HEATING SYSTEMS

THERMO DC 200

Bus

Installation and

operating instructions

Rev. 01/2017

Id.No. 11118910A

Thermo DC 200

Highlighted words like Warning!, Caution!, ATTENTION: and NOTE: in these Installation and operating instructions signify the following precautions:

Other symbols used in these Installation and operating instructions:

This caption is used to indicate possible severe injuries

or fatal accidents if instructions or procedures are carried out incorrectly or entirely disregarded.

This caption is used to indicate possible minor injuries

if instructions or procedures are carried out incorrectly

or entirely disregarded.

ATTENTION:

This caption points to actions which may cause material

damage.

NOTE:

This caption is used to draw attention to an important

feature.

Symbol

tightening

torque

Identifies in graphics parts (e.g. nuts, bolts) that are to

be mounted with a specific tightening torque. The torque values are shown at the symbol and are binding.

Warning!

Caution!

NOTE: Subject to modification. In multilingual versions the German language is binding. The latest version of this document is provided for download

on www.spheros.de.

II

Thermo DC 200

Table of Contents

1 Statutory regulations governing installation 1

1.1 Statutory regulations governing installation 1

1.2 Model plate 2

2 Safety regulations 3

3 Use / Version 4

3.1 Installation example 5

4 Operating and maintenance instructions 6

5 Installation 7

5.1 Grounding, additional protective equipotential

bonding 7

5.2 690 VDC supply line 7

5.3 Overcurrent protection / insulation

monitoring device 11

5.4 External power supply hook-up 12

5.5 Testing 12

6 Maintenance 13

7 Faults, troubleshooting, repairs 14

8 Control elements 15

8.1 Switch or relay 15

8.2 Pre-selection timer 16

8.3 Activation via mains power 21

8.4 Operation indicator 21

9 Circulation pump 22

10 Switching thresholds 22

11 Installation of the heater - fitting of important

assemblies 23

11.1 Installation 23

11.2 Connection to the vehicle's cooling system 26

11.3 Installation of the circulation pump 27

11.4 Tightening torques 28

12 Technical data 29

III

Thermo DC 200

IV

Thermo DC 200 Statutory regulations governing installation

1 Statutory regulations governing installation

1.1. Statutory regulations governing installation

For the heater exists a type approval according to the ECE Regulations

R10 (EMC) No. 04 6641 and

R122 (Heater) No. 00 0377.

Installation is governed above all by the provisions in Annex 7 of the

ECE Regulation R122. In addition, the electrical safety requirements of

ECE Regulation R100 are to be observed.

NOTE: The provisions of these Regulations are binding within the

territory governed by ECE Regulations and should similarly be observed in countries without specific regulations!

Extract from ECE Regulation R122, Annex 7:

4 The heater must have a manufacturer’s label showing the manufacturer’s name, the model number and type together with its rated

output in kilowatts. The operating voltage and the electric power must

also be stated.

7.1 A clearly visible tell-tale in the operator’s field of view shall inform

when the heater is switched on or off.

Extract from ECE Regulation R122, Part I:

5.3 Installation Requirements for Combustion Heaters and

Electrical Heaters into Vehicles

5.3.1 Scope

5.3.1.1 Subject to paragraph 5.3.1.2., heaters shall be installed

according to the requirements of paragraph 5.3.

5.3.2 Positioning of combustion heater

5.3.2.1 Body sections and any other components in the vicinity of the

heater must be protected from excessive heat and the possibility of fuel

or oil contamination.

5.3.2.2 The heater shall not constitute a risk of fire, even in the case of

overheating. This requirement shall be deemed to be met if the installation ensures an adequate distance to all parts and suitable ventilation,

by the use of fire resistant materials or by the use of heat shields.

5.3.2.3 In the case of M2 and M3 vehicles, the heater must not be positioned in the passenger compartment. However, an installation in an

effectively sealed envelope which also complies with the conditions in

paragraph 5.3.2.2 may be used.

5.3.2.4 The label referred to in Annex 7, paragraph 4 or a duplicate,

must be positioned so that it can be easily read when the heater is installed in the vehicle.

5.3.2.5 Every reasonable precaution should be taken in positioning the

heater to minimize the risk of injury and damage to personal property.

5.3.6 Heating air inlet

not applicable

5.3.7 Heating air outlet

not applicable

1

Statutory regulations governing installation Thermo DC 200

Danger to life and health!

Warning!

Thermo DC

0Hz/30A

690 VDC / 20kW

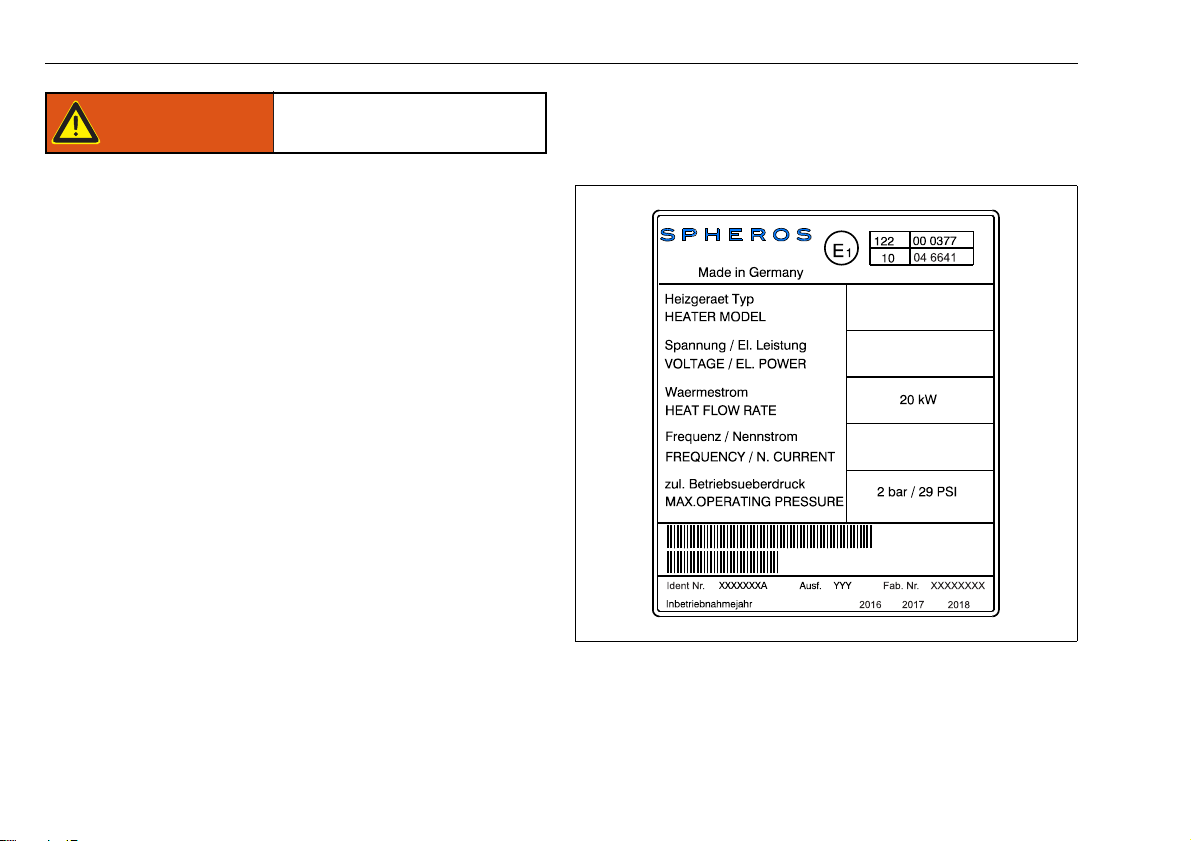

1.2. Model plate

The model plate must be protected from damage and must be clearly

legible when the heater is installed (otherwise a duplicate model plate

must be used).

Applicable local regulations, laws and standards for electrical installations, in particular the provisions of ECE Regulation R100 are

to be observed by the vehicle manufacturer and should be appropriately implemented.

ATTENTION:

Failure to follow the installation instructions and the notes contained therein will lead to all liability being refused by Spheros. The

same applies if repairs are carried out incorrectly or with the use of

parts other than genuine spare parts. This results to the invalidation of the type approval of the heater.

2

Figure 1: Model plate (example)

NOTE: The year of the initial operation must be durably marked by

removing the year numbers that are not applicable.

Thermo DC 200 Safety regulations

High voltage! Danger to life!

Warning!

2 Safety regulations

NOTE:

The provisions of these Regulations are binding within the territory

governed by DGUV Regulations and should similarly be observed in

Installation, maintenance and repairs may only be carried out when

the vehicle's engine is not running and the high voltage supply is

switched off.

Before starting the work at the heater, it is to make voltageless acc.

to DIN VDE 0105-100 and this state must be ensured for the duration of the work.

In particular, the following safety precautions must be observed:

– switch off the power supply to the heater

– ensure it cannot be switched on again

– verify, system is voltage-free, all poles

– ground and short circuit

– cover or block neighbouring parts under voltage

Electrical cables and operating elements of the heater must be arranged in the vehicle in such a way that their functioning is faultless under normal operating conditions and cannot be hampered.

Work at electrical equipment may only be started if protective

measures against electric shock, short circuits and arcing faults

have been carried out.

Electrical work may only be performed by a qualified electrician for

HV systems in motor vehicles, craftsman, activity with repetitive

character. Training acc. to DGUV 200-005 (previously BGI 8686).

countries without specific regulations.

3

Use / Version Thermo DC 200

Danger to life and health!

Warning!

Hot surfaces!

Caution!

3 Use / Version

The fully electrical water heater Thermo DC operates independently of

the vehicle engine and is connected to the vehicle’s cooling and

electrical systems.

The electrical heater can be used in a depot for pre-heating purposes.

For this it is connected stably to the depot 690 VDC power supply.

Further more the heater also can be used in electric driven buses or

hybrid buses where a 690 VDC power supply is provided, in association

with the vehicle‘s own heating system:

– to heat the passenger cabin,

– to defrost the vehicle windows,

– for pre-heating.

The heaters are approved for horizontal installation only (see Figure 18).

The heater Thermo DC is approved for heating the diesel engine

and the passenger cabin of buses, but not for use in vehicles

subjected to the Directive 94/55/EC (ADR, TRS).

General Information / Safety

Check the information given on your heaters rating plate and compare

this with your mains voltage!

In addition to the statutory regulations the specific connection conditions

of local electricity companies are to be observed.

No alterations to the electrical installation may be undertaken.

The installation and commissioning may only be carried out by a qualified electrician.

Only have any work on the appliance carried out by a specialist

company or a qualified person.

The installation instructions are to be considered.

Under no circumstances touch the heat exchanger and the water

hoses during operation, in particular when they are overheated due

to lack of water.

Ensure an adequate distance to all surrounding parts and a sufficient

ventilation during installation.

Alternately use fire resistant materials or heat shields (see Statutory

Regulations governing installation, para. 5.3.2.2).

4

Thermo DC 200 Use / Version

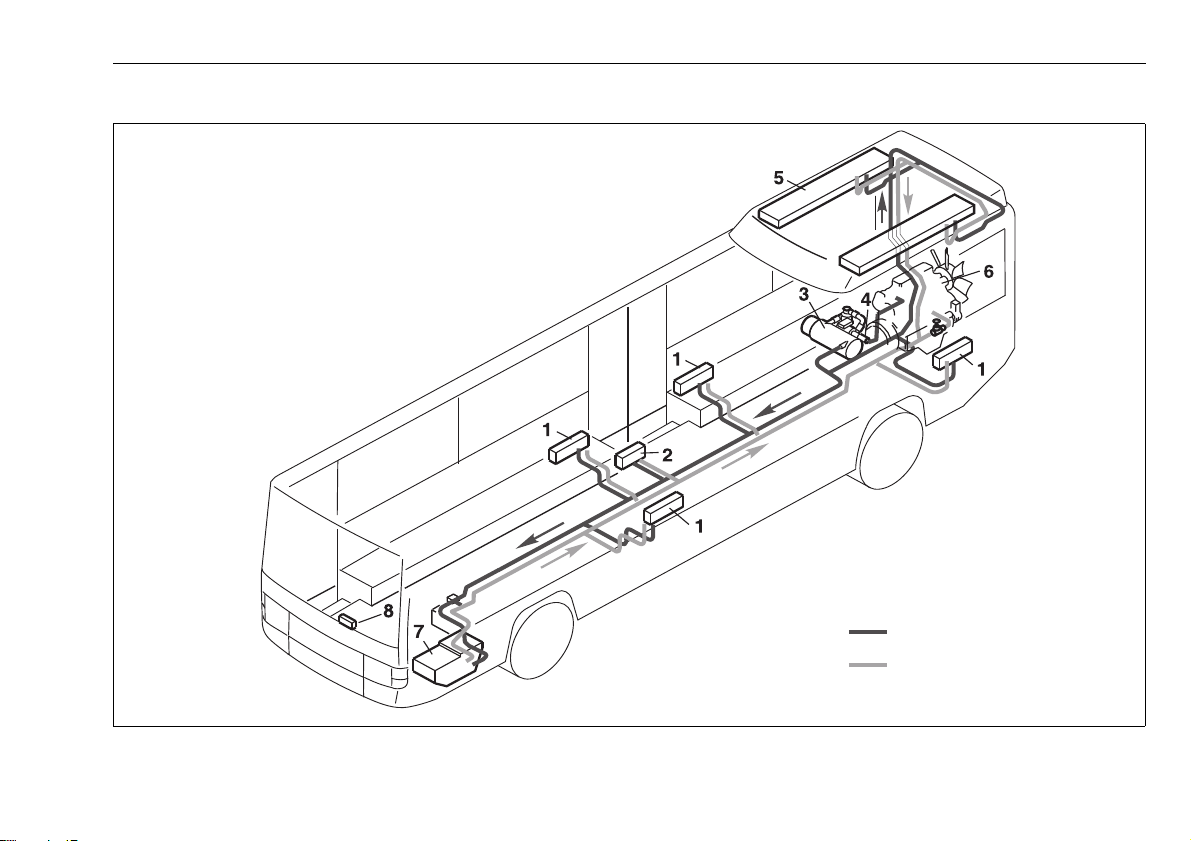

1 Wall heater with blower

2 Heat exchanger at entry

3 Heater

4 Circulating pump

5 Roof heat exchanger

6 Vehicle engine

7 Driver’s seat heating system

8 Control panel

Water heating circuit – wall heater and roof duct heating system

Supply

Return

3.1. Installation example

Figure 2: Installation example for the heater

5

Operating and maintenance instructions Thermo DC 200

4 Operating and maintenance instructions

The Thermo DC heating appliance may not be operated at temperatures

of more than +85°C. Amount of antifreeze in the water circuit - see

technical data.

ATTENTION:

The heaters may be only used in closed vehicle systems for warming up water.

They must not be operated in the depot unattended for a longer

period. The pump operation, the water cycle and the water temperature of the vehicle should be monitored. In case of any

malfunction unplug immediately the 2-pole mains plug.

Another utilization or any utilization going beyond these ones is to

be considered as unintended use. The manufacturer/supplier shall

not be liable for damages resulting from unintended use; the user

shall bear the risk alone.

6

Thermo DC 200 Installation

5Installation

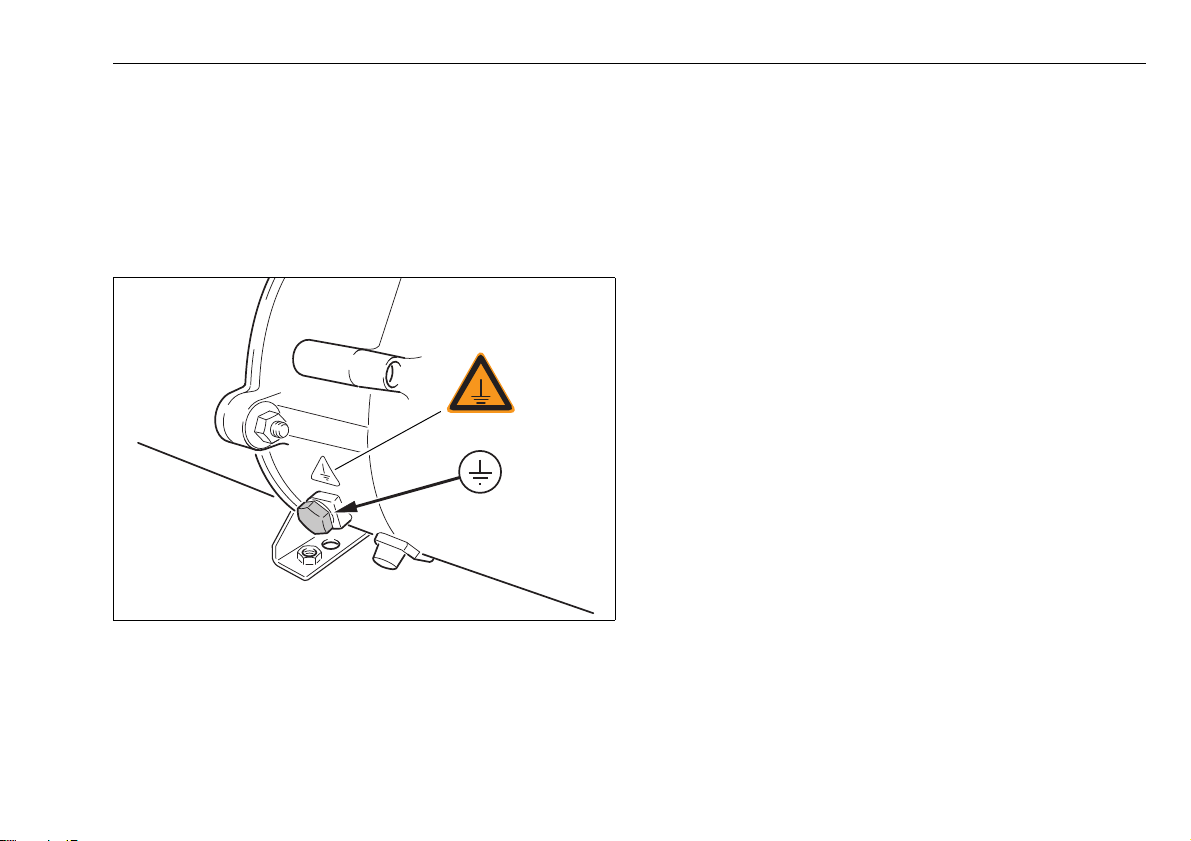

5.1. Grounding, additional protective equipotential

bonding

A grounding cable, at least 1x4 mm² Cu, should be attached to the position on the housing which is marked and provided for it. Ideally this

should be carried out with a ring cable lug for fastening with the M10x1

grounding screw (for tightening torque, refer to figure 19).

Figure 3: Grounding screw

The connecting screws on the heating appliance may only be replaced

with genuine original parts from Spheros, since these are part of the

electrical equipment and they ensure proper grounding.

5.2. 690 VDC supply line

The connection line must have a cross section of at least 2 x 4mm² Cu.

The cable cross-section must be chosen according to the power and

installed cable length. For the cable feed through, the cable gland at the

device is to be used.

Use a dedicated power circuit for the heating system.

The appliance must have a fixed connection to the DC power supply.

The heating appliance must be connected to the protective equipotential

bonding.

The connection must be carried out in accordance with the enclosed

connection diagram (see Figure 4).

7

Installation Thermo DC 200

4mm², GR, 180mm, Radox 3 GKW 12545290

0,75mm², RT,200mm, FLRY

Schütz Siemens

3TC4417/0AB4

2,5mm², RT,250mm

2,5mm², RT,250mm

QUINT/PS/ 3AC/

24DC

Radox 3 GKW 12545290

4mm², GR, 180mm,

SW

BL

BR

RT

1

1

2

2

3

4

68 ... 75 °C

125 °C

M12x1,5

1

7

283

9

4

10

5

11

6

12

14

14

-

-

-

16

13

17

18

19

20

1313

DC

OK

15

+

N

++

L1 L2 L3

GND

2

T1

4

T2

A2

24-

4mm², RT

4mm², SW

1

L1

3

L2

A1

24+

Cable colors

SW black

BL blue

BR br own

GN green

GR grey

OR orange

RT red

GNGE gr een/

yellow

690 VDC

Note the prescribed

means of protection!

- overcurrent protective device

see Section “Installation“, Figure 8

Note: Heater internal connections not shown.

Load

Contactor

Figure 4: Connecting schematic with integrated DC-DC converter (Thermo DC compact distributor board)

8

Thermo DC 200 Installation

+

-

ϑ 68.. 75°C

ϑ 125°C

1L1

+

L-

2T1

A1

24+

A2

24-

0,75mm², SW, 130mm, FLRY

15

16 19

6mm²,GR, 220mm,Radox 3GKW 12548127

1

2

3

4

RD

BR

BU

BK

1

2

10 11 12

6mm²,GR, 180mm,Radox3

GKW 1254 8127

L+

0,75mm², BK

2

1

-

DC

+

M12x1,5

0,75mm², BN

13

14

7 8 91 2 3

4 5 6

17 19

2018

6mm², RT

6mm², BL

Cable colors

SW black

BL blue

BR br own

GN green

GR grey

OR orange

RT red

GNGE gr een/

yellow

690 VDC

Note the prescribed

means of protection!

- overcurrent protective device

see Section “Installation“, Figure 8

Note: Heater internal connections not shown.

Load

Contactor

Figure 5: Connecting schematic without integrated DC-DC converter (Thermo DC compact distributor board)

9

Installation Thermo DC 200

Hook-up data:

Cord grip range: 9 - 17 mm

Use suitable tools for installation!

Contactor connections

Stripping length 11 - 13 mm

Kind of wire single wire or wire strand

or wire strand with cable end sleeves

Cable cross section 4 - 6 mm

2

Torque 3 - 4.5 Nm

250

Cable ends with end sleeves

Cord grip

Cable diameter

9 - 17 mm

Power cable

at least 2x4 mm²

10

Cable gland

for control line

(M12x1.5)

Cable gland

for power

cable (M25x1.5)

4mm², 12 mm length and

square pressure

black

red

Figure 6: Preparation of the cables and hook-up

10

Thermo DC 200 Installation

L1 und L2

Cable to the terminal

already exists

High voltage! Danger to life!

Warning!

5.3. Overcurrent protection / insulation monitoring device

ATTENTION:

The power supply circuit is to be protected through an all pole

overcurrent protection device that allows a max. current of 35A.

If the overcurrent device has been triggered, the heater is to be switched

off. It is essential that the cause is identified and the error rectified by a

qualified electrician in a specialised workshop. Only then the heating

appliance can be reconnected to the mains.

The use of overcurrent protection devices with another as specified load

ability is not permitted and will result in loss of the operating approval!

The heater must be protected on the vehicle side with all poles by

an insulation monitoring device (tripping resistance 0.5 MΩ)

against fault currents.

If the Thermo DC is monitored as a subcomponent of the BUS

system, the value can be adapted according to the applicable

statutory requirements.

The connecting schematic of the insulation monitoring device is shown

in figure 8 (for example if monitoring the stand alone device).

The specified for the fasteners torque value must be met.

Figure 7: Terminals L1 and L2

11

Installation Thermo DC 200

L1 L2

L1

L2

35A

Overcurrent

Spheros Thermo DC

Circuit breaker

protection device

all pole, 35A

DC 690 V 0Hz

after electricity

IMD 0.5 MΩ

meter

5.4. External power supply hook-up

ATTENTION:

It should be noted that with vehicles, which are to be connected to

the earthed external power supply unit via the conductive connection, a device must be present by which the galvanic connection of

the electrical earth with the ground can be made.

Before an external voltage is applied to the vehicle, the connection with

the ground must be established by this device and must be able to be

maintained until the external voltage is interrupted.

5.5. Testing

After the installation is completed, the heating appliance is to be

checked by a qualified electrician for operational safety and function!

Before the mains power is applied, close the appliance (fit the hood).

A current measurement ensures that all cartridge heaters are functioning. The current should be at 28.5A ±3A per phase.

Testing of individual cartridge heaters

Limit values for evaluation:

Insulation measurement of each connection against the housing:

R Iso > 100 MΩ

Resistance measurement between the two connection wires at 20°C

Ambient temperature: 23.3 Ω ±10%

ATTENTION:

Under no circumstances may the heaters be operated “dry“

(without water filling), since the internal construction could be

damaged!

12

Figure 8: Connection schematic

Thermo DC 200 Maintenance

High voltage! Danger to life!

Warning!

6 Maintenance

– Maintenance work on the electrical equipment may only be car-

ried out by a qualified electrician.

– The appliance must be disconnected from the power supply pri-

or to any maintenance work and in particular prior to repair work

(see 2 Safety regulations).

– The heating appliance, and in particular the electrical control

system, must be checked at least once a year according to DIN

VDE 0701/0702 (VDE 0701/0702) or according to comparable

test specifications. Independently of this the mandatory local

regulations must be observed.

ATTENTION:

– Under no circumstances may the heaters be operated 'dry' to

the air, since the internal construction will be damaged!

– Do not operate the cartridge heaters for a short period of time,

even for checking purposes, since they can be permanently

damaged or destroyed by this. Only carry out checks as

instructed.

NOTE:

The connecting screws on the heating appliance may only be replaced

with genuine original parts from Spheros.

A current measurement ensures that all cartridge heaters are functioning. The current should be 28.5A ±3A.

13

Faults, troubleshooting, repairs Thermo DC 200

High voltage! Danger to life!

Warning!

7 Faults, troubleshooting, repairs

ATTENTION:

If a safety switch has been triggered, this should only be reset after

a qualified electrician has determined the cause of the fault and

eliminated the error.

The opening of the appliance, troubleshooting and repairs must

only be carried out by a qualified electrician. In all cases the heating appliance must be disconnected from the mains.

NOTE:

Damaged or defective components should only be replaced with identical components.

ATTENTION:

The temperature limiter is triggered at 125°C and interrupts the

heating process. To reset you must activate the reset button. Prior

to this the heating appliance must be checked for any possible

damage or faults and the cause of the fault established and

eliminated.

14

Thermo DC 200 Control elements

8 Control elements

The control line should be kept as short as possible so that the voltage

drop is not too great. Max. length: 10 meters and at least 2.5mm². If

greater lengths have to be bridged, a relay must be used to split the

power circuits and limit the length.

A cable harness with the following plug is attached to the heating

appliance:

2 pin connector:

Manufacturer: FEP

Manufacturer No.: 42064500 or identical design 42064000

Only use the following mating connector:

Manufacturer: FEP

Manufacturer No.: 42121100, Spheros-ID: 11114939_

to continue the wiring.

4 pin connector:

Manufacturer: FEP

Manufacturer No.: 42122100

Only use the following mating connector:

Manufacturer: FEP

Manufacturer No.: 42064100, Spheros-ID: 11123027_

to continue the wiring.

Kinds of control:

– switch - para. 8.1

– relay - para. 8.1 or via

– pre-selection timer - para. 8.2

8.1. Switch or relay

When switching the heater with a switch or relay, these must be designed for a voltage range of 18-30V DC and a current carrying capacity

of at least 1.5A.

For monitoring purposes in the vehicle an operation indicator has to be

provided, which displays the status of the heater switching signal.

When using a 2-pole external control (see fig. 10) the required operation

indicator must be realized and controlled vehicle-mounted.

If the heater has, as shown in fig. 11, a 4-pole external control, the

operation indicator can be actuated by a switch with two contacts and

powered by the heater.

Use preferably the Spheros switch: 2711011A, switch complete with

light.

Figure 9: Spheros switch

15

Control elements Thermo DC 200

1

2

max. 10m

RD

Spheros

Thermo DC

RD

+

690V DC

24V DC 1.5A

5A

External control

input

Switch

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

at least 2.5mm

2

1

BN

4

RD

-

-

+

3

2

+

RD/WH

BK

max. 10m

Spheros

Thermo DC

690V DC

24V DC 1.5A

5A

5A

24V DC

max. 250mA

External control

input

Switch

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

at least 2.5mm

2

Operation indicator

1

2

BK

BN

+

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

External control

input

max. 10m

at least 2.5mm

2

Spheros

Thermo DC

690V DC

Switch

at least 30V DC 1.5A

5A

Operation indicator

24V DC max. 250mA

Figure 10: Wiring diagram with switch, 2 pole

Figure 11: Wiring diagram with switch, 4 pole

16

Figure 12: Wiring diagram with switch, 2 pole, without DC-DC

converter

8.2. Pre-selection timer

If the Spheros pre-selection timer is used as an operational element, a

24V vehicle relay (switching current >1.5A), with a current consumption

smaller than 400mA, must be used in accordance with the following

circuit diagrams.

When using a 2-pole external control (see fig. 13), the required operation indicator must be realized and controlled vehicle-mounted.

If the heater has, as shown in fig. 14, a 4-pole external control, the

operation indicator can be actuated by a switch with two contacts and

powered by the heater.

5A

11011

12 4

5A5A

2

0,75mm²

0,75mm²

0,75mm²

External control

input

T. 58

T. 15

T. 30

T. 31

max.

max. 10m

at least 2.5mm

2

2

1

RD

Spheros

Thermo DC

24V

RD

690V DC

24V DC 1.5 A

5A

0.4A

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

Spheros

Pre-selection

Timer

Thermo DC 200 Control elements

Figure 13: Wiring diagram with pre-selection timer, 2 pole

17

Control elements Thermo DC 200

BK

RD

RD/

1

2

WH

BN

4

3

-

-

+

+

5A

11011

12 4

5A5A

2

0,75mm²

0,75mm²

0,75mm²

max. 10m

690V DC

Spheros

Thermo DC

T. 58

T. 15

T. 30

T. 31

max.

24V

0.4A

24V DC 1.5A

Operation indicator

24V DC max. 250mA

5A

5A

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

External control

input

at least 2.5mm

2

Spheros

Pre-selection

Timer

Figure 14: Wiring diagram with pre-selection timer, 4 pole

18

5A

11011

12 4

5A5A

2

8

0,75mm²

0,75mm²

0,75mm²

BN

2

1

BK

T. 58

T. 15

T. 30

T. 31

max.

Spheros

Thermo DC

24V

690V DC

at least 30V DC

0.4A

1,5 A

max. 10m

24V DC max. 250mA

Consider prescribed protection!

- Overcurrent protection device

See para.: „Installation“, Fig. 8

External control

input

at least 2.5mm

2

Spheros

Pre-selection

Timer

Operation indicator

Thermo DC 200 Control elements

Figure 15: Wiring diagram with pre-selection timer, without DC-DC converter

19

Control elements Thermo DC 200

2

MO

heater ’’on’’ indicator

standard

timer

forward

reverseinstant

heating

program

day of the week

time

alarm

memory

time

indicator

location

display

selection

ATTENTION:

Never connect the timer directly to the heating appliance. This will

damage the timer. You can use the following relay: ID: 98559A (Fa.

Wehrle, 29 201 045).

Figure 16: Pre-selection timer

The pre-selection timer enables you to preset the start of the heater

operation up to 7 days in advance. It is possible to program 3 different

starting times, only one of which can be activated. The standard digital

timer features a wake-up alarm function. When the ignition is switched

on, the timer displays the current time and the day of the week. When

the heater is switched on, the display and the buttons are illuminated.

After the power supply has been connected, all symbols on the display

will flash. The current time and weekday must be set.

Operation

The timer can be operated in that all flashing symbols can be adjusted

20

by means of the and buttons. If the buttons are not pressed

within 5 seconds, the time displayed will be stored. If the and

buttons are pressed for more than 2 seconds, the fast time-setting mode

is activated.If the ignition is switched off while the heater is operating in

the continuous mode, the remaining operating time of 15 minutes is

displayed and the heater continues to operate for this period of time.

Switching the heater on

Manually: by pressing the button (continuous heating mode)

Automatically: by programming the heater starting time

Switching the heater off

Manually: by pressing the button

Automatically: by programming the operating time

With the heater running: by programming the remaining operating time

Setting time/day of the week

Press the button for more than 2 seconds - time of the day is flashing

- and set the clock using the and buttons. Day of the week is

flashing - adjust the day of the week.

Viewing the time

With the ignition switched off: press the button

Programming heater starting time

Press the button - the memory location is flashing - using the

and buttons, set the heater starting time. Day of the week is flashing

- set the day of the week. By repeatedly pressing the button,

memory locations 2 and 3 can be programmed or the time display mode

can be reached.

Thermo DC 200 Control elements

Recalling/erasing preset times

Repeatedly press the button until the desired memory location is

displayed.

To erase the preset time, press the button several times until the

time of the day is displayed instead of the memory location.

Programming duration of operating time

The heater must be switched off. Press the button for 3 seconds operating time is flashing - and set the desired operating time (10 to 120

minutes) using the and buttons.

Setting the remaining operating time

Set the desired remaining operating time (1 to 120 minutes) using the

and buttons. The remaining operating time refers to the time the

heater still continues to remain in operation. It can only be changed

while the heater is in operation and the ignition switched off.

Setting the wake-up time

A wake-up time can only be programmed on the standard digital timer.

The wake-up time is not bound to a specific day of the week. Repeatedly

press the button until the bell symbol appears on the display.

Set the desired wake-up time using the and buttons. The alarm

clock turns off after 5 minutes or when one of the buttons is pressed.

Recalling/erasing the wake-up time

Repeatedly press the button until the bell symbol appears on

the display - read off wake-up time. To erase the wake-up time: press

the button until the bell symbol is no longer visible on the

display.

Remote control

Possible by means of an optional external "instant heating" button

Vehicles with ADR equipment

On ADR vehicles it is not possible to program a preset starting time. The

remaining time is shown on the display while the heater is in operation.

The clock can be set. The alarm clock function can be programmed on

the standard digital timer.

8.3. Activation via mains power

If you bridge the contacts of the control line, the heating system is activated when mains power is applied.

8.4. Operation indicator

For monitoring there should be an operation indicator provided at the

vehicle, which displays the status of the switching signal/heating

system.

If the operation indicator is integrated into the power circuit for external

control, it may require a current of max. 250mA. Only suitable lamps for

the voltage range of 18 - 30V are to be used (ref. also para. 8.1, Fig. 11

and 12).

21

Circulation pump Thermo DC 200

9 Circulation pump

ATTENTION:

For a correct switching on of the heating appliance an adequate

circulation of the cooling medium must be ensured before switching on.

The heating appliance is preferably to be equipped with Spheros circulation pumps, refer to technical documents “Aquavent Circulation

Pumps“. Further information on the Spheros circulation pumps and their

installation can be found at www.spheros.eu/Products/Pumps.html.

The water flow rate through the heat exchanger of the Thermo DC must

be more than 1,500 litres/hour. The system must be completely bled.

The triggering/activation of the circulation pump is not carried out by the

heating appliance. For this reason the coolant demand must be

provided for at the vehicle.

10 Switching thresholds

Upper switching threshold: 75°C

Lower switching threshold: 68°C

22

Thermo DC 200 Installation of the heater - fitting of important assemblies

Risk of scalds and burns!

Caution!

11 Installation of the heater - fitting of important assemblies

11.1. Installation

ATTENTION:

– The legal regulations for the installation are to be observed.

– If the operation of the water heating appliance is to be part of a

separately installed heating system, an installation plan should

be presented in all cases to Spheros for approval.

If this approval is not given, the installation is not permitted and

all warranties and liability claims become void.

– Mechanical strain must not be applied to the cables of the tem-

perature switches (e.g. by using them to carry the heating

appliance).

– Heating appliances and circulation pumps must fundamentally

be built in such that any damage through contamination from

the track, water spray, exhausts and other damaging influences

is excluded.

– The disassembly of the individual components (contactor, cart-

ridge heaters) is not permitted and makes all warranty claims

void.

The cooling water and the components of the cooling water circuit

achieve high temperatures.

– Water-carrying parts are to be routed and fastened in such a

manner that no temperature risk to humans, animals or material

sensitive to temperature due to radiation / contact occurs.

– Before working on the cooling water circuit, switch off the hea-

ter and wait until all parts are cooled down, if necessary wear

protective gloves.

The dimensions of the heating appliance, the permitted installation locations, and the hole pattern for the fastening can be found in figures 17

and 18.

Installation location

Attention should be paid to the particular location conditions of the

specific vehicle type.

The heating appliance and the circulation pump are integrated into the

cooling system (or into a separate heating circuit). The heating

appliance should be installed as low as possible so that bleeding of the

heating appliance and the circulation pump is automatically assured.

This is particularly important since the circulation pump is not selfpriming. If the heating appliance and the circulation pump can not be

accommodated in the engine room of the vehicle, they can be installed

in a sealed housing. This housing must be adequately ventilated from

the outside, so that a maximum temperature of +85°C inside is not

exceeded.

23

Installation of the heater - fitting of important assemblies Thermo DC 200

1

2

3

4

1 Coolant - Inlet

2 Coolant - Outlet

3 Space required for removal of the electric

components and the cartridge heaters

HLP20x300

4 Vent screw

Figure 17: Dimensions of the heating appliance Thermo DC

24

Thermo DC 200 Installation of the heater - fitting of important assemblies

10.8

Welded nut M8 - DIN 929

1 Attachment variant 1

4x screw M8 (15Nm +5Nm)

2 Attachment variant 2

4x screw M8 (through going) +

4x hexagonal nut M8 (15Nm +5Nm)+

4x Washer 8.4

Figure 18: Installation position and hole pattern Thermo DC

25

Installation of the heater - fitting of important assemblies Thermo DC 200

11.2. Connection to the vehicle's cooling system

The heating appliance is connected to the vehicle's cooling system

according to figure 17. The volume of coolant fluid present in the circuit

must be at least 35 liters. The water in the heating circuit of the heating

appliance must contain at least 30 to 60% of a branded antifreeze agent.

An up-to-date list of Spheros recommended anti-freeze agents can be

found on the Spheros website.

Basically, the by Spheros approved water hoses must be used. If this is

not the case, the hoses must at least comply with DIN 73411. The hoses

are to be laid without kinks and also rising where possible for the proper

bleeding of the heating appliance. The heater must be mounted below

the minimum water level of the cooling circuit. Hose connections are to

be secured with hose clamps against slipping off.

When installing the electric heater the direction of the flow of the cooling

water in the circuit is to be considered (see figure 17).

ATTENTION:

The specified tightening torques of the hose clamps used must be

adhered.

In the vehicle cooling system, or in the case of a separate heating circuit,

only overpressure valves with an opening pressure of maximum 2 bar

should be used.

Attention should be paid to the careful bleeding of the cooling system

without usage of the circulating pump, before the first commissioning of

the heating appliance, or after the coolant fluid has been replaced.

For that the additional venting option via the vent screw item 4, figure 17

is to be used after the system has been filled and the pump has been

switched on.

The heat exchanger and the water hoses of the Thermo DC should be

pre-filled completely. Loosen the vent screw slightly until no air further

emerges, but only water. Then retighten the screw (tightening torque see figure 19).

ATTENTION:

If air bubbles are present, they could cause destruction of the cartridge heaters!

The heating appliance and pipes must be installed in such a way that

they ensure a static bleeding of the system.

The correct degree of bleeding results in an almost silently operating

circulation pump. An inadequate bleeding can lead during heating

operation to the switching-off of the heating appliance due to overheating.

Where the U 4855 / Aquavent 6000C circulation pump is used, the circulation pump is automatically switched off ca. 10 seconds after switching

on, if the cooling agent is not present or there is blockage of the pump

impeller, and it can be started up again after ca. 2 minutes.

Where the U 4856 / Aquavent 6000SC circulation pump is used, the

circulation pump is automatically switched off ca. 45 seconds after switching on, if the cooling agent is not present or there is blockage of the

pump impeller, and it can be started up again after ca. 2 minutes.

ATTENTION:

Before commissioning the heating system, the water hoses, the

circulation pump and the heating appliance must be filled completely.

Only by Spheros recommended anti-freeze agents may be used.

26

Thermo DC 200 Installation of the heater - fitting of important assemblies

11.3. Installation of the circulation pump

Consider the information regarding the installation provided in the

documentation of your circulation pump. Note the installation position!

NOTE:

The pump ports and connection lines from the water intake and water

outlet must be flush (no stress).

ATTENTION:

If the pump is not controlled by the heater, its operation is to be ensured by all means during whole heater operation (initial cycle,

heating operation and purge cycle). At least turn on the Thermo DC

and pump at the same time, but ensure the operation of the pump

by an appropriate control circuit at least 2 to 3 min. after switchingoff the heater.

27

Installation of the heater - fitting of important assemblies Thermo DC 200

Grounding screw

Cable gland

Cable gland control

power supply cable

(M12x1.5):

(M10x1):

Bleed

screw

20 ±1 Nm

1.5 -0.3 Nm

8 -1 Nm

16 +1 Nm

(M25x1.5): cable

11.4. Tightening torques

28

Figure 19: Tightening torques

Thermo DC 200 Technical data

12 Technical data

Unless limit values are given, the technical data below is understood to

be subject to the usual tolerances for heating appliances of +/-10% at an

ambient temperature of +20°C and at nominal voltage.

NOTE:

The allocation of the circulation pumps to the heating appliances must

be carried out according to the upstream resistances and the minimum

flow rate.

Heating appliance Thermo DC 200

Design Fully electrical heater

Nominal heating flow max.

Nominal heating flow at 540 VDC

Rated voltage V 690

Rated power consumption

Rated power consumption at 540 VDCkWkW

Frequency

Rated current

Electrical circuit protection / overcurrent

protection device

Ambient temperature during operation °C -40 … +85

Storage temperature °C -40 … +90

Operating overpressure bar max. 2.0

Capacity of the heat exchanger I 9.4

Minimum water flow l/h > 1500

Minimum capacity of the water system I 25

Amount of antifreeze in cooling sytem % 30 up to 60

Dimensions heater

(tolerance +/-3 mm)

Weight kg 15

kW

kW

Hz

A

mm

20

12.6

20

12.6

0

540 VDC = 24

690 VDC = 30

750 VDC = 32

35A

length: 578

width: 247

height: approx. 225

29

Technical data Thermo DC 200

For notes:

30

memos

HEATING SYSTEMS

Valeo Thermal Commercial Vehicles Germany GmbH

Postfach 1371 - 82198 Gilching - Germany - Tel. +49 (0)8105 7721-0 - Fax +49 (0)8105 7721-889

www.valeo-thermalbus.com - service-valeobus@valeo.com

Loading...

Loading...