Page 1

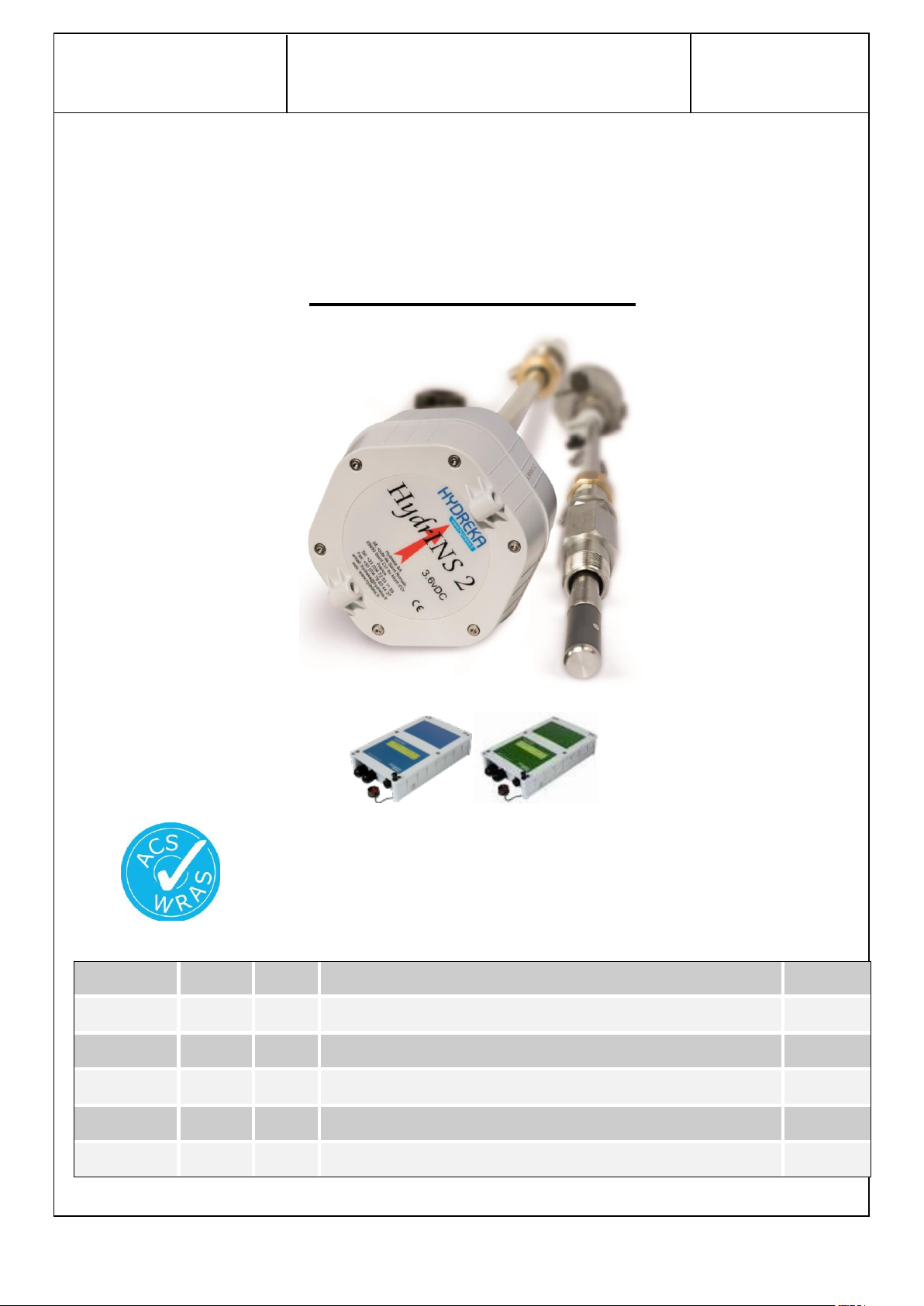

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 1 / 83

Revision

Date

Author

Modifications

Signature

04

29/03/16

CBR

Downstream length and translation.FCC statement.

03

30/03/15

BLA

Lid closing procedure and SIM insertion

CBR

02

03/11/14

BLA

Update units (inches) add communicating display

CBR

01

15/02/2011

GSE

Approval

GSE

00

15/12/2010

MRE

Updated

HydrINS 2 and HydrINS 2 Mini

Electromagnetic Insertion Flow Meters

Installation Manual

Page 2

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 2 / 83

CONTENTS

1 SAFETY INSTRUCTIONS .................................................................................................... 6

2 INTRODUCTION ............................................................................................................... 8

2.1 Measurement Principle ........................................................................................................... 9

2.2 Environmental and safety conditions ..................................................................................... 10

2.3 Conditions in the measurement environment ........................................................................ 10

2.4 Safety ................................................................................................................................... 11

2.5 Product transport .................................................................................................................. 12

2.6 Product guarantee................................................................................................................. 14

2.7 Conditioning the product before use ...................................................................................... 14

3 DESCRIPTION OF THE HYDRINS2 / HYDRINS 2 MINI PRODUCT RANGE ............................ 15

3.1 Mechanical description: ........................................................................................................ 15

3.2 Models in the HydrINS 2 / HydrINS 2 Mini flow meter range ................................................... 17

4 INSTALLATION LOCATION OF THE HYDRINS 2 / HYDRINS 2 MINI FLOW METER ............... 19

4.1 Choice of installation location and installation and flow conditions ........................................ 19

4.2 Velocity limits for measurement ............................................................................................ 20

4.3 Choice of position for the electromagnetic sensor .................................................................. 21

4.4 Typical installation of HydrINS 2 / HydrINS 2 Mini flow meters ............................................... 22

4.5 Inside diameter measurement gauges ................................................................................... 23

5 INSTALLATION OF THE HYDRINS 2 / HYDRINS 2 MINI FLOW METER ................................ 24

5.1 Method for installation at the centre: .................................................................................... 24

5.1.1 Step 1/3: Measuring the inside diameter DI using the gauge .................................................. 25

5.1.2 Step 2/3: Measure length of insertion at the centre LI

5.1.3 Step 3/3: Probe insertion ......................................................................................................... 27

........................................................ 26

1/2

Page 3

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 3 / 83

5.2 Method for installation at 1/8 ............................................................................................... 28

5.3 Aligning the guide bar with the direction of flow .................................................................... 29

6 INSTALLING THE PRESSURE CHANNEL ON A DATA RECORDER ........................................ 30

7 VIEWING MEASUREMENTS BY DISPLAY OR RECORDING ................................................. 31

8 INSTALLATION OF A DISPLAY ......................................................................................... 32

8.1 Preview of Displays ............................................................................................................... 32

8.2 Mounting the display unit on a wall ....................................................................................... 33

8.3 Mode change of the HydrINS 2 and HydrINS 2 Mini probes ..................................................... 34

8.3.1 Equipment ................................................................................................................................ 34

8.3.2 Removal .................................................................................................................................... 34

8.3.3 Mode change ............................................................................................................................ 36

8.4 Closing the display lids .......................................................................................................... 38

8.5 Electrical power supply of Display A ....................................................................................... 39

8.5.1 Internal power supply using 3.6 VDC lithium batteries ........................................................... 41

8.5.2 External power supply using 3.6 VDC lithium batteries ........................................................... 41

8.5.3 Internal power supply using alkaline batteries ........................................................................ 42

8.5.4 External 9 to 28 VDC power supply connected to the internal terminals. .............................. 42

8.5.5 External power supply by military connector .......................................................................... 43

8.6 Electrical power supply of Display C ....................................................................................... 43

8.7 Electrical power supply of Display and Recording Unit ............................................................ 44

8.8 Wiring of the entities of the measurement chain .................................................................... 45

8.9 Internal wiring ...................................................................................................................... 48

8.9.1 Connections of the HydrINS probe to the Display terminal block ........................................... 48

8.9.2 Pulse output connections to the Display terminal block ......................................................... 49

8.9.3 Wiring the 4-20 mA outputs to the terminal block of Display C .............................................. 50

8.9.4 Wiring of the alarm outputs (Display A, C & G) ....................................................................... 51

Page 4

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 4 / 83

8.9.5 SIM insertion with Display G & E .............................................................................................. 52

8.10 External connection to Display G & E .................................................................................. 53

8.11 Display G & E installation ................................................................................................... 53

8.11.1 FCC/IC compliance information ............................................................................................... 53

8.11.2 Installing Display G & E and the external antenna ................................................................... 55

9 TECHNICAL CHARACTERISTICS: ....................................................................................... 57

9.1 Hydrins II Probe ..................................................................................................................... 57

9.2 Display units ......................................................................................................................... 58

10 MAINTENANCE ........................................................................................................... 59

11 MAINTENANCE ........................................................................................................... 59

11.1 Calibration ......................................................................................................................... 60

11.2 Replacing the batteries of the HydrINS 2 / HydrINS 2 Mini flow meter ................................. 61

11.3 Replacing the display batteries ........................................................................................... 61

12 PRODUCT DISPOSAL ................................................................................................... 62

APPENDIX 1: SELECTION GUIDE: THE RIGHT HYDRINS 2 MODEL FOR YOUR MEASUREMENT

SITE ACCORDING TO YOUR PIPE ........................................................................................... 63

APPENDIX 2: INSIDE DIAMETER GAUGES .............................................................................. 72

APPENDIX 3: CATALOGUE NUMBERS ASSOCIATED WITH THE RANGE OF HYDRINS 2 / HYDRINS

2 PRODUCTS ........................................................................................................................ 73

APPENDIX 4: TEMPLATE FOR HYDREKA CALIBRATION CERTIFICATE FOR THE HYDRINS 2 /

HYDRINS 2 MINI FLOW METER ............................................................................................. 77

TABLE OF ILLUSTRATIONS .................................................................................................... 78

LIST OF TABLES .................................................................................................................... 80

Page 5

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 5 / 83

Qualified personnel:

The electromagnetic insertion flow meter described in this document must be handled only by

personnel qualified for each specific task. The documentation concerning this task must be obeyed.

This applies in particular to safety instructions and warnings. Thanks to their training and experience,

qualified persons are able to recognise and avoid the risks involved in handling this electromagnetic

insertion flow meter.

Use of the flow meter and its display unit for their intended purpose

Remember the following points:

HYDREKA products must only be used for the applications described in the catalogue and the related

technical documentation. Their use in conjunction with products and components from other brands

is subject to HYDREKA approval. For the products to operate properly and safely, they must be

transported, stored, installed, assembled, commissioned, used, and maintained in accordance with

good professional practice. The allowable environmental conditions and the recommendations in the

related documentation must be observed.

Disclaimer:

We have checked the compliance of the contents of the present document. We are however unable

to rule out the possibility of any discrepancy, and cannot guarantee complete compliance. If any

errors are discovered during the use of this manual, we will make a note of them and make the

necessary corrections in the next edition.

Page 6

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 6 / 83

1 Safety instructions

For the flow meter and its display unit to operate properly and safely, they must be transported,

stored, positioned and assembled in accordance with precise rules, and must be used and

maintained with care. This equipment must be installed and used exclusively by qualified

personnel.

No alterations to the equipment are permitted, including opening it or making inappropriate

modifications.

If this instruction is not obeyed, the CE marking and the guarantee will cease to be valid.

This equipment includes lithium batteries, which can cause a hazard if misused. Obey the

following rules:

Do not short-circuit or charge the batteries or reverse the polarity.

Do not expose the batteries to temperatures outside the specified range. Do not

incinerate them.

Do not crush, puncture, or open the cells. Do not disassemble the battery packs.

Do not solder the body of the batteries.

Do not expose the batteries or packs to water.

When returning the devices for calibration or maintenance:

Lithium batteries are classified as dangerous goods in accordance with dangerous goods

regulations UN 3090 and UN 3091. These directives impose the use of special transport

documents.

In accordance with EC Directive 2006/66/EC, batteries must not be disposed of with domestic waste.

NOTE: Must not be used in explosion-hazard areas!

Devices used in explosion-hazard areas must be Ex approved and marked as such. This device

is not approved for use in explosion-hazard areas!

Page 7

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 7 / 83

This document is the user manual for the following electromagnetic insertion flow meter: HydrINS

2/HydrINS 2 Mini in the configuration with or without displays.

For acquisition programming, refer to the HydrINS 2 / HydrINS 2 Mini flow meter programming

manual, or the programming manual for the data logger used.

For additional information, please contact us:

HYDREKA

34, route de Saint Romain – 69450 ST CYR AU MONT D’OR – France

Tel: +33 (0)4 72 53 11 53 – Fax: +33 (0)4 78 83 44 37

Email: hydreka@hydreka.fr or accueil@hydreka.fr

Customer Service: Cservice@hydreka.fr

Rental: rent@hydreka.fr

Sales: sales@hydreka.fr

Export: export@hydreka.fr

Page 8

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 8 / 83

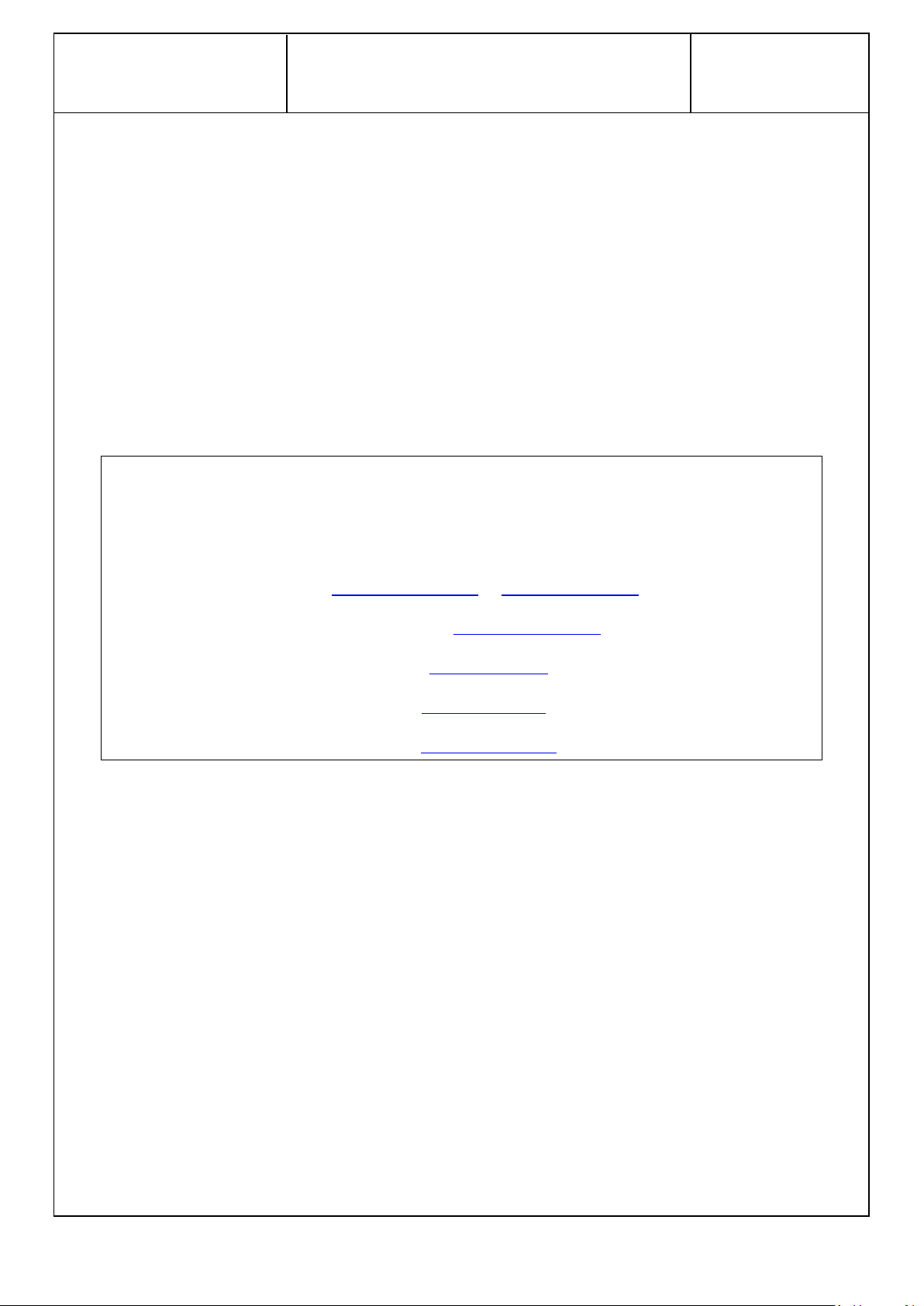

Connected to a standalone recorder with a digital input channel

(records data on site): Lolog, Vista +

Connected to a standalone recorder with a digital input channel with

communications capability (records data remotely): Octopus LX

Connected to a Display, (possibility of a Pulse or 4-20 mA output to a

remote management system or data transfer via the GSM network).

2 Introduction

The HydrINS 2/ HydrINS 2 Mini electromagnetic insertion flow meter is intended to measure flow in

pipes carrying drinking water or raw water. The probe performs a velocity measurement and

calculates the flow rate by integrating the velocity over the flow cross-section.

ACS certification and WRAS-certified materials.

The measurement scale is from 2 cm/s to 5 m/s (0.787 inches to 16.4 feet) and the relative

measurement accuracy is +/-2% or +/-2 mm/s (0.0787 inches), where the error applied is the larger

of the two.

The HYDREKA range of electromagnetic insertion flow meters comprises the HydrINS 2, which comes

in five standard lengths (300, 500, 700, and 1000 mm) and the HydrINS 2 Mini, covering diameters

from 70 mm (2.75 in) to more than 2000 mm (78.74 in).

Flow meters are installed using a 1" BSP or NPT insert collar equipped with a ball valve (also possible

using a 3/4" BSP or NPT collar for the HydrINS 2 Mini).

HydrINS 2 and HydrINS 2 Mini electromagnetic insertion flow meters can operate in several different

configurations:

Two measurement positions are used for flow measurement:

The position at the centre of the pipe, which represents the maximum speed position

The position at one eighth of the diameter, which represents the mean speed position

The sensor of the HydrINS 2/HydrINS 2 Mini flow meter can be inserted in different positions across

the cross-section of the pipe. This allows a flow velocity profile to be created in order to refine the

mean speed calculation and therefore also the flow measurement. A set of default parameters is

available in the Winfluid software (refer to the HydrINS 2 / HydrINS 2 Mini Flow Meter

Programming Manual).

All Catalogue Numbers for the products presented in this manual are listed in Appendix 3.

Page 9

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 9 / 83

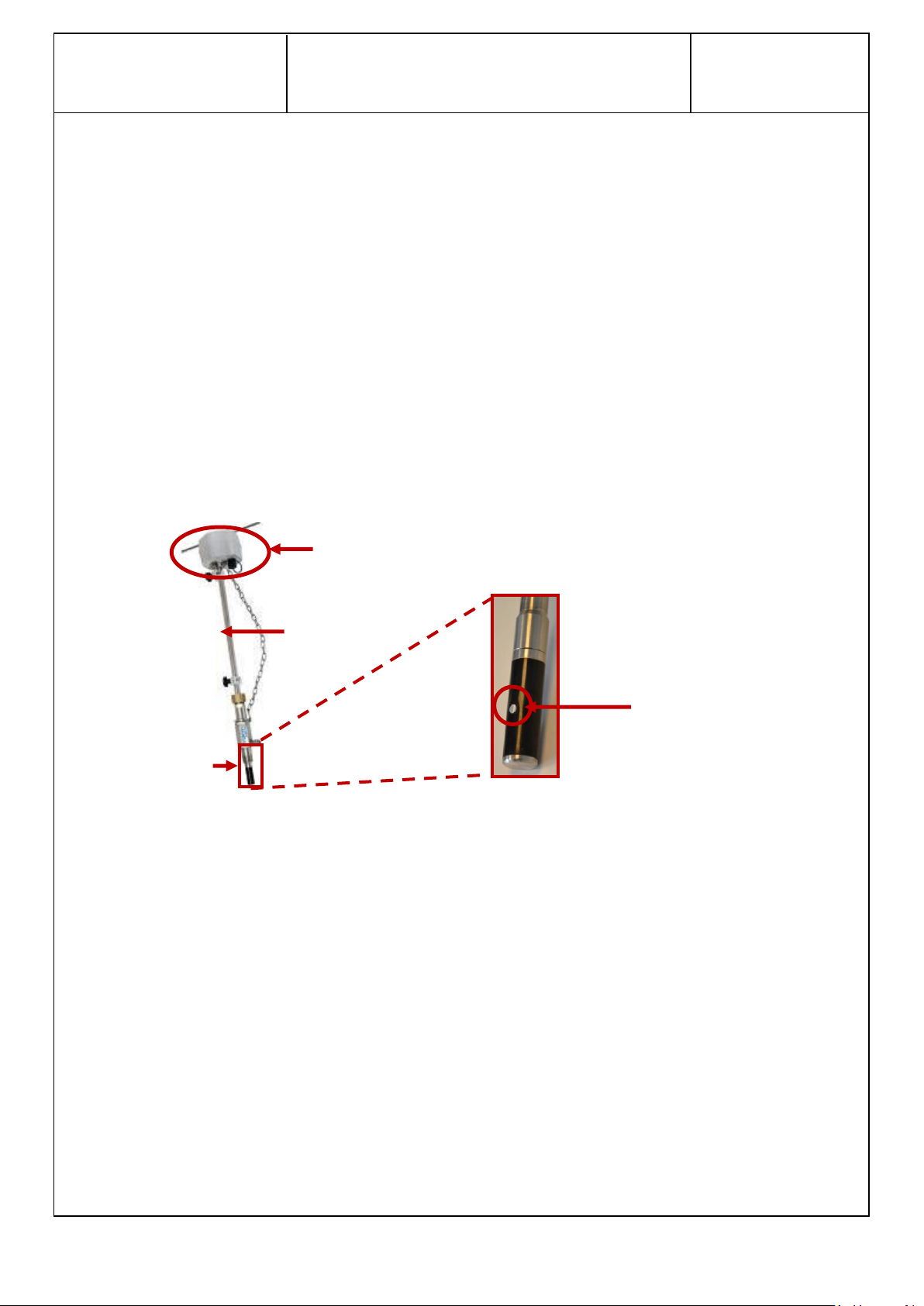

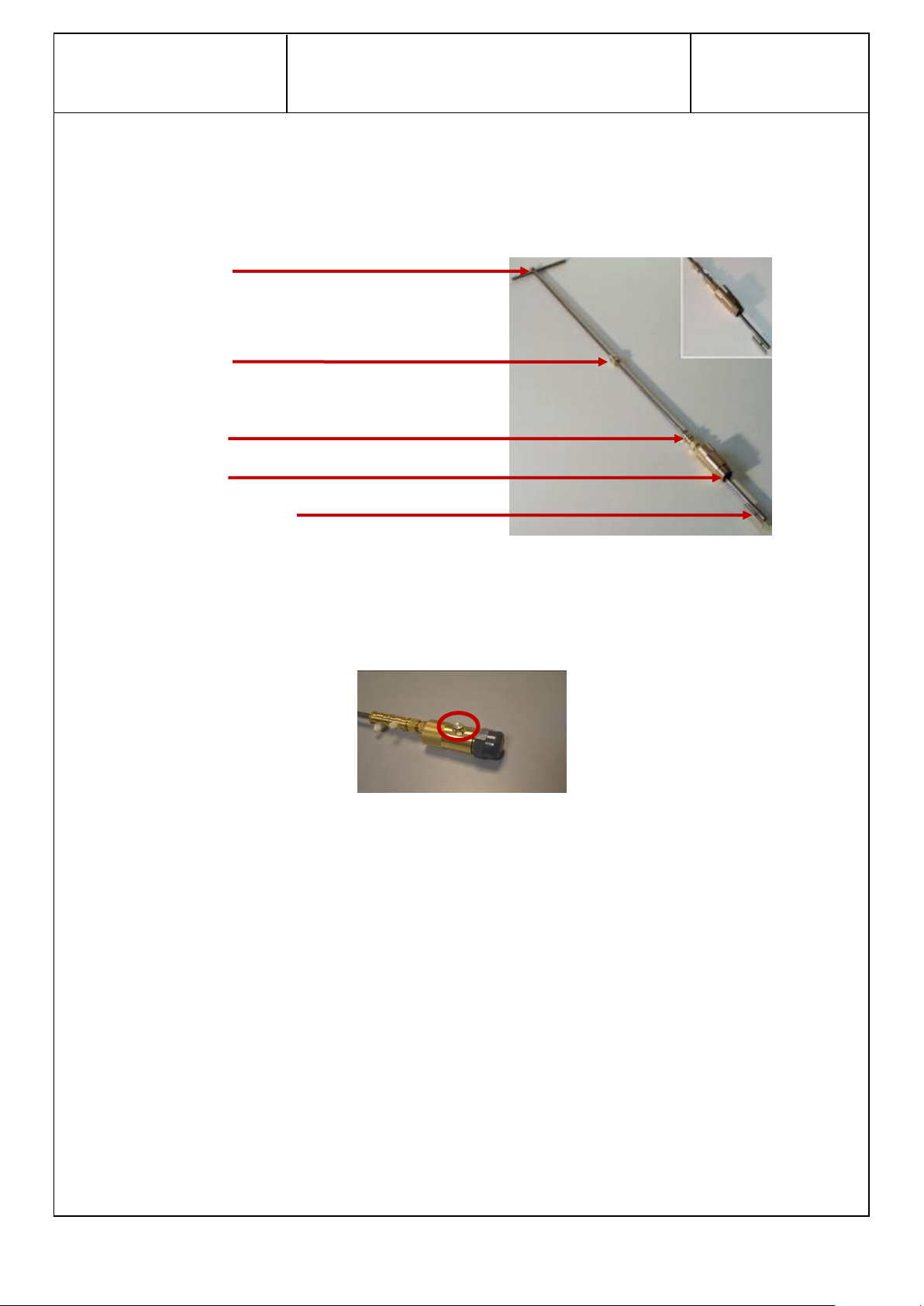

Probe head and guide bar

Insertion stem

Electrodes

Sensor

2.1 Measurement Principle

The velocity measurement principle is based on the application of Faraday's Law, which states that a

voltage is generated by the movement of a conductor through a magnetic field.

In the case of HydrINS 2/HydrINS 2 Mini, the magnetic field is generated by a coil at the end of the

probe, and the water passing through the pipe, whose conductivity must be at least 20 µS/cm,

represents the conductor.

The electromotive force generated by the passage of the water through the magnetic field,

comparable to a voltage, is measured by the two electrodes, which are visible on both sides of the

stem. Because this electromotive force is proportional to the velocity, the HydrINS 2/ HydrINS 2 Mini

probe carries out a velocity measurement derived from the electromotive force of the water. The

flow rate is then deduced from this velocity measurement.

The electromagnetic sensor is located at the tip of the insertion rod. It has an exciter coil and two

electrodes, seen on the side of the sensor.

Figure 1: Location of the sensor on the HydrINS2/HydrINS 2 Mini flow meter

Page 10

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 10 / 83

Measured velocity Vm

Q = A × Fi × Fp × Vm

Where:

Q: flow rate

A: internal cross-section (calculated by Winfluid software from the inside diameter,

DI)

Fi: insertion factor (calculated by the Winfluid software)

Fp: profile factor (calculated by the Winfluid software)

The flow value is obtained via the following processing chain:

Figure 2: HydrINS 2/HydrINS 2 Mini data processing system

2.2 Environmental and safety conditions

Optimum use of the HydrINS 2 flow meter requires a suitable measurement environment in order to

avoid as far as possible any environmental disturbances that could affect the measurement.

Hydreka shall not be held liable for the quality of the measurements performed using the HydrINS 2 /

HydrINS 2 Mini flow meter if the recommendations given below are not observed.

2.3 Conditions in the measurement environment

Protection: IP 68 (NEMA 6):

HydrINS 2: 72 hours under 10 metres (32.8 feet)

Display units: 72 hours under 2 metres (6.56 feet)

Operating temperature range: -20°C (-4°F) to +60°C (140°F)

Storage temperature range: -20°C (-4°F) to +70°C (158°F)

Page 11

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 11 / 83

: A danger arises during the physical installation of the

HydrINS 2/HydrINS 2 Mini probe. Because of the intrusive nature of

the procedure, the probe can be ejected if there is excessive

pressure inside the pipe. The probe is supplied with a safety chain,

which must be used. Ensure compliance with the installation

conditions (pumps shut off, wait for night-time conditions before

installing, etc.).

ENSURE THAT THE CHAIN IS OPERATIONAL BEFORE OPENING THE

INSERT VALVE

PROPERTY DAMAGE CAUSED BY EJECTION OF THE PROBE IS NOT

UNDER ANY CIRCUMSTANCES COVERED BY THE GUARANTEE

THE CONDUCTIVITY OF THE WATER PASSING THROUGH THE PIPE

MUST BE GREATER THAN 20µS/cm.

NOTE: It is essential to avoid sites where the pipes vibrate. If the

probe vibrates excessively after installation, the measurement will

not be correct. In this case, remove the probe.

2.4 Safety

Page 12

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 12 / 83

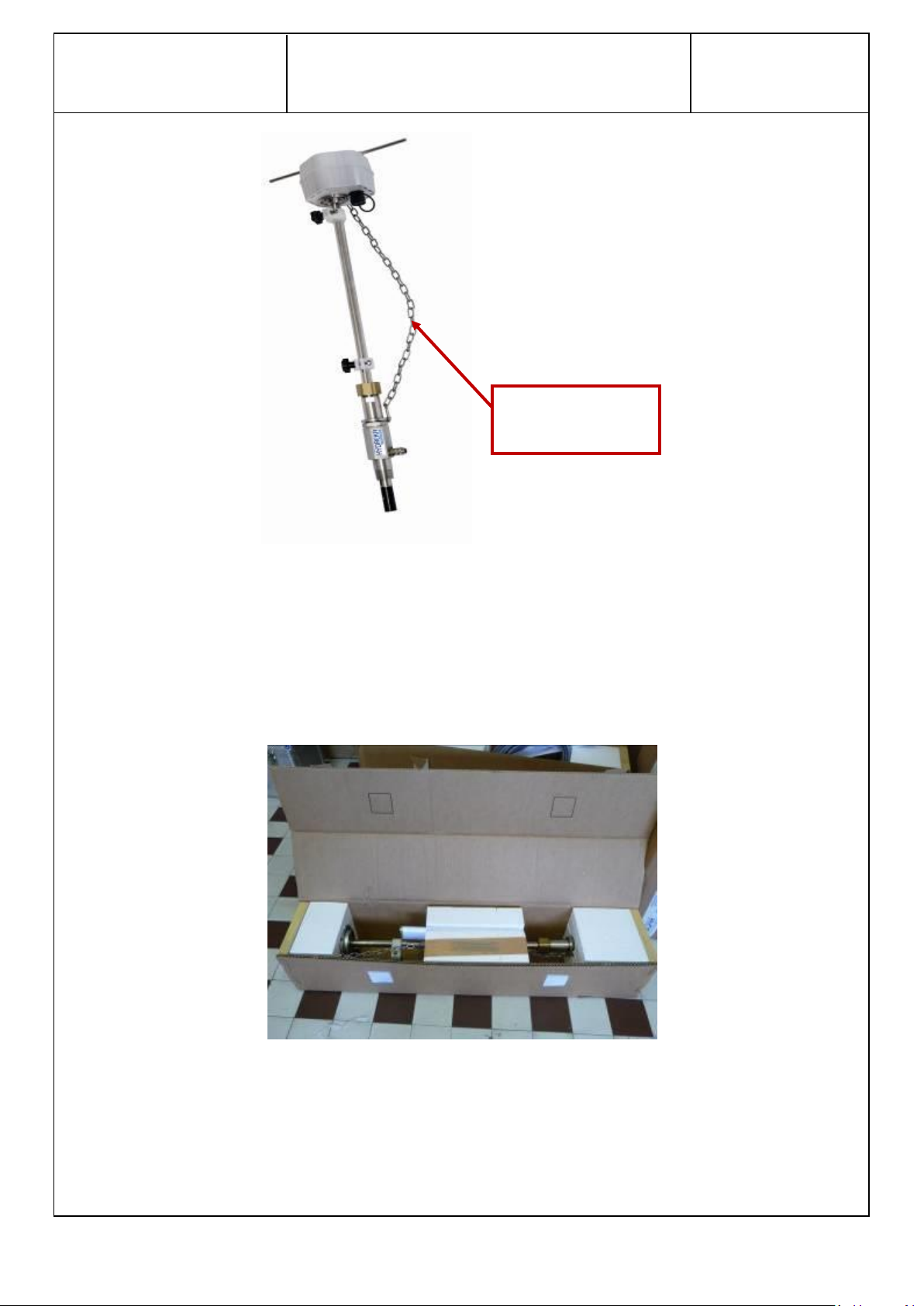

Safety chain

Figure 3: Safety chain

The safety chain is also used to ensure that the probe is fully reinstalled after the flow meter has

been removed. It is connected to a hook that can pivot around the probe.

2.5 Product transport

The HydrINS 2 / HydrINS 2 Mini flow meters are delivered in an appropriate box with polystyrene

blocks to protect them during transport.

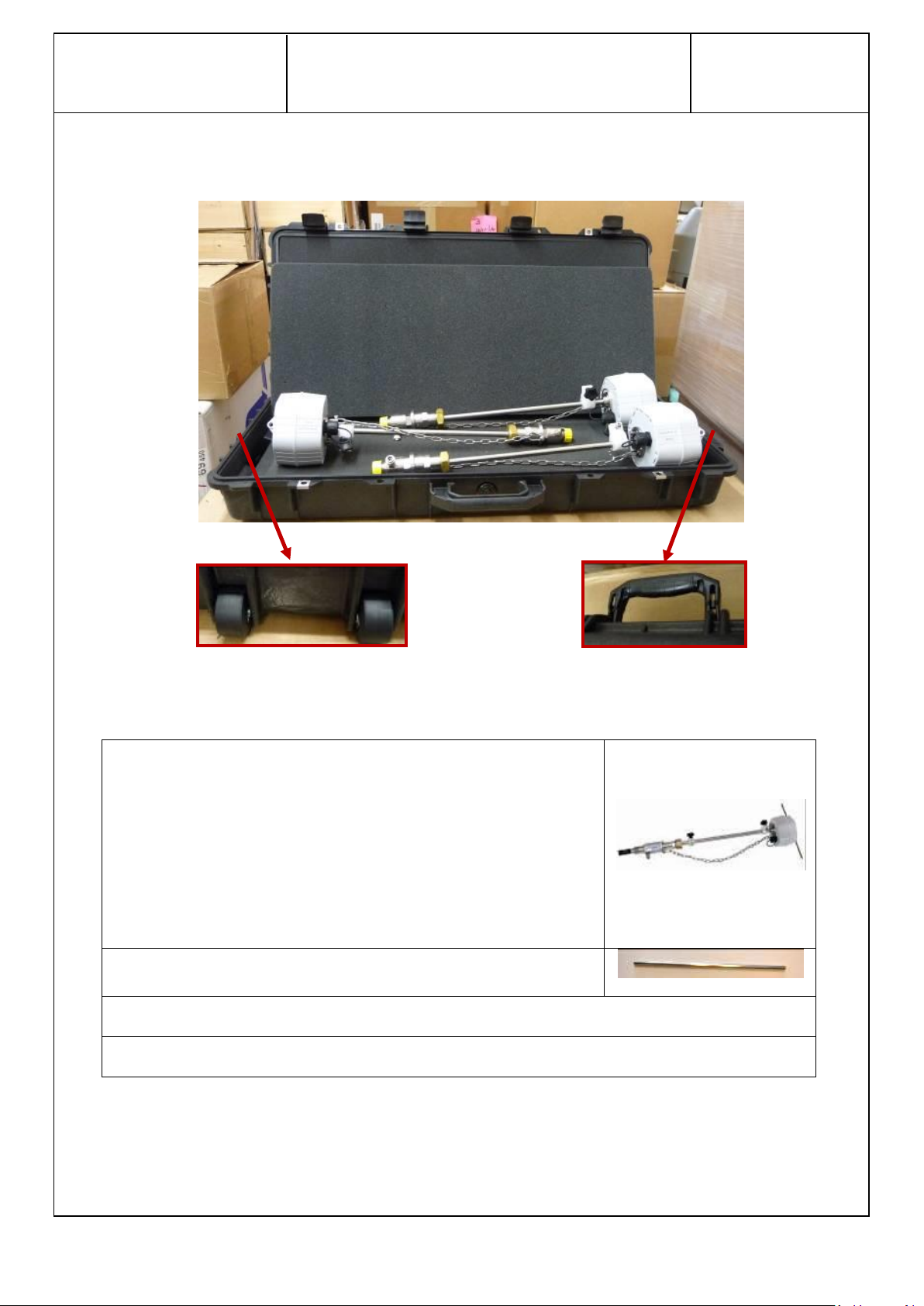

Figure 4: Typical packaging of the HydrINS2/HydrINS 2 Mini

Page 13

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 13 / 83

The HydrINS 2 / HydrINS 2 Mini flow meter with plug

Guide bar, attached or bonded to the flow meter

This installation manual

The programming manual

Reinforced cases, called PELICASE, are also available for the transport of HydrINS 2 / HydrINS 2 Mini

300 to 700 models and their accessories:

Figure 5: Pelicase transport case

Your package, whether a box or a case, must contain:

Page 14

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 14 / 83

: ENSURE THAT THE GUIDE BAR IS IN THE PACKAGE. IT IS

ESSENTIAL FOR THE OPERATION OF THE HYDRINS 2 / HYDRINS 2 MINI.

IT IS CONNECTED TO THE FLOW METER

Figure 6: HydrINS 2 / HydrINS 2 Mini guide bar connected to the flow meter in the packaging

The HydrINS 2 / HydrINS 2 Mini flow meter is delivered with a protective plug. Please remove it

before installing the HydrINS 2 in the pipe.

Figure 7: Flow meter protection plug

2.6 Product guarantee

The HydrINS 2 / HydrINS 2 Mini has a three-year guarantee when used in accordance with the

conditions of use. Contact Hydreka Customer Service to invoke this guarantee if necessary.

2.7 Conditioning the product before use

The sensor of the HydrINS 2 / HydrINS 2 Mini flow meter must be soaked in water for one

day before use in order to obtain stable measurements.

Page 15

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 15 / 83

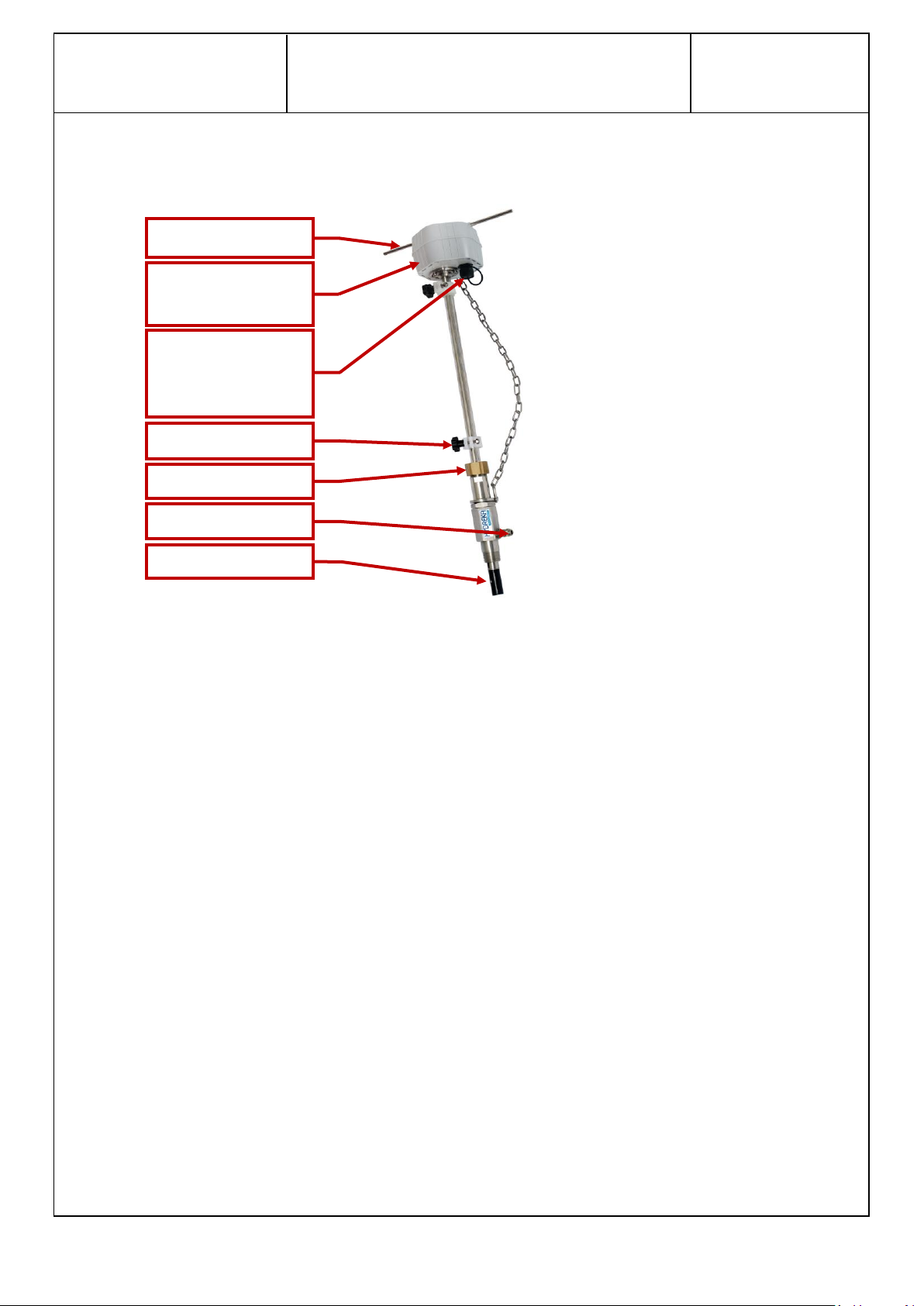

Probe head with

orientation arrow

Alignment stem

Communication

port and pulse

output

Insertion marking

Clamp ring

Pressure output

Sensor

3 Description of the HydrINS2 / HydrINS 2 Mini product range

3.1 Mechanical description:

Figure 8: Mechanical description of the HydrINS 2 / HydrINS 2 Mini flow meter

Page 16

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 16 / 83

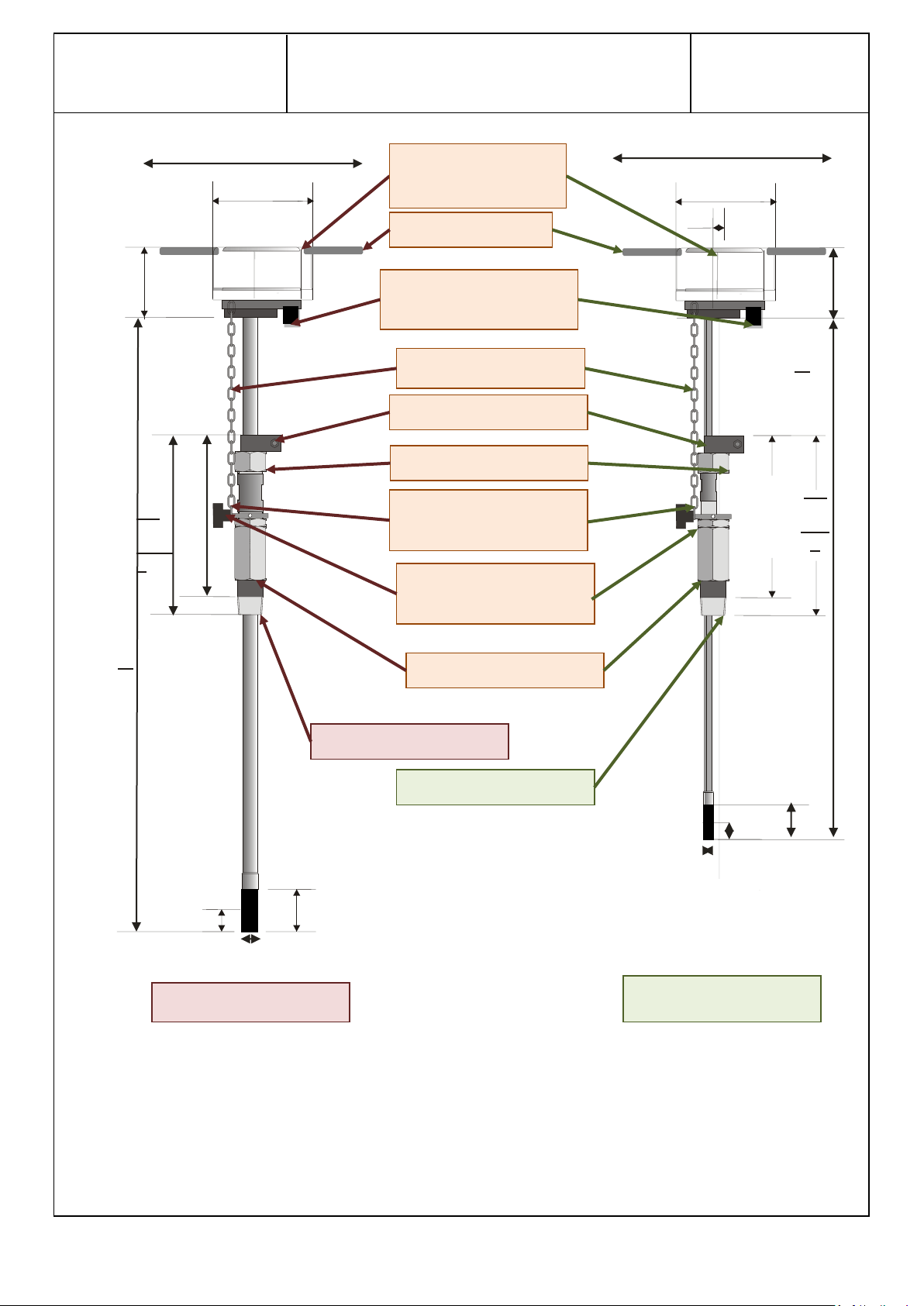

100

(3.93)

29

(1.14)

55

(2.16)

215

(8.46)

130 (5.42)

Alignment stem

Watertight military

connector

Insertion marking

Clamp ring

Adapter

1" BSP/NPT

Chain mounting ring

Chain attachment and

adjustment hook

Safety chain

Reinforced ABS

housing

100

(3.93)

50

(1.97)

22

50

(1.97)

145

(5.7)

130 (5.42)

HydrINS 2

HydrINS 2 Mini

3/4" BSP/NPT

300 (11.8)

300 (11.8)

15 (0.59)

21 (0.83)

234

(9.21)

B

165

(6.5)

B

A*

A*

*A: dimension A is 689(27.12) for Cat. No.: SI_HYDA2P-30 / 869(34.2) for Cat. No. SI_HYDA2P-50 / 1109(43.66)

for SI_HYDA2P-70 / 1409(55.47) for SI_HYDA2P-100 / 500(19.68) for Cat. No. SI_HYDE2-15

Dimensions in mm (inches)

Figure 9: Drawing of HydrINS 2 and HydrINS 2 Mini probes

Page 17

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 17 / 83

HYDREKA

Catalogue

Number

Model

Hydrins

Dimension

A

mm

(inches)

Dimension

B

mm

(inches)

Dimension

C*

mm

(inches)

Available

insertion

length

= A-(B+C)

mm

(inches)

Usable on pipe

diameters

mm

(inches)

Profile

Centre

SI_HYDA2P-30

300

689

(27.12)

234

(9.21)

200

(7.87)

255

(10)

< 250

(9.84)

< 500

(19.68)

SI_HYDA2P-50

500

869

(34.21)

234

(9.21)

200

(7.87)

400

(15.75)

< 400

(15.75)

< 800

(31.5)

SI_HYDA2P-70

700

1109

(43.66)

234

(9.21)

200

(7.87)

675

(26.57)

< 650

(25.59)

< 1300

(51.18)

SI_HYDA2P-

100

1000

1409

(55.47)

234

(9.21)

200

(7.87)

975

(38.38)

< 950

(37.4)

< 1900

(74.8)

SI_HYDE2-15

Mini

500 (19.68)

165

(6.5)

200

(7.87)

175

(6.89)

< 180

(7.08)

< 300

(11.81)

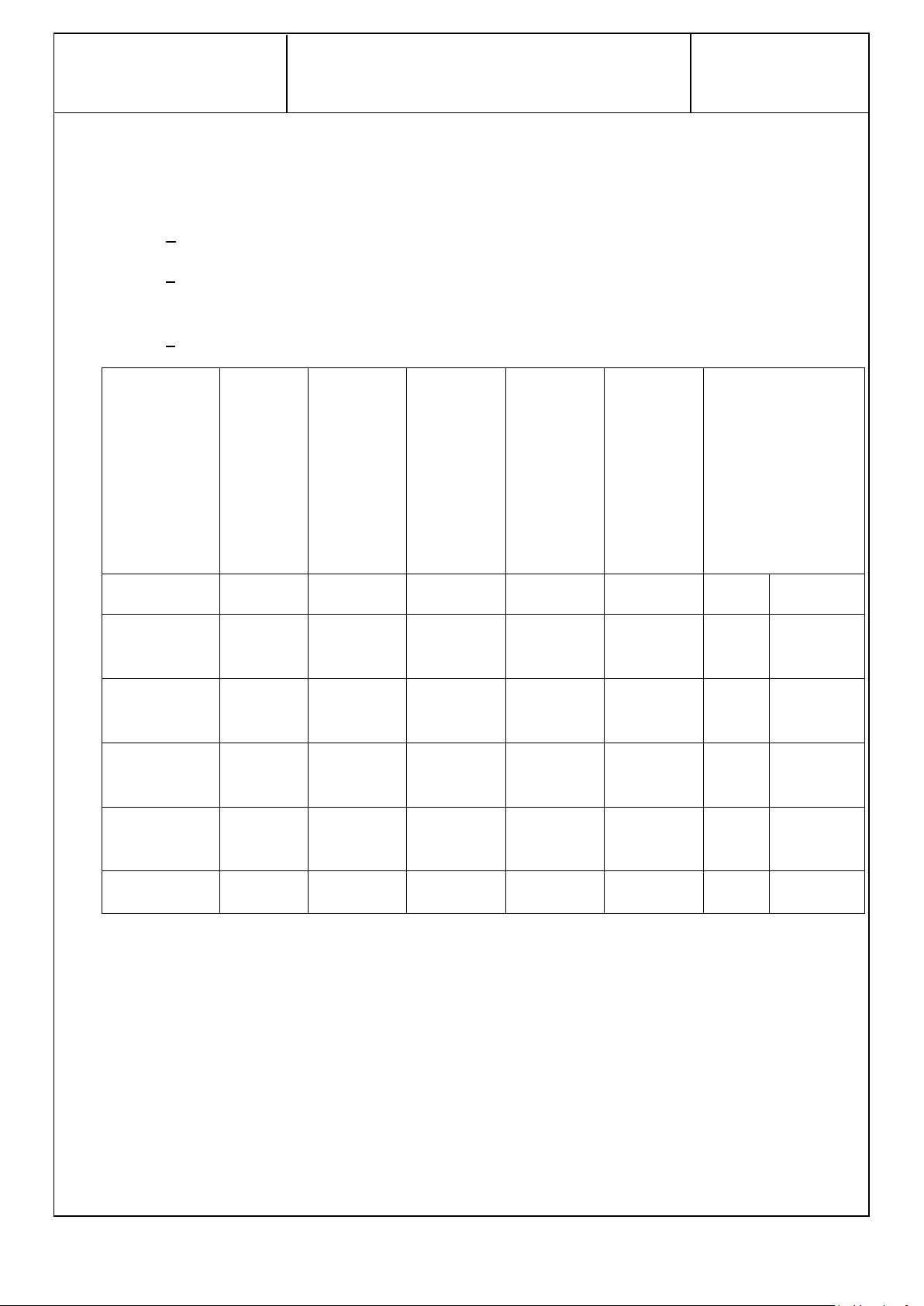

3.2 Models in the HydrINS 2 / HydrINS 2 Mini flow meter range

The following table is a selection guide to identify the most appropriate HydrINS 2 model according

to the pipe diameter and dimensions as shown in the diagram above:

A: Total stem length (see the above diagram)

B: Stacking length of HydrINS 2/HydrINS 2 Mini accessories (see dimensions on the diagram

above)

C: Stacking height at insertion level (theoretical value, must be checked on site)

Table 7: Flow meter selection table according to the flow range to be measured

Note: This is a theoretical value. It is provided as an indication, but must be checked on site.

The model is also chosen according to the space available in the port. Allow sufficient distance above

the insertion point for installation in a port or valve chamber, known as the clearance height.

Page 18

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 18 / 83

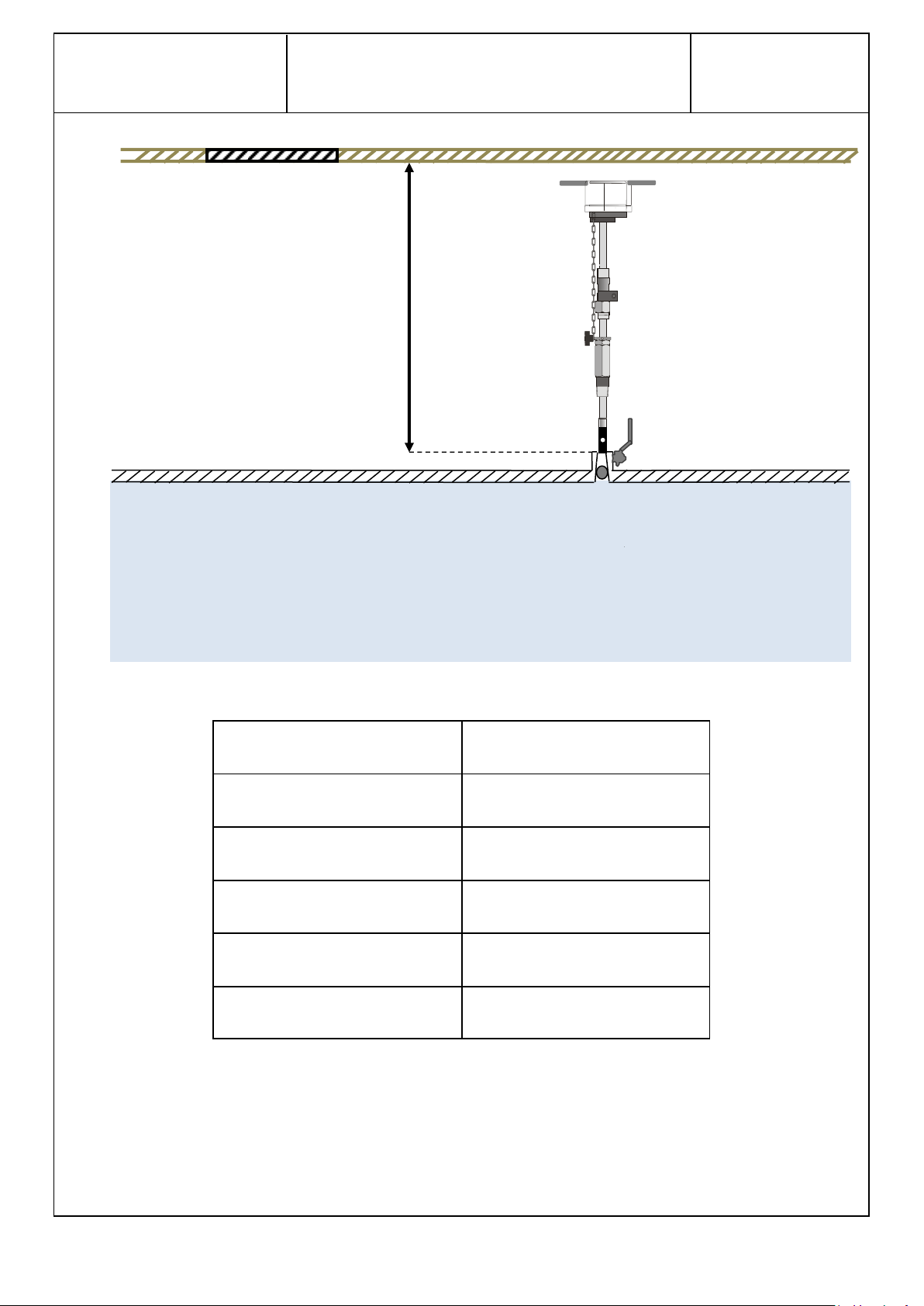

Model

Clearance height (mm) (in)

300

800 (31.5)

500

980 (38.6)

700

1220 (48)

1000

1520 (59.8)

Mini

610 (24)

Clearance height

The clearance heights are presented in the table below:

Table 7: Clearance heights above the insertion point required for installation of a HydrINS 2 / HydrINS 2 Mini flow meter.

Appendix 1 presents the HydrINS 2 / HydrINS 2 Mini flow meter models that can be used for several

standardised diameters.

Page 19

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 19 / 83

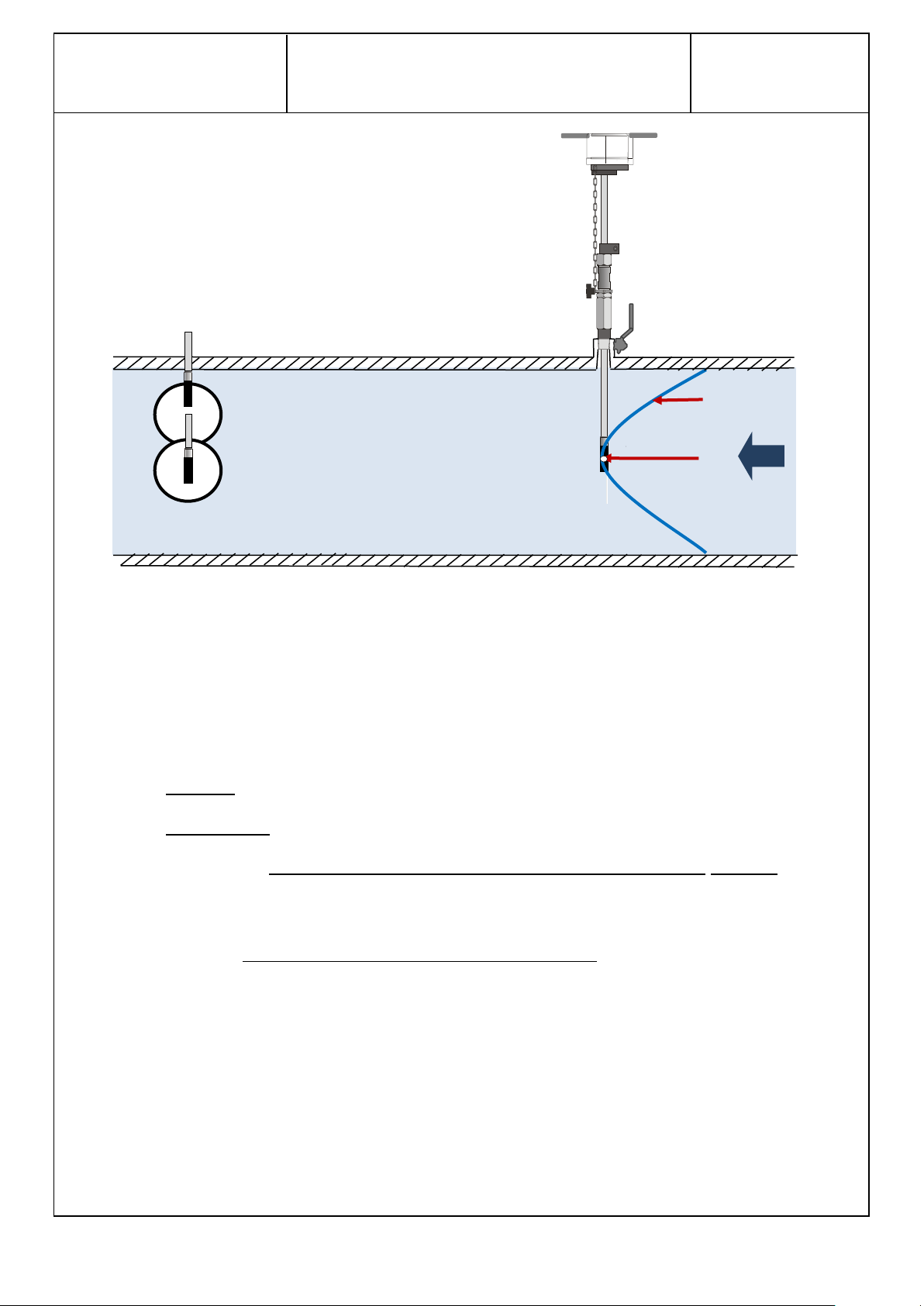

DI

UPSTREAM STRAIGHT LENGTH: See Table 1

DOWNSTREAM

STRAIGHT LENGTH:

5×DI

DIRECTION OF FLOW

*DI: inside diameter of pipe

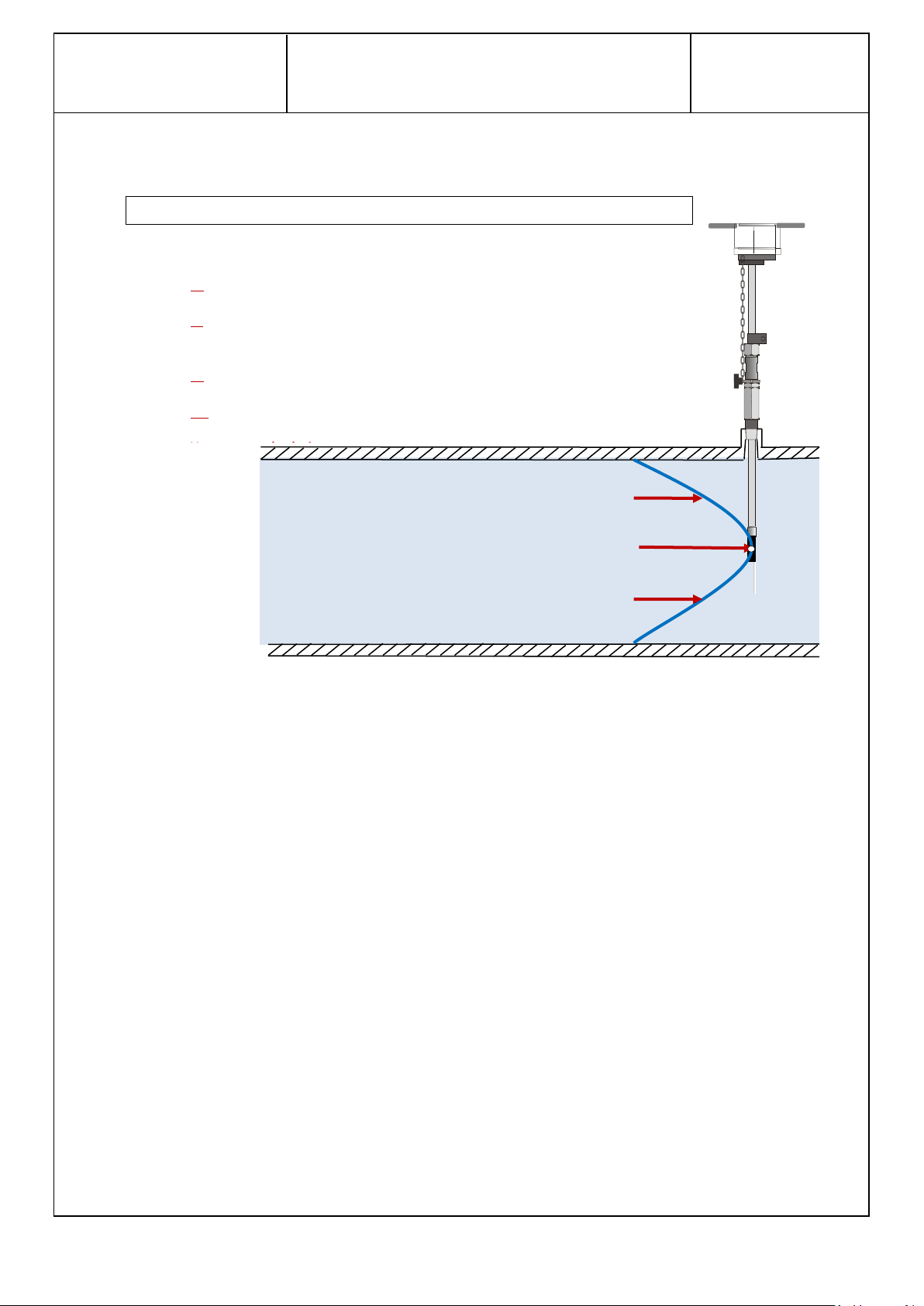

4 Installation location of the HydrINS 2 / HydrINS 2 Mini flow meter

4.1 Choice of installation location and installation and flow conditions

For accurate measurement of the flow, the pipe must be continuously carrying a flow, and

disturbance-free upstream and downstream distances ('straight lengths') must be observed. The

table below summarises the upstream distances to be observed according to the disturbing element.

Figure 10: Flow conditions to be observed

Page 20

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 20 / 83

Disturbances

Upstream straight length to be observed (multiple of

the internal diameter DI)

Measurement to the

centre

Measurement to 1/8th

90° connection or elbow

25

50

Convergent cone (18 to 36°)

10

30

Divergent cone (14 to 28°)

25

55

Open gate valve

15

30

Open butterfly valve

25

45

Table 1: Upstream disturbance-free straight lengths to be observed

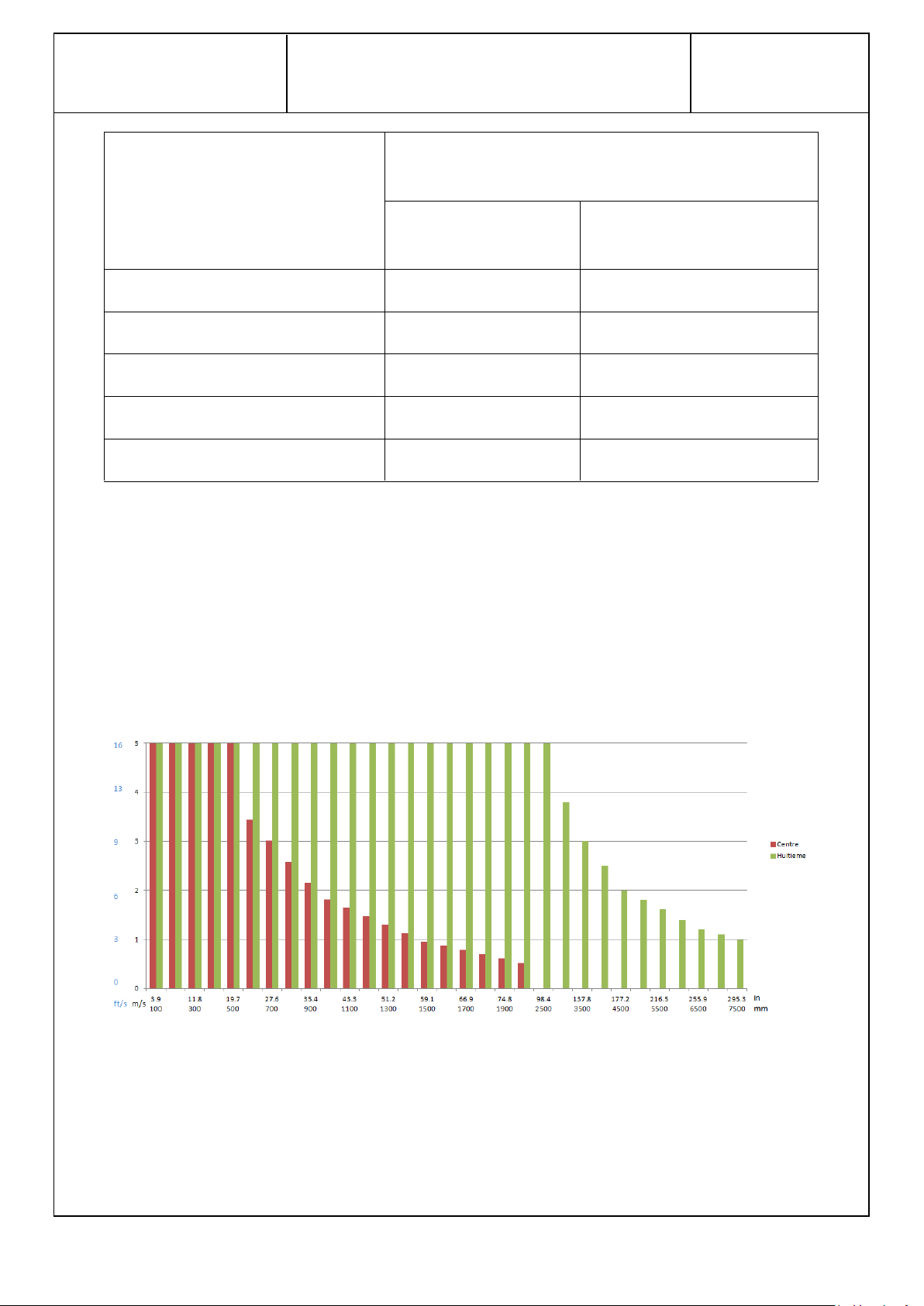

4.2 Velocity limits for measurement

Maximum velocities must be observed in order to prevent irreversible damage to the sensor. The

following charts show the maximum velocity applicable to the probe according to the chosen sensor

diameter and position. These values are provided as an indication. They are used when programming

the flow meter in Winfluid in the form of the maximum flow rate tolerated by the probe (refer to

the HydrINS 2 / HydrINS 2 Mini flow meter acquisition programming manual)

The flow rate is calculated based on a perfectly developed flow profile. Refer to the ISO 7145-1982

standard.

Figure 11: Maximum velocity for different pipe internal diameters

The creation of a velocity profile is used to refine the insertion factor and profile factor values (refer

to the HydrINS 2 / HydrINS 2 Mini flow meter acquisition programming manual). The order of

magnitude of the maximum velocities to be observed are indicated on the chart below.

Page 21

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 21 / 83

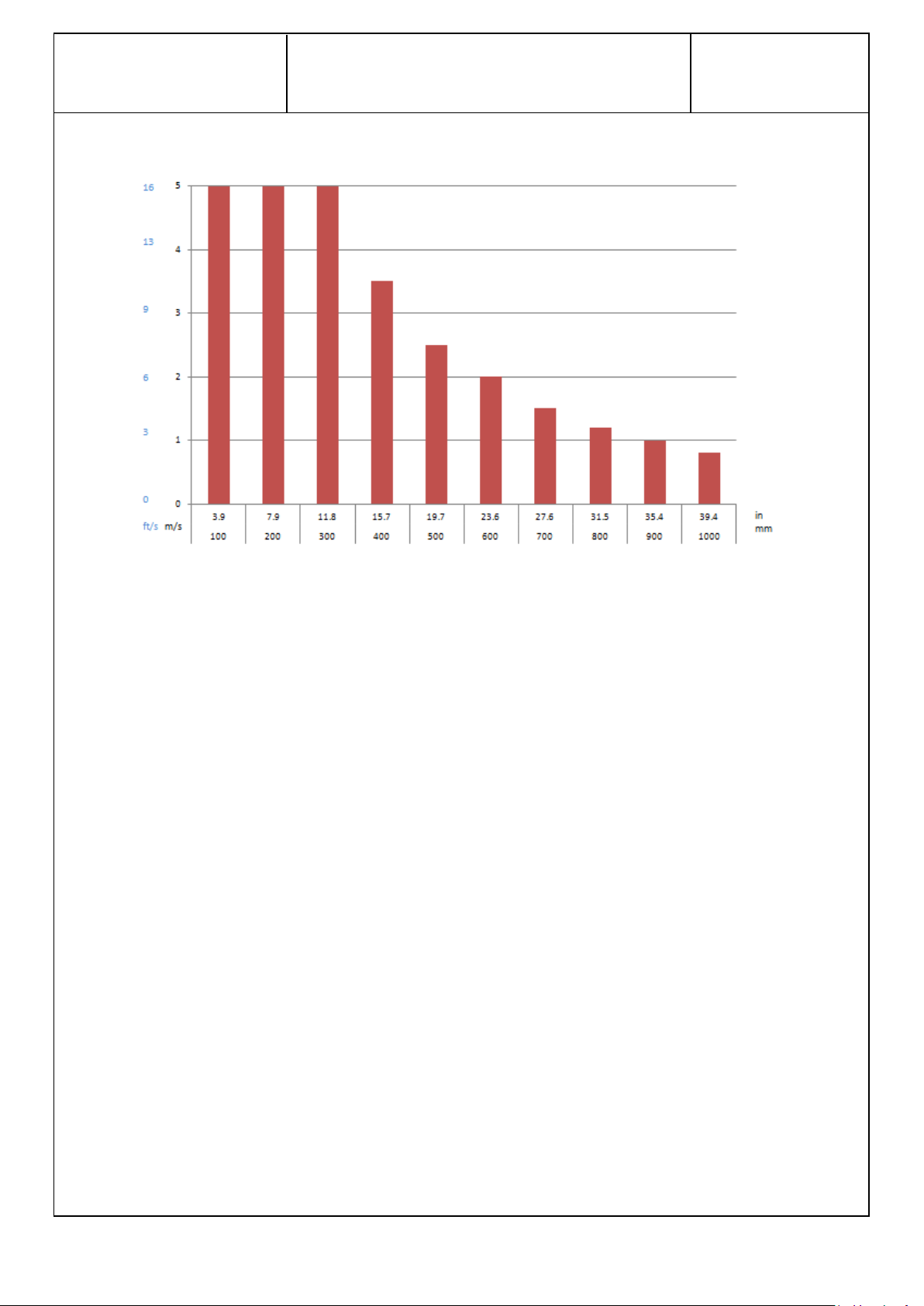

Velocities not to be exceeded to achieve a velocity profile

Figure 12: Orders of magnitude of maximum velocities not to be exceeded to create a velocity profile

4.3 Choice of position for the electromagnetic sensor

Two precise positions are chosen for the electrodes in order to take a flow measurement:

At the centre of the pipe

At 1/8th of the pipe diameter

Page 22

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 22 / 83

Position at 1/8 diameter

Position at 1/2 diameter

Figure 13: Valid positions of the HydrINS 2/HydrINS 2 Mini flow meter sensor for flow measurement

4.4 Typical installation of HydrINS 2 / HydrINS 2 Mini flow meters

Typical installations are as follows:

HydrINS 2: 1" insertion – drill 25 mm (0.98 inches) at least

HydrINS 2 Mini: two possibilities:

o Either 1" insertion plus 1"-3/4" adapter – drill 25 mm (0.98 inches) minimum: this

can measure the inside diameter of pipes using diameter gauges marketed by

HYDREKA and adaptable to 1" tappings.

o Or 3/4" insertion – drill 19 mm (0.75 inches) minimum: does not need an adapter.

The preparation of an insertion point compatible with HydrINS 2 or HydrINS 2 Mini is exactly the

same as for the preparation of a classic insertion point for the installation of a connection. No

additional accessories are required. After drilling the pipe, tighten the HydrINS 2 /HydrINS 2 Mini

probe to the ball valve.

Page 23

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 23 / 83

Handle

Ring A

Ring B

1" thread

Stop of the

standardised length

4.5 Inside diameter measurement gauges

Before the probe is installed, measurements may be performed using an adaptable diameter gauge

on a 1" insertion thread. Their use requires the appropriate clearance above the pipe.

Figure 14: View of the different components of the diameter gauge

The diameter gauge has a bleed screw to evacuate the pressure. This is useful when excessive

pressure prevents the user from bringing the gauge down to the bottom of the pipe.

Figure 15: Gauge pressure evacuator

Note that a gauge can be created with a personalised size and thread (please ask us). Available gauge

models and their sizes are described in detail in Appendix 2.

Page 24

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 24 / 83

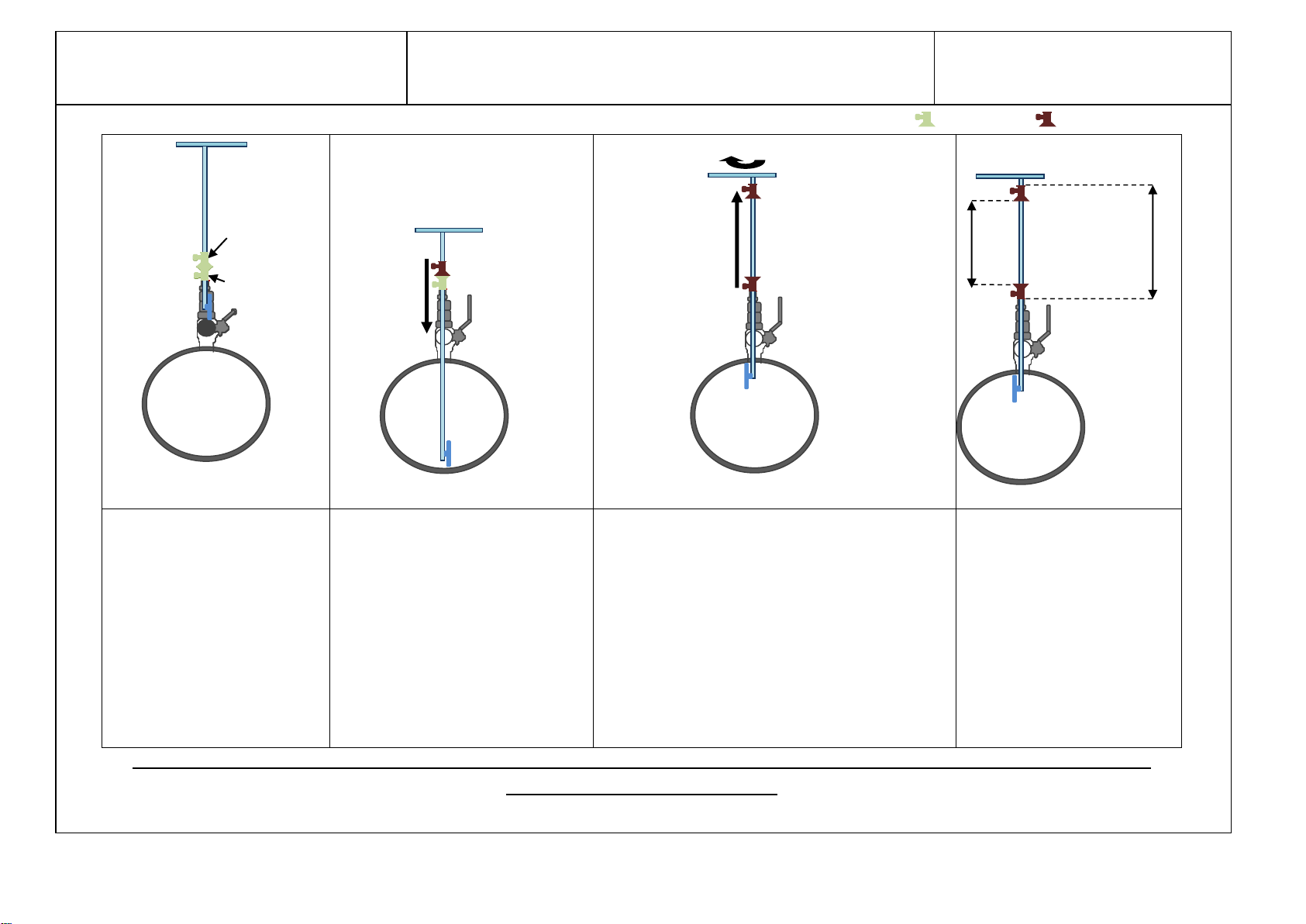

5 Installation of the HydrINS 2 / HydrINS 2 Mini flow meter

5.1 Method for installation at the centre:

The method for installing the probe at the centre, described below, includes three stages:

1. Measuring the inside diameter DI using the gauge. If the inside diameter cannot be

measured using the gauge, refer to the standardised characteristics of the pipes according to

their nominal diameters and materials. See example in Appendix 1.

2. Measurement of insertion length LI

3. Installation of probes at the calculated insertion lengths.

, as defined below.

1/2

Page 25

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 25 / 83

Tighten the diameter gauge,

taking care to align the handle

with the pipe axis.

1. Open the insert valve and lower

the gauge until it stops against the

bottom of the pipe.

2. Lower the two identification

rings onto the gauge watertight

fitting.

3. Lock Ring A in this position using

the knurled screw.

1. Rotate the gauge through 180°.

2. Bring the gauge back up until it stops against

the upper surface of the pipe.

3. Position Ring B where it stops against the

watertight fitting of the gauge. Secure Ring B in

this position using the knurled screw

Measure the inside diameter

DI between the external faces

of the two rings.

DI

L

2 1 3

1

2

3

Ring A

Ring B

Freely

Immobilised

5.1.1 Step 1/3: Measuring the inside diameter DI using the gauge

It might not be possible to measure the DI (lack of space in the port or diameter too large). In that case, replace the DI value with an

estimate (e.g., manufacturer data).

Page 26

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 26 / 83

1. From the last position,

place Ring A half-way along

the length L and lock Ring A

in position.

2. Loosen Ring B.

3. Rotate the gauge

through 180°.

1. Raise the gauge fully.

2. Close the insertion valve and place the tip of the gauge on the ball of the

valve.

1. Tighten Ring B.

2. Measure the insertion length LI

1/2

between the two internal faces of the

rings.

LI

1/2

1

2

1 2 L/2

1

3

2

L

5.1.2 Step 2/3: Measure length of insertion at the centre LI

1/2

Page 27

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 27 / 83

Installation at the centre

1. Close the insertion valve, tighten

the probe, and lower the probe until it

stops on the ball of the valve.

2. Place the insertion mark at the

insertion length LI

1/2

calculated above.

3. Open the insert valve and lower the

probe until the insertion mark stops

against the insert valve, and then

tighten the cable gland and adjust the

position of the safety chain.

3

LI

1/2

1

2

5.1.3 Step 3/3: Probe insertion

Page 28

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 28 / 83

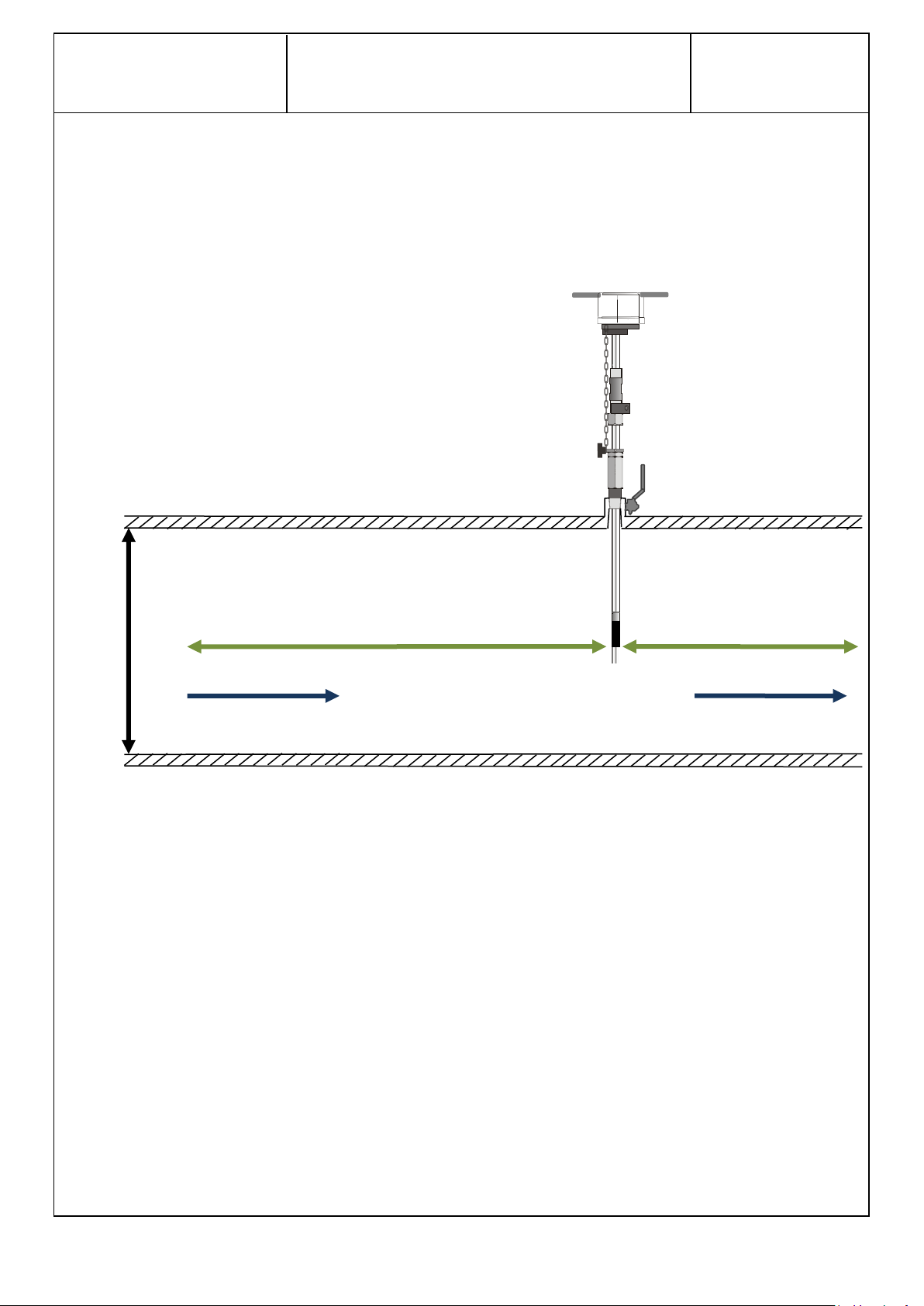

Figure 16: Diagram of installation at 1/8 diameter

For an installation at 1/8 diameter, the distance Z

1/8

after probe insertion

must be equal to:

Z

1/8

= L - E - 1/8 DI

Z

1/8

: Distance between the lower edge of the guide bar and the

top of the pipe (mm or in)

E: Pipe thickness (mm or in)

D: Inside diameter of pipe (mm or in)

L: Length (mm or in) – value according to model, equal to the

distance between the lower edge of the guide bar and the two

measurement electrodes located on the sensor

Model

L mm (inches)

300

760 (29.92)

500

935 (36.81)

700

1175 (46.26)

1000

1475 (58.07)

Mini

575 (22.64)

Table 2: Correspondence of lengths L with the HydrINS probe model for an installation at

1/8th diameter

Z

1/8

E

1/8 DI

DI

Guide Bar

5.2 Method for installation at 1/8

Page 29

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 29 / 83

Main direction of flow

Correct arrow direction

Flow direction

Guide bar direction

5.3 Aligning the guide bar with the direction of flow

After adjusting the insertion distance and placing the flow meter in the desired position, tighten the

cable gland to maintain the position. The orientation of the HydrINS 2/ HydrINS 2 Mini flow meter

must now be adjusted. The head of the HydrINS 2 / HydrINS 2 Mini flow meter has a red arrow to

orient the flow meter in the main direction of flow. Flow in this direction will count as positive, whilst

flow in the reverse direction will count as negative.

Figure 17: Position of the positive direction arrow on the probe head

The guide bar supplied with the flow meter allows the electrodes to be positioned in the direction of

flow. Insert the bar in its lodging in the flow meter head, and then match the arrow with the positive

direction using the guide bar by placing it in the direction of flow.

Once the direction and alignment have been adjusted, tighten the cable gland more tightly to hold

the flow meter firmly in its final measurement position.

Figure 18: Aligning the flow meter in the direction of flow

Page 30

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 30 / 83

Quickfit pressure

connection hose

Internal pressure

input

HydrINS 2 /

HydrINS 2 Mini

flow meter

pressure output

6 Installing the pressure channel on a data recorder

The HydrINS 2 / HydrINS 2 Mini insertion flow meter has a Quickfit connector to measure the

pressure at the same point as the flow measurement.

This channel can be connected to a recorder with an internal pressure channel (10 or 20 bars). This

applies to Lolog, Vista +, Octopus LX and other recorders.

Figure 19: Quickfit connector for the pressure channel between recorder and probe

To program acquisition on this channel, refer to the manual on Programming an internal pressure

channel.

Page 31

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 31 / 83

7 Viewing measurements by display or recording

The flow data measured can be used in different ways:

Archived by a data recorder that supports a digital channel (Lolog, Vista +, Octopus LX, etc.)

or by an external system (SCADA or remote management)

Displayed on a display unit

Displayed on a Display and archived by an external recorder

Displayed and recorded by a Display recording unit

The displays show:

The flow rates (positive and negative)

The mean/instantaneous speed

The total normal/inverse/net volumes

Alarms

There are some noteworthy differences between the two display units:

With a Display A: The display unit can be equipped with batteries to obtain 10 years of

operating life. Two pulse outputs are available.

With a Display G &E and recording unit: Data are recorded and can be sent via the GSM

network. Two pulse outputs are available, with optional external power supply.

With a Display C: External 20-36 V DC power supply (from Serial Number 41754; if below,

then: 20-28 volts) with two 4-20 mA outputs (on terminal block) and four pulse outputs (two

on terminal block, two on output connector).

The HydrINS 2/HydrINS 2 Mini flow meter operates in two separate modes:

Mode 1 (without Display): The flow meter operates in standalone mode thanks to two

batteries in the head of the flow meter.

Mode 2 (with Display): The flow meter operates thanks to the power supply from the display.

A back-up battery is kept in the head of the flow meter. In the event of an interruption of the

electrical power supply from the display, this battery allows pulses proportional to the flow

rate to be sent until a normal electrical power supply is restored (except for Display C).

Page 32

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 32 / 83

Configuration with pulse

output in bare wire to a

SCADA system

Configuration with a

standalone recorder

Configuration with

Display (standalone or

supplied from outside)

Mode 1

Mode 1

Mode 2

NOTE: This point is essential before putting the unit in operation. If an

incorrect operating mode is selected, the probe electronic board could

suffer irreversible electrical damage.

Figure 20: Installation configurations for HydrINS 2 / HydrINS 2 Mini

It is essential to ensure that the HydrINS 2 / HydrINS 2 Mini flow meter is configured in the

appropriate operating mode before placing it in operation; otherwise, the probe will suffer

irreversible damage (see paragraph 8.2).

8 Installation of a display

It is necessary to check in advance that the HydrINS 2/HydrINS 2 Mini flow meter is configured in

Mode 2 (see paragraph 8.23). It is important to specify that there is always the possibility of

communicating with the flow meter from a computer to perform checks or acquisition

reprogramming because the display is 'transparent' in communication between the computer and

the HydrINS 2 / HydrINS 2 Mini flow meter.

8.1 Preview of Displays

The Displays have cable gland fittings and/or military connectors and/or a TNC connector.

To reduce energy consumption, the display is activated manually using a magnet included with the

Display. This magnet must be applied to the area represented by the symbol

on one of the sides of the housing (Figure 22), to activate the Display. The display time is

adjustable when programming the probe.

Page 33

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 33 / 83

Figure 21: Application of the magnet to the magnetic switch to activate the Display

Figure 22: Dimensions for wall-mounting a Display

237 mm

(9.33 in)

139 mm (5.47 in)

248 mm

(9.76 in)

154 mm (6.06 in)

Ф 5 mm

(0.2 in)

Magnetic

switch

8.2 Mounting the display unit on a wall

The Display can be mounted according to the following dimensions:

The substrate must have a perfectly flat surface.

Page 34

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 34 / 83

Potential damage to the device. The internal electronic components of the device can

be damaged by static electricity, which might affect its performance characteristics and

operation.

8.3 Mode change of the HydrINS 2 and HydrINS 2 Mini probes

The change of the probe power supply mode must be performed with care. If not, there is a risk of

causing severe electrical damage to the flow meter.

8.3.1 Equipment

The following equipment is required to remove the HydrINS 2/HydrINS 2 Mini probe head:

Flat head screwdriver

3-mm Allen key

Brand new Silicagel bag

8.3.2 Removal

1 - Remove the six screws from the head of the flow meter:

Figure 23: Remove the screws from the head of the HydrINS 2 flow meter

2 – Remove the cover:

There are two possible cases:

It is possible to switch the probe from one mode to the other thanks to the light that is

present (see the indication below). In this case, after switching, immediately begin

reinstalling the reinforced ABS cover as explained below.

Page 35

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 35 / 83

Position of numbers 1 and 2 for battery

(and mode) identification

1

2

Light to switch

between modes

without the need to

remove the yellow

battery holder.

No light is present, and in this case, it is necessary to identify and then remove Battery 1

and/or Battery 2, taking care not to pull the wires off, and then to disassemble as explained

below:

Figure 24: Overview of the inside of the HydrINS 2 flow meter head

Loosen the three flat-head screws securing the battery holder, and remove it.

Page 36

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 36 / 83

Mode 1: WITHOUT DISPLAY (switch to the right)

Mode 2: WITH DISPLAY (switch to the left)

Figure 25: Removal of the cover from the head of the HydrINS 2 flow meter

8.3.3 Mode change

According to the desired mode, set up the configuration described below:

Page 37

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 37 / 83

Internal

connection

Battery 1 kept

Figure 26: Mode 1/Mode 2 change and arrangement of batteries in the HydrINS 2 flow meter

Reinstall the cover using the alignment guides:

Figure 27: Locating guides for the head of the HydrINS 2 flow meter

Also be sure to reposition the foam, the new silicagel bag, and battery wire protectors (transparent

plastic).

Page 38

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 38 / 83

8.4 Closing the display lids

Follow the instructions below to close the lids of display units (A,C,E and G)

1. Put the first lid in place by pushing "A" point then "B" point", hold in place then screw points

1 and 2 at 0.85 Nm.

2. Put the second lid in place by pushing "C" point then "D" point, hold in place then screw

points 3,4,5, and 6 at 0.85Nm.

Page 39

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 39 / 83

Risk of electrocution. Always disconnect the power supply before making any electrical

connections.

Potential damage to the device. The internal electronic components of the device can

be damaged by static electricity, which might affect its performance characteristics and

operation.

8.5 Electrical power supply of Display A

Display A can be powered according to one of the following five modes:

Internal 3.6 VDC lithium battery pack

External 3.6 VDC lithium battery pack

Internal 9 to 28 VDC alkaline battery pack

An external 9 to 28 VDC power supply connected to the labelled 9-28 VDC terminals

A 9 to 28 VDC external power supply connected to the military connector

These different power supply modes can be implemented using the two elements illustrated below:

Switch SW2 with two positions: Internal or External

Connector J15

Page 40

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 40 / 83

Connector J15

Connector SW2

Figure 28: Positions of Connector J15 and Switch SW2 inside Display A

In a case other than lithium battery power supply, an electronic board, Cat. No. 400511, is connected

to Connector J15. Two switches, SW1 and SW2, are present on this board.

Page 41

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 41 / 83

8.5.1 Internal power supply using 3.6 VDC lithium batteries

1 – Create the following configuration:

Switch SW2: Internal

Connector J15: Connect 1-2 and 15-16

2 – Connect the battery pack in the upper compartment and close the cover of Display A.

Figure 29: Connection of the lithium battery

8.5.2 External power supply using 3.6 VDC lithium batteries

1 – Create the following configuration:

Switch SW2: External

Connector J15: Connect 1-2 and 15-16

2 – Connect the battery pack to the +/- 3.6 V positions of the POWER connector, observing the

polarities.

Figure 30: Position to use for an external 3.6 V power supply

Page 42

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 42 / 83

8.5.3 Internal power supply using alkaline batteries

1 – Remove all connections from Connector J15, and then connect the additional board, Cat. No.,

4005511 to the same connector. In this case, the position of Switch SW2 used earlier is no longer

relevant. Switches SW1 and SW2 of the additional board will be used.

2 - Create the following configuration:

Switch SW1 of the additional board: Any position

Switch SW2 of the additional board: Internal

3 – Connect the battery pack to the +/- 9 to 28 V positions of the POWER connector, observing the

polarities.

8.5.4 External 9 to 28 VDC power supply connected to the internal terminals.

1 – Remove all connections from Connector J15, and then connect the additional board, Cat. No.,

4005511 to the same connector. In this case, the position of Switch SW2 used earlier is no longer

relevant. Switches SW1 and SW2 of the additional board will be used.

2 - Create the following configuration:

Switch SW1 of the additional board: Terminal

Switch SW2 of the additional board: External

3 – Connect the external power supply to the +/- 9 to 28 V positions of the POWER connector,

observing the polarities.

Figure 31: Position to use for an external 9-28 V power supply

Page 43

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 43 / 83

Risk of electrocution. Always disconnect the power supply before making any electrical

connections.

Potential damage to the device. The internal electronic components of the device can

be damaged by static electricity, which might affect its performance characteristics and

operation.

8.5.5 External power supply by military connector

For connection to the military connector, use a CNT104/CNT105 cable, and then connect the banana

plugs to an external power supply.

1 – Remove all connections from Connector J15, and then connect the additional board, Cat. No.,

4005511 to the same connector. In this case, the position of Switch SW2 used earlier is no longer

relevant. Switches SW1 and SW2 of the additional board will be used.

2 - Create the following configuration:

Switch SW1 of the additional board: MilSpec

Switch SW2 of the additional board: External

8.6 Electrical power supply of Display C

Display C may be powered in two different ways:

Terminal: By external power supply connected to the 20-36 VDC (20-28 VDC for serial

numbers below 41574) terminals,

MilSpec: By power supply via the military connector and a CNT 104 or CNT 105 cable.

Select the appropriate switch position indicated on the image below:

Page 44

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 44 / 83

Risk of electrocution. Always disconnect the power supply before making any electrical

connections.

Potential damage to the device. The internal electronic components of the device can

be damaged by static electricity, which might affect its performance characteristics and

operation.

Figure 32: Selection of the type of power supply for Display C

8.7 Electrical power supply of Display and Recording Unit

The power supply options are exactly the same as for Display A see § 8.5

Page 45

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 45 / 83

Receiver

Cat. No. of cable used

Standalone recorder: Lolog, Vista +, etc.

CNT 90S

Octopus LX standalone recorder

CNT 102S

SCADA system or remote management

CNT 93S

Other recorders

(please ask us)

CC_HYDAUSBS-3

To other

recorders: (please

ask us)

Computer, Tablet

Remote

CNT 102S

CNT 93S

CNT 90S

Vista + (local recorder)

Octopus LX

(SMS/GPRS)

(pulses)

(pulses)

(pulses)

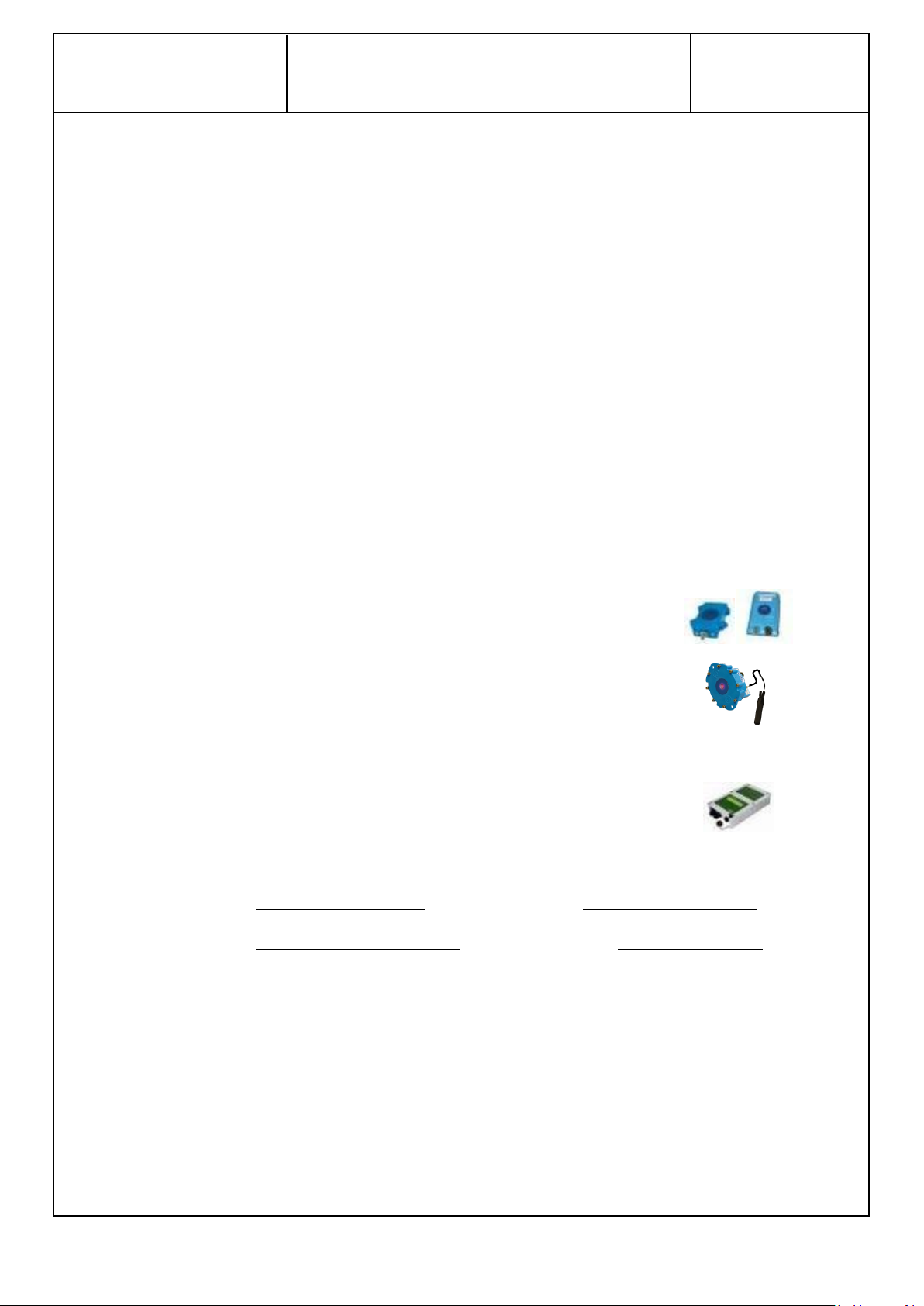

8.8 Wiring of the entities of the measurement chain

The connections between the various entities of the HydrINS 2 / HydrINS 2 Mini chain, created using

military connectors, are summarised in the diagram below:

Figure 33: Wiring possibilities from a HydrINS 2 / HydrINS 2 Mini flow meter without Display (Mode 1)

Table 3: Wiring of HydrINS 2 / HydrINS 2 outputs in Mode 1

Page 46

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 46 / 83

Receiver

Cat. No. of cable used

Display A

CNT 120S

CC_HYDUSBS-3

Computer, Tablet

Remote

CNT 102S

CNT 93S

CNT 90S

Vista + (local

recorder)

Display A

Octopus LX

(communicating

recorder)

CNT 120S

(200 metres max)

To other recorders:

(please ask us)

(pulses)

(pulses)

(pulses)

(Communication)

Figure 34: Wiring possibilities from a HydrINS 2 / HydrINS 2 Mini flow meter with Display (Mode 2)

It is also possible to retrieve a pulse output from a Display on another pulse acquisition system

(standalone recorder, SCADA or remote management) by connecting the Display and the acquisition

system. To do this, use the same cables that were used to connect the HydrINS 2 / HydrINS 2 Mini

flow meter and acquisition system, to connect the acquisition system to the Display communication

military connector.

In the event of failure of the Display A power supply, the acquisition system will continue to receive

pulses proportional to the flow. The probe head contains a back-up battery.

Page 47

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 47 / 83

Receiver

Cat. No. of cable used

Display C

CNT 120S

Computer, Tablet

Display C

CNT 120S

(200 metres max)

Remote

4-20 mA

and/or

pulses

CC_HYDUSBS-3

Figure 35: 4-20 mA outputs on Display C

The power supply for Display C must be a DC supply from 20 - 36 VDC (20-28 VDC for Serial Numbers

below 41574)

Four pulse outputs are available: Two on a terminal block inside the display unit, and two on the

communication connector.

Two 4-20 mA outputs are available on a terminal block.

Page 48

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 48 / 83

8.9 Internal wiring

8.9.1 Connections of the HydrINS probe to the Display terminal block

Each pin number on the military connector corresponds to a coloured wire at the other end of the

cable connecting the HydrINS 2/HydrINS 2 Mini to the display.

Figure 36: Diagram: connecting the HydrINS probe to the display

Page 49

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 49 / 83

Pin Number on Probe

Connector

Colour

Display terminal block

designation

C

BLACK

- V IN (0V)

D

RED

+ V IN

A

PURPLE

COM FRQ

H

WHITE/YELLOW

FRQ OUT 2

B

WHITE/BLUE

FRQ OUT 1

F

GREEN

RS232 GND

J

BLUE

RS232 H IN

K

WHITE

RS 232 H OUT

SCREEN

BRAID

N C

Table 4: Cable connections according to colour and terminal block designation

8.9.2 Pulse output connections to the Display terminal block

Figure 37: Location of pulse outputs

Page 50

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 50 / 83

Terminal block designation (output)

Function

Com Frq

Pulse output common

Frq Out 1

Frequency output (normal direction)

Freq Out 2

Frequency output reverse direction or direction

Route the cable using the cable gland, and then fasten the various wires to the pulse connector

according to the correspondence table below:

Table 5: Connection of pulse outputs – Terminal block designation – Output

Reconnect the connector and retighten the cable gland.

If the cable has a braid, it can be connected to the Screen terminal of the connector in case of

electrical interference.

8.9.3 Wiring the 4-20 mA outputs to the terminal block of Display C

Figure 38: Location of the 4-20 mA outputs (Display C)

Page 51

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 51 / 83

Terminal block (4-20 mA outputs) SDU only

Function

Screen

Not Connected

Common

4-20mA GND

Forward

4-20 mA output normal direction

Reverse

4-20 mA output reverse direction

Terminal block Alarm outputs

Function

Screen

Not Connected

Alarm 1A

Alarm 1 +

Alarm 1B

Alarm 1 -

Alarm 2A

Alarm 2 +

Alarm 2B

Alarm 2 -

Route the cable using the cable gland, and then fasten the various wires to the 4-20 mA connector

according to the correspondence table below:

Table 6: Connections for the active 4 – 20 mA outputs (power supplied by the display unit)

If the cable has a braid, it can be connected to the Screen terminal of the connector in case of

electrical interference.

8.9.4 Wiring of the alarm outputs (Display A, C & G)

The outputs are N-O (normally open)

Page 52

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 52 / 83

: The SIM card must be enabled before use, and the PIN input

request must be disabled. To do this, insert the SIM card into a mobile

phone and disable the PIN input request.

8.9.5 SIM insertion with Display G & E

Insert the SIM card to the associated location, push the SIM card until it clicks (you should hear a

"CLICK") in the guide.

Below, the direction of insertion: Mismatch protection (beveled part) on the top left.

Page 53

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 53 / 83

HydrINS II

flow meter

Pressure

sensor

Aerial

Serial port

8.10 External connection to Display G & E

Hydrins flowmeter is connected to the display via a cable gland, the pressure sensor via a military

connector and aerial via a TNC-type connector.

Figure 39 : External connection to Display G and E

8.11 Display G & E installation

8.11.1 FCC/IC compliance information

Display G and E complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) this device may not cause harmful interference and

2) this device must accept any interference received, including interference that may cause

undesired operation of the device.

15.21

You are cautioned that changes or modifications not expressly approved by the part

responsible for compliance could void the user’s authority to operate the equipment.

Page 54

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 54 / 83

15.105(b)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-Consult the dealer or an experienced radio/TV technician for help.

1. This Transmitter must not be co-located or operating in conjunction with any other

antenna or transmitter.

2. This equipment complies with FCC RF radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with a

minimum distance of 20 centimeters between the radiator and your body.

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence.

.L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement

Caution: Exposure to Radio Frequency Radiation.

To comply with RSS 102 RF exposure compliance requirements, a separation distance of at least 20

cm must be maintained between the antenna of this device and all persons.

Page 55

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 55 / 83

: An aerial can also be placed under the cast iron plate, but

remember that there is a risk of knocking the aerial off each time the

port is opened. This installation is recommended for occasional

measurements.

8.11.2 Installing Display G & E and the external antenna

This can be installed inside a chamber or, because it is watertight, on the outside in a protective

casing or in a building. The device shall be positioned according to site accessibility and the

surrounding environmental conditions. For countries with a harsh winter climate, it is best to place

the device underground (deep enough to be protected from the cold) or in a building.

According to the type of installation envisaged, several types of aerial are available. It is essential to

make a careful installation method in order to guarantee good data transmission subsequently. The

quality of the signal level (value from 0 to 31) must be verified for each site, and the measured value

must be greater than 7 for data transmission by SMS, or greater than 12 if data is being sent via

GPRS.

There are three possible aerial installation cases:

Aerial outside in a protective casing:

This type of installation has the major advantage of providing a high signal level, ensuring better data

transmission. The aerial can also be positioned on a mast or pole near the port, whilst installing the

HydrINS display logger inside the port.

Aerial in a port/valve chamber:

This installation can be created with a half-wave aerial or a dipole aerial, because both have a

magnetic base. Because each site has different characteristics, a signal level test must be carried out

with the port closed. In the event of a negative result, try a different aerial position.

Page 56

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 56 / 83

Aerial

HydrINS display logger in a port/valve chamber and aerial buried in asphalt:

Figure 40 : Aerial buried under asphalt

This installation should be considered for permanent CPU or long-term measurements. Once the

aerial is set in asphalt or epoxy adhesive, it can no longer be retrieved. This installation can however

be a useful alternative if placing the aerial inside the port does not produce satisfactory results.

Page 57

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 57 / 83

Measurement range

Two-way, from 0.02 m/s to 5 m/s, limited only by the stability and stiffness of the probe.

Fluid with conductivity of at least 20 µS/cm.

Precision

Point speed measurement: at mean or smoothed speed: ±2% if V ≥ 10cm/s and ±2mm/s with respect to the

reading if V < 10cm/s.

Mean speed and volume: refer to the ISO 7145-1982 standard.

Units

mm, metres, litres, Megalitres, m3, feet, ft3, ImpGal, USGal, MegaImpGal,

MegaUSGal, seconds, minutes, hours, days.

Electrical power

On internal lithium batteries with four-year battery life (for one measurement per minute). Ten-year option.

Sensor identity and parameters

Internal calibration, serial number, calibration date, file history.

Calibration

Performed at the factory on hydraulic bench connected to COFRAC calibration standards.

Self-test

Via the embedded electronics in accordance with OIML R49 Type P.

Internal parameters

Volume totalizer in non-volatile memory. Negative / Positive / Net volume

Several modifiable parameters (unit, period, insertion factor, etc.).

Outputs

RS 232

Configurable for: point speed, mean speed, instantaneous flow rate, volume totalisers.

Pulses

Two pulse outputs, opto-isolated open collectors Maximum frequency: 50 Hz Pulse width: 10ms - 28V 50 mA

maximum - Max. impedance 35 Ohms - Typical capacitance: 25 pF

Possibility: one positive flow channel and one negative flow channel, or one flow channel and one channel for the

flow direction.

External connector

10-pin waterproof military connector.

Software

Interfaced with Winfluid.

Operating temperature

Electronics: -20 to +60°C, Inserted part: unfrozen water at +60°C.

Maximum operating pressure

20 bars - 1/8" BSP pressure fitting, Quickfit connector included.

Waterproofing

IP68/NEMA6 for immersion at 10 m for 72 hours (with fittings connected).

Installation

On insertion valve (ball valve) 1" BSP internal free bore diameter 25 mm (1"NPT as an option). Probe antiejection chain.

Insertion length

300, 500, 700 and 1000 mm.

Dimensions

Sensor diameter: 22 mm. Stem diameter: 19 mm.

Head diameter: 130 mm x 100 mm high.

Weight

< 3.5 kg.

Materials used

Inserted part:

316 stainless - grey PVC, WRAS approval No. 0307501.

Nitrile seals, WRAS approval No. 0470NBR70.

ACS certification

External part: Stainless 316 - Bronze CZ 121 - Reinforced ABS housing.

Guarantee:

36 months.

Metrological certification

Calibrated using electromagnetic flow meters (100 and 200 mm) calibrated according to COFRAC

procedures.

Gauge

Measurement of pipe inside diameters. Standard length 500/700/900.

Other lengths available as options.

9 Technical Characteristics:

9.1 Hydrins II Probe

Page 58

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 58 / 83

Display A

Outputs

Two pulse outputs, opto-isolated open collectors.

Maximum frequency: 50 Hz Pulse width: 10ms - 28V

50 mA maximum - Max. impedance 35 Ohms Typical capacitance: 25 pF

Two alarm outputs: Pulse width: 10ms - 28V 50 mA

maximum - Max. impedance 75 Ohms - Typical

capacitance: 10 pF

LCD screen: Timed or continuous backlit, two lines of

16 characters

Magnetic switch control.

Display: mean speed, real-time flow rate, positive negative - net totalizer, alarms.

Alarms: Two dry contacts Programmable using

Winfluid software via RS 232

Alarm type: Absence of water, sensor error, low

battery, higher or lower flow rate, power supply error,

HydrINS not connected.

Connection: 5-metre cable supplied to connect the

display to the HydrINS 2®.

Max. length: 200 m.

Communication: Probe and display programmed via

RS 232.

Firmware updated via RS 232. Interfaced with

Winfluid.

Waterproofing: IP68/NEMA6 under 2 metres of water

(with fittings connected) for 72 hours

Dimensions: 154 mm / 248 mm / 56 mm.

Weight: 1 kg.

Guarantee: 36 months.

Electrical power

3.6 V - 38 A/h internal lithium batteries.

Battery life: 4 to 10 years according to the options

Possible power supply via external batteries or DC

power supply (optional)

Battery compartment isolated from the electronics.

Display C

Outputs

Four pulse outputs, opto-isolated open collectors.

Maximum frequency: 50 Hz Pulse width: 10ms - 28V

50 mA maximum - Max. impedance 35 Ohms Typical capacitance: 25 pF

Two active 4-20mA outputs with common negative

connection. 1 Kohm maximum loop resistance (20 V

at 20 mA).

Two alarm outputs: Pulse width: 10ms - 28V 50 mA

maximum - Max. impedance 75 Ohms - Typical

capacitance: 10 pF

Electrical power

DC power supply = 20 - 36V DC, with polarity

reversal protection (20V - 28V DC for Serial Numbers

below 41574)

Display with

recorder

Outputs

Two pulse outputs, opto-isolated open collectors.

Maximum frequency: 50 Hz Pulse width: 10ms - 28V

50 mA maximum - Max. impedance 35 Ohms Typical capacitance: 25 pF

Two alarm outputs: Pulse width: 10ms - 28V 50 mA

maximum - Max. impedance 75 Ohms - Typical

capacitance: 10 pF

RS232 communication output (optional Bluetooth)

Electrical power

On 3.6 V / 57 Ah lithium batteries, internal battery

with standard 3-year battery life, with one reading

every 15 minutes and 1 sms/day.

Communication

Data sent via SMS or GPRS.

9.2 Display units

Page 59

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 59 / 83

10 Maintenance

Maintenance of the HydrINS2 / HydrINS 2 Mini product is very easy: Simply remove the probe from

the insert (ensure that the chain is taut when removing).

This maintenance procedure is very economical and practical compared to the maintenance of an

electromagnetic sleeve, for example.

For water loaded with metal particles, in particular, remember to clean the probe regularly.

Figure 41: Maintenance of a flow meter measuring water loaded with metal particles

11 Maintenance

The operations described in this section of the manual must be performed by qualified personnel.

These operations may be performed by you in accordance with Hydreka procedures, or they may be

covered by a maintenance contract. In this case, contact our Customer service department

(Cservice@hydreka.fr).

Several planned maintenance operations are necessary. These are described below.

Page 60

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 60 / 83

11.1 Calibration

Calibration of the HydrINS 2 / HydrINS 2 Mini flow meter every two years is recommended. This

service can be performed by HYDREKA, which has a COFRAC-connected hydraulic bench for flow

meter calibration.

Figure 42: Hydraulic bench for the calibration of HydrINS 2 / HydrINS 2 Mini flow meters and HYDREKA calibration

certificate

A calibration certificate is issued at the end of the calibration phase (see Appendix 4).

Page 61

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 61 / 83

11.2 Replacing the batteries of the HydrINS 2 / HydrINS 2 Mini flow meter

Apply the following procedure to replace the batteries in the head of the HydrINS 2 / HydrINS 2 Mini

flow meter:

1 – Open the head of the flow meter (see Para. 8.3).

2 – Disconnect the used battery and connect the new one.

3 – In Winfluid, click the HydrINS II or Mini HydrINS input channel. In the Sensor tab, click

Properties, and then Advanced. In the Maintenance tab, select the boxes for Batteries 1 and 2 in the

head, and then confirm by clicking OK. The battery level will then be reinitialised during probe

programming.

4 – Click "Sensor" and then "program".

Figure 43: Reinitialisation of the battery levels in HydrINS 2 in Mode 1 in Winfluid

11.3 Replacing the display batteries

1 – Open the upper cover of the Display.

2 – Remove the used battery and insert the new battery.

3 – Close the cover of the Display.

4 – In Winfluid, click the HydrINS II or Mini HydrINS input channel. In the Sensor tab, click

Properties, and then Advanced. In the Maintenance tab, select the boxes for Battery 2, indicate the

capacity in Ah of the new battery, and then confirm by clicking OK. The battery level will then be

reinitialised during probe programming.

Page 62

HydrINS 2 / HydrINS 2 Mini flow meter

Installation Manual

Page 62 / 83

Figure 44: Reinitialisation of battery levels in HydrINS 2 / HydrINS 2 Mini in Mode 2 with a Display A in Winfluid

12 Product disposal

The product must be disposed of in accordance with local regulations concerning the

disposal of electronic waste (European WEEE legislation or other).

Page 63

HydrINS 2 / HydrINS 2 Mini Flow Meter

Installation Manual

Page 63 / 83

HydrINS 2

"300"

HydrINS 2

"500"

HydrINS 2

"700"

HydrINS 2

"1000"

HydrINS 2 Mini

Material

PN

Type of

material

DN

(mm)

DN

(in)

Inside

diameter

(mm)

Inside

diameter

(in)

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Steel

/

Galvanised

90

3.5

80.0

3.1

114

4.5

102.0

4.0

Black

100

3.9

107.1

4.2

125

4.9

131.7

5.2

150

5.9

159.3

6.3

175

6.9

182.9

7.2

200

7.9

207.3

8.2

225

8.9

231.9

9.1

250

9.8

260.4

10.3

300

11.8

309.7

12.2

350

13.8

339.6

13.4

400

15.7

388.8

15.3

500

19.7

486.0

19.1

Appendix 1: Selection Guide: The right HydrINS 2 model for

your measurement site according to your pipe

The following table shows the compatibility of standardised diameters with the available HydrINS 2 / HydrINS 2 Mini models

Steel

This table is for information only and is not contractually binding

Page 64

HydrINS 2 / HydrINS 2 Mini Flow Meter

Installation Manual

Page 64 / 83

HydrINS 2

"300"

HydrINS 2

"500"

HydrINS 2

"700"

HydrINS 2

"1000"

HydrINS 2 Mini

Material

PN

Type of

material

DN

(mm)

DN

(in)

Inside

diameter

(mm)

Inside

diameter

(in)

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Asbestos-

Cement

/

Class 20

100

3.9

100

3.9

125

4.9

125

4.9

150

5.9

150

5.9

175

6.9

175

6.9

200

7.9

200

7.9

250

9.8

250

9.8

300

11.8

300

11.8

400

15.7

400

15.7

500

19.7

500

19.7

600

23.6

600

23.6

Class 30

100

3.9

100

3.9

125

4.9

125

4.9

150

5.9

150

5.9

200

7.9

200

7.9

400

15.7

400

15.7

500

19.7

500

19.7

Asbestos - Cement

This table is for information only and is not contractually binding

Page 65

HydrINS 2 / HydrINS 2 Mini Flow Meter

Installation Manual

Page 65 / 83

HydrINS 2

"300"

HydrINS 2

"500"

HydrINS 2

"700"

HydrINS 2

"1000"

HydrINS 2 Mini

Material

PN

Type of

material

DN

(mm)

DN

(in)

Inside

diameter

(mm)

Inside

diameter

(in)

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

Speed

profile

Centre

HDPE

PN16

PE100 -

SDR11

90

3.5

73.6

2.9

110

4.3

90.0

3.5

125

4.9

102.2

4.0

140

5.5

114.6

4.5

160

6.3

130.8

5.1

180

7.1

147.2

5.8

200

7.9

163.6

6.4

225

8.9

184.0

7.2

250

9.8

204.6

8.1

315

12.4

257.8

10.1

400

15.7

327.4

12.9

500

19.7

409.2

16.1

630

24.8

515.6

20.3

HDPE

This table is for information only and is not contractually binding

Page 66

HydrINS 2 / HydrINS 2 Mini Flow Meter

Installation Manual

Page 66 / 83

HydrINS 2

"300"

HydrINS 2

"500"

HydrINS 2

"700"

HydrINS 2

"1000"

HydrINS 2 Mini

Material

PN

Type of

material

DN

(mm)

DN

(in)

Inside

diameter

(mm)