Valeo REVO-E Workshop Manual

AIR CONDITIONING

REVO®-E Heat pump

Volvo

Workshop Manual

Rev. 06/2019

Id.No. 11123006A

REVO-E Heat pump Content

1 Introduction

1.1 Content and purpose 101

1.2 Validity of the workshop manual 101

1.3 Meaning of emphasis 101

1.4 Symbols 101

1.5 Additional documentation to be used 101

1.6 Safety information and condition 101

1.6.1 General safety information 102

1.6.2 Working with high-voltage air-conditioning systems 102

1.6.3 Working with refrigerants 102

1.6.4 Working with pressurized containers 103

1.6.5 Technical rules for pressurized gases (TRG) 103

1.6.6 Waste and residual materials 103

1.7 Suggestions for improvement and change 103

1.8 Abbreviations 104

2 Technical specifications

3 Description of assemblies and components

3.1 REVO-E HP versions on the Volvo 79xx Electric 301

3.2 Total overview of the design and components of the REVO-E heat pump 302

3.3 Overview of high-voltage cable harnesses / components (400V AC / 600V DC) 303

3.4 Cable harnesses overview (high-voltage / low-voltage) in the REVO-E HP 304

3.5 Design / task and function of the assemblies 305

4 Function and functional schematics of the REVO-E Heat pump

4.1 General function 401

4.2 Functional schematic of the REVO-E heat pump 402

4.3 Functional schematic of the REVO-E heat pump Volvo 7900 Electric 403

4.4 Work modes of the REVO-E heat pump in the Volvo 7900 Electric 404

4.4.1 Heating and Ventilation Mode (HV Mode) 405

4.4.2 Heating and Ventilation Mode Ready for cooling 406

4.4.3 Heating and Ventilation Mode Ready for Heat Pump Mode 407

4.4.4 Cooling Mode 408

4.4.5 Heat Pump Mode 410

4.4.6 Operating Mode De-Icing) (Version HP+ only) 412

4.4.7 Operating Mode Oil Recovering (Version HP+ only) 413

4.4.8 Reheat Mode 414

4.4.9 Waste Energy Mode 415

4.4.10 Gas Charging Mode 416

4.5 Refrigerant circuit function schematic of the heat pump 417

4.5.1 Refrigerant circuit function schematic of the heat pump in the Cooling Mode 418

4.5.2 Refrigerant circuit function schematic of the heat pump in the Heat Pump Mode 419

4.5.3 4-way reversing valve function schematic 420

4.5.4 Refrigerant circuit function schematic of the heat pump with hot gas de-icing (

11123865_ only) 422

5 Troubleshooting

5.1 General 501

5.2 Malfunctions in the air-conditioning circuit 501

5.2.1 Causes of malfunctions in the air-conditioning system 501

5.2.2 What to do for malfunctions in the refrigerant circuit 501

5.2.3 Why the desired conditions are not reached when testing pressure 501

1

REVO-E Heat pump Content

5.3 Malfunctions in the electrical system 501

5.4 Table of error codes 503

5.5 Error codes 504

5.6 Inspecting functionality of individual components 509

5.6.1 General visual inspection 509

5.7 Diagnosing the REVO-E units using the Diagnosis Control Test – DCT diagnostic software 509

5.8 Diagnosing the frequency converter 509

6 Wiring diagrams

6.1 Electrical fuses 601

6.2 Wiring diagram REVO-E HP (11120816*) 601

6.3 Wiring diagram REVO-E HP+ (11123865*) 608

6.4 Frequency converter - electrical connections 615

6.4.1 600V DC power supply including HVIL connector 615

6.4.2 400V AC voltage output 616

6.4.3 PE connection (potential equalizing) 616

6.5 Compressor - electrical connections 617

6.5.1 400V AC voltage supply 617

6.5.2 PE connection (potential equalizing) 617

7 Maintenance

7.1 Safety information 701

7.2 Versions of ADA 701

7.3 Maintenance and upkeep 701

7.4 Inspection and maintenance 701

7.4.1 Changing the fresh air filter 701

7.4.2 Changing the filter dryer 701

7.4.3 Inspecting the oil level of the compressor 702

7.4.4 Changing the compressor oil 702

8 Removal and installation of components (high-voltage system)

8.1 Safety information 801

8.2 Versions of ADA 801

8.3 Preparation/follow-up 801

8.3.1 High-voltage system 801

8.3.2 Refrigeration section 801

8.4 Frequency converter removal/ inst alla tio n 802

8.4.1 Remove the frequency converter 802

8.3.2 Install the frequency converter 803

8.4 Refrigerant compressor removal/ installation 804

8.4.1 Remove the compressor 804

8.4.2 Comparing the old/new oil level 806

8.4.3 Install the compressor 806

8.5 600V DC/ 400V AC high-voltage cable removal/ installation 808

8.5.1 Remove the 600V AC cable 808

8.5.2 Install the 600V DC cable 808

8.5.3 Remove the 400V AC cable 808

8.5.4 Install the 400V AC cable 809

9 Removal and installation of components

9.1 Safety information 901

9.2 Versions of ADA 901

9.3 Preparation/follow-up 901

9.4 Condenser module removal/ installation 901

2

REVO-E Heat pump Content

9.4.1 Removal of the condenser module 901

9.3.2 Installation of the condenser module 902

9.4 Expansion valves removal/ installation 903

9.4.1 Positions of the expansion valves and the associated contact sensors 903

9.4.2 Remove an expansion valve 904

9.4.3 Install an expansion valve 904

9.5 Filter dryer removal/ installation 905

9.5.1 Remove the filter dryer 905

9.5.2 Install the filter dryer 905

9.6 Receiver removal/ installation 905

9.6.1 Remove the receiver 905

9.6.2 Install the receiver 905

9.7 Double radial blowers / axial fans removal/ installation 906

9.7.1 Remove a double radial blower 906

9.7.2 Install a double radial blower 906

9.7.3 Remove an axial fan 906

9.7.4 Install an axial fan 906

9.8 Recirculating air flap actuator motor removal/ installation 907

9.8.1 Remove the actuator motor 907

9.8.2 Install the actuator motor 907

9.9 Temperature sensor (duct / recirculating air suction) removal/ installation 907

9.9.1 Remove the duct temperature sensor (blow-out temperature) 907

9.9.2 Install the duct temperature sensor (blow-out temperature) 907

9.9.3 Remove the recirculating air suction temperature sensor (passenger compartment) 907

9.9.4 Install the recirculating air suction temperature sensor (passenger compartment) 907

9.10 Suction pressure sensor removal/ installation 908

9.10.1 Remove the suction pressure sensor 908

9.10.2 Install the suction pressure sensor 908

9.11 High-pressure sensor removal/ installation 908

9.11.1 Remove the high-pressure sensor 908

9.11.2 Install the high-pressure sensor 908

9.12 Pressure switch removal/ installation 909

9.12.1 Remove the pressure switch 909

9.12.2 Install the pressure switch 909

9.13 Compressor suction and pressure lines removal/ installation 909

9.13.1 Remove the pressure line 909

9.13.2 Install the pressure line 909

9.13.3 Remove the suction line 909

9.13.4 Install the suction line 909

9.14 Solenoid valve removal/ installation 910

9.14.1 Remove the coil 910

9.14.2 Install the coil 910

9.14.3 Remove the screw-in valve 910

9.14.4 Install the screw-in valve 910

Attachment A

Torque values/ seales A-1

3

REVO-E Heat pump 1 Introduction

Potential risk to health

and life!

Warning!

Potential risk to health

and life!

Warning!

Hazardous to health!

Caution!

1Introduction

1.1 Content and purpose

This workshop handbook is for repairs and maintenance

purposes of the rooftop system (subsequently referred to

as air-conditioning system) REVO-E.

Work on the air-conditioning system is only to be

conducted by personnel who are qualified pursuant

to DGUV Information 200-005 (old BGI 8686) or,

outside of the German market, by personnel who are

instructed/trained according to corresponding local

regulations.

The required qualifications differ depending on the

content and scope of the work on the a ir-conditioning

system. See point 1.6.1 below.

1.2 Validity of the workshop manual

This workshop manual is valid for all of the air-conditioning systems listed on the cover page.

It may be subject to changes and addenda. The currently

valid version is binding. These are found on the Valeo

homepage in the Service / Downloads area.

NOTE:

Is used when something is to be emphasized.

1.4 Symbols

Symbol of tightening torque:

Used in graphics, indicates parts (e.g. lock

nuts, screws) that must be attached with a

certain tightening torque. The values of the

tightening torque are found in the torque t able

in Attachment A and are binding.

1.5 Additional documentation to be used

The use of additional servicing literature is required. This

is indicated in the workshop manual in the corresponding

location.

Use the following documents when operating and

servicing the air-conditioning system:

• Installation instructions for the REVO-E

• Evacuation and filling instructions for the REVO-E

• Maintenance and service plan for the REVO-E

• Spare parts list for the REVO-E Heat pump

• Technical information (TI)

This servicing literature is also available for download at

www.valeo-thermalbus.com/eu_en/Service/Downloads/

Air-Conditioning.

1.3 Meaning of emphasis

In this handbook, the emphases of Warning!, Caution!,

ATTENTION: and NOTE: mean the following:

This heading is used when improperly following or

not following instructions or processes can lead to

serious injuries or fatal accidents.

This heading is used when improperly following or

not following instructions or processes can lead to

minor injuries.

ATTENTION:

Indicates procedures which may lead to material

damage.

1.6 Safety information and condition

The air-conditioning system was designed and produced

according to EC directives. The system is safe to operate

if properly installed and used

in accordance with the installation, operation and

servicing instruction.

Nonobservance of the servicing literature listed under 1.5

and the instructions included within excludes Valeo from

liability.

Always observe the general accident prevention regulations. The “general safety conditions” beyond the framework of these regulations are listed below.

101

REVO-E Heat pump 1 Introduction

High voltage!

Caution

Mortal danger!

Warning!

Danger of serious injury

or death by falling!

Warning!

High voltage!

Caution

Mortal danger!

Warning!

Hazardous to health!

Caution!

1.6.1 General safety information

Required qualifications

To work on the refrigeration section of the air-conditioning system, proof of both of the following qualifications is required:

– electrically qualified person (EQP)

EQP: Trained in non-electrical work on/near highvoltage systems, knows the dangers, does not work

independently (supervision and controls), trained according to DGUV 200-005 (old BGI 8686)

– Specialists trained in refrigeration technology with cer-

tificate of competence pursuant to Directive (EC) no.

307/2008

To work on the high-voltage section of the air-conditioning system, proof of both of the following qualifications is required:

– Electrician for HV systems in powered vehicles Voca-

tional education, job of repeating character, training

pursuant to DGUV 200-005 (old BGI 8686)

– Specialists trained in refrigeration technology with cer-

tificate of competence pursuant to Directive (EC) no.

307/2008

1.6.2 Working with high-voltage airconditioning systems

Only conduct installation, maintenance and repair

work if the motor is still and the 24V DC power s upply

as well as the high-voltage has been switched off.

Before starting work on the air-conditioning system,

ensure that the system is voltage-free and make sure

it remains so for the duration of the work.

In certain cases, the following safety rules must be

followed:

– make the system voltage-free

– ensure that the system cannot be reactivated

– check whether the system is voltage-free

– ground and short-circuit

– cover or block off neighboring voltage-carrying

parts

Electrical work may only commence if protective

measures against electrical shock, short-circuits and

electric arcs have been taken.

1.6.3 Working with refrigerants

NOTE:

The conditions of these rules are valid within the jurisdiction of DGUV (German Social Accident Insurance) and

must be followed even in countries without special provisions.

Know and follow the operating and servicing instruction

for the systems, tools and aids used as well as their

accompanying safety information from the manufacturer

when evacuating and filling the air-conditioning system.

Working on the bus roof

When working on the bus roof or hydraulic lifts, scaf folding, etc, take suitable measures to prevent falling.

Observe EN 378 when working on cooling systems. There

is an info data sheet or material sheet (available from

manufacturer) for each refrigerant as well as the general

information from professional organizations within the

chemical industry.

Certain conditions apply, that must be maintained, for the

safe and proper use of refrigerants:

– Wear protective eye wear when working with refriger-

ants. If a refrigerant gets into the eye, serious fr ostbite

damage may occur. Thoroughly rinse the eyes with

water immediately and seek medical attention.

– Wear protective gloves when working with refriger -

ants. Liquids refrigerant is not to come into contact

with the skin. The hands must be protected from frostbite (leaking R 134a condenses at -26.5°C) and from

erosion to the skin's protective layer (refrigerants dissolve fat)! If a refrigerant comes into contact with the

skin, thoroughly rinse the point of contact with water

immediately and seek medical attention.

102

REVO-E Heat pump 1 Introduction

Potential risk to health

and life!

Warning!

Potential risk to health

and life!

Warning!

– Never warm refrigerant cylinder s with an open flame.

The material may become damaged from the excessive temperature, resulting in decomposition of the refrigerant.

– There is a possible risk of suffocation if the r efrigerant

leaks into the atmosphere. Refrigerants are heavier

than air. At and beyond a concentration of approx.

12% in the air, there will not be sufficient oxygen to

breathe. Loss of consciousness and increased ca rdiovascular problems caused by stress and lack of

oxygen will result. This is a fatal hazard!

– It is forbidden to smoke when handling refrige rants. A

burning cigarette can break the refrigerant down. Poisonous substances will form as a result.

– Before welding and soldering cooling systems, the

cooling system must be completely evacuated and

any residue removed by blowing in nitrogen. If

exposed to heat, refrigerants will release products of

decomposition that are not hazardous but can also

cause corrosion.

– Nonflammable refrigerants also pose a fire risk via the

ignition of displaced oil residue and insulating material

as well as the oil mist caused by strong leakages.

– Close empty containers to prevent the entry of mois-

ture.

– Never overfill refrigerant cylinders, since an increase

in temperature can lead to enormous pressures.

1.6.5 Technical rules for pressurized gases

(TRG)

The applicable rules for the manufacturer and workshop

are listed in the Technical Rules for Pressurized Gases

(TRG). Personnel who conducted maintenance and re pair

work on the air-conditioning system must know and follow

these rules.

1.6.6 Waste and residual materials

The valid legal conditions and regulations, that concern

waste disposal as well as how to process residual material, must be followed.

1.6.4 Working with pressurized containers

– Ensure that the container does not fall over or roll

away

– Do not throw the container. If struck, the containers

may be so deformed that they rupture. Considerable

forces are let free if the heat exchanger is suddenly

struck and refrigerants leak out. The same applies if

cylinder valves break. Therefore, the cylinders are

only to be transported with protective cap.

– Refrigerant cylinders are not to be kept near heating

units. Higher temperatures mean higher pressures,

which may lead to the container exceeding its

maximum allowed pressure. The rules for pressur ized

containers stipulate that containers are not to be

warmed beyond 50 °C.

Disposing of refrigerant and refrigerator oil

The refrigerants to be disposed of are to be placed into the

labeled recycling containers, taking into consideration the

present fill level.

Used refrigerator oils from systems with halogenated

hydrocarbons must be disposed of as special waste. It is

forbidden to mix these with other oils or substances.

Follow country-specific guidelines for proper storage and

disposal.

1.7 Suggestions for improvement and

change

Please refer any complaints, suggestions for improvement or change for this manual to:

service-valeobus@valeo.com

103

REVO-E Heat pump 1 Introduction

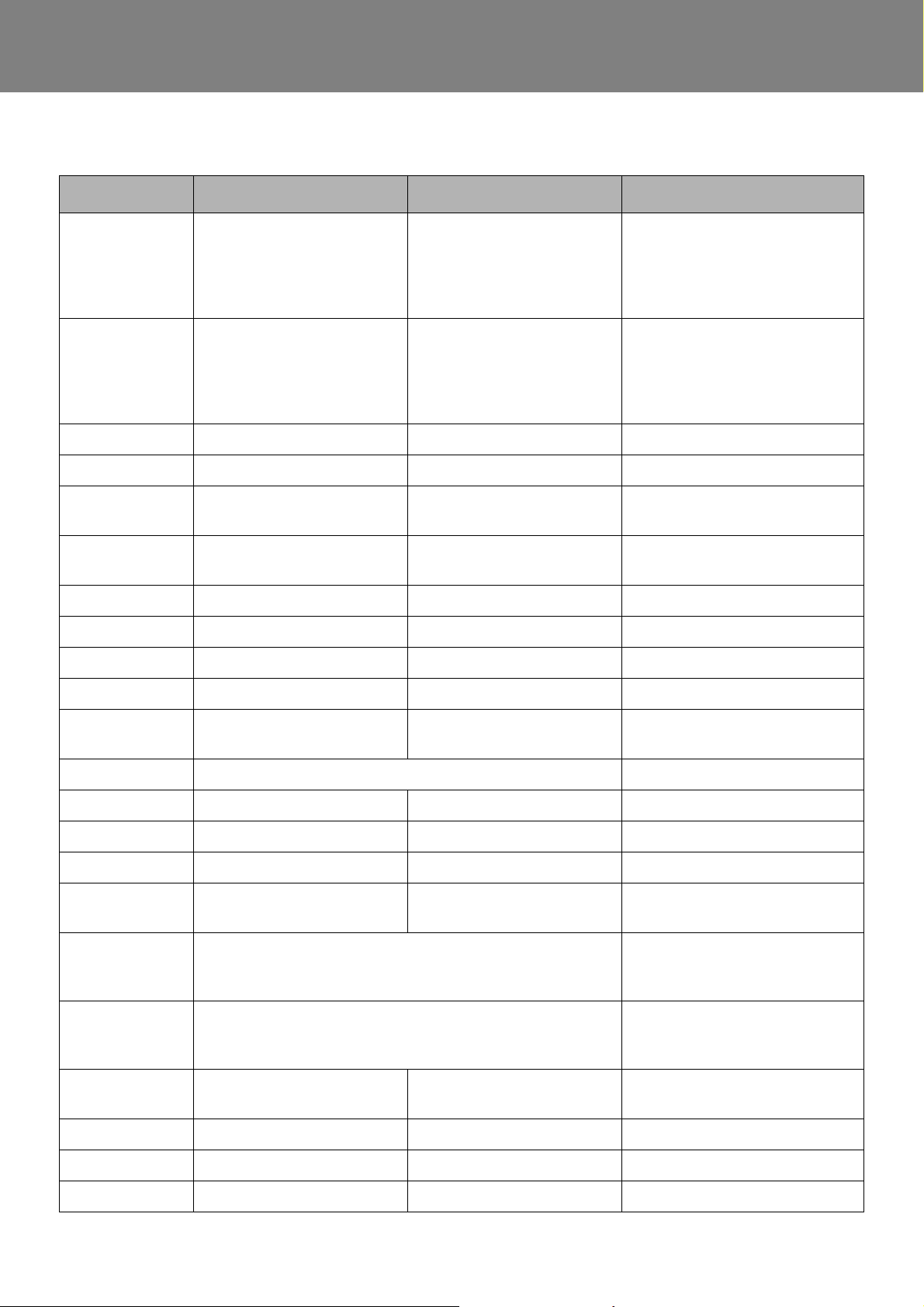

1.8 Abbreviations

Abbreviations DE EN Description

REVO-E HP - ident no. 11120816_

- installed on Volvo E Bus

1st Generation

- lower operating limit

HP ≥ 3°C

REVO-E HP

AC Klimaanlage Air Condition air conditioning only

ADA Aufdachanlage Roof Top Unit

BEA (el.) Body Electrical Architecture electronic regulations of the pas-

DCT Diagnose Control Test Diagnosis Control Test previously Spheros Control Test

EU6 Euro 6 Euro 6 Europe variant

GH Global Hybrid global chassis application

HGA Heißgasabtauung Hot Gas Deicing

HV Hochvolt High Voltage

HVAC Heizen/ Lüften/ Klima Heating/ Ventilation/ Air-

HVIL High Voltage Interlock Loop High voltage interlock loop

+

Conditioning

- ident no. 11123865_

- installed on Volvo E Bus

2nd Generation

- llower operating limit

HP ≥ -5°C

senger compartment

–SCT

i.O. / OK in Ordnung in working order

n.i.O. / NOK nicht in Ordnung not in working order

PE Potentialausgleich Potential Equalizing safety earthing

PTC positiver Temperatur-

koeffizient

SC600 ECU REVO-E AC electronic control unit

SC610 ECU REVO-E AC electronic control unit

SC620 ECU REVO-E WP ECU REVO-E HP electronic control unit

V AC Wechselspannung Volts Alternating Current

V DC Gleichspannung Volts Direct Current

HP Wärmepumpe Heat Pump ADA with heat pump function

Positive Temperature

Coefficient

REVO-E AC (replaced by

SC610)

REVO-E AC (replaced by

SC610)

REVO-E WP

104

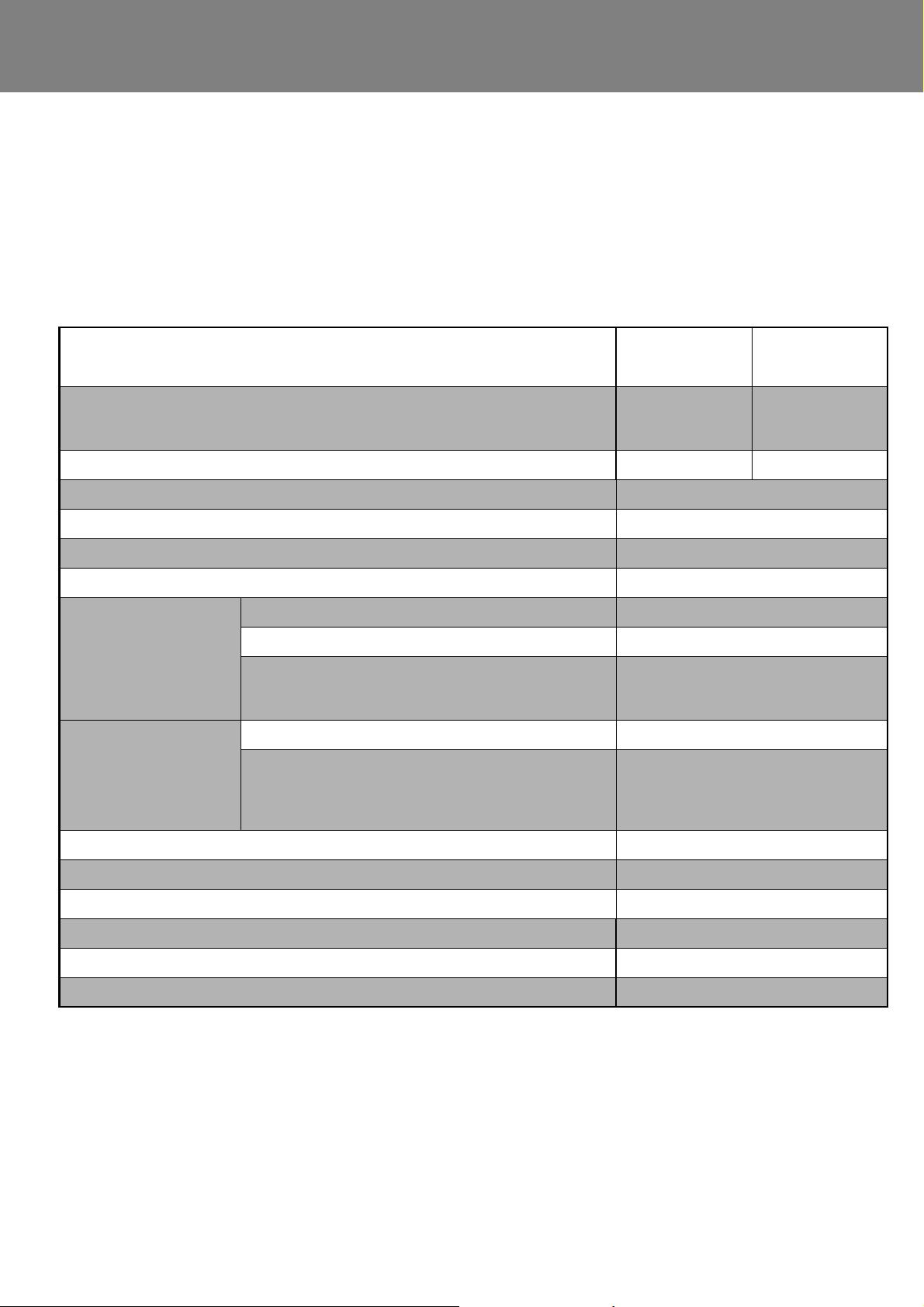

REVO-E Heat pump 2 Technical specifications

2 Technical specifications

The technical specifications, provided that there are no

limit values given, comply with the standard tolerances for

air-conditioning systems of ±10% for an ambient temperature of +20° C and nominal voltage.

Table 201 Technical specifications

REVO-E heat pump

11123865_

Application Volvo E-Bus 2nd

Generation

(from 2018)

Operating range heat pump [°C] ≥ -5 ≥ 3

Cooling capacity [kW]

Heating capacity in heat-pump-mode [kW]

Heating capacity coolant circuit [kW] 40

Air volume [m³/h] 6960

Current consumption [A]

(24 V DC)

Current consumption [A]

(600 V DC)

1

2

maximum (all 100 %) 85

nominal (condenser 80%, evaporator 70%) 55

regulated

(the temperature in the passenger compartment is at set

point)

maximum (compressor speed at 50Hz) 22

regulated

(the temperature in the passenger compartment is at set

point 25°C - ambient temperature 35 °C, reduced compressor speed)

3

11120816_

Volvo E-Bus 1st

Generation

(till 2018)

25

16

11

9

REVO-E HP+ REVO-E HP

Weight [kg] 272

Dimensions (length x wide x height) [mm] 2802x2091x406

Operation voltage range [V DC] 450-750

Refrigerant R134A

Filling capacity w/o front box[kg] 5

Filling capacity with front box [kg] 5.5

1

) T

2

) T

3

) Version installed two times in articulated vehicle

ambient

ambient

= 35 °C, T

= 5 °C , T

cabin

cabin

= 40 °C

= 20 °C

201

REVO-E Heat pump 3 Assemblies and components

REVO-E HP/HP+ (Zone 1)

For connection to front box

REVO-E HP

(11120816_) 1st generation - on solobuses

REVO-E HP+

(11123865_) 2nd generation - on solobuses und

articulated variants

ADA on solobus

REVO-E HP+ (Zone 1)

REVO-E HP

+

(Zone 2)

ADA on articulated system

air conditioning only

11120816_ / 11123865_

11123865_

11123865_

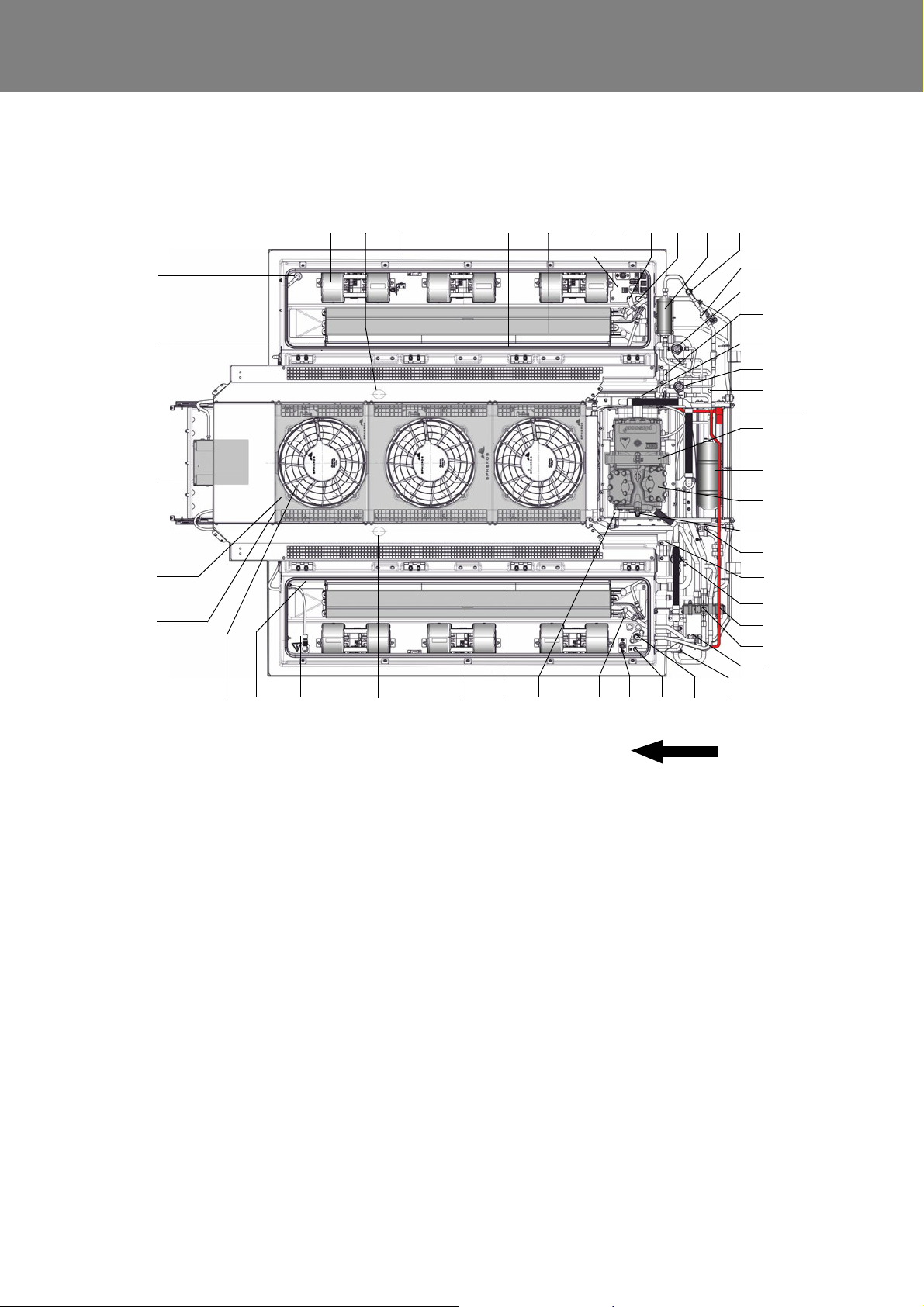

3 Description of assemblies and components

3.1 REVO-E HP versions on the Volvo 79xx Electric

Abb. 1 REVO-E HP Installation variants

301

REVO-E Heat pump 3 Assemblies and components

Direction of travel

373839

40

41

42

43

1

14

23

468 97 10

13

5 11

12

15

16

17

18

19

20

21

22

23

24

3435

26

25

27

282930313336

1

) Figure shows 11123865_

2

) Red marked components in 11123865_ only

44

46

45

1 Double radial bl ower

2 Right-hand forward safety lift

point of the unit

3 Blow-out temperature sensor

4 Temperature sensor, passenger

compartment (hidden)

5 Air filter

6 Electrical interface 24V

7 Bleeding port, heating element

NW6

8 Water feed flow NW20

9 Water return NW20

10 Filter Dryer

11 Sight glass

12 Solenoid valve

13 Expansion valve cooling circuit

14 Right-hand rear safety lift point

of the unit

15 Refrigerant charging valve,

suction side

16 Expansion valve heating circuit

heat pump

17 Safety valve, 30bar

18 Bracket, refrigerant compressor

19 Refrigerant collector

20 Refrigerant compressor

21

Refrigerant charging valve,

discharge side

22 Suction pressure sensor

(hidden)

23 Left-hand rear safety lift point of

the unit

24 Expansion valve cooling circuit

25 4-way reversing valve

26 Coil 4-way reversing valve

27 High pressure sensor

28 Refrigerant connection, suction

side, defroster

29 Refrigerant connection, dischar-

ge side, defroster

30 Protective Earth (PE), high

voltage components

31 Bleeding port, heating element

NW6

32 Low pressure safety switch *

33 High pressure safety switch

34 Air filter

35 Inner heat exchanger

36 Left-hand forward safety lift point

of the unit

37 Electrical interface 600V DC

38 Flap actuator (hidden)

39 Axial fan

40 Outer heat exchanger

41 Fan module

42 Frequency inverter

43 Flap actuator (hidden)

44 Solenoid valve hot gas deicing

45 Muffler

46 diagnostics port frequency inver-

ter

* not in 11123865_

3.2 Total overview of the design and components of the REVO-E heat pump

Fig. 2 REVO-E Heat pump total overview

302

REVO-E Heat pump 3 Assemblies and components

1 - High-voltage power supply of the frequency converter 600V DC

2 - High-voltage power supply of the compressor 3x 400V AC

1

2

Frequency converter

Compressor with 3x 400V AC e-motor

600V DC -> 3x400V AC

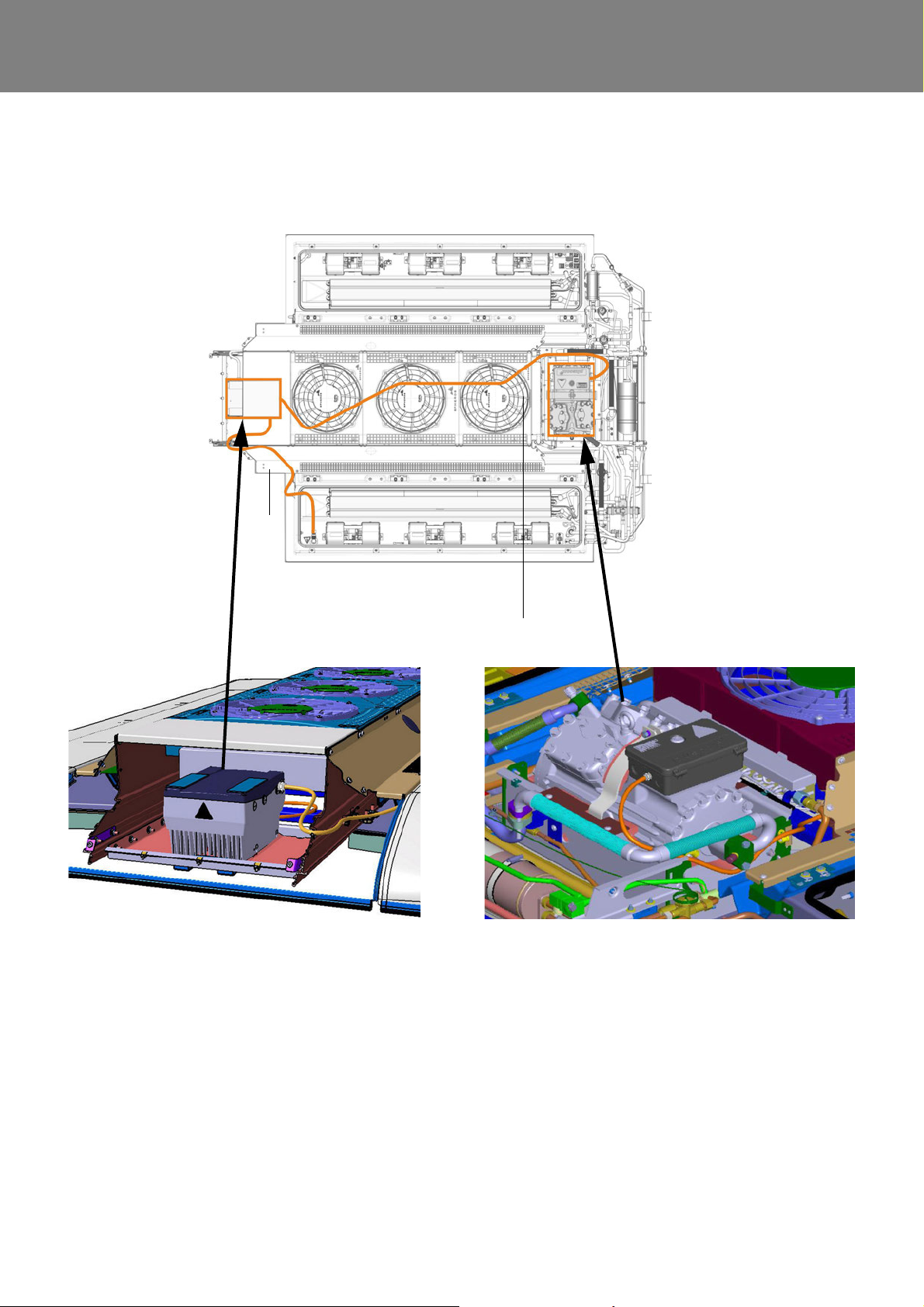

3.3 Overview of high-voltage cable harnesses / components (400V AC / 600V DC)

Fig. 3 Overview of high-voltage cable harnesses / components (400V AC / 600V DC)

303

REVO-E Heat pump 3 Assemblies and components

Item Description Remarks

1 wiring harness incl. connection board 24V interface ADA

2 temperature sensor blow out temperature

3 temperature sensor passenger compartment temperature

4 wiring harness temperature sensor passenger compartment

5 wiring harness axial fan, 4-way reversing valve

6 solenoid valve hot gas deicing in 11123865_ only

7 wiring harness kit, 400V AC frequency converter

8 PE connection compressor

9 compressor

10 suction pressure sensor

11 wiring harness double radial fan

12 high pressure sensor

13a high pressure safety switch

13b low pressure safety switch not in 11123865_

14 wiring harness, 600V DC HV interface, vehicle - frequency converter

15 frequency converter 600V DC -> 3x400V AC

16 diagnostic cable frequency converter

17 wiring harness control unit SC620 to ADA

18 SC620 control device installed in Volvo E bus

18

14

4321

5

6

7

17

8

9

10

15

11

12

13a/13b

16

3.4 Cable harnesses overview (high-voltage / low-voltage) in the REVO-E HP

Fig. 4 Cable harnesses overview (high-voltage / low-voltage) in the REVO-E HP

304

REVO-E Heat pump 3 Assemblies and components

3.5 Design / task and function of

the assemblies

The REVO-E heat pump features an outer and an inner

heat exchanger.

They consist of aluminum tubes and aluminum fins which

are jointly connected and form a large heat excha ng e r

surface.

Outer heat exchanger

In the air-conditioning mode it works as condenser. If the

unit is in the heat pump mode, it is working as evaporator.

Inner heat exchanger

In the air-conditioning mode they work as evaporator. If

the unit is in the heat pump mode, they are working as

condenser.

Condenser function

It cools the hot refrigerant gas in such a way that it liquefies, subcools and transfers the condensation heat to the

external air flowing through it via the fins.

Evaporator function

The evaporator absorbs the heat from its environ ment and

delivers it to the refrigerant. In this process the evaporation temperature must be lower than the ambient temperature.

By the simultaneous suction action of the refrigerant

compressor and the constriction of the expansion

member, the desired evaporation temperature can be

achieved in a targeted manner.

The heat flowing because of the temperature difference

between the evaporator and the environment causes the

refrigerant liquid fed in by the expansion element to evaporate (evaporation zone) and to overh eat (o ve rh ea tin g

zone) in the evaporator.

balances out changes in the refrigerant circ uit .

Dryer

The interior of the dryer cont ains a granulate that removes

small amounts of water from the refrigerant and chemically binds to it.

The dryer also filters contaminates from the refrigerant

that might lead to malfunctions.

A further expansion valve for heat pump operation is

installed in the heat pump.

Thermostatic expansion valve

The thermostatic expansion valve with external pressure

equalization regulates the refrigerant flow to the

compressor, depending on the refrigerant needs or the

condenser temperature. The thermostatic expansion

valve is the control element between the high and low

pressure sections of the refrigerant circuit.

Pressure switch

The high and low pressure switches are installed on the

compressor and are a key component of the safe ty chain

of the air-conditioning system.

High pressure switch

– Monitors the pressure level in the high-pressure area

of the refrigerant circuit

– Deactivates the air-conditioning system if pressure is

too high (e.g. too much refrigerant)

Low pressure switch

– Monitors the pressure level in the low-pressure area

of the refrigerant circuit

– Deactivates the air-conditioning system if pressure is

too low (e.g. too little refrigerant)

– T he low pressure switch is not installed in the

11123865_ and is replaced by an SW algorithm.

Compressor (HGX34P/315-2 A)

This semi-hermetic, 4 cyl. reciprocating compressor is

driven by a 2 pole, asynchronous motor integrated into the

housing. It is flushed / cooled by R134a, a gaseous r efrigerant, and an integrated PTC element monitors the

temperature level. Signals are evaluated by the frequency

converter . The frequency converter also provides power

and controls the speed.

The duty of the compressor is to condense vaporous

refrigerant from low pressure to a higher pressure. To do

so, it must ensure the necessary discharge (refrigerant

flow) required for cooling.

The compressor is integrated into the air-conditioning

system. The compressor with patented vibration decoupling design is created using a special absorption foam.

The compressor is embedded and fixed in this foam.

Receiver

The receiver is a compensating/ storage tank which

Switch point

Switch point High pressure

switch

On 19 ± 1.5 bar

(relative)

Off 24 ± 1.0 bar

(relative)

1

) not in 11123865_

Low pressure

switch

1.8 ± 0.3 bar

(relative)

0.3 ± 0.3 bar

(relative)

1

Axial fans

The three axial fans are driven by EC motors.

If Cooling Mode is activated, the fans are continuously

controlled depending on the load (refrigerant pressure)

via the PWM, and provide the outer heat exchanger with

sufficient fresh air.

305

REVO-E Heat pump 3 Assemblies and components

Double radial blowers

The six double radial blowers are driven by EC motors.

The blowers move recirculated / fresh air through the heat

inner exchanger and blow it at the right temperature

(depending on the mode) into the air ducts of the vehicle.

Speed controls are continuous (PWM); e.g. speed is

reduced when the desired passenger compartment

temperature has been reached. This reduces energy

needs and helps to stabilize the passenger cabin temperature.

Frequency converter

This component is supplied via the 600V DC electrical

system of the vehicle and provides 400V AC for the threephase AC motor of the compressor. Depending on system

requirements, the compressor speed is set between

10Hz-50Hz.

The frequency converter is placed onto an adapter plate

(Fig. 803), which makes it easy to remove / install.

4-Way reversing valve

Depending on the position, the 4-way reversing valve activates the air conditioning mode or the heat pump mode.

In zero position, the air conditioning mode is active.

High pressure

The high pressure sensor determines the pressure level in

the permanent high-pressur e ar ea .

In heat pump mode, the target pressur e is approx. 12 bar

depending on the ambient temperature.

Passenger compartment temperature

This sensor measures the air temperature of the

passenger cabin around the intake area of the recirculating air (Fig. 908).

Air duct temperature (blow-out temperatur e)

This sensor measures the air intake temperature of the

air-conditioning system at the first double radial blower,

front right (Fig. 908).

Monitoring the temperature of the e-motor of the

compressor

A PTC element monitors the temperature of the

compressor e-motor. The frequency converter evaluates

the signal without directly influencing the air-conditioning

control.

R25 ≤ 300 Ω

If the e-motor overheats, the frequency converter stops

the compressor immediately (safety func tio n).

Solenoid valve hot gas deicing REVO-E HP +

The hot gas deicing solenoid valve is installed on the

11123865_ ONLY. It is activated to defrost the outer heat

exchanger with hot gas from the refrigerant circuit.

Sensors

Suction pressure

The suction pressure sensor determines the pressure

level in the permanent low-pressure area. The system

attempts to manage the suction pressure between 3.0 bar

and 3.7 bar (absolute).

Central parameters for:

– climate/ heat pump control

– recognizing icing

– recognizing low pressure

Air valves

Regulate the intake of fresh air or use of recirculated air

from the passenger cabin. The BEA body sends the positional signals “open / closed” via CAN to the SC620 in all

operating modes (except for Gas Charging mode). If both

signals are active, the valves will move to the Recirculating position. Intermediate positions (air mixing) are not

provided in this vehicle.

SC620

This control unit is used as the control device in the Volvo

7900 Electro system (display / keyboard inactive).

HVAC demands are only managed by the BEA body, the

SC620 works as a “slave system” and controls the functions of the ADA.

Two LEDs become active when the system is turned on

(permanent & blinking).

306

REVO-E Heat pump 4 Function and functional schematics

4 Function and functional

schematics of the REVO-E Heat pump

4.1 General function

The fully electric rooftop air-conditioning system (in the

following referred to as ADA) REVO-E for hybrid, electric

and trolley buses is a proven system, especially with its

intelligent energy management, meaning cooling is

provided as needed depending on existing power, and

with the special way its compressor has been installed.

The electric compressor is located on the roof in an

exceptionally compact manner, and not on the rear of the

vehicle as in previous versions. This has, in the purest

sense of the word, obvious advantages and makes the

system closed by integrating all of the components

carrying refrigerant, an efficient, tight and almost maintenance free design (solo design without front box connection).

The REVO-E as heat pump

The REVO-E air-conditioning system is the basis for the

REVO-E heat pump.

The refrigeration cycle of the REVO-E air-conditioning

system has been modified in such a way that it can also

represent the functionality of a heat pump in addition to

the air-conditioning operation. The basic principle is

based on the reversal of the refrigeration cycle.

Regulation and control in the air-conditioning mode correspond to the REVO-E air-conditioning system. Details can

be found in the Workshop Manual REVO-E.

Explanations in the following chapters refer largely to the

new functions of the heat pump.

The intelligent controller logic of the SC620 controls

further the entire system. It communicates with the vehicle

via CAN bus.

The climate control works identical as in the REVO-E

air-conditioning system (see Workshop Manual REVO-E).

The two variants of the REVO-E HP are listed in the Table

201.

Both systems differ only slightly. With the additional function "hot gas de-icing", the REVO-E HP + is able to heat

the passenger compartment in heat pump mode at significantly lower temperatures (≥ -5 ° C). This is realized with

adapted software and additional components in the refri geration cycle.

Functionality of the REVO-E Heat pump in the vehicle

line of the Volvo 7900 Electric

The HVAC control system of the vehicle is responsible for

regulating the Heating, Ventilation and Cooling modes in

the Volvo E Bus. The REVO-E system is operated only as

a “slave” system and only follows the vehicles requir ements.

If the ADA is activated by switching on the vehicles electrical network. all of the system’s sensor values are au tomatically verified for plausibility and the system will be set

to “Standby Mode”. Various sensor values are used as the

basis for calculating the bus-side requirements, including

those from the passenger cabin sensors of the ADA.

These requirements are sent via CAN bus over the Dbus

to the SC620 as needed.

The SC620 implements these requirements (mode /

blower speed, etc.).

The REVO-E will turn off if there are any limitations in the

temperature / high-voltage supply, etc.

401

REVO-E Heat pump 4 Function and functional schematics

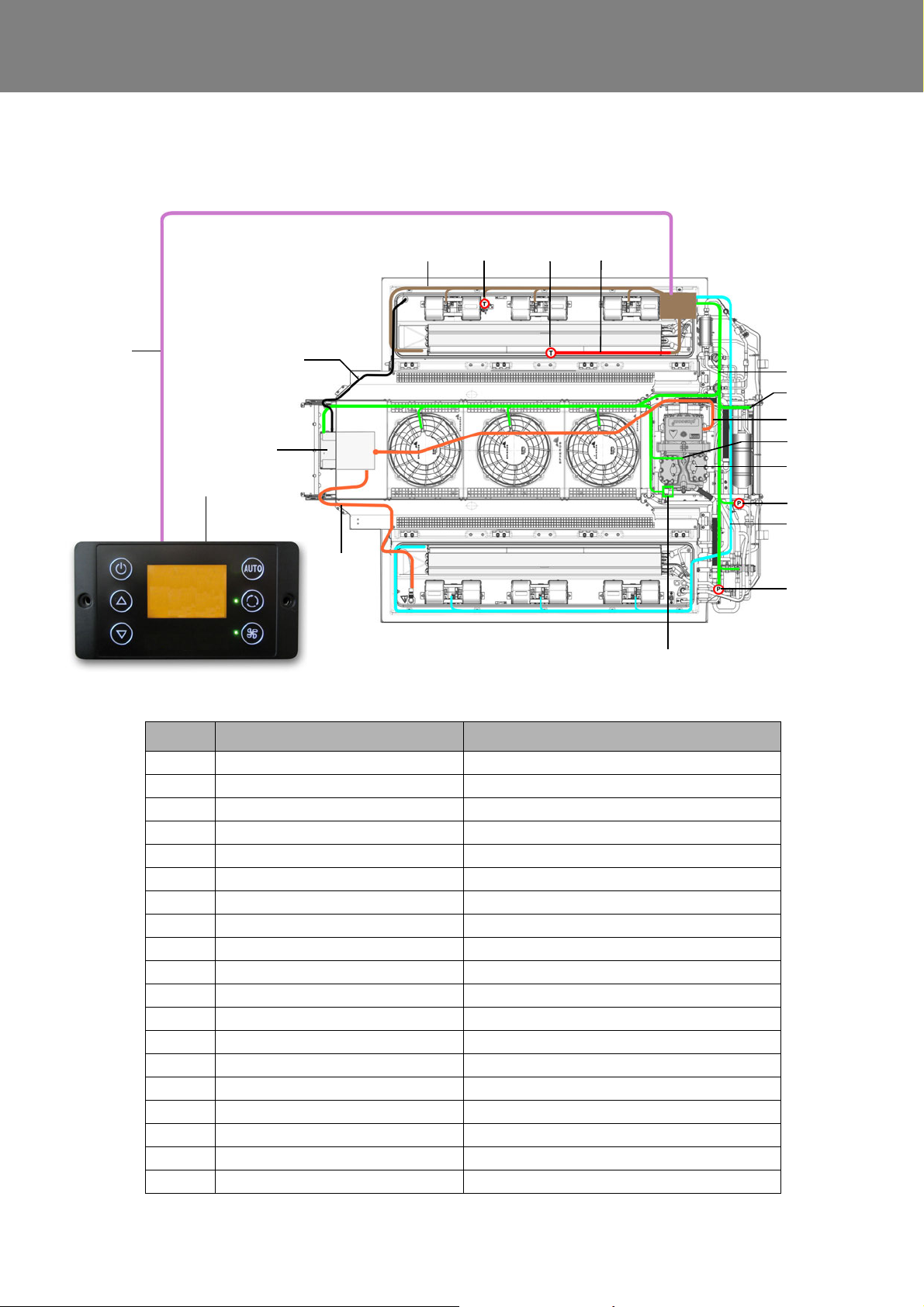

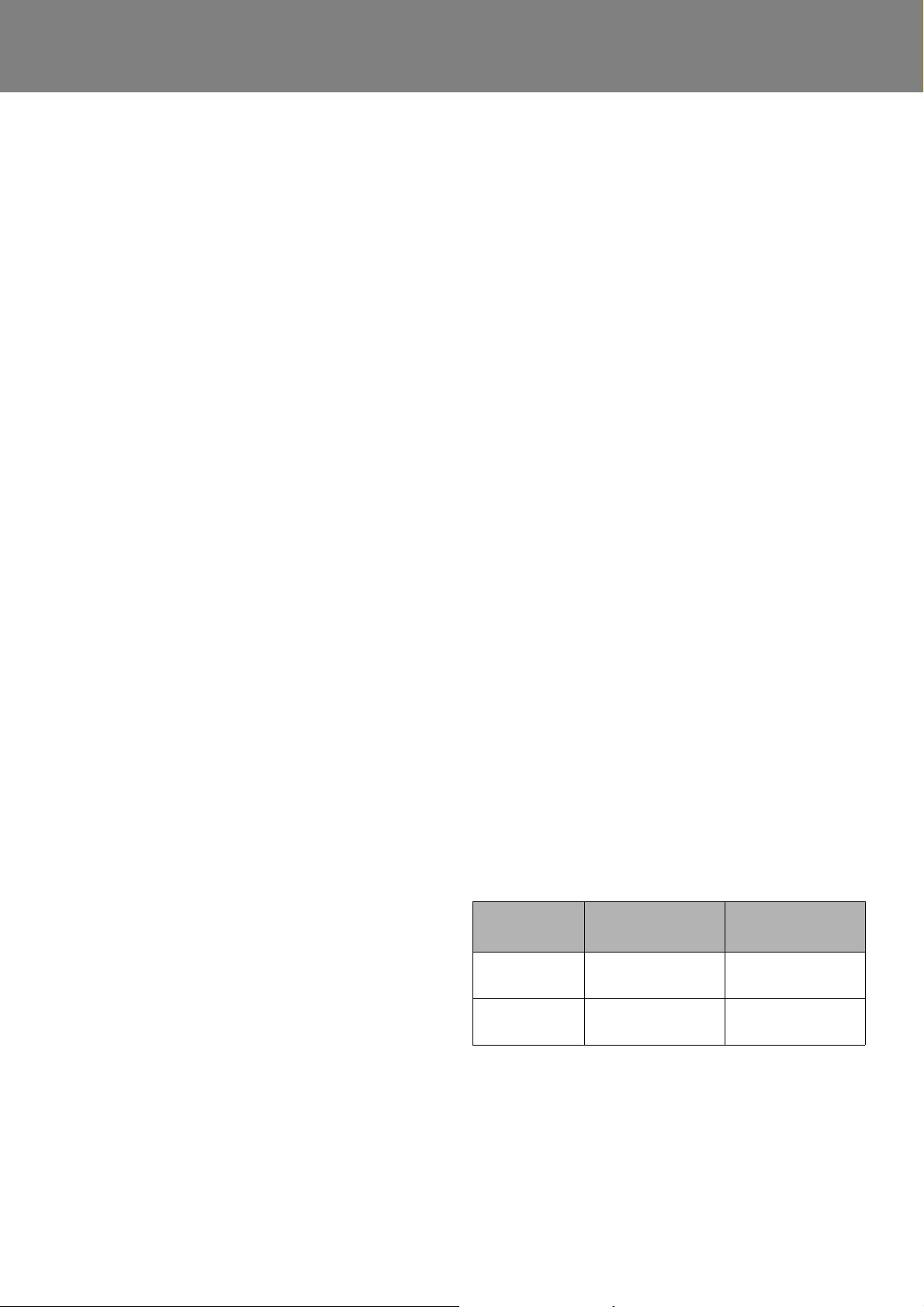

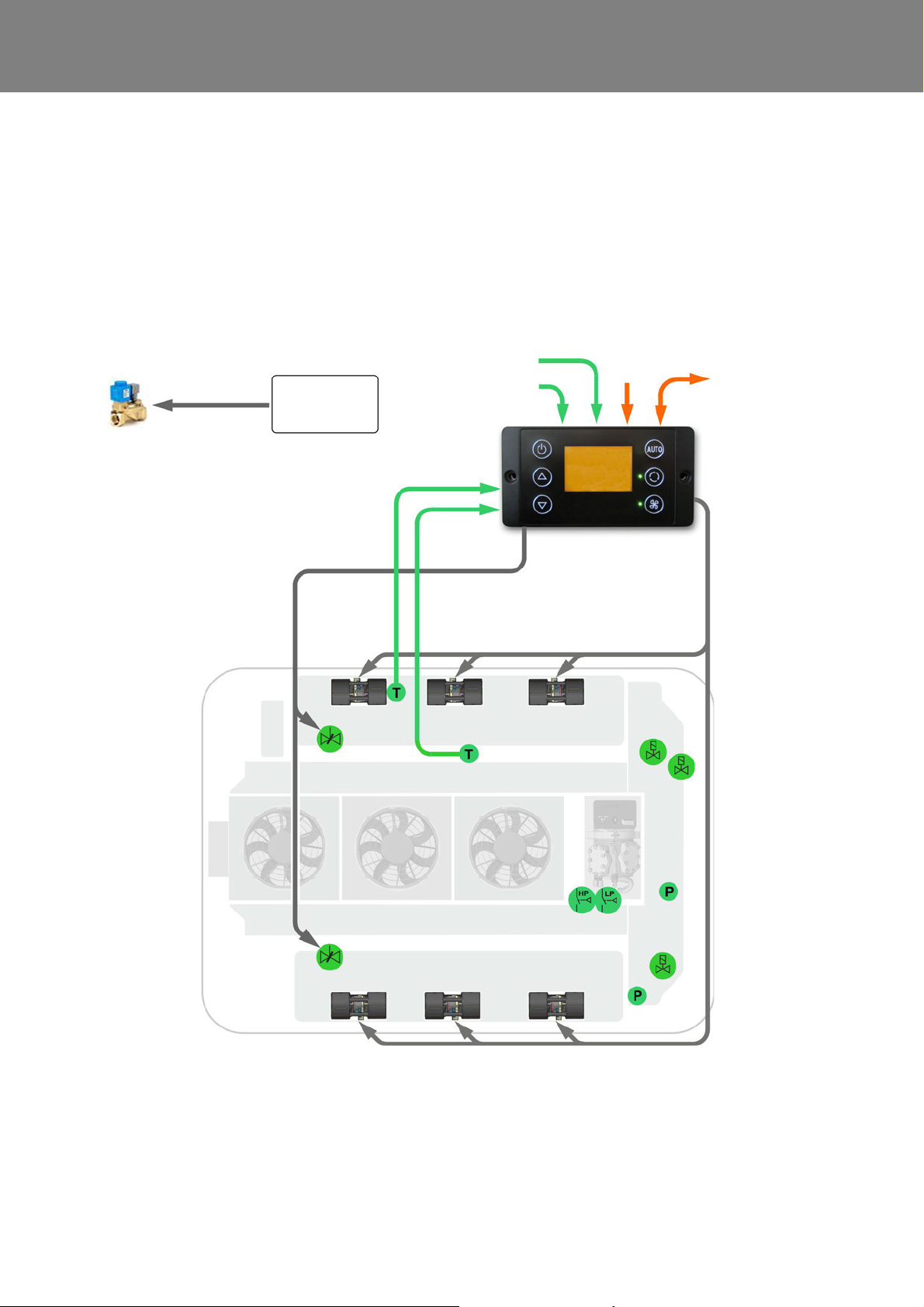

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

Sensor

blow-out

temperature

Sensor

pass. comp.

temperature

Double radial blower

Speed

Compressor

Fresh air

flaps actuator

Double radial blower

Axial fans

Frequency

converter

Fresh air

flaps

actuator

active

Compressor activate

4

5

1

2

3

6

7

NOTE:

Details about the positions can be found in

the overview Fig. 2 in Chapter 3 of the

workshop manual.

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

24V

4-way reversing valve works as actuator

4.2 Functional schematic of the REVO-E heat pump

Tasks of the SC620

– Implementing climatic and heat pump requirements

– Turning off high-voltage components in case of error

(HVIL)

– Component protection of the climate unit if overloaded

Required to start the system:

– Power supply clamp 30 (main switch of battery)

– Ignition on (clamp 15)

– CAN communication between vehicle and SC620 ac-

tivated - approval for system start shared

– High voltage to the frequency converter, that means

high voltage system active

– Approval (D_AuxiliaryPowerEnable) and supply

Fig. 401 Functional schematic of the REVO-E

402

REVO-E Heat pump 4 Function and functional schematics

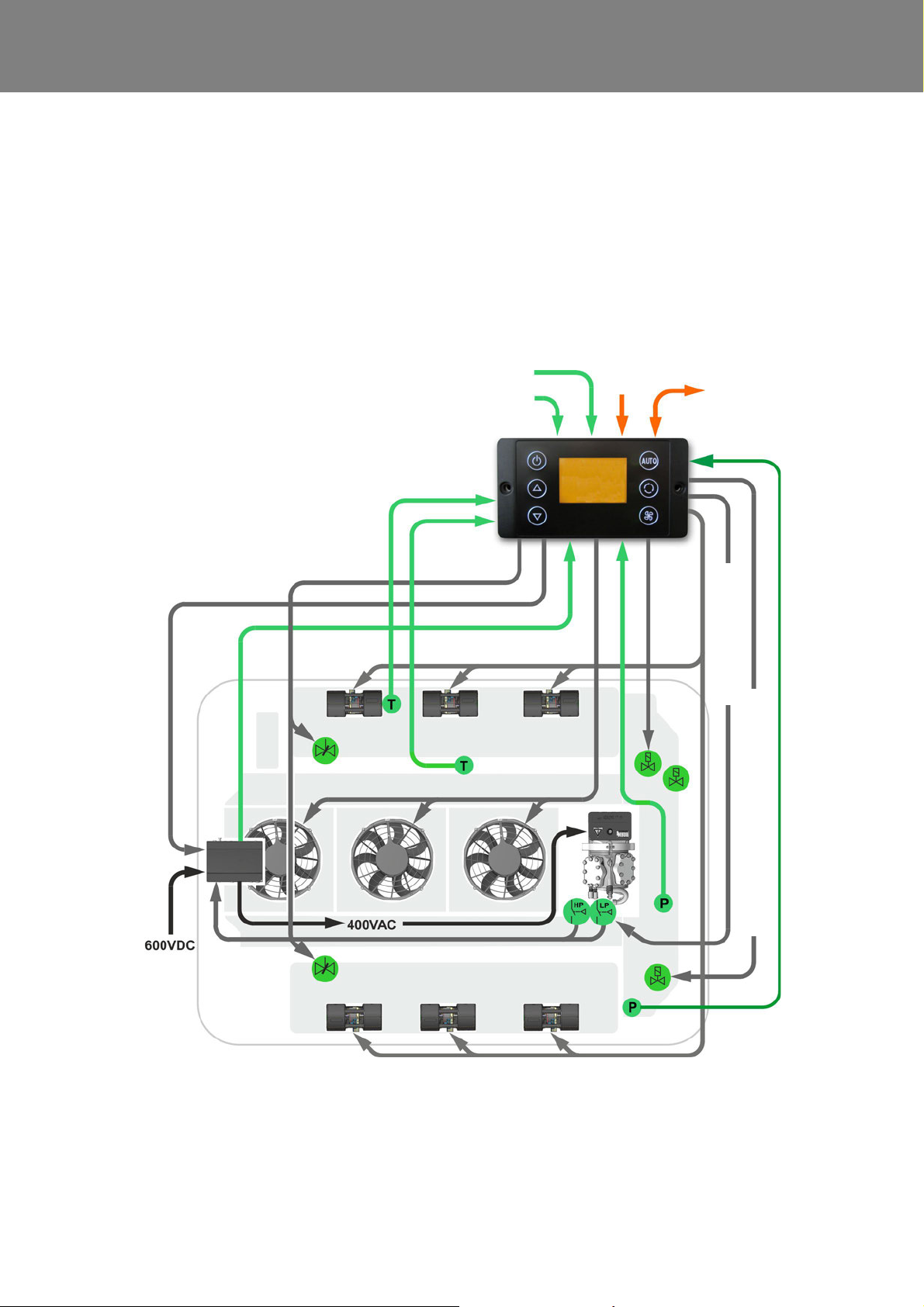

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

Sensor

blow-out

temperature

Sensor

pass. comp.

temperature

Double radial blower

Speed

Compressor

Fresh air

flaps actuator

Double radial blower

Axial fans

Frequency

converter

Fresh air

flaps

actuator

active

Compressor activate

4

5

1

2

3

6

7

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

24V

D-Bus Volvo

4-way reversing valve works as actuator

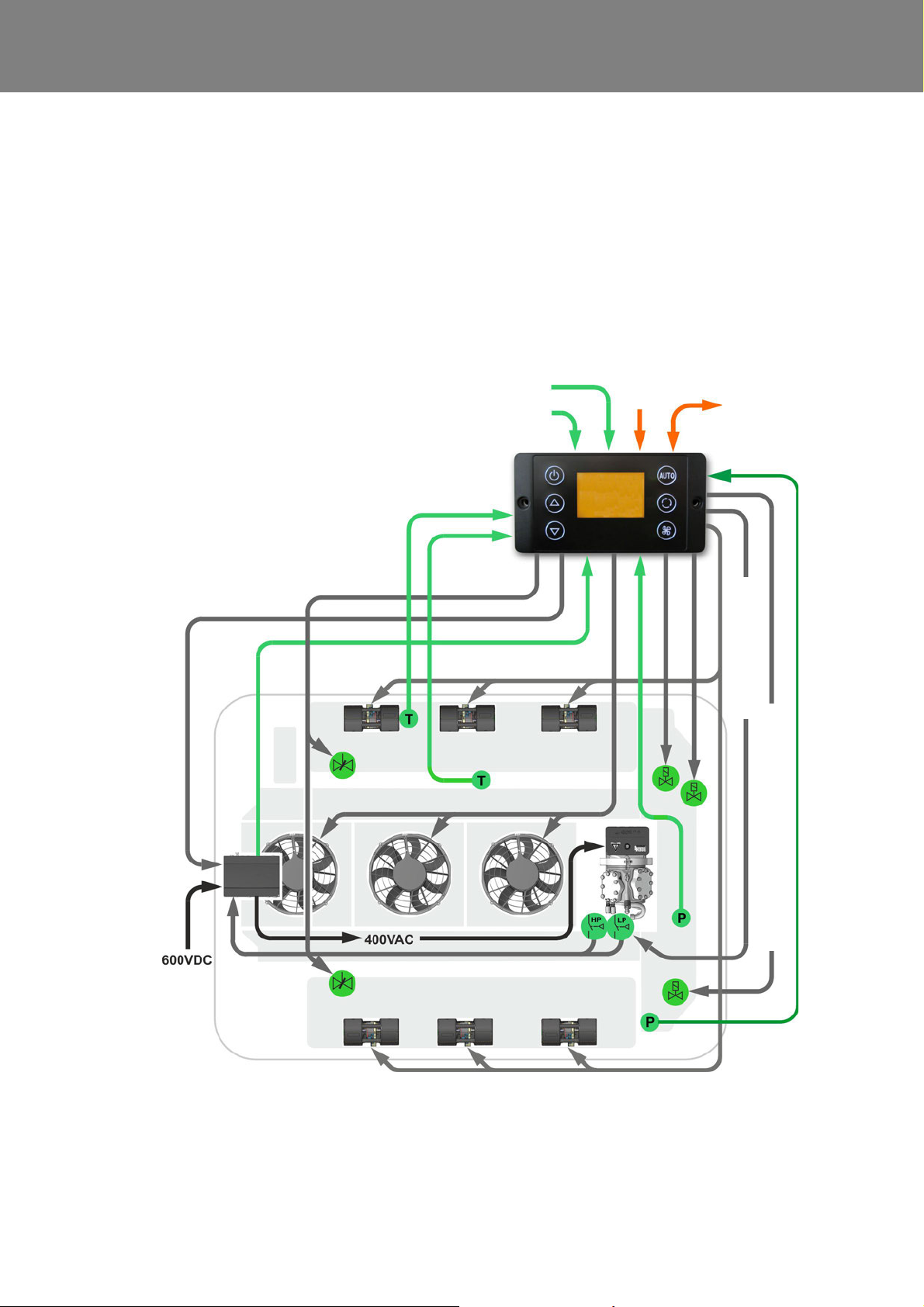

4.3 Functional schematic of the REVO-E heat pump Volvo 7900 Electric

On single buses, the ADA and SC620 are connected to

one another using a Valeo cable harness.

The HVAC control system of the BEA body system is responsible for regulating the Heating, Ventilation, Cooling

and Heat pump modes in the Volvo e-bus.

The REVO-E system therefore behaves only as a “slave”

system and implements the particular requirements.

In Heating / Ventilation or Reheat Mode, the vehicle

controller gives the speed of the double radial blowers.

In Cooling, Waste Energy or Gas Charging Mode, the

double radial blowers are controlled by the SC620.

.

Fig. 402 Functional schematic of the REVO-E, internal

403

REVO-E Heat pump 4 Function and functional schematics

4.4 Work modes of the REVO-E heat

pump in the Volvo 7900 Electric

There are 9 different operating modes.

The well-known 6 operating modes of the REVO-E airconditioning system (see WM REVO-E) are extend ed by

three working modes.

In the following explanations, only the new working modes

are considered.

Choosing or switching between modes occurs according

to defined criteria of the BEA body climate control system.

1. Heating/ Ventilation Mode

2. Heating/ Ventilation Mode Ready for Cooling

3. Heating/ Ventilation Mode Ready for Heat Pump *

4. Cooling Mode

5. Heat Pump Mode *

6. De-Icing Mode ** (11123865_only)

7. Reheat Mode

8. Waste Energy Mode

9. Gas Charging Mode

*) new mode for heat pump

**) in 11123865_only

This is a list of priorities in case several modes are simultaneously required by the BEA body system. The SC620

must employ the mode with the highest priority.

Operating mode De-Icing (in 11123865_ only)

This mode is activated by the SC620 depending on the

state of icing. The BEA body control is only informed

about the mode. In this mode, the heat pump function is

disabled.

General operating mode conditions:

- mode required by BEA body (e.g. Cooling Mode to

reduce the temperature in passenger compartment or

Heat Pump Mode to increase the temperature in

passenger compartment)

- general system conditions (e.g. external temperatures

/ status of 600V DC system)

- operating mode de-icing not activated

Depending on the mode, the SC620 or BEA body system

will control the actuators.

404

REVO-E Heat pump 4 Function and functional schematics

Double radial blower

Double radial blower

Fresh air

flaps

Sensor

pass. comp.

temperature

Sensor

blow-out

temperature

I/O-A module

Vehicle

Requirement

open / close

Heating valve

actuator

Fresh air

flaps

actuator

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

4

5

1

2

3

6

7

24V

for hot water

heat exchanger

ADA

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

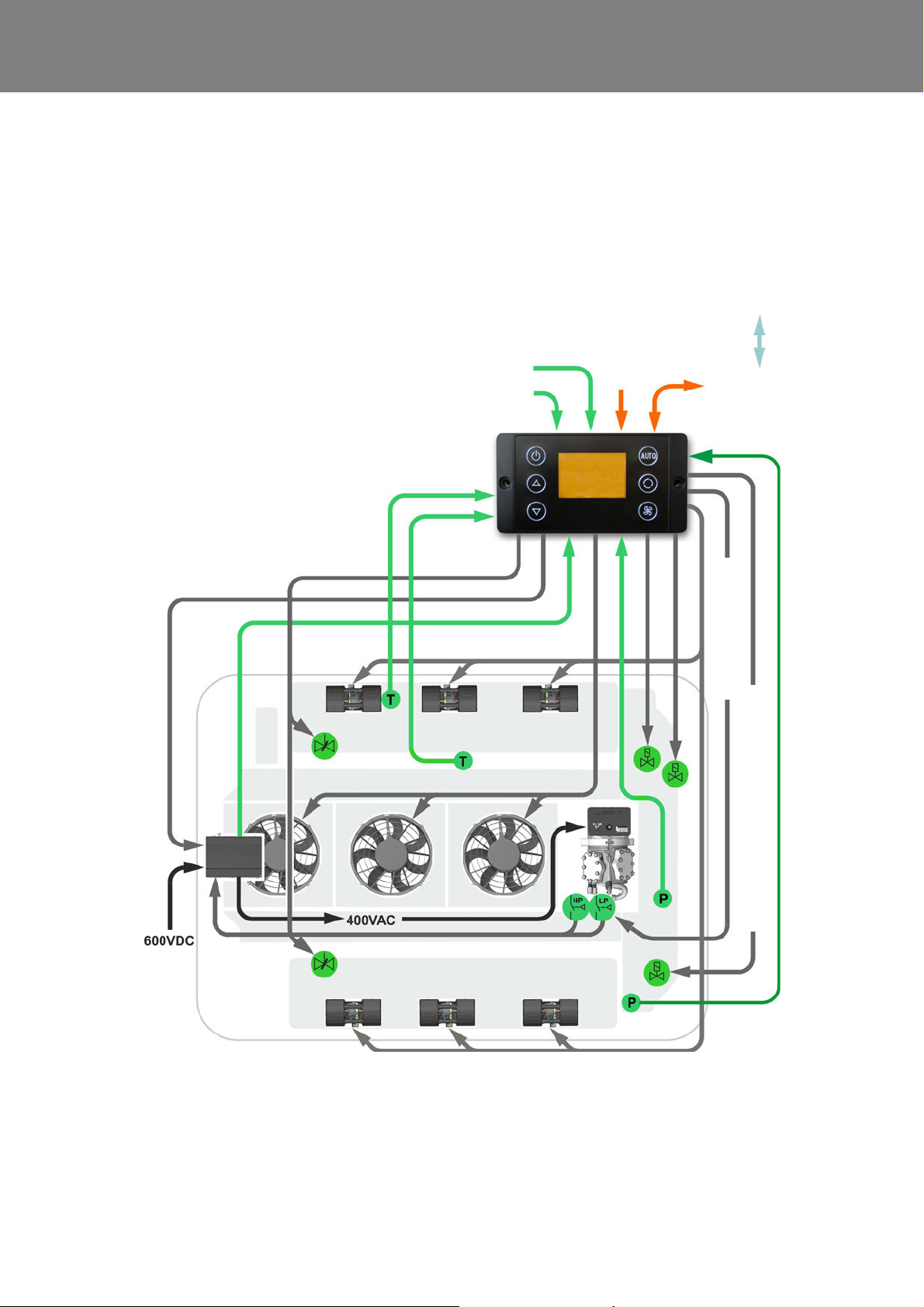

4.4.1 Heating and Ventilation Mode (HV Mode)

Requirements:

– Clamp 30 active

– HV Mode required by BEA body

Both modes are required directly by the BEA body.

CAN messages from the BEA body to SC620 for defined

speed of double radial blowers and position of air flaps

(fresh air / recirculating air).

Water valves are controlled by the BEA body directly.

Fig. 403 Heating and Ventilation Mode (HV Mode)

405

REVO-E Heat pump 4 Function and functional schematics

Double radial blower

Double radial blower

Fresh air

flaps

Sensor

pass. comp.

temperature

Sensor

blow-out

temperature

I/O-A module

Vehicle

Requirement

open / close

Heating valve

actuator

Fresh air

flaps

actuator

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

4

5

1

2

3

6

7

24V

for hot water

heat exchanger

ADA

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

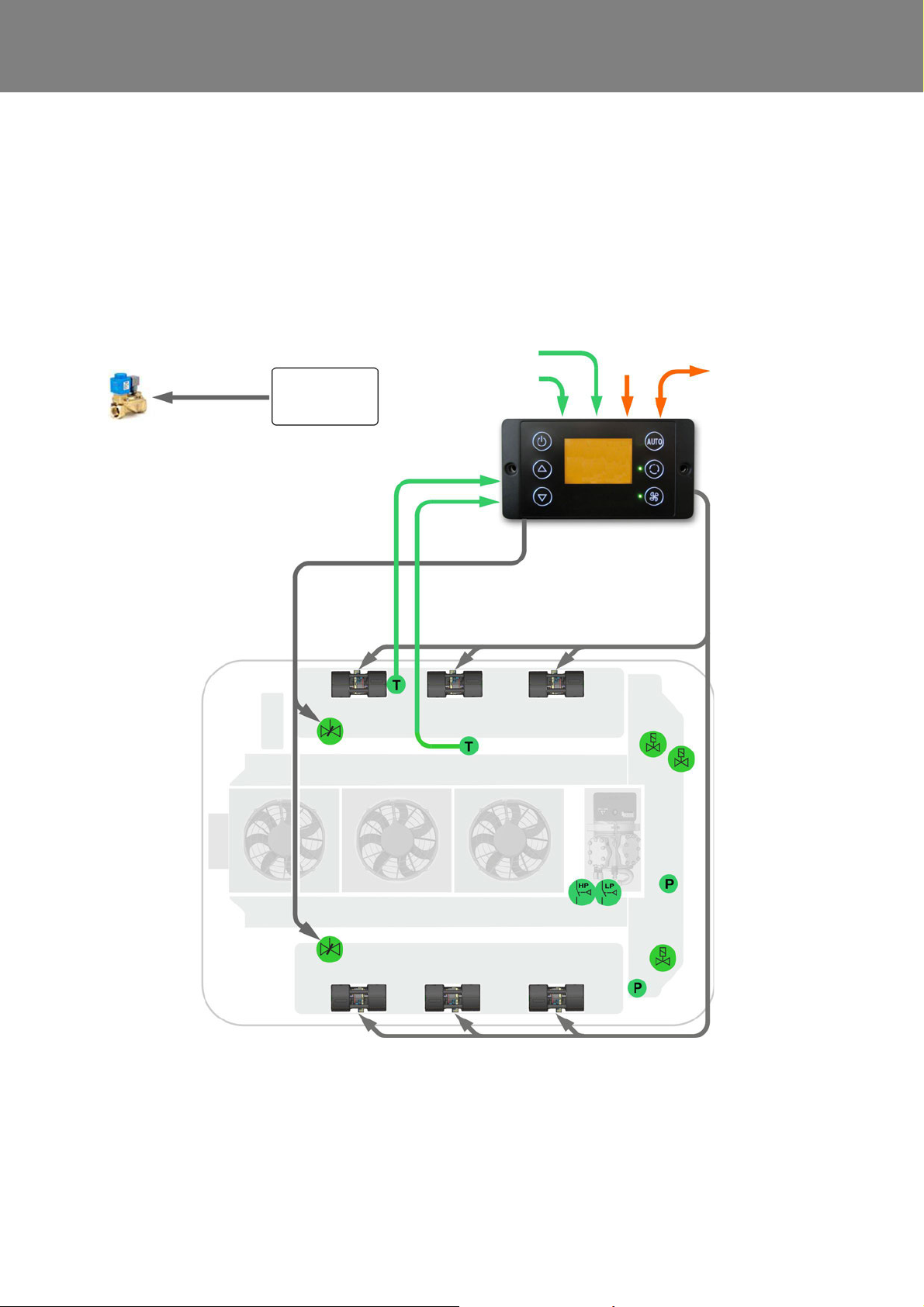

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

4.4.2 Heating and Ventilation Mode Ready for

cooling

Requirements:

– Clam p 30 / 15 act ive

– Vehicle hybrid system active

– HV Mode required by BEA body

Preconditions for Cooling Mode filled shortly before or

after this, however cool request not sent by BEA body.

System works primarily in Heating / Ventilation Mode.

Fig. 404 Heating and Ventilation Mode Ready for Cooling

406

REVO-E Heat pump 4 Function and functional schematics

Double radial blower

Double radial blower

Fresh air

flaps

Sensor

pass. comp.

temperature

Sensor

blow-out

temperature

I/O-A module

Vehicle

Requirement

open / close

Heating valve

actuator

Fresh air

flaps

actuator

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

4

5

1

2

3

6

7

24V

for hot water

heat exchanger

ADA

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

4.4.3 Heating and Ventilation Mode Ready

for Heat Pump Mode

Requirements:

– Clam p 30 / 15 act ive

– Vehicle hybrid system active

– HV Mode required by BEA body

Preconditions for Heat Pump Mode filled shortly before or

after this, however cool request not sent by BEA body.

System works primarily in Heating / Ventilation Mode.

Fig. 405

Heating and Ventilation Mode Ready for Heat Pump

407

REVO-E Heat pump 4 Function and functional schematics

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

Sensor

blow-out

temperature

Sensor

pass. comp.

temperature

Double radial blower

Speed

Compressor

Fresh air

flaps actuator

Double radial blower

Axial fans

Frequency

converter

Fresh air

flaps

actuator

active

Compressor activate

4

5

1

2

3

6

7

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

24V

4-way reversing valve works as actu at o r

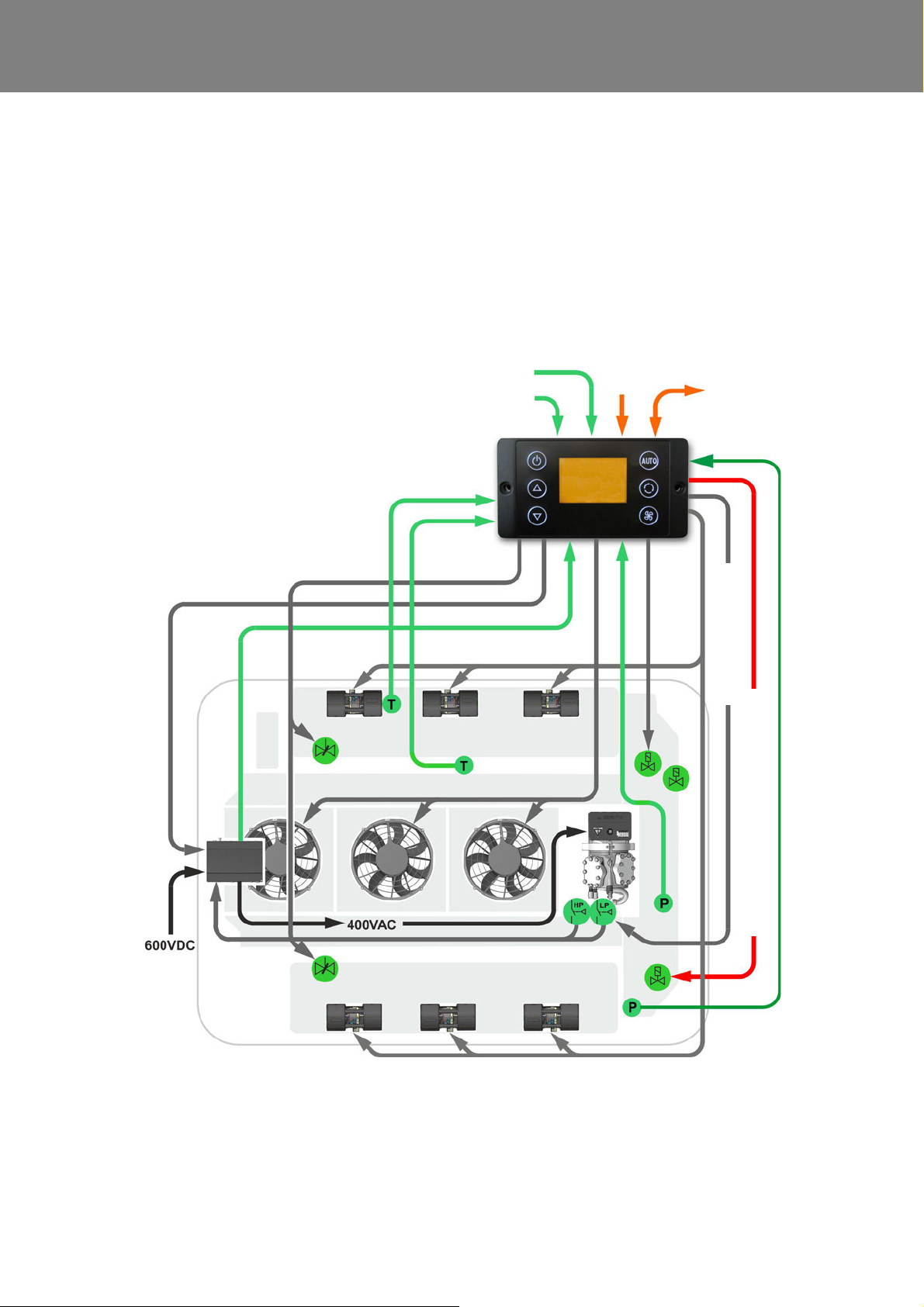

4.4.4 Cooling Mode

Requirements:

– Terminal 15 active

– Vehicle hybrid system active

– Mode “Ready for Cooling“ active

– HVAC power consumption enabled by

“D_AuxiliaryPowerEnabled” signal

– Signal “D_CabinCoolReq” sent by BEA-Body

– environmental temperature > 5°C

The Cooling Mode is requested by the BEA body system

in order to cool down the air in the passenger cabin. The

SC620 therefore assumes internal control of the components in the system in order to cool down the air in the

passenger cabin to the Delta T value requested by the

BEA Body.

Fig. 406 Cooling Mode

408

REVO-E Heat pump 4 Function and functional schematics

Task of the SC620:

– Control the speed of the double radial blowers / axial

fans

– Activation and speed setting of the compressor (via

frequency converter)

In Cooling mode Mode, the BEA body is not able to influence the speed of the double radial blowers.

The value of the interior temperature to be reached is

given by the difference of the external temperature and

the ∆T required by the BEA body.

Example of ∆T – 7 Kelvin

T

passenger cabin

T

passenger cabin

= [T

external

= 28°C

(35°C) + ∆T (7K)]

This value is sent via CAN by the BEA body and is used

as an internal control signal.

The "D_ElAcMaxPowerAllowed" CAN signal (from the

vehicle's power system) specifies the maximum power

consumption of the compressor.

If the cooling requested cannot be implemented (e.g.

malfunction), the system automatically switches to

Heating/ Ventilation Mode.

409

REVO-E Heat pump 4 Function and functional schematics

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

Sensor

blow-out

temperature

Sensor

pass. comp.

temperature

Double radial blower

Speed

Compressor

Fresh air

flaps actuator

Double radial blower

Axial fans

Frequency

converter

Fresh air

flaps

actuator

active

Compressor activate

4

5

1

2

3

6

7

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

24V

4-way reversing valve works as actu at o r

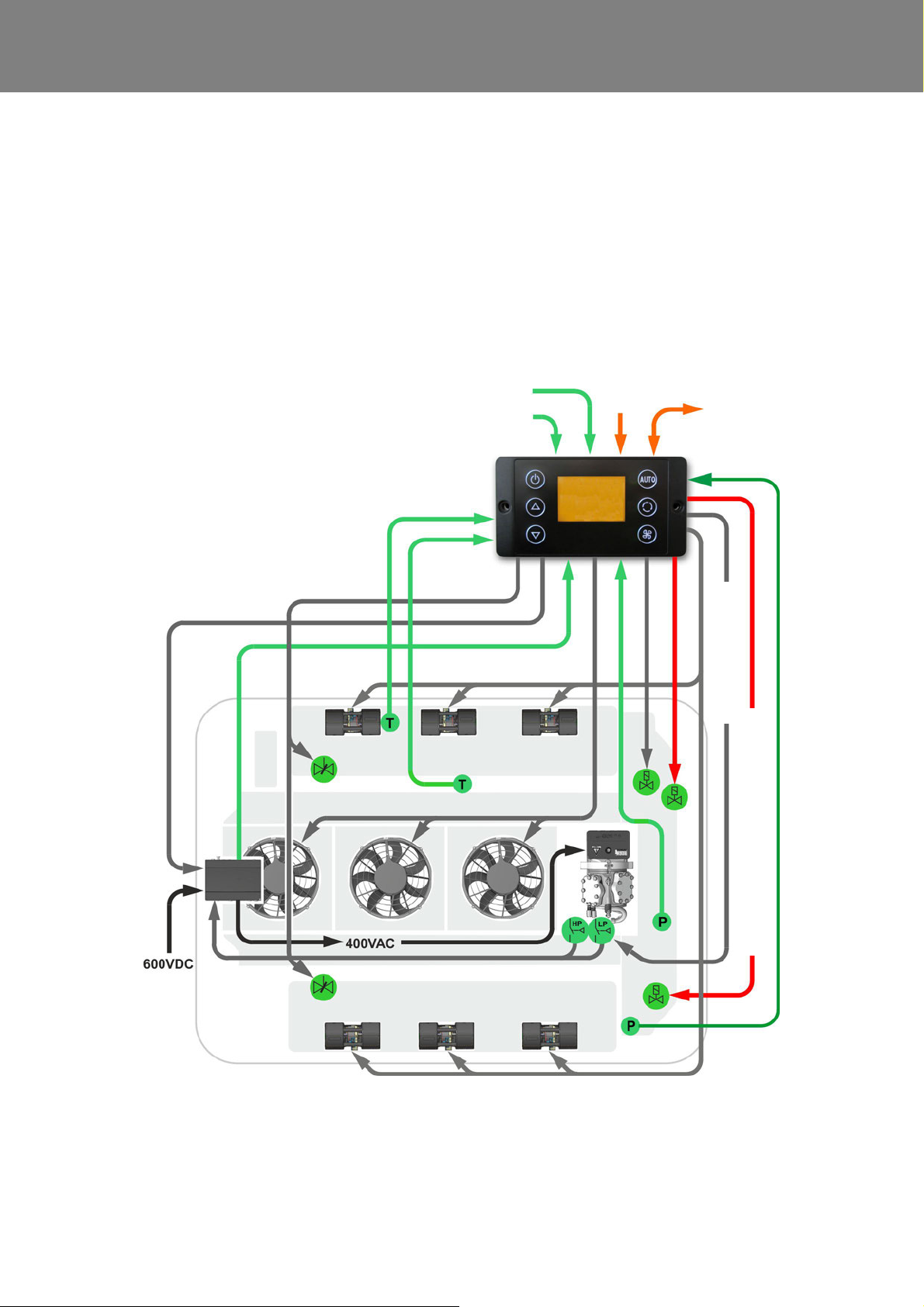

4.4.5 Heat Pump Mode

Requirements:

– Environmental temperature ≥ -5°C (11123865_)

– Environmental temperature ≥ 3°C (11120816_)

– no frequency converter or compressor errors

– no low-voltage error

– Terminal 15 active

– Vehicle hybrid system active

– HVAC power consumption enabled by

“D_AuxiliaryPowerEnabled” signal

– n o HVIL error

– ∆T temperature passenger compartment > 0K

– SC 620 CAN message “heat pump available“ to BEA

body

– “D_CabinHeatpumpReq” signal sent by BEA body

Fig. 407 Heat Pump Mode

410

REVO-E Heat pump 4 Function and functional schematics

The Heat Pump Mode is requested by the BEA body

system in order to warm up the air in the passenger cabin.

The SC620 therefore assumes internal control of the

components in the system in order to warm up the air in

the passenger cabin to the Delta T value r equested by the

BEA Body.

In the heat pump mode, the refrigerant circuit to the front

box (driver's work station) is closed by a solenoid valve

controlled of the BEA-Body SW. This prevents a sudden

fogging of the front windscreen (flash fogging).

Task of the SC620:

– Control the speed of the double radial blowers / axial

fans

– Activation and speed setting of the compressor (via

frequency converter)

In Heat Pump Mode, the BEA body is not able to influence

the speed of the double radial blowers.

The value of the interior temperature to be reached is

given by the difference of the external temperature and

the ∆T required by the BEA body.

Example of ∆T – 7 Kelvin

T

passenger cabin

T

passenger cabin

= [T

external

= 17°C

(10°C) + ∆T (7K)]

This value is sent via CAN by the BEA body and is used

as an internal control signal.

The "D_ElAcMaxPowerAllowed" CAN signal (from the

vehicle's power system) specifies the maximum power

consumption of the compressor.

If the heat required cannot be implemented (e.g. ma lfunction), the system automatically switches to Heating/ Ventilation Mode.

411

REVO-E Heat pump 4 Function and functional schematics

Analog input

HVIL 1 voltage

Analog input

HVIL 2 voltage

CAN interface

vehicle

SC620

Sensor

blow-out

temperature

Sensor

pass. comp.

temperature

Double radial blower

Speed

Compressor

Fresh air

flaps actuator

Double radial blower

Axial fans

Frequency

converter

Fresh air

flaps

actuator

active

Compressor activate

4

5

1

2

3

6

7

1 Solenoid valve

2 Solenoid valve HGA / actu-

ator (in 11123865_only)

3 Suction pressure sensor

4 High pressure safety switch

5 Low pressure safety switch

(not in 11123865_)

6 4-way reversing valve

7 High pressure sensor

24V

4-way reversing valve works as act u at o r

4.4.6 Operating Mode De-Icing)

(Version HP+ only)

Requirements:

– Start of Heat Pump Mode or 1h Heat Pump Mode op-

eration

– Environmental temperature ≥ -5°C (REVO-E HP+)

– no frequency converter or compressor errors

– no low-voltage error

– Terminal 15 active

– Vehicle hybrid system active

– HVAC power consumption enabled by

“D_AuxiliaryPowerEnabled” signal

– n o HVIL error

– ∆T temperature passenger compartment > 0K

– SC 620 CAN message “heat pump available“ to BEA

body

– “D_CabinHeatpumpReq” signal sent by BEA body.

Fig. 408 Operating Mode De-Icing

412

Loading...

Loading...