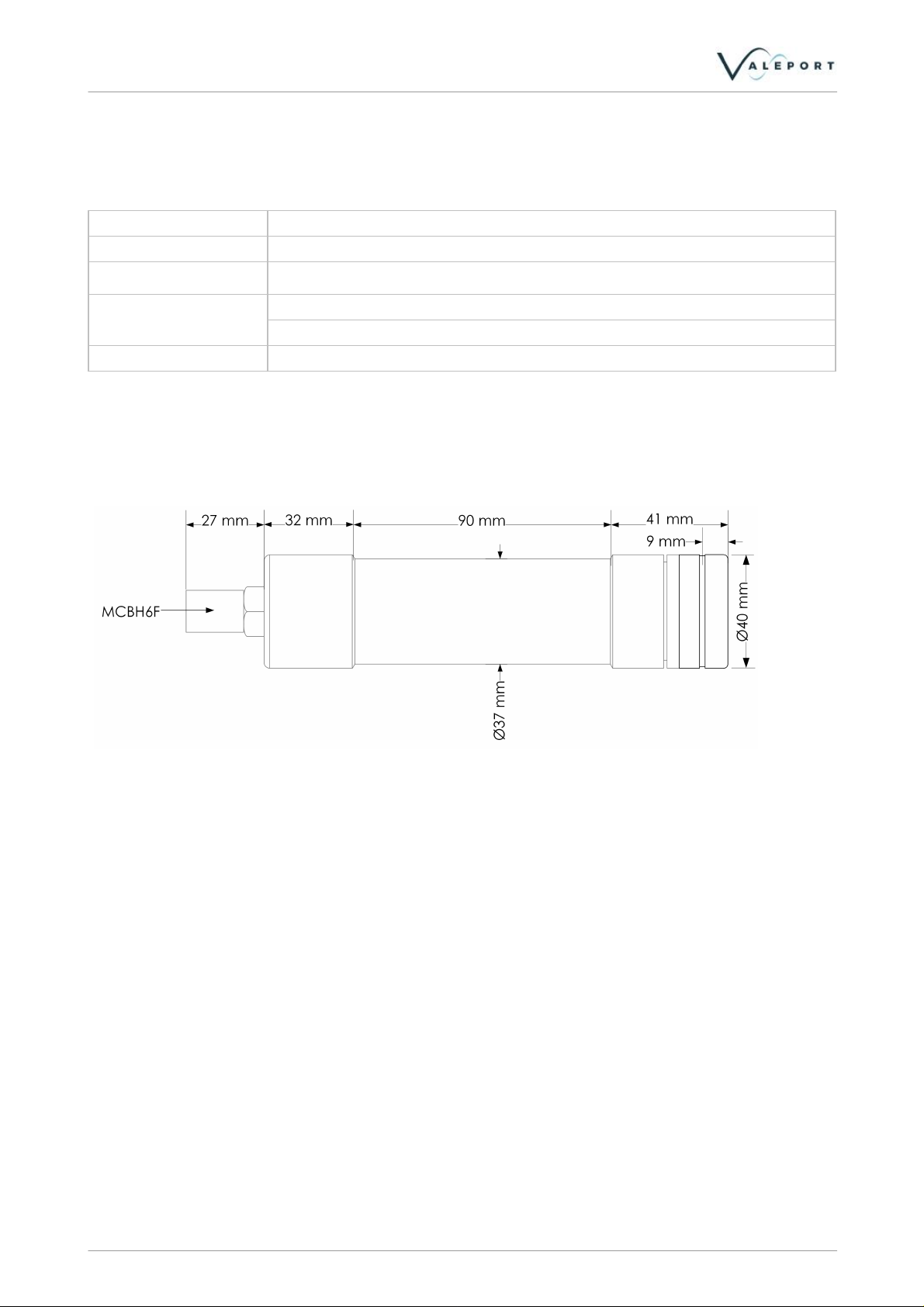

4. Physical Characteristics

4.1. Materials

4.2. Dimensions

Please refer to factory for detailed dimensions if required.

© 2019 Valeport Ltd

Page 6

Page 7

Communications

You are connected to a Valeport Mini IPS Sensor

0760700B 14/09/2019 07:00

Copyright 2019

#209;OFF (or ON)

This command will disable (or enable) the welcome message when power

is applied.

All commands must be “sent” by pressing the Enter key, with the exception of the single ‘#’ character required

to enter set up mode

You must use the main Enter key on the keyboard, not the smaller number pad Enter key. The large key

actually sends two instructions – “Carriage Return” (or <CR>) and “Line Feed” (or <LF>). The miniIPS requires

both these instructions to terminate a command. The smaller Enter key on a keyboard only sends the <CR>

instruction

#

When the instrument is running, the miniIPS may be put into set up mode at any time by

typing the ‘#’ character. The device will respond with a command prompt ‘>’ and wait the

next instruction.

Note: that there is a “watchdog” function here – if the unit is interrupted with the ‘#’

character, and no further command is received for a period of 5 minutes, the sensor will

automatically begin sampling data using the existing settings

#028

Starts sampling from set up mode, or takes a single reading if unit is in “Single” sampling

mode.

5. Communications

5.1. Welcome Message

When power is applied to the miniIPS, it will normally output a welcome message as follows, detailing the software

version:

5.2. Data Requests and Output Formats

Control of the miniIPS is achieved through the use of “# codes”, as described below.

5.2.1. Start / Stop

When power is applied to the miniIPS, it will immediately begin to operate according to the settings already

programmed. The most basic level of Stop / Start control is, therefore, by switching power on and off.

Page 7

© 2019 Valeport Ltd

Page 8

0760824b - miniIPS Operating Manual

Command

Notes

#059;{baud rate}

Sets the sensor baud rate as required.

Available baud rates are 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200.

Example:

#059;9600

#001;nn

Sets the sensor address to any number from 01 to 99

#002

Responds with current sensor address

#005;ON (or OFF)

Turns the miniIPS address mode on (or OFF). In address mode, the sensor will only

respond to commands prefixed by its address, or the global address “00”.

Example:

03:#028

Sensor address “03” begin sampling

Example:

00:#028

All sensor addresses begin sampling

CONT

Continuous mode, where data is output at a fixed frequency from 1 to 16Hz

SINGLE

Single mode is effectively “Sample on Demand” – when instructed, the sensor will

measure and report a single reading

BURST

Burst mode is useful for longer term deployments, where data is measured for a number of

samples, and the sensor then “sleeps” for a defined period of time. The measured data

may be averaged or output as it is.

5.2.2. Communications Setup

5.2.3. Sampling Pattern

The miniIPS will operate in 3 different modes:

In each case, the sampling mode is set using the command #003. Note also that the command #004 will return

the current sampling pattern.

© 2019 Valeport Ltd

Page 8

Page 9

The command string to set the sampling parameters is as follows:

Mode:

Enter CONT, SINGLE or BURST as required

rate:

Enter 1, 2, 4, 8 or 16 as the required sampling rate in Hz. Note that this value must be

included in the string for SINGLE mode, even though it is not used.

period:

This value defines the Burst sampling mode, but must be entered for the other modes

even though it is not used. Enter the number of samples that should be taken in the Burst,

from 1 to 65535

interval:

This value defines the Burst sampling mode, but must be entered for the other modes

even though it is not used. Enter the number of seconds between the start of each

measurement burst, from 1 to 65535

average:

This parameter defines the Burst sampling mode, but must be entered for the other modes

even though it is not used. Enter FIXED, MOVING or NONE as required. Fixed averaging

means that a single average number of all the readings in the burst will be output.

Moving average is a sliding window of defined duration, averaging several data points

within the burst, and updating with each single reading. None means that no averaging

should be done, with each data point in the burst being output as it is measured.

length:

Defines the number of samples in the “sliding window” of the Moving Average. Enter a

value from 1 to 120. Note that this value is part of the definition of Burst mode, but must

also be entered for the other modes, even though it is not used.

#003;mode;rate;period;interval;average;length where:

Communications

Examples:

1: Continuous data output at 4Hz

#003;CONT;4;1;1;NONE;1

Note: that the characters shown in italics must be included, even though they are not part of the definition of

Continuous mode. It does not matter what values are used here, provided they fit within the general constraints

defined above (1 to 65535 etc).

2: Data on demand

#003;SINGLE;1;1;1;NONE;1

Note: that the characters shown in italics must be included, even though they are not part of the definition of this

mode. It does not matter what values are used, as long as they fit within the general constraints for each term

defined above (1 to 65535 etc).

3: Burst Mode, 80 readings over 5 secs, once per minute. Output average value only

#003;BURST;16;80;60;FIXED;1

Note: that the last value (shown in italics) must be included, even though it is not part of the definition of Fixed

Averaging. It does not matter what values is used here, provided it fits within the general constraints defined above

(1 to 120 etc.).

Page 9

© 2019 Valeport Ltd

Page 10

0760824b - miniIPS Operating Manual

#009

Unit takes a single reading to use as the Tare value. Output at that

pressure should now be approximately zero.

#009;0

Tare value is removed (i.e. set to zero)

#009;nnnn

Sets specific tare in dBar or Bar (max resolution of 0.000001) depending

on units selected by #020 command.

Example:

#009;10.325 sets tare to 10.325dBar

#010

Unit responds with current Tare value

5.2.4. Pressure Tare

The pressure sensor fitted to the miniIPS measures absolute pressure, i.e. it includes atmospheric pressure. The

pressure tare function allows the atmospheric pressure (as measured by the sensor before deployment) to be

removed from the readings, so the output is simply pressure of water. Note also that by taking a tare reading at

any fixed point in the water column, readings will then be output relative to that point.

The pressure tare should be taken with the sensor in the same orientation as it

will be deployed (horizontal, pointing up or pointing down) to negate any

effects of the weight of the sensing element itself. Whilst this effect is small, it

is an unnecessary contribution to the error budget.

The location of the sensor (i.e. the point relative to which all measurements

are made) is indicated by a groove and cross in the acetal sensor cap.

© 2019 Valeport Ltd

Page 10

Page 11

Communications

#020;M

Outputs data in Metres

#020;F

Outputs data in Feet

#020;B

Output data in Bar (firmware version m onwards)

#020;D

Outputs data in dBar

#020;P

Outputs data in PSI

#135;{latitude}

Sets the local operating latitude in decimal degrees. This is required for an accurate

pressure / depth conversion, since the relationship is partially dependent on local gravity,

which varies with distance from the equator. Positive / negative signing for North / South

of the equator is not relevant.

Example:

#135;50.426

Sets latitude to 50.426° (50° 25’ 34”), (Totnes UK).

Command:

#013;VALEPORT

Format:

0009.914

DBAR

Example:

#026;/

0009.914/DBAR

Command:

#13;CSV

Format:

00/00/00, 00:00:00, 0009.9, 0.0, 00.0

Notes:

DD/MM/YY, HH:mm:SS, Output Data, Spare, Spare

5.2.5. Data Output Formats

The miniIPS has a selection of different data output formats built in, allowing easy interface to software packages

and third party instrumentation.

5.2.5.1. Units

The default output units for the miniIPS are deciBar (dBar), equivalent to 0.1Bar, or approximately 1m of seawater.

The miniIPS can also output pressure in PSI. It is also possible to present the data in units of metres or feet of

seawater, calculated using the UNESCO Simple Pressure / Depth relationship, which assumes “standard” water

density.

All output formats are affected by changing the output units.

5.2.5.2. Valeport Format

Default separator is TAB. This may be changed to any chosen character using the command #026.

5.2.5.3. CSV Format

Page 11

© 2019 Valeport Ltd

Page 12

0760824b - miniIPS Operating Manual

Command:

#013;NMEA

Format:

$PIPS,0009.91, M*78

Notes:

NMEA Identifier, Output Data, Units + Checksum

Last three characters are a checksum

Command:

#013;HYPACK

Format:

009.9 0000.0

Notes:

Output Data + Spare field

Command:

#013;DIGIQUARTZ

Format:

*00019.914

Notes:

This format emulates the Paroscientific Digiquartz sensor output

Command:

#013;DIGIQUARTZ_CDL

Format:

*0001+0009.9139318

Notes:

This format emulates the Paroscientific Digiquartz CDL sensor output

5.2.5.4. NMEA Format

5.2.5.5. HYPACK Format

5.2.5.6. Digiquartz Format

5.2.5.7. Digiquartz CDL Format

© 2019 Valeport Ltd

Page 12

Page 13

Communications

#032

Software version number

#034

Instrument serial number

#093

PCB serial number

#138

Year of manufacture, month and year of last inspection/service

#202

Maximum transducer pressure range

#900

Outputs a full list of all command codes applicable to the sensor.

Note that not all of these codes are covered by this manual – use this feature with care.

5.2.6. Information #Codes

The following commands will cause the sensor to report back various pieces of information, as described:

5.2.7. Calibration

The miniIPS may be returned to Valeport or one of its approved laboratories for recalibration, or it may be recalibrated by the customer using a Class A deadweight tester, or defined standard of the customer’s choosing.

Page 13

© 2019 Valeport Ltd

Page 14

0760824b - miniIPS Operating Manual

SubConn 6 pin male line (MCIL6M)

9 Way D

Type

4mm Banana Plugs

Pin

Function

Pin

Pin

1

RS232 GND

5 (Link to 1,6,8,9)

2

RS232 Tx (Out of sensor) or RS485A

23RS232 Rx (Into sensor) or RS485B

3

4+VRed Plug

5

Link to Pin 1 for RS485. N/C for RS232

6

Power GND

Black Plug

6. Electrical

Power

9 – 28V DC input (isolated)

Draws approximately 40mA at 12vDC

Output

Units are fitted with both RS232 and RS485 communications as standard. RS485 is enabled by grounding a pin in

the communications lead (refer to Section 4). Protocol is 8 data bits, 1 stop bit, no parity, no flow control.

Baud rate is factory set to 19200. User may choose between 2400, 4800, 9600, 19200, 38400, 57600 or 115200.

Note that fast data rates may not be possible with low baud rates

6.1. Wiring Information

Wiring colours are correct at the time the manual was printed. However, it is advised that continuity checks are

performed prior to all terminations.

Systems are supplied with a short (50cm) lead for splicing or testing

© 2019 Valeport Ltd

Page 14

Page 15

7. Software

The miniIPS is fully compatible with Valeport Datalog X2 and Terminal X2. These can be downloaded from

Valeport's website.

Software

Page 15

© 2019 Valeport Ltd

Page 16

0760824b - miniIPS Operating Manual

· After deployment, remove the outer acetal sensor cap.

· Use the tool supplied to carefully unscrew the inner protective cap, exposing

the sensor diaphragm.

· Rinse all parts in fresh water removing any growth or debris as necessary

· Take exceptional care not to touch or damage the diaphragm itself as

irreparable damage can result

Any damage to this diaphragm will render the instrument warranty invalid.

8. Care & Maintenance

The miniIPS is remarkably robust, being primarily constructed of titanium. The only maintenance required, other

than periodic recalibration as necessary, is to keep the sensor as clean as possible.

After cleaning, simply reassemble the sensor and store in the packing case provided.

© 2019 Valeport Ltd

Page 16

Page 17

9. Ordering and Part Numbers

Part No.

DESCRIPTION

Standard System

0760001-XX

mini IPS

Fitted with:

· 0.01% accuracy piezo-resistive pressure sensor.

Supplied with:

– Interface lead

– Calibration adapter fitting

– Operating manual and transit case.

Note: XX on code denotes pressure transducer range

select from 5, 10, 30, 50, 100, 300 or 600 bar

0760005-XX

mini IPS - OEM remote sensor and PCB

Fitted with:

· 0.01% accuracy piezo-resistive pressure sensor

Supplied with:

– Interface lead

– Calibration adapter fitting

– Operating manual and transit case.

Note: XX on code denotes pressure transducer range

select from 5, 10, 30, 50, 100, 300 or 600 bar

Components and Spares

0760EA1

Replacement Titanium SubConn bulkhead connector

(SubConn part MCBH6F - Specify Titanium)

0652EA1

Housed system 0.5m pigtail

(SubConn parts MCIL6M and MCDLSF)

Fitted with:

· 4mm bunch pins for power

· 9 pin D type for communications.

0760002

Calibration adapter fitting

Ordering and Part Numbers

Page 17

© 2019 Valeport Ltd

Loading...

Loading...