Valeo thermo plus 230, thermo plus 350, thermo plus 300 Workshop Manual

HEATING SYSTEMS

Thermo plus 230

Thermo plus 300

Thermo plus 350

Workshop Manual

Rev. 07/2017

Id.No. 11121156A

Thermo plus 230/300/350 Content

1 Introduction

1.1 Content and purpose 101

1.2 Effectivity of the workshop manual 101

1.3 Meaning of highlighted content 101

1.4 Symbols 101

1.5 Further documentation to be used 101

1.6 Safety information and regulations 101

1.6.1 General safety regulations 101

1.6.2 Other safety information 102

1.7 Suggestions for improvement and change 102

2 Technical Data

2.1 Elektrical components 201

2.2 Fuel 201

3 Description of assemblies and components

3.1 Burner head 302

3.1.1 Combustion air fan 302

3.1.2 Control device 302

3.1.3 Fuel pump 304

3.1.4 Electronic ignition unit with ignition electrodes 305

3.1.5 Nozzle block preheater 305

3.1.6 Temperature sensors with water temperature sensor and integrated overheating protection 305

3.2 Heat exchanger 307

3.3 Combustion chamber 307

3.4 Circulating pump 307

3.5 Fuel filter 307

4 Heater functions

4.1 General heater functionality description 401

4.2 Operational heater sequence 402

4.2.1 Switching on and start 402

4.2.2 Heating operation 402

4.2.3 Switching off 403

4.3 Diagnosis interface and (Spheros Thermo Test) STT diagnosis 403

4.4 Fault lock-out and heater lock-out 404

4.5 Fault lock-out 404

4.5.1 Malfunctions during switching-on and start procedure 404

4.5.2 Malfunctions during heater operation 404

4.5.3 Malfunctions during purge cycle 404

4.5.4 Fault lock-out release and error clearance 405

4.6 Heater lock-out 405

4.6.1 Heater lock-out release 405

5 Troubleshooting

5.1 General 501

5.2 Disconnecting the heater from the vehicle electrical system 501

5.3 General error symptoms 501

5.4 Malfunction output via flash code 504

5.5 Error symptoms during functional tests with malfunction code output or diagnosis 505

5.5.1 Error symptom "No start within safety period" 505

5.5.2 Error symptom "Flame interruption" 505

1

Thermo plus 230/300/350 Content

5.5.3 Error symptom "Low voltage" 507

5.5.4 Error symptom "Extraneous light detected prior to ignition or during purge cycle" 508

5.5.5 Error symptom "Flameguard defective" 509

5.5.6 Error symptoms "Temperature sensor / overheating protection defective" and "Overheating" 509

5.5.7 Error symptom "Circulating pump defective" 509

5.6 Individual component tests 510

5.6.1 General visual inspection 510

5.6.2 Heat exchanger visual inspection 510

5.6.3 Combustion chamber visual inspection 510

5.6.4 Resistance check of the temperature sensor with integrated overheating protection 510

5.6.5 Fan and combustion air intake line visual inspection 512

5.6.6 Burner motor inspection 512

5.6.7 Electronic ignition unit inspection 513

5.6.8 Ignition electrode inspection 514

5.6.9 Flameguard inspection 514

5.6.10 Fuel pump inspection 515

5.6.11 Solenoid valve inspection 516

5.6.12 Nozzle block preheater inspection 517

5.6.13 Circulating pump inspection 518

6 Wiring diagrams

6.1 General 601

7 Servicing

7.1 General 701

7.1.1 Heater servicing 701

7.2 Servicing 701

7.2.1 Periodic heater maintenance 701

7.2.2 CO2 content adjustment 701

8 Burner head, components and heater removal and installation

8.1 General 801

8.2 Burner head removal and installation 802

8.3 Removal and installation of the temperature sensor with integrated overheating protection 803

8.4 Hood removal and installation 803

8.5 Fan wheel removal and installation 803

8.6 Electronic ignition unit and ignition electrode removal and installation 804

8.7 Control device removal and installation 805

8.8 Fuel pump removal and installation 805

8.9 Solenoid valve removal and installation 807

8.10 Nozzle block preheater removal and installation 808

8.11 Fuel nozzle removal and installation 809

8.12 Combustion chamber removal and installation 809

8.13 Heat exchanger removal and installation 810

8.14 Heater removal and installation 810

8.15 Start-up after burner head or heater installation 811

8.15.1 Bleeding the fuel system 811

8.15.2 Bleeding of the coolant circuit 811

9 Modifications and retrofits

9.1 General 901

2

Thermo plus 230/300/350 Content

10 Packing/storage/shipping

10.1 General 1001

Appendix

Periodic heater maintenance A-1

3

Thermo plus 230/300/350 1 Introduction

Danger to life and health!

Warning!

Hazardous to health!

Caution!

Danger to life and health!

Warning!

1Introduction

1.1 Content and purpose

This workshop manual is used during maintenance and

repair of water heaters (further referred to as heaters)

Thermo plus 230, plus 300 and plus 350.

ATTENTION:

Work on the heater may only be performed by briefed

and/or trained by Spheros personnel.

1.2 Effectivity of the workshop manual

The workshop manual applies to heaters listed on the title

page of this document.

It may be subjected to modifications and amendments.

The respectively currently effectife version is binding. This

version can be found on the Spheros homepage under

Service/Downloads/Heating systems.

1.3 Meaning of highlighted content

1.4 Symbols

Symbol tightening torque value:

Identifies in graphics parts (eg nuts, bolts)

that are to be mounted with a specific tightening torque. The torque values are shown

at the symbol and are binding.

1.5 Further documentation to be used

The use of additional service literature is required.

References are provided in the workshop manual at

appropriate locations.

Use the following documents during operation and maintenance of the heaters:

• Operating and Service Instructions

• Installation Instructions

• Technical Information (TI)

• Spare Parts List

• Operating Instructions for the Spheros Thermo Test,

further referred to as STT Diagnosis

Throughout this manual the emphasized words Warning!,

Caution!, ATTENTION: and NOTE: used as follows:

This caption is used to indicate possible severe injuries or fatal accidents if instructions or procedures

are carried out incorrectly or entirely disregarded.

This caption is used to indicate possible minor injuries if instructions or procedures are carried out

incorrectly or entirely disregarded.

ATTENTION:

This caption points to actions which may cause material damage.

NOTE:

This caption is used to draw attention to an important

feature.

1.6 Safety information and regulations

Basically, general accident pevention provisions and the

valid industrial safety directions must be adhered to.

"General Safety Regulations" which exceed the framework of these provisions are listed below. The specific

safety regulations which affect the present manual are

issued highlighted in the individual sections or procedures.

1.6.1 General safety regulations

Read the Thermo plus Operating and Service Instructions before operating the heater for first time.

Familiarize yourself with the Thermo plus Installation

Instructions before you make any modifications to the

existing heater installation.

NOTE:

The Thermo plus Operating and Service Instructions

contain safety instructions and regulations to be followed

for safe operation of the heater.

The Thermo plus Installation Instructions contain the

statutory regulations and other safety hints and regulations for the proper installation of the heater.

101

Thermo plus 230/300/350 1 Introduction

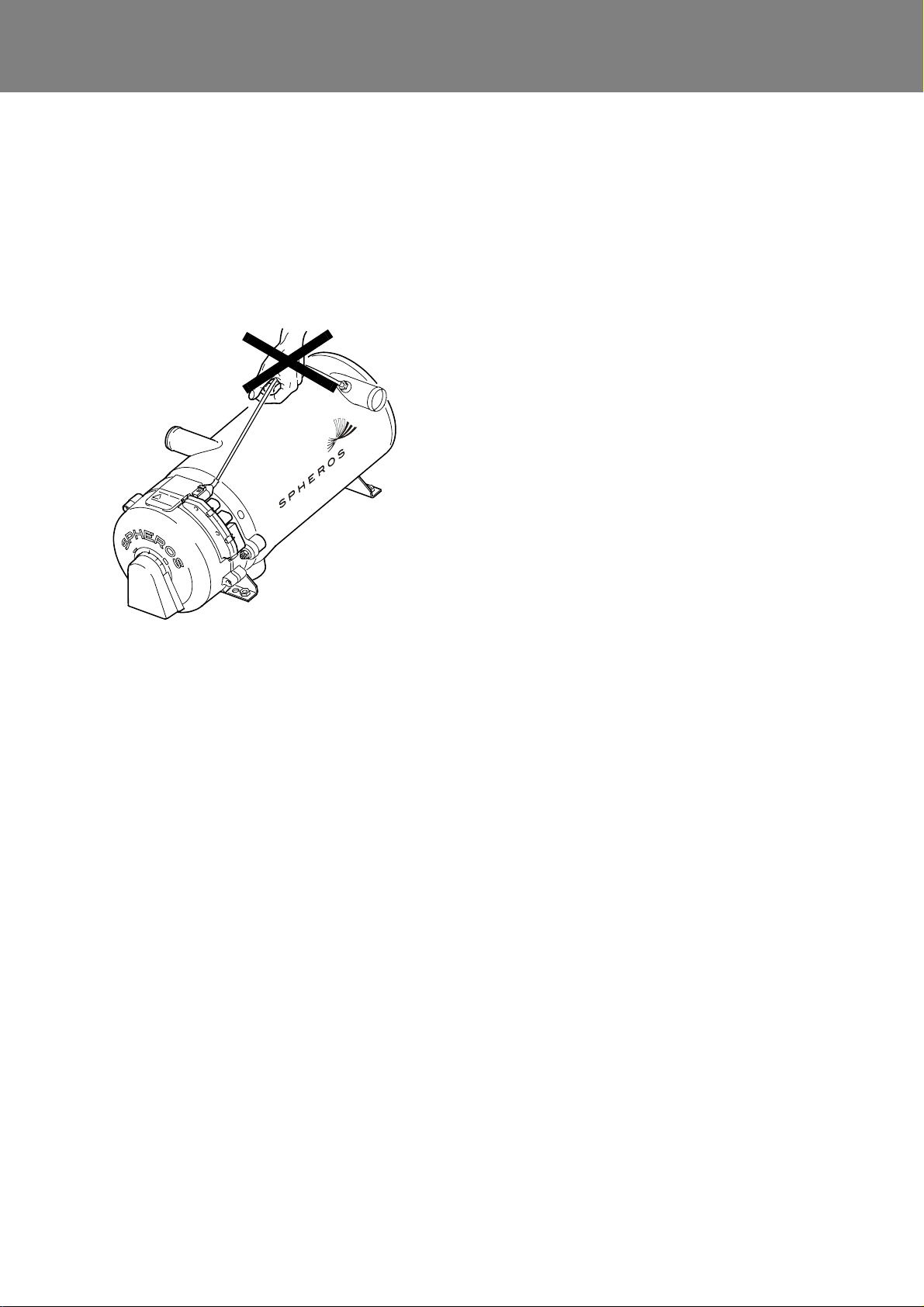

STOP!

1.6.2 Other safety information

1.6.2.1 Temperature sensors

ATTENTION:

The temperature sensors cable may not be mechanically stressed (pull on the cable, carry the heater at

the cable etc.).

1.7 Suggestions for improvement and

change

Please direct any complaints, improvement or modification suggestions regarding this manual to:

service@spheros.de

102

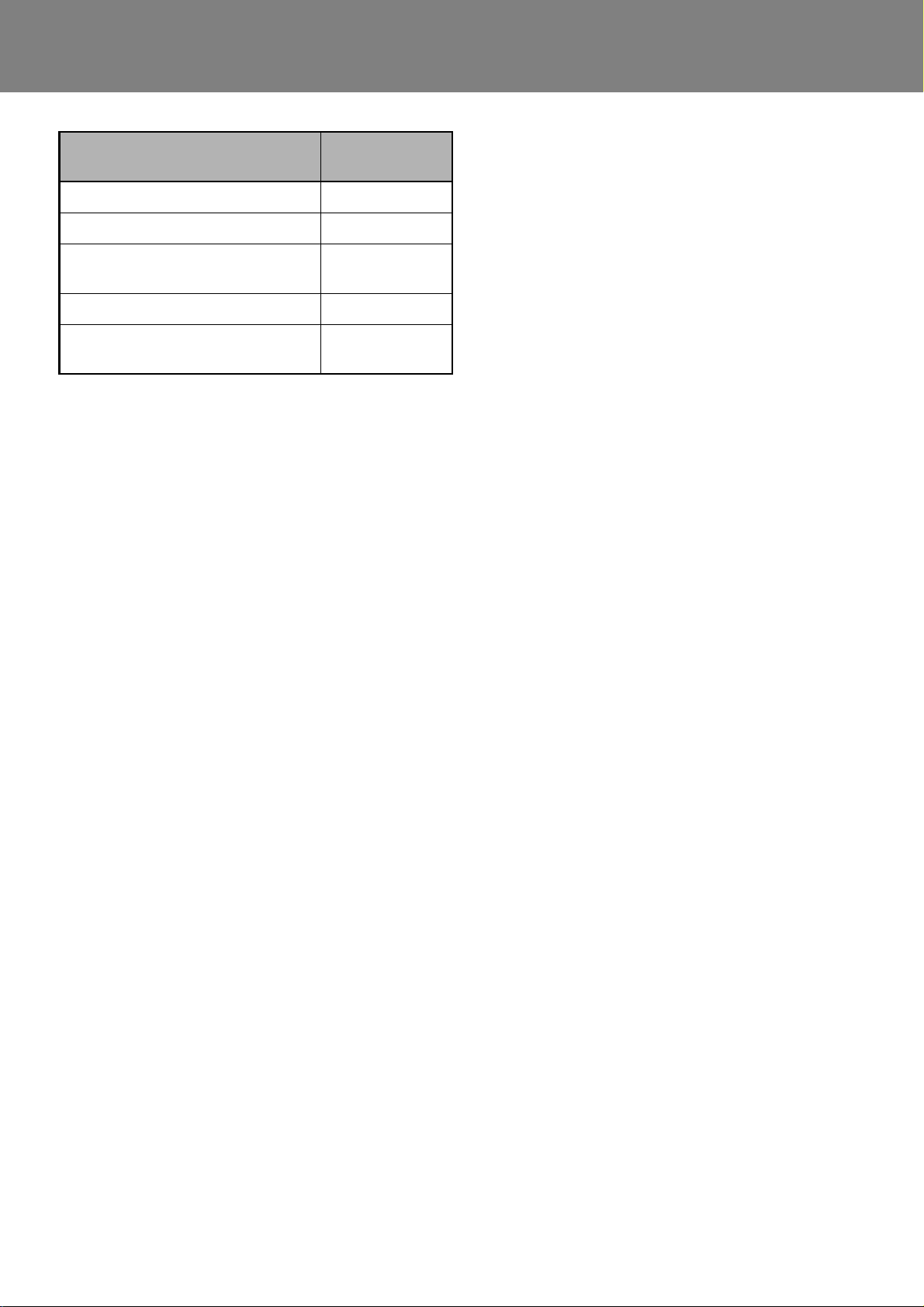

Thermo plus 230/300/350 2 Technical Data

2 Technical Data

Unless limiting values are defined, the technical data

should be understood with tolerances of ±10% common

for heaters at an ambient temperature of +20°C, and at

nominal voltage.

Table 201 Technical Data

Heater Thermo plus 230 Thermo plus 300 Thermo plus 350

ECE Type Approval Number E1 122R 00

Kind of construction

Heating flow (at ambient temperature of

20°C)

Fuel

Fuel consumption kg/h

Rated voltage V =

Operating voltage range V =

Rated power consumption at 24V * W

Max. permitted temperature of sucked

combustion air at < 85°C ambient temperature

Max. permitted temperature of sucked

combustion air at > 85°C ambient temperature

Permitted ambient temperature during operation

Permitted storage temperature °C

Permitted operating overpressure bar

Capacity of the heat exchanger l

Minimum water flow *** l/h

Minimum capacity of the water system l

CO

in exhaust gas at rated voltage Vol %

2

Heater dimensions (tolerance ± 3 mm) mm

Weight kg

kW

(kcal/h)

°C

°C

°C

0466 0467 0468

High pressure atomizer

23

(20 000)

Diesel / Heating oil

2.5 3.0 3.6

60 90 120

-40...+ 85 (100**)

1900 2400 2700

9.0 + 1.5

Length 540 / Width 250 / Height 222

30

(26 000)

24

20.5 ... 30

85

60

-40...+ 110

max. 2.0

1.8

25

9.5 + 1.5 9.5 + 1.5

16.8

(30 000)

35

* without circulating pump

** When operating in ambient temperatures >85°C a special Spheros wiring harness is to be used.

** Minimum water flow at coolant temperatures above 50°C

Below 50°C a lower water flow is permitted, if the occurence of vapor bubbles due to local overheating safely can be excluded.

2.1 Elektrical components

Control unit, circulating pump, solenoid valve, electronic

ignition and the digital timer are designed for 24V nominal

voltage. The burner motor supply voltage is controlled by

the control device.

NOTE:

2.2 Fuel

Suitable fuel is the diesel fuel specified by the vehicle manufacturer. Only the on the model plate of the heater

specified fuel must be used.

The following table lists the by Spheros approved fuels

and their specifications.

Circulating pumps must be assigned to the heaters

according to the flow resistance in the coolant circulation

system.

201

Thermo plus 230/300/350 2 Technical Data

Fuel Requirements

acc.

Summer diesel DIN EN 590

Winter diesel DIN EN 590

Arctic diesel and Diesel for a strong

winter climate

Bio diesel (FAME)

Paraffinic diesel fuel from synthesis

or hydrogenation (HVO)

Further information on approved fuels contains the TI

*

(Technical Information) Fuels.

It can be found on the Spheros homepage under Service/Technical Updates/Heating systems.

In case of air temperatures below 0°C a commercial available winter Diesel fuel must be used.

The usage of flow improvers respectively additives is permitted. There are no negative influences due to additives

known.

While using the fuels, their operating limits must be

considered and if necessary, suitable measures

(nozzle preheating, electrical heated filter) should be

applied.

If fuel is supplied from the vehicle tank, follow the

vehicle manufacturer’s instructions on additives.

*

*

ATTENTION:

DIN EN 590

DIN EN 12214

DIN EN 15940

202

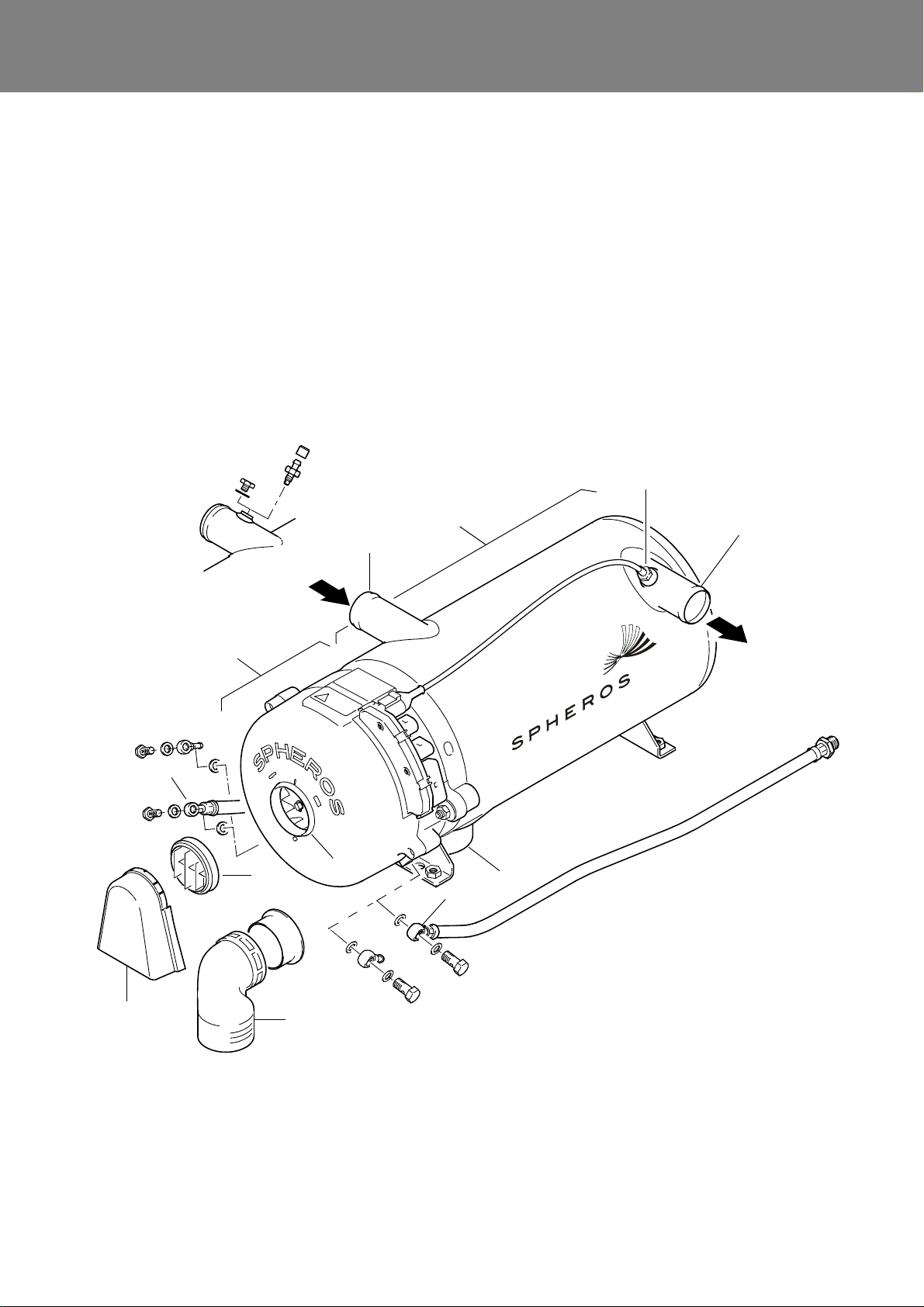

Thermo plus 230/300/350 3 Assemblies and components

1

2

4

5

6

7

8

9

10

1 Burner head

2 Coolant, intake

3 Temperature sensors

4 Coolant, outlet

5 Heat exchanger

6 Exhaust outlet

7 Fuel, return

8 Combustion air, intake

Version for

additional sensor

11

9 Fuel, supply

10 Splashguard

(grid alternative)

11 Grid

12 Intake air elbow

incl. adapter

(grid alternative)

12

3

3 Description of assemblies and

components

The heaters Spheros Thermo plus 230, plus 300 and

plus 350 are used in conjunction with the vehicle heating

system

– to heat the passenger compartment

– to defrost the windows

– to preheat water-cooled vehicle engines.

The water heater operates independently from the vehicle

engine and is connected to the cooling system, the fuel

system and the electrical system of the vehicle. It is bolted

down to the vehicle chassis or is secured using an additional cross beam.

Heat is generated by combustion of liquid fuels. Via the

heat exchanger of the heater, the heat is dissipated to a

coolant circuit. The adaptation to the changing demand of

heat is reached by intermittent operation (intermittend

mode).

The control device controls on the basis of the signals of

a temperature sensor the on and off switching of the

burner.

Fig. 301 Heater overview

301

Thermo plus 230/300/350 3 Assemblies and components

Fan wheel

Burner motor

(displayed transparently)

The heaters of the Thermo plus series basically consist of

the main components:

• burner head

• combustion chamber

• heat exchanger

External in the vehicle a circulation pump is installed or in

case of compact device directly on the heater.

3.1 Burner head

The burner head consists of the components

• combustion air fan

• control device with burner motor and flame guard

• fuel pump with solenoid valve and atomizer nozzle

• electronic ignition unit with ignition electrodes

• nozzle preheater (optional)

• disc with sight window

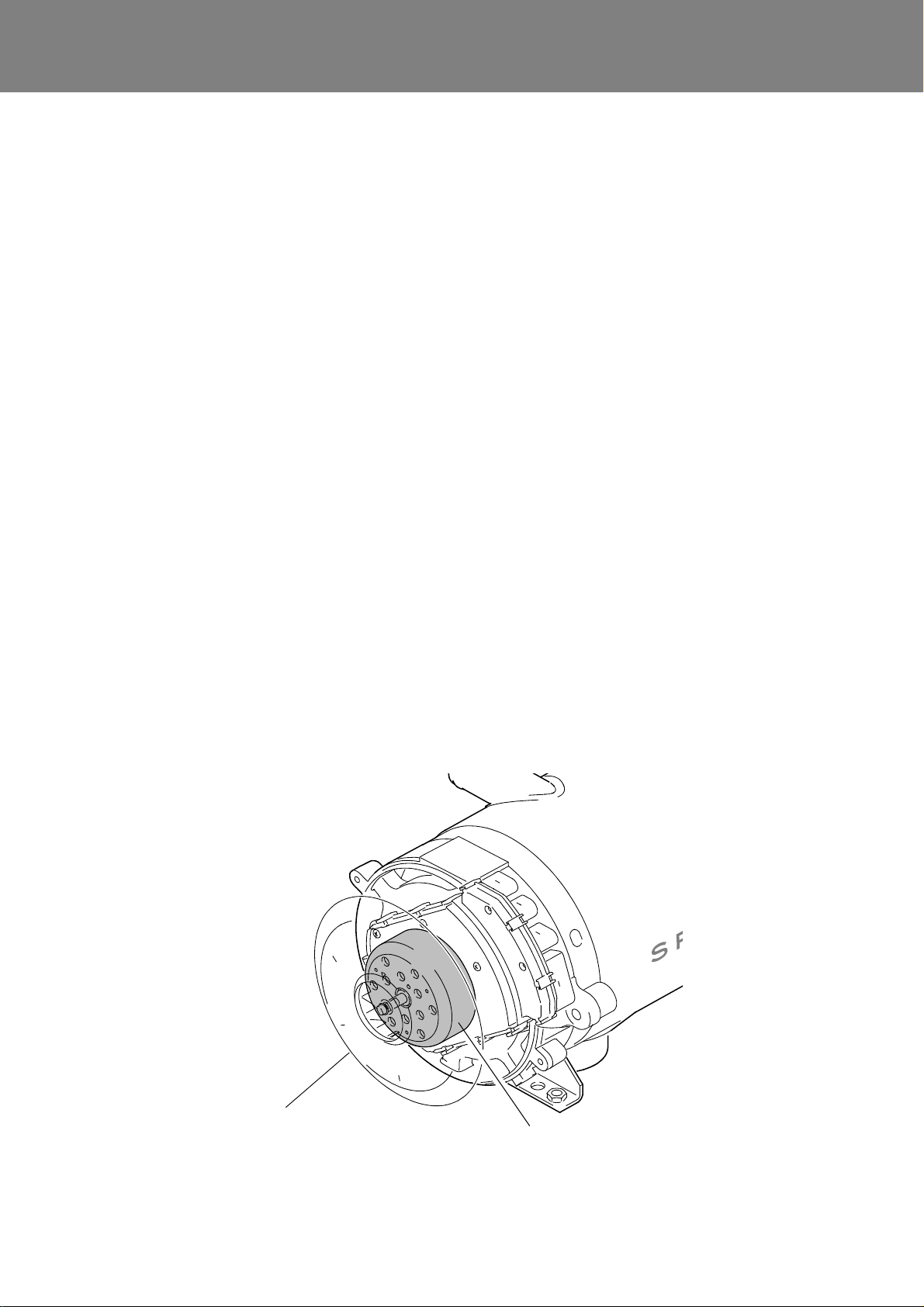

3.1.1 Combustion air fan

The combustion air fan (Fig. 302) transports the air

required for combustion from the combustion air intake to

the combustion chamber.

The combustion air fan consists of the burner motor at the

control device and the fan wheel. Air is drawn in through

the air intake opening in the hood.

This air intake opening is equipped with a splashguard, a

protective grid or an intake air elbow (see Fig. 301).

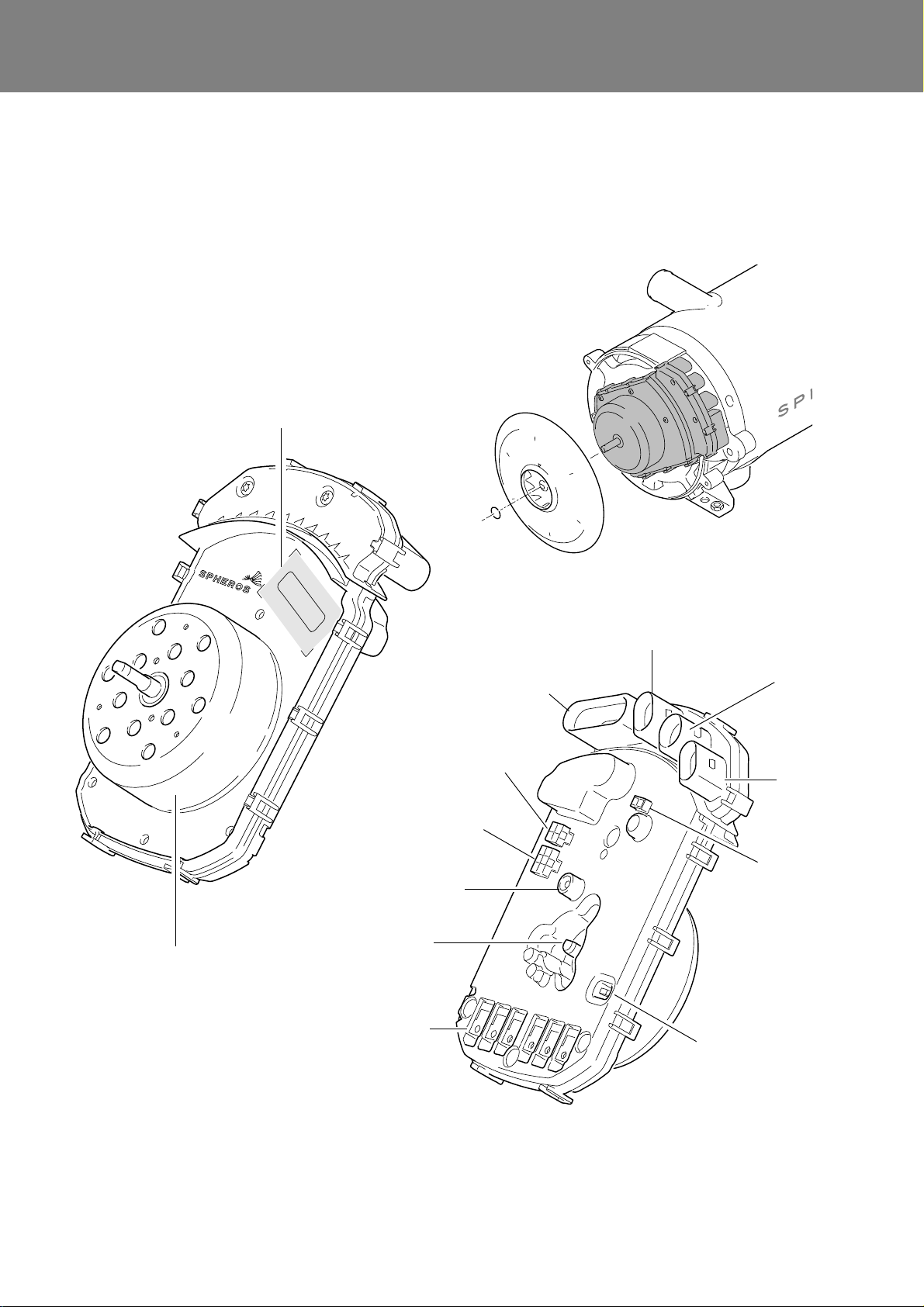

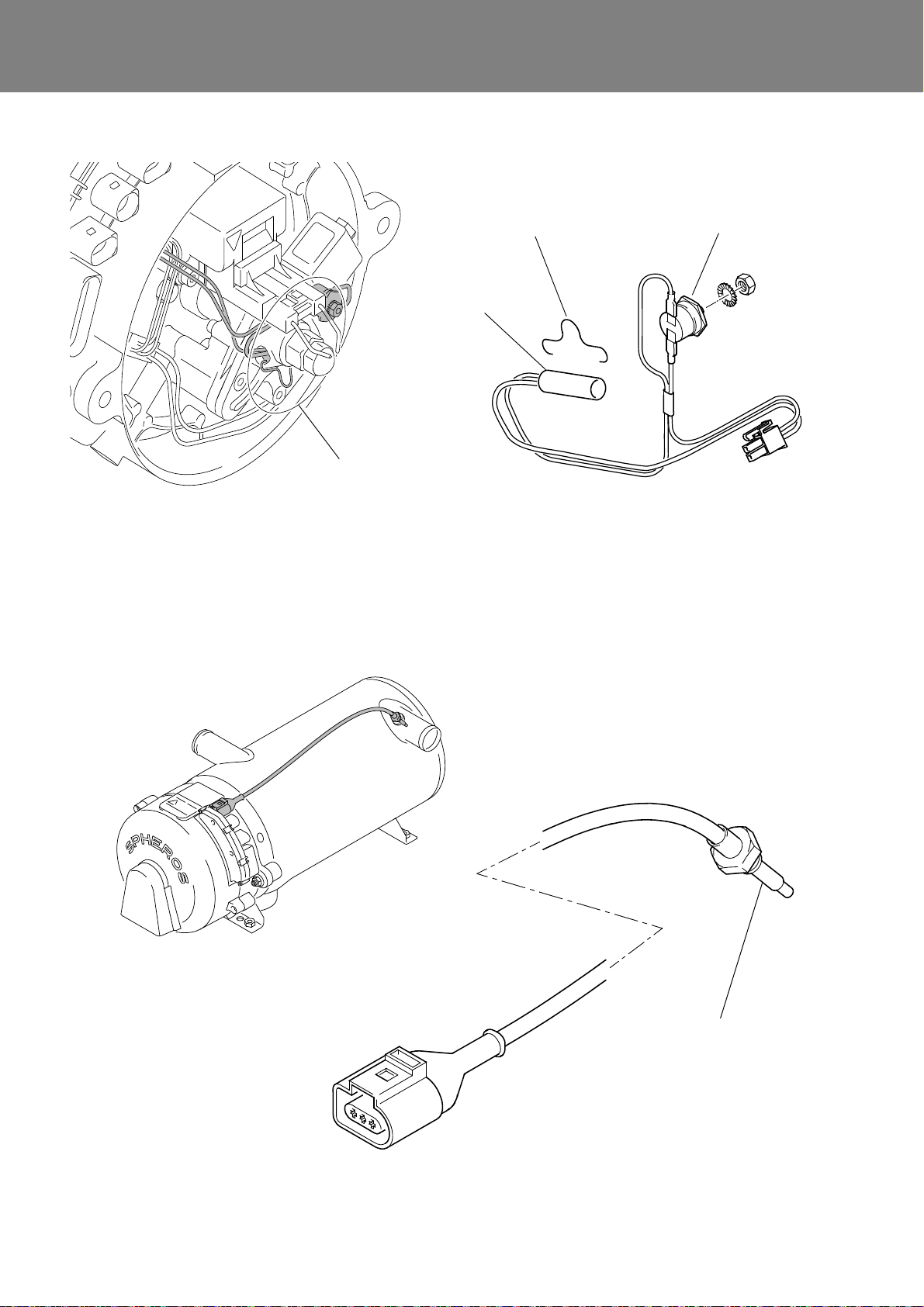

3.1.2 Control device

The control device (Fig. 303) ensures the operating

sequence and burner operation monitoring. It constitutes

a unit with the burner motor.

The control device is mounted onto the front of the burner

housing, under the hood. It protrudes with four external

electric ports out the heater:

• Port C - power/control,

• Port P - circulating pump,

• Port T - temperature sensors and

• Port G - diagnosis interface

Internally the control device provides the ports

• connector V - nozzle preheater,

• connector M - solenoid valve, and

• connector Z - electronic ignition unit.

3.1.2.1 Burner motor

The control device constitutes a unit with the brushless

EC burner motor which is installed at the burner housing.

This arangement allows its direct power supply via the

control device board. The speed measurement is done by

a Hall sensor module.

The shaft of the external rotor motor protrudes through the

control device. To the forward end the fan wheel is installed and on the backside of the control device via a coupling the fuel pump is driven.

The speed of the burner motor is controlled depending on

the operating status by the control device.

Fig. 302 Combustion air fan

302

Thermo plus 230/300/350 3 Assemblies and components

Flameguard

Motor shaft

burner motor

Heat transition

Port C

power supply

Port Z

electronic

Port M

solenoid

Port P

circulating pump

Diagnostic

Interface

Port T

temperature

sensors

Burner motor

ignition unit

valve

Model plate with Id.no.

control device/motor

Port G

Diagnosis

Port V

nozzle block

preheating

Ground terminal

to housing

surfaces to

housing

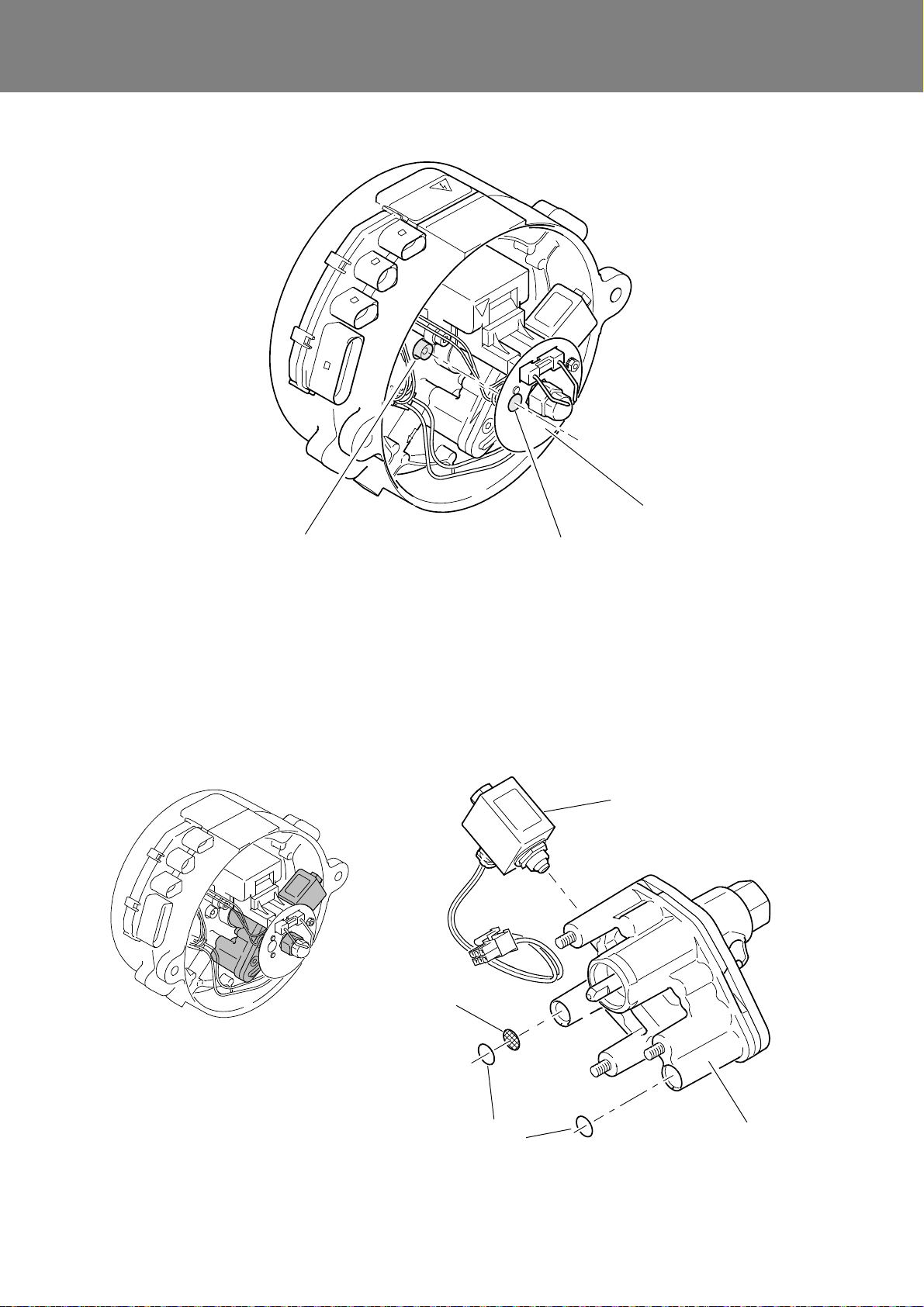

3.1.2.2 Flameguard

The flameguard (see Fig. 304) is integrated in the control

device.

The flameguard monitors the combustion flame condition

during heater operation.

The flame guard is a photo transistor that changes its

resistance depending on the incident light.

Fig. 303 Control device SG1589

303

Thermo plus 230/300/350 3 Assemblies and components

Disc

Sight window

Flameguard

Fuel pump

Solenoid valve

Screen

O-ring

Burner head

Fig. 304 Flameguard

3.1.3 Fuel pump

The fuel pump is responsible for fuel supply. (Fig. 305).

The pump is driven by the burner motor via a coupling.

Fuel is compressed in the fuel pump to approx. 10 bar and

atomized by the atomiser nozzle.

The solenoid valve installed at the fuel pump opens and

closes the fuel supply to the atomizer nozzle.

For all three heating capacity classes the same fuel pump

is installed.

Fig. 305 Fuel pump with solenoid valve

304

Thermo plus 230/300/350 3 Assemblies and components

Ignition electrodes

Burner head

Electronic ignition unit

The fuel pump can be used in dual-line operation only

(fuel supply and return line).

If the heater is operated with

– a long fuel supply line

– check valves in the fuel supply and return line

– a fuel filter in the fuel supply line

the fuel supply line must be filled prior to first heater startup (see 8.15).

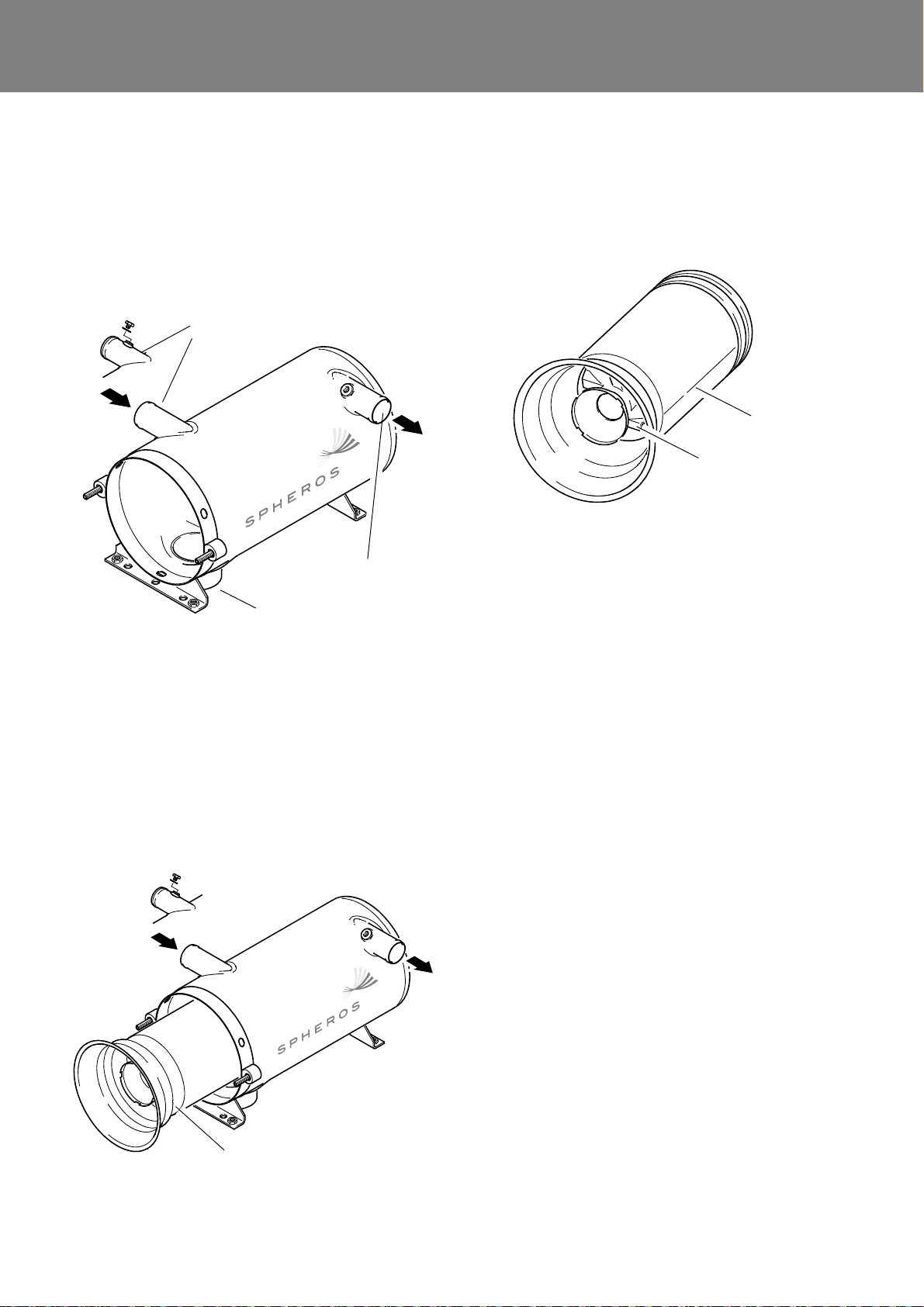

3.1.4 Electronic ignition unit with ignition

electrodes

The electronic ignition unit (Fig. 306) induces the high

voltage required for ignition of the fuel-air mixture. Ignition

is triggered by a high voltage spark, which is initiated on

the ignition electrodes.

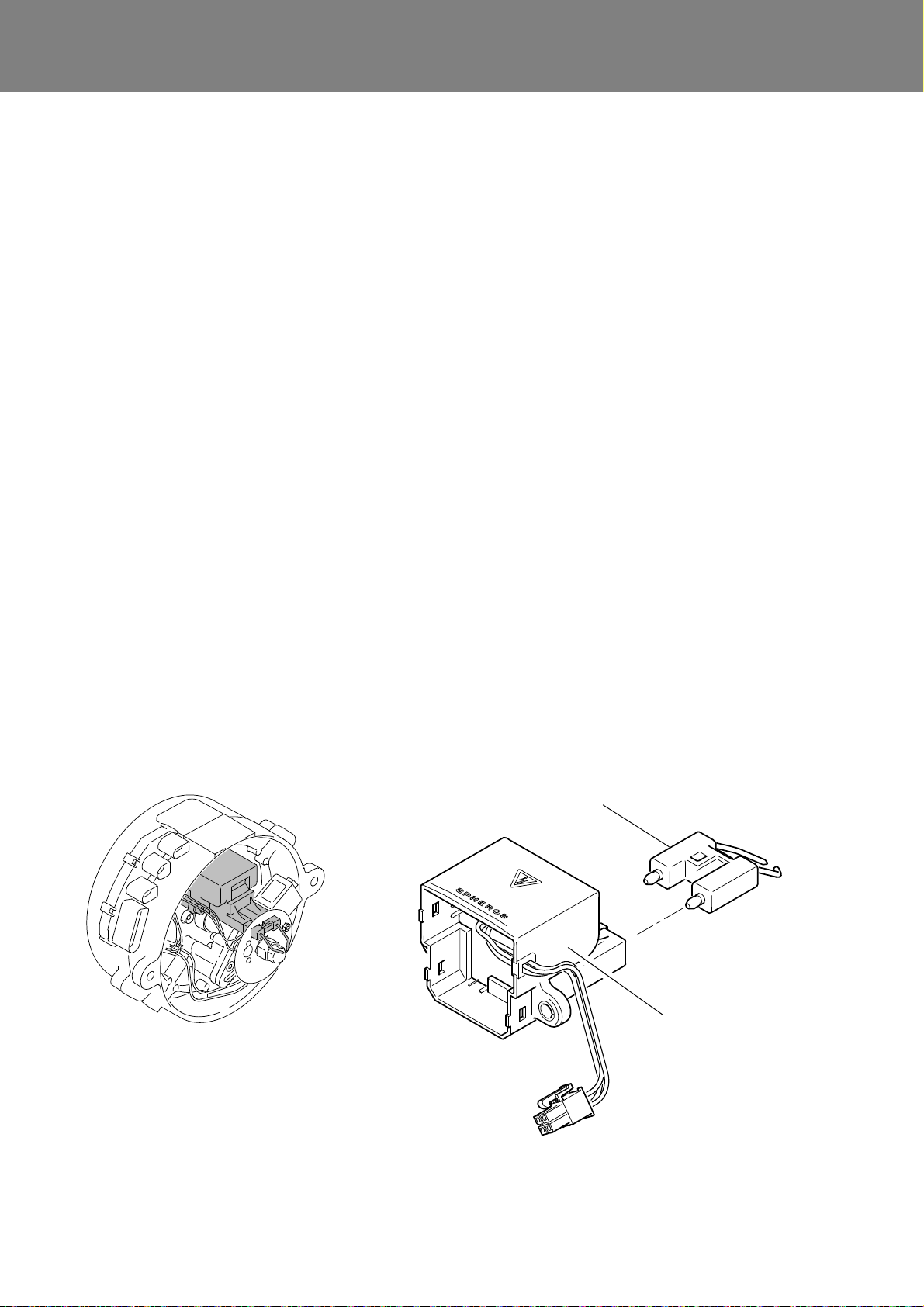

3.1.5 Nozzle block preheater

In case of very low temperatures fuel may exhibit severely

modified viscosity. Due to insufficient fuel atomization

functional heater malfunctions may occur.

Depending on the fuel used, these temperatures vary.

When used in cold regions or if fuels different from diesel

fuel are used, we recommend the use of a nozzle block

preheater (Fig. 307).

The nozzle block preheater consists of a heating element

and a thermostat. It is supplied with electricity via the fuse

of the circulating pump and works only when the circulating pump output is error-free.

At a temperature of < 5°C the heating element heats the

nozzle holder and thus, fuel and atomizer nozzle. Fuel

viscosity is reduced and atomization improved.

The heating time depends on the temperature of intake air

and the heat reflection from the combustion space. Above

8 °C the thermostat switches off. The control device

defines the preheating time depending on the temperature when starting.

The use of the nozzle block preheater is optional. The

retrofitting can be done without control device modification.

NOTE:

The nozzle block preheater is supplied with electricity via

the fuse of the circulating pump and works only when the

circulating pump output is error-free.

3.1.6 Temperature sensors with water

temperature sensor and integrated

overheating protection

The water temperature sensor (Fig. 308) captures the

coolant temperature at the heat exchanger outlet as

electrical resistance.

This signal is transmitted to the control device, where it is

processed.

The overheating protection integrated into the temperature sensor is responsible for temperature limitation.

Overheating protection prevents inadmissibly high heater

operating temperatures.

At a temperature greater than 135°C heater deactivation

and interlocking is initiated.

Fig. 306 Electronic ignition unit with ignition electrodes

305

Thermo plus 230/300/350 3 Assemblies and components

Thermostat

Heating element

Burner head

NOTE:

The disc is displayed

transparently.

Retaining clamp

Water temperature sensor

with integrated overheat

protection

Fig. 307 Nozzle block preheater

Fig. 308 Temperature sensors

306

Thermo plus 230/300/350 3 Assemblies and components

Coolant inlet

Coolant outlet

Exhaust outlet

Combustion chamber

Welding seam

Swirl plate

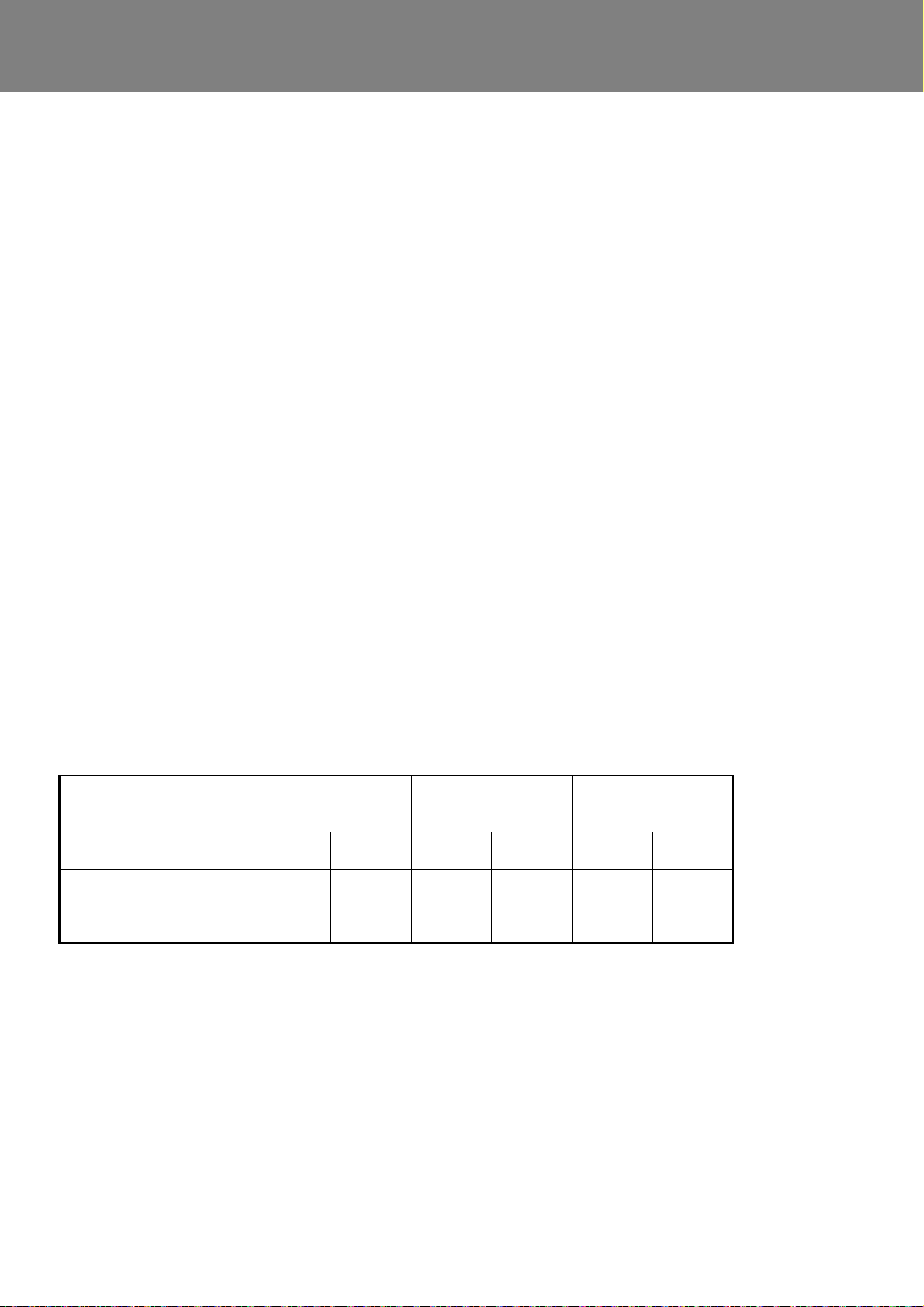

3.2 Heat exchanger

The heat exchanger (Fig. 309) transfers the heat generated by combustion to the coolant circulation system.

Depending on the system integration a heat exchanger

with or without thread in the coolant inlet socket can be

installed.

NOTE:

In the heaters are used different combustion chambers

depending on the heating capacity class.

Fig. 311 Combustion chamber

Fig. 309 Heat exchanger

3.3 Combustion chamber

The combustion chamber (Fig. 311) is used for generation

and combustion of the fuel air mixture. The generated

exhaust gas heats the coolant flowing through the heat

exchanger.

3.4 Circulating pump

The externally arranged circulating pump ensures coolant

transport within the vehicle and/or heater circulation

system.

Depending on the application, the circulating pump is switched on via the control device or directly via the vehicle

electrical system and operated during the entire heater

operation duration.

Further information on the installation and operation of the

circulating pump is contained in the Thermo plus Installation Instructions.

All service information regarding your Spheros circulating

pump(s) can be found under www.spheros.eu/products/

pumps.html.

3.5 Fuel filter

As an option a heated fuel filter is available (see

www.spheros.eu/service/spare parts and accessories).

The integrated filter heating is switched on at a fuel temperature of ≤ 0.5 ± 2.5 °C and off at ≥ 5.5 ± 2.5 °C by a

temperature switch.

When the heater is operated at low temperatures,

depending on fuel used a heated fuel filter must be

installed. See TI.

Fig. 310

307

Thermo plus 230/300/350 4 Heater functions

4 Heater functions

4.1 General heater functionality

description

The heater principle is based on a high-pressure atomizer

burner and is monitored by an integrated control unit.

The burner motor powers the fan and the fuel pump. The

fuel pump is coupled to the motor using a plastic coupling.

The fan produces the required combustion air, the combustion air volume is impacted by the burner motor speed.

The speed is read and monitored by a Hall sensor.

The speed required for the CO

during first calibration at Spheros and is stored in the

control unit.

In a maintenance event the workshop can adjust the CO

setting using the STT diagnosis (Spheros-Thermo-TestDiagnosis) (siehe 4.3).

The fuel pressure is generated in the fuel pump and

reduced to the required pressure using a pressure limiting

valve.

A solenoid valve releases the fuel via the atomizer nozzle

for combustion in the combustion chamber.

As an option, the fuel pump can be equipped with a nozzle

block preheater. The nozzle block preheater heats the

content is determined

2

nozzle holder with the atomizer nozzle at low temperatures, and thus the fuel. The fuel air mixture is ignited in

the combustion chamber via a high-voltage ignition spark.

The flame is monitored by a flame detector integrated into

the control device.

Depending on the equipment, the heater is switched on

and off using a

• digital timer

•switch

• or climate control.

During heating operation the burner is automatically switched on and off. For control a temperature sensor is

installed in the coolant outlet of the heat exchanger.

The heater is switched on, when the temperature falls

short of a lower temperature threshold, and is switched

off, if the upper temperature threshold is reached (see

2

Table 401).

The switching thresholds depend on the operation mode

of the heater and are programmed into the control device.

An operation indicator is available for monitoring the

operation status of the heater. A flame indication can be

optionally installed.

The operation indicator is also used to output error

messages via flash code.

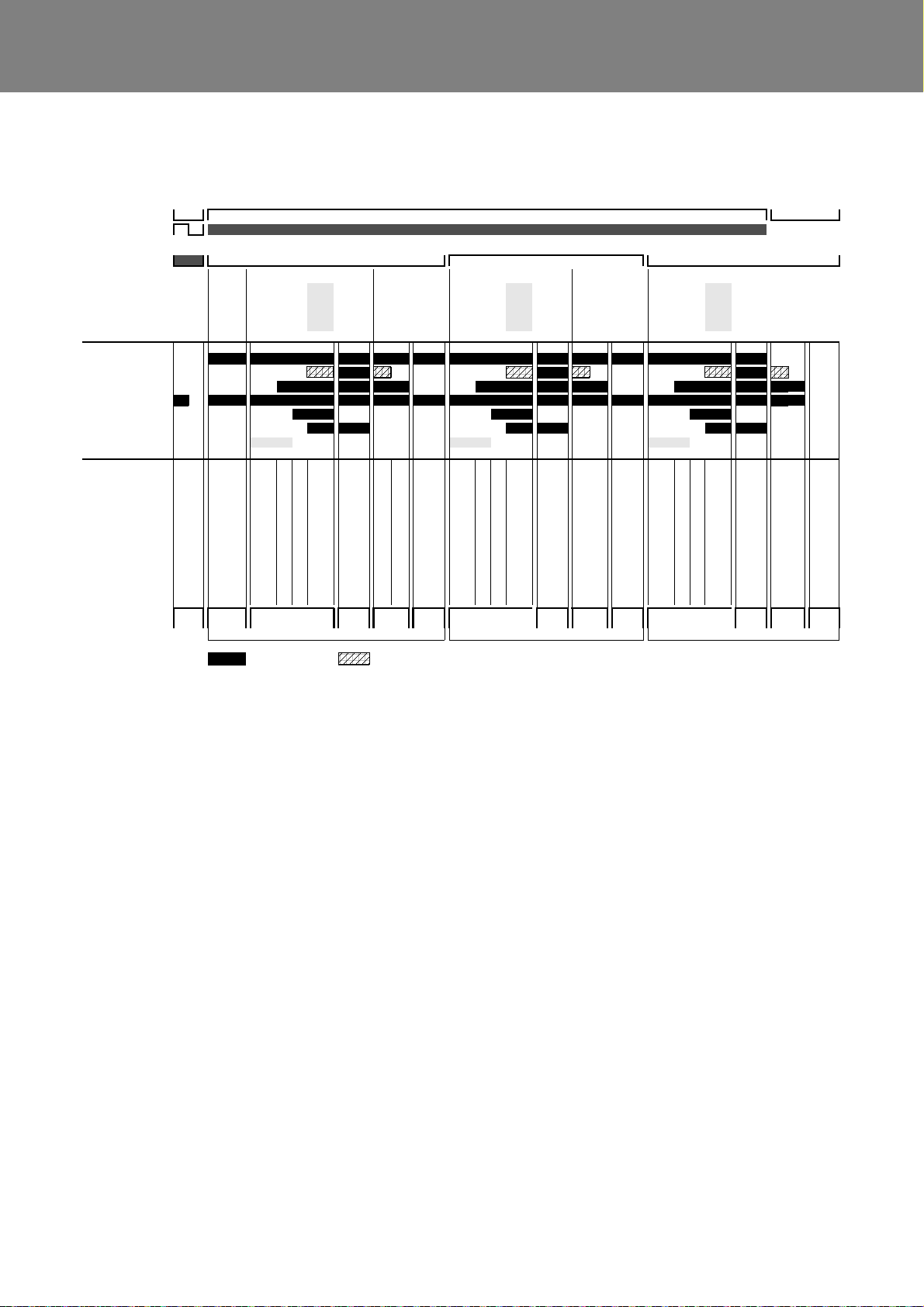

Table 401 Water Temperature Control Thresholds (standard data set)

Heater Aux. heating

(terminal 61)

on off (CI) on off (CI) on off (CI)

Thermo plus 230

Thermo plus 300

Thermo plus 350

CI: Control idle

on/off : lower/upper threshold

Aux. heating: Heater is operating, engine is opera-

ting

Parking heating: Heater is operating, engine is off

Economy setting: Control temperature is on a lower level

NOTE:

Auxiliary heating has priority over the economy setting!

72 82 67 77 55 70

Parking heating Econ. setting

401

Thermo plus 230/300/350 4 Heater functions

Signals

Main switch off on off

UPFA

Econ. mode

Terminal 61

off (parking heating) on (aux. heating)

Coolant temperature T > T_min T < T_min T >= T_max T >= T_max

Flame

generation

Flame

generation

Flame

generation

Actuators

Operation indicator

Flame indicator

Comb. air motor

Circulating pump

Electronic ignition unit

Solenoid valve

Nozzle block preheater

Time in s 0..128 12 1 15 ... 30 90 0..128 12 1 15 ... 30 90 0..128 12 1 15 ... 30 90

Status

Look for

Nozzle block preheater

Initial cycle with light check

Pre-ignition

Ignition

Purge cycle 1 with safety period

Purge cycle 2

Nozzle block preheater

Initial cycle with light check

Pre-ignition

Ignition

Purge cycle 1 with safety period

Purge cycle 2

Nozzle block preheater

Initial cycle with light check

Pre-ignition

Ignition

Purge cycle 1 with safety period

Purge cycle 2

OFF Standby Start Heating Purge

cycle

Standby Start Heatin g Purge

cycle

Standby Start H eating Purge

cycle

OFF

Parking heating Aux. heating Parking heating

On On or Off

4.2 Operational heater sequence

Fig. 401 Operational sequence

4.2.1 Switching on and start

With optional nozzle block preheater:

With activated circulating pump the bimetal at the nozzle

the control unit starts controlled operation and checks the

coolant temperature.

If the coolant temperature is below the lower temperature

threshold, the initial cycle starts.Combustion air fan and

circulating pump are switched on. The initial cycle is used

to flush the combustion chamber.

In the start phase until to the pre-ignition the in the control

When switched on, the operating display is illuminated,

device integrated flameguard must continuously detect

„dark“, otherwise it comes to a fault lock-out and the

heater changes into the standby.

After approx. 12 seconds (initial cycle time) the high-voltage spark is ignited. Approx. 1 second later the solenoid

valve in the fuel pump is opened.

The fuel injected via the atomizer nozzle and mixed with

the air of the combustion air fan, is ignited by the ignition

spark and burned in the combustion chamber.

The monitoring of the flame is done by the flame guard.

A few seconds after a flame is detected, the control device

switches the electronic ignition unit off. Until then the

flame is stabilized and the heater is not yet in heating

mode.

block preheater controls its operation. When the ambient

temperature is less than 5 °C it is turned on. Not timedependent and not limited.

Starting from a temperature <5 °C, the duration of the

nozzle block preheating is prolonged, depending on the

determined temperature. The maximum duty cycle is

limited to 140 seconds. The further procedure is as

described.

4.2.2 Heating operation

After the flame is stabilised, the heater is in controlled

(normal) operation.

Depending on the coolant temperature, the coolant

temperature is maintained at one level by switching the

burner alternately on and off.

Once the upper switching threshold is exceeded, heating

operation is finished and the purge cycle initiated.

The solenoid valve is closed, the flame expires, however

the combustion air fan and the circulating pump continue

running.

402

Thermo plus 230/300/350 4 Heater functions

The purge cycle ends approx. after 120 seconds. The

combustion air fan is switched off.

The heater is in a controlled break.

The operation indicator is on.

Once the temperature falls short of the lower switching

threshold, the heater restarts burner operation. It runs

through the same sequence as the switching-on

sequence.

4.2.2.1 Auxiliary heating mode and parking heating

mode

From the terminal D+/+61 the control device receives the

information either the vehicle engine is running or not.

If the engine is running the heater is in the auxiliary

heating mode.

The switching thresholds are higher than in the parking

mode with the engine not running.

In the parking heating operation an economy mode may

be activated.

4.2.2.2 Economy circuit

If the economy circuit is activated (economy mode) the

controlled temperatures inthe heating system are maintained at a low temperature level. The lower and upper

switching threshold are reduced.

Due to lower radiation loss the fuel consumption can be

reduced for a lower heat demand (e.g. warmer mode).

The heater burner output is not reduced.

n auxiliary heating mode (signal from terminal D+/+61)

saving mode is automatically deactivated.

4.2.2.3 Gradient evaluation

always achieved.

In order to achieve the minimum combustion period, the

lower switching threshold is variably adjusted by the

control device.

This process is also called hysteresis adaptation and is

applied in parking heating operation as well as auxiliary

heating operation.

If the combustion period falls short of the minimum

combustion period of 120 seconds, the lower switching

value is lowered by 1K for the following combustion

process. The upper switching threshold remains as is.

This can be repeated until the minimum combustion

period is reached or the lower switching threshold is

reduced by 5K.

A further lowering is not possible.

Following a combustion process, where the required

minimum combustion period was reached, the lower switching threshold is raised in steps of 1 K, max. up to the

initial level.

4.2.3 Switching off

Switching the heater off ends the combustion process.

The operation indicator goes out and and the purge cycle

is initiated.

The solenoid valve closes, the flame expires, the combustion air fan and the circulating pump continue running.

The purge cycle ends approx. after 120 seconds. The

combustion air fan is switched off.

If a malfunction occurs during purge cycle (e.g. flame

detection), the purge cycle may be shorter than 120

seconds.

During purge cycle it is permitted to switch the heater back

on. The burner will restart after a purge cycle time of 30

seconds and subsequent initial cycle time.

In case of low coolant flow or poor coolant circuit venting

the temperature quickly increases in heating operation.

The control device recognises the quick temperature

increase and automatically sets the upper switching threshold to a lower value.

The quicker the temperature increases, the lower the switching threshold for starting the controlled break is set.

In addition, the burner is also switched back on again after

the controlled break at a lower switching threshold.

This prevents residual heat triggering the overheating

protection.

4.2.2.4 Minimum combustion period

NOTE:

Frequent burning time under 120 seconds may result in

soot build and increased smoke formation.

A minimum burner combustion period of 120 second is

targeted.

For ambient and operating conditions this target is not

4.3 Diagnosis interface and (Spheros

Thermo Test) STT diagnosis

Heaters of the Thermo S series support diagnosis capabilities. Using the STT diagnosis adapter, STT diagnosis

and a PC, the heaters in a vehicle can be checked.

Information on the hook-up of the heater to the diagnosis

and its usage can be found in the STT Operation Instructions which are supplied with the device.

The Operation Instructions are also available for download on the Sheros homepage in the area Service/

Technical Documents/Accessories.

NOTE:

For protection against moisture and contamination ensure

that the diagnosis interface is sealed using a dummy plug,

if not in use.

403

Thermo plus 230/300/350 4 Heater functions

4.4 Fault lock-out and heater lock-out

A distinction is made between fault lock-out and heater

lock-out.

The lock-outs protect the heater and the surrounding

vehicle assemblies against sequence errors after a failure

or a malfunction of individual heater components.

In a heater lock-out safety-related components are

affected by the failure or malfunction. It may only be

released by Spheros trained personnel after eliminating

the cause.

Each fault lock-out and heater lock-out is stored in the

control device.

4.5 Fault lock-out

If one of the malfunctions listed below occurs, the heater

will initiate a fault shut-down, followed by a fault lock-out.

Depending on the error timing, no purge cycle or a 120

seconds purge cycle will be executed.

Flash impulses are outputted via the operation indicator.

In case of several sequential fault lock-outs a heater lockout is initiated (see 5.4).

NOTE:

If the circulating pump is externally actuated it will continue operating, if it is not affected itself.

30 V within a duration of 6 seconds (purge cycle only,

no fault lock-out).

4.5.2 Malfunctions during heater operation

In case of malfunctions during heater operation, a 120

seconds purge cycle will be executed first. Subsequently

the heater status is switched to fault lock-out.

Malfunction criteria:

• Circulating pump - short circuit and/or interruption

• Water temperature greater than the upper switching

threshold

• Temperature sensor delivers unacceptable tempe-

rature values.

• Heater operation outside the permissible temperature

range.

• Burner motor speed signal faulty.

• Flame interruption (combustion interruption for longer

than 15 seconds).

• Voltage falls short of the low voltage threshold of

approx. 20.5 V within a duration of 20 seconds after a

heating request.

• Voltage exceeds the high voltage threshold of approx.

30 V within a duration of 6 seconds (purge cycle is

applied only, but no fault lock-out).

• Control device malfunction

4.5.3 Malfunctions during purge cycle

In case of several sequential fault lock-outs a heater lockout is initiated (see 4.6).

4.5.1 Malfunctions during switching-on and

start procedure

If malfunctions occur during switching-on or during the

start process prior to ignition, the heater will be switched

off without purge cycle.

The heater is in fault lock-out.The motor stops immediately or does not start.

Malfunction criteria:

• Short circuit and/or interruption of electrical

components:

– Circulating pump

– Electronic ignition unit

– Optional nozzle block preheater

• Flame or extraneous light detection by the flameguard

prior to opening of the solenoid valve.

• No start: No flame detection within 15 seconds after

opening the solenoid valve.

• Temperature sensor delivers unacceptable

temperature values.

• Burner motor speed signal faulty.

• Voltage falls short of the low voltage threshold of

approx. 20.5 V within a duration of 20 seconds after a

heating request.

• Voltage exceeds the high voltage threshold of approx.

After the purge cycle the heater goes into the fault lockout.

Malfunction criteria:

• Circulating pump - short circuit and/or interruption

• Heater operation outside the permissible temperature

range.

• Burner motor speed signal faulty.

• Voltage falls short of the low voltage threshold of

approx. 20.5 V within a duration of 20 seconds after a

heating request.

• Voltage exceeds the high voltage threshold of approx.

30 V within a duration of 6 seconds (purge cycle is

applied only, but no fault lock-out).

• Control device malfunction

404

Loading...

Loading...