Valeo ClimFill Maxi Use And Maintenance Manual

ClimFill® Maxi

Service station for air conditioning systems of

vehicles with refrigerant gas R-134a.

Use and maintenance manual

Ver. 2.0

ClimFill Maxi

CAP. 1 - CONTENTS

CAP. 1 - CONTENTS .................................................................................................................. 2

CAP. 2 - GENERAL INSTRUCTIONS............................................................................................ 4

2.1 GENERAL NOTES...................................................................................................................4

2.2 GENERAL INSTRUCTIONS .....................................................................................................4

2.3 MANUFACTURER IDENTIFICATION ......................................................................................4

2.4 MARKING ..............................................................................................................................5

CAP. 3 - SAFETY CONDITIONS.................................................................................................. 6

3.1 PERSONAL SAFETY INFORMATION ......................................................................................6

3.1.1

Definitions........................................................................................................ 6

3.1.2

Personal safety information ........................................................................... 6

3.2 IMPORTANT INFORMATION ON SERVICE EQUIPMENT SAFETY .......................................11

3.3 SAFETY DEVICES..................................................................................................................11

CAP. 4 - LAYOUT AND USE OF THE MANUAL ......................................................................... 12

4.1 USE OF THE MANUAL ..........................................................................................................12

4.2 SYMBOLS .............................................................................................................................12

4.2.1

Safety ............................................................................................................ 12

4.3 GLOSSARY...........................................................................................................................13

4.4 GUIDELINES FOR HANDLING REFRIGERANT .....................................................................14

4.4.1

Precautions for refrigerant storage............................................................. 14

4.4.2

Refrigerant conditions.................................................................................. 14

4.4.3

Recycling capacity...................................................................................... 14

CAP. 5 - GENERAL DESCRIPTION............................................................................................ 15

5.1 FRONT VIEW (EXTERIOR).....................................................................................................16

5.2 FRONT VIEW (INTERIOR) .....................................................................................................17

5.3 REAR VIEW (EXTERIOR).......................................................................................................18

5.4 REAR VIEW (INTERIOR)........................................................................................................19

5.5 RIGHT SIDE VIEW .................................................................................................................20

5.6 LEFT SIDE VIEW.....................................................................................................................21

5.7 FRONT SIDE VIEW ................................................................................................................22

5.8 TOUCHSCREEN ...................................................................................................................23

5.9 STATUS BAR..........................................................................................................................24

5.10

FUNCTION KEYS............................................................................................................26

5.11

CLIMFILL®-LOCK PATENTED TECHNOLOGY QUICK COUPLERS ...............................28

5.12

INCLUDED ACCESSORIES............................................................................................28

5.13

OPTIONAL ACCESSORIES............................................................................................29

CAP. 6 - TECHNICAL FEATURES .............................................................................................. 30

CAP. 7 - INSTALLATION........................................................................................................... 32

7.1 EQUIPMENT INSTALLATION ................................................................................................32

7.1.1

Unpacking ClimFill® Maxi.............................................................................. 32

CAP. 8 - COMMISSIONING .................................................................................................... 34

8.1 CONNECTIONS...................................................................................................................34

8.2 P

8.3 FIRST TANK FILLING..............................................................................................................36

8.4 NEW OIL BOTTLE FILLING ....................................................................................................37

8.5 DETECTION DYE BOTTLE FILLING........................................................................................38

CAP. 9 - SETUP......................................................................................................................... 39

CAP. 10 - A/C SYSTEM RECHARGE ........................................................................................ 42

10.1

10.2

OSITIONING AND ELECTRIC CONNECTIONS

REMARKS ......................................................................................................................42

NON-CONDENSABLE GAS DISCHARGE VALVE........................................................43

..............................................................................34

ENGLISH 2 / 74 CAP. 1 - CONTENTS

ClimFill Maxi

10.3

RECHARGE Q-MODE AND S-MODE...........................................................................44

CAP. 11 - AUTOMATIC CYCLES.............................................................................................. 45

11.1

AUTOMATIC A/C SYSTEM SERVICE.............................................................................45

11.2

AUTOMATIC CYCLE (BUSES) .......................................................................................45

11.2.1

Last cycle ...................................................................................................... 45

11.2.2

User-defined cycles...................................................................................... 45

11.2.3

Search parameters by vehicle registration plate number........................ 45

11.3

AUTOMATIC CYCLE (OTHER VEHICLES).....................................................................45

11.3.1

Vehicle selection from database ............................................................... 45

11.3.2

Last cycle ...................................................................................................... 45

11.3.3

User-defined cycles...................................................................................... 46

11.3.4

Search parameters by vehicle registration plate number........................ 46

11.3.5

Automatic cycle parameters configuration.............................................. 46

11.3.6

OIL TYPE REPLACEMENT................................................................................ 47

CAP. 12 - MANUAL CYCLES ................................................................................................... 48

12.1

PRELIMINARY OPERATIONS.........................................................................................48

12.2

RECOVERY....................................................................................................................48

12.3

VACUUM PHASE ..........................................................................................................48

12.4

INJECTION ....................................................................................................................49

12.5

OPERATION CONTROL (EXCLUDING BUSES).............................................................50

12.6

EMPTYING HOSES.........................................................................................................50

12.7

FLUSHING......................................................................................................................50

12.8

NITROGEN TEST.............................................................................................................51

CAP. 13 - MAINTENANCE....................................................................................................... 52

13.1

SELF LEAK TEST...............................................................................................................53

13.2

PUMP MONITORING SYSTEM SPECIAL FUNCTION - VACUUM PUMP OIL CHANGE

53

13.3

13.3.1

13.4

13.5

13.6

13.7

13.8

13.9

13.10

CAP. 14 - DISPOSAL................................................................................................................ 63

14.1

14.2

14.3

CAP. 15 - SPARE PARTS........................................................................................................... 64

CAP. 16 - MESSAGE AND ALARM CODES.............................................................................. 65

CAP. 17 - MAINTENANCE FORMS .......................................................................................... 71

DRYER FILTER CHANGE................................................................................................55

MESSAGE FOR FILTER ALMOST EXHAUSTED ................................................. 58

COUNTERS ....................................................................................................................58

VESSEL FILLING (A/C SERVICE STATION TANK) ..........................................................58

NON-CONDENSABLE GAS DISCHARGE ....................................................................59

TANK REFRIGERANT INTERNAL RECYCLING...............................................................59

SYSTEM INFORMATION ................................................................................................60

MAINTENANCE OF PRINTER ........................................................................................60

PERIODIC CHECKS.......................................................................................................60

A/C SERVICE UNIT DISPOSAL ......................................................................................63

RECYCLED MATERIALS DISPOSAL...............................................................................63

PACKAGING DISPOSAL ..............................................................................................63

CAP. 1 - CONTENTS 3 / 74 ENGLISH

ClimFill Maxi

CAP. 2 - GENERAL INSTRUCTIONS

2.1 GENERAL NOTES

All rights reserved.

This manual may not be reproduced, in part or entirely, either in printed or digital form.

It may be printed out solely for use by the user and operators of the equipment to

which it refers.

VALEO SERVICE and resources used for the drawing up of this manual will not be held

responsible for the incorrect use of the manual while they guarantee that information in

the manual have been duly checked.

The product can be subject to changes and improvements. VALEO SERVICE reserves

the right to change without notice the information contained in the manual.

2.2 GENERAL INSTRUCTIONS

Pressure equipment undergoes checks before commissioning and periodical checks

during operation in compliance with rules and law provisions in force in the country

where the equipment is used.

The operator is responsible for operating the equipment in conformity with local

legislation.

The equipment is designed for recovering and recycling R134a refrigerant fluid from

A/C systems of buses, cars and similar vehicles.

The equipment is intended to be used by repair and service garages for buses, cars

and similar vehicles.

This equipment is intended solely for use by professionally trained operators familiar with

the basics of refrigeration, refrigeration systems, refrigerants and the hazards associated

with pressurised equipment.

Careful reading of the present manual by the owners, the users and the operators is

required for a correct and safe use of the equipment.

The user shall not be entitled to open the product since maintenance operations are

reserved to the authorised service centre.

2.3 MANUFACTURER IDENTIFICATION

The ClimFill® Maxi equipment is manufactured by:

VALEO SERVICE

70 rue Pleyel Cedex

93285 Saint Denis (France)

CAP. 2 - GENERAL INSTRUCTIONS 4 / 74 ENGLISH

ClimFill Maxi

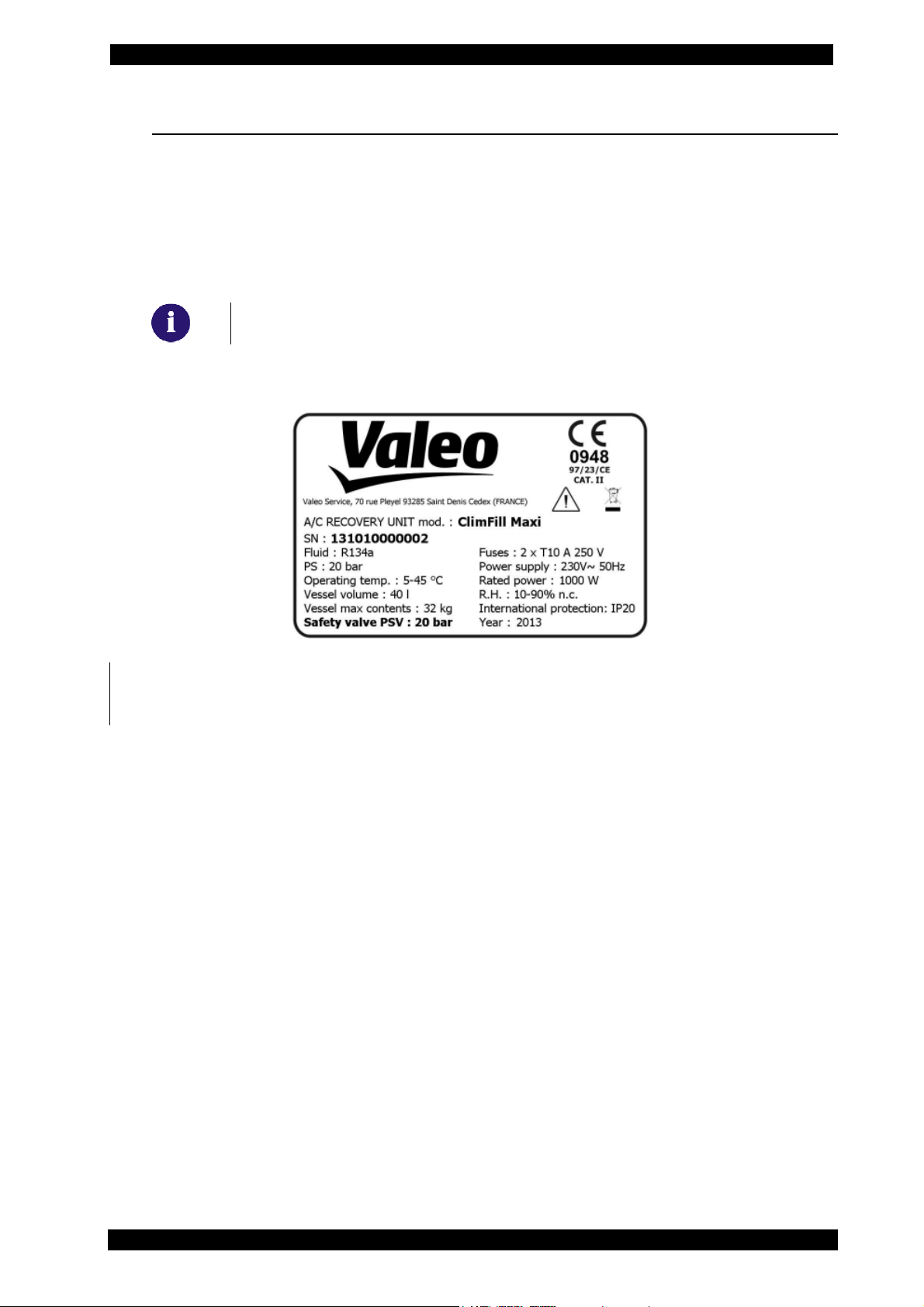

2.4 MARKING

The ClimFill® Maxi equipment has been manufactured in compliance with the European

Union directives listed in the Declaration of Conformity supplied with the pressure

equipment.

The equipment is a PED risk class III device (97/23/EC).

The characteristic data of the equipment are indicated on the specific data plate

applied onto the equipment side part.

It is prohibited to remove, damage or tamper with the equipment

NAMEPLATE

“data plate”.

Fac-Simile

CE MARKING: The present CE declaration is enclosed to the equipment. Store correctly

and provide on request.

ENGLISH 5 / 74 CAP. 2 - GENERAL INSTRUCTIONS

ClimFill Maxi

CAP. 3 -

SAFETY CONDITIONS

3.1 PERSONAL SAFETY INFORMATION

3.1.1 Definitions

DANGEROUS AREAS:

Any area within or close to the equipment implying risk for the safety and health of

exposed persons.

EXPOSED PERSON:

Any person completely or partially standing in a dangerous area.

OPERATOR:

The person/s charged with operating the machine for its intended purpose.

CLASSIFICATION OF OPERATORS

The operator can be classified according to two main categories, which, in some

cases, refer to one single person:

• The operator charged with the equipment operation has the duty to:

o Start up and monitor the machine's automatic cycle;

o Carry out simple setting operations;

o Remove the causes of equipment stop not implying breakings of

members but simple operating anomalies.

• Maintenance technician: a technician trained by an authorised VALEO SERVICE

centre, capable of working on the machine’s mechanical and electrical

components with its guards open to make adjustments and to service and repair

it.

USER

Body or person legally responsible for the equipment.

3.1.2 Personal safety information

The VALEO SERVICE ClimFill® Maxi A/C service station is particularly simple and reliable

due to its adjustments and functions. When used correctly it presents no hazard for the

operator, provided he observes the following general safety instructions and that the

service station is regularly serviced (incorrect maintenance/use compromise the

equipment's safety).

Before operating the service station for the first time, read these instructions carefully. If

any part of the instructions is unclear, contact your reseller or VALEO SERVICE. This

service station may be used by only one equipment operator, familiar with A/C and

refrigeration systems and the hazards associated with refrigerants and high pressure

equipment.

CAP. 3 - SAFETY CONDITIONS 6 / 74 ENGLISH

ClimFill Maxi

WORKPLACE: The equipment must be operated outdoor or in a well-ventilated location

(at least 1 air change per hour). The workshop has to be equipped with ventilation

systems able to ensure air change in every environment area or carry out a periodical

ventilation by opening the areas. Use the equipment away from heat sources or hot

surfaces . The equipment must not be used in explosion risk environments (potentially

explosive atmospheres). Before using it, put the equipment on a levelled plane and

secure position, blocking it with suitable wheel stops.

Do not expose the tool to direct sunrays, heat sources, rain and jets of water. Do not

smoke close to the equipment and during operations (keep at a distance of at least 1

m).

The work area must be monitored by the operator while the equipment is operating.

ATTENTION: the R134a refrigerant fumes/gases are heavier than air and can gather on

the floor or inside cavities/holes and cause choke by reducing the oxygen available for

breathing.

At high temperatures, the refrigerant breaks down releasing toxic and aggressive

substances, harmful for the operator and the environment.) Avoid inhaling the system

coolants and oils. Exposure can irritate eyes and the respiratory tract.

ELECTRICAL CONNECTION: Connect the power cord solely to a mains supply which

conforms with the ratings on the machine's nameplate (mounted on its side). Make sure

the mains socket is grounded.

Maximum impedance allowed in the point of connection to the mains shall comply

with standard EN 61000-3-11. Starting currents can cause short voltage drops, which

may affect other equipments under unfavourable conditions. If impedance in the point

of connection to the mains is not compliant, this may lead to interference so please

consult the electrical power network operator before connecting the equipment.

Never use the service station with a defective power cord or a different one from that

supplied with the machine. If damaged, immediately have it replaced with an original

spare part or equivalent by a VALEO SERVICE centre. Before opening the service

station, extract completely the supply cable from the plug, or you can get an electric

shock.

Do not tamper with or bypass the safety equipment and settings.

Do not leave the machine powered up when not in use; shut off the power supply

before leaving the equipment unused for a long time. Do not forget that the tool

(pressure tool) must always be protected.

ENGLISH 7 / 74 CAP. 3 - SAFETY CONDITIONS

ClimFill Maxi

REFRIGERANTS AND LUBRICANTS – PERSONAL PROTECTION EQUIPMENT AND

PRECAUTIONS: The refrigerants and the pressure vessels have to be handled with care,

otherwise there will be possible health risks.

The operator must wear safety glasses, gloves and protective clothing suitable to the

work. Contact with the refrigerant can cause blindness (eyes) and other physical

damage (freezing) to the operator. Avoid contact with the skin; the low boiling

temperature (about –26 °C for R134a) may cause burns.

Further information about safety can be obtained from the safety sheets of lubricant

and refrigerant producers.

Do not inhale refrigerant or oil vapour. Keep away from the vent valves and ventilation

coupling, especially when non-condensable gas is being vented.

Never direct the quick couplings (taps) towards your face or other persons or animals.

OTHER PROHIBITIONS AND USE LIMITATIONS: Use only pure R134a refrigerant, and do not

use it on vehicles containing other types of refrigerants. The mixture with other types of

refrigerant produces serious damage to the conditioning and cooling systems. Mixed

gases have to be disposed of according to current regulations. Do not use the ClimFill®

Maxi station with compressed air systems, R134a and air mixtures can be potentially

explosive.

Do not modify calibration of safety devices. Do not remove seals of safety valves and

of control systems. Do not use external tanks or other storage containers that are not

type-approved or without safety valves.

Make sure the equipment's aeration and ventilation ports are not obstructed or

covered while the equipment is operating.

CAP. 3 - SAFETY CONDITIONS 8 / 74 ENGLISH

ClimFill Maxi

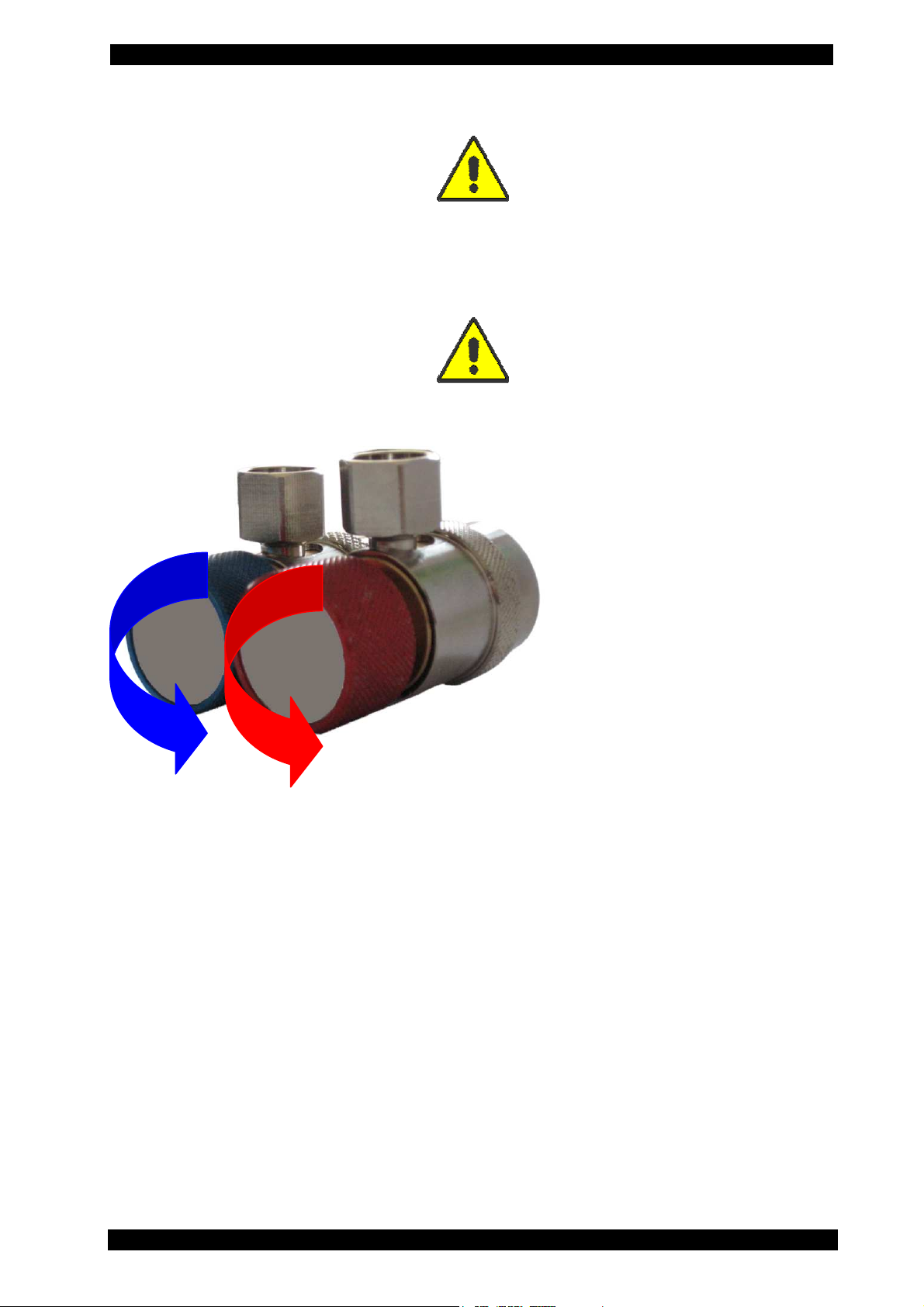

HOSE CONNECTIONS: Hoses may contain pressurised refrigerant. Before changing the

service couplers, check the respective pressures in the hoses (pressure gauge).

Before connection to a car A/C system, to an external tank/vessel, check that the

quick couplers are closed (unscrewed HP and LP valves).

Scrupulously follow the instructions on the equipment's display.

QUICK COUPLERS CLOSING/OPENING:

Opening (connect to the

vehicle):

clockwise

Closing (detach from the

vehicle):

counter clockwise

MAINTENANCE/GENERAL CLEANING: The equipment has to be serviced at the intervals

indicated by the equipment itself. These controls include also a leak self-test that the

equipment performs automatically.

The service station maintenance has to be performed according to the procedures

described in this manual and to the current safety regulations.

Use only VALEO SERVICE original parts.

When the equipment requires the dryer filter and the vacuum pump oil to be changed,

you have to be careful in the replacement.

A/C service station maintenance can be carried out exclusively by a trained operator

or by a service man of a VALEO SERVICE certified seller. If the maintenance is not

performed according to the expected schedule, the equipment will be blocked.

Do not use chemical agents for the service station cleaning, as they could attack the

material or the surface.

ENGLISH 9 / 74 CAP. 3 - SAFETY CONDITIONS

ClimFill Maxi

STOP FOR LONG PERIOD: Store the equipment in a safe place, disconnected from the

mains, away from excessive temperatures, humidity and the risk of damaging impact.

Contact the Technical Service to run a safety shutdown of the equipment, and if

scrapping the unit, to drain and recycle the R134a gas as required by local legislation.

To resume operation, repeat the installation (there is no need to register the unit anew

on the website) and run the commissioning trials and regular operational checks as

required by local legislation.

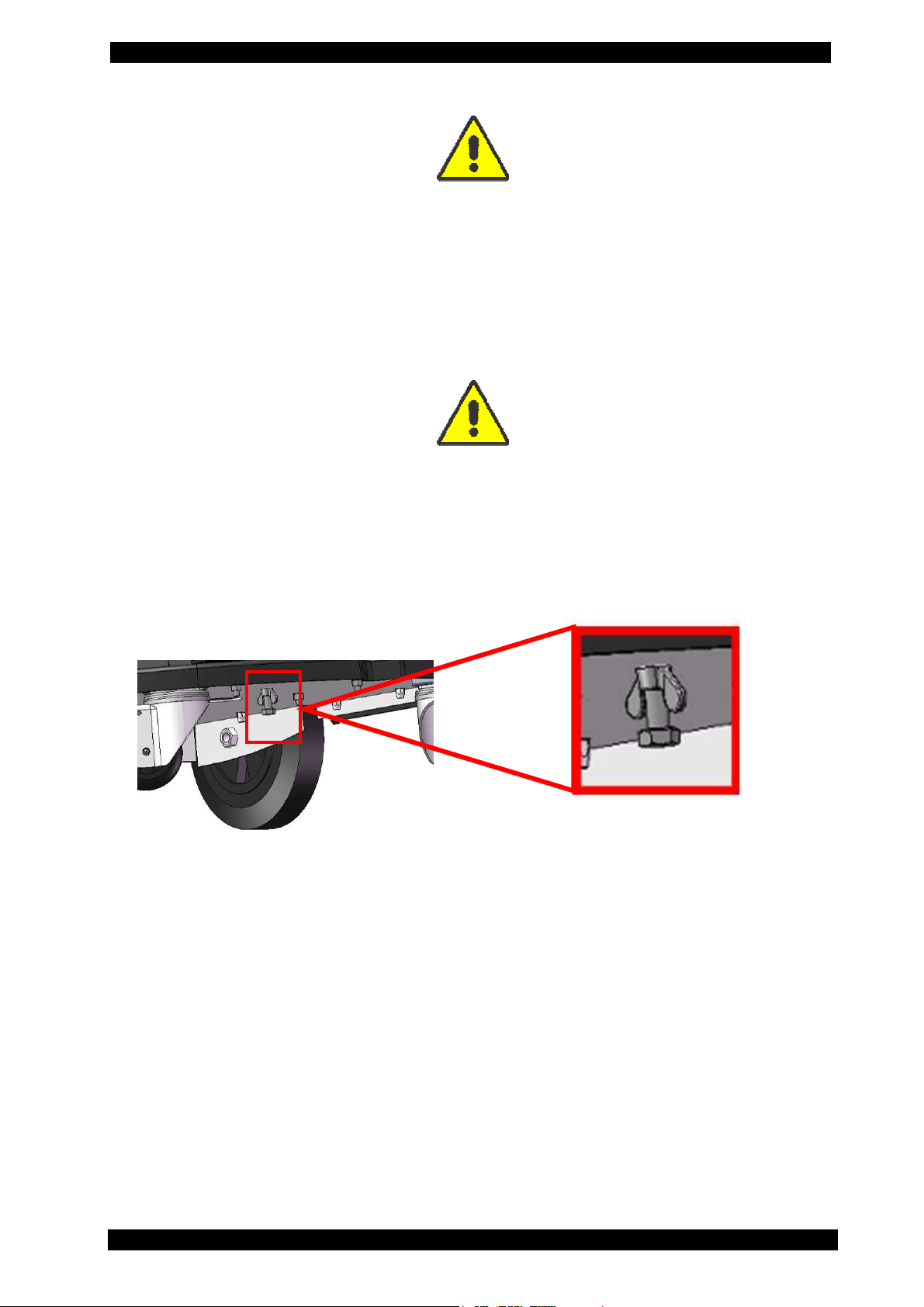

TRANSPORT: If the equipment has to be transported, you have to screw the safety screw

in order to fix the equipment scale. The safety device for transport is on the back of the

equipment and it consists of a bolt with wing-nut. Commissioning: Slacken the wing-nut,

unscrew the screw for about 4 mm. and fix it again with the wing-nut. Transport: slacken

the wing-nut, screw the screw by hand and then fix it again with the wing-nut. For the

transport of the R134a refrigerant, specific regulations are in force in every country.

Therefore, refer to your reseller or your authorised service centre for information.

CAP. 3 - SAFETY CONDITIONS 10 / 74 ENGLISH

ClimFill Maxi

3.2 IMPORTANT INFORMATION ON SERVICE EQUIPMENT

SAFETY

When using the equipment, the following operations are not allowed as they might

cause, under certain circumstances, danger for persons and cause permanent

damage to the equipment itself.

- Do not remove or make unreadable labels, signs and/or dangers signs

placed on the equipment and in the area nearby.

- Do not disable the unit's safety devices.

- Use only fuses identical to the originals as specified on the nameplate;

do not tamper with or attempt to repair the fuses.

If the power supply is known or can be expected to vary beyond the

limits specified for the service equipment, immediately disconnect it.

- The electrical system to which the service equipment is connected

must be configured as provided for by local legislation.

- Only operators or qualified staff instructed or certified for the

equipment maintenance can open the equipment. The equipment

contains parts which can cause electrocution: shut off power to the

equipment before servicing/repairing it.

3.3 SAFETY DEVICES

ClimFill® Maxi is equipped with the following safety devices:

SAFETY PRESSURE SWITCH: It stops the compressor in case of excessive

pressure.

SAFETY VALVE: The safety valve opens when the pressure inside the

Failure to observe any of the above safety instructions voids the equipment's warranty.

system reaches a level higher than the fixed limits.

MAIN SWITCH: Switches the equipment off by interrupting the power

supply. It is advisable to pull the power cord plug out of the mains

socket in any case before starting maintenance work.

ANY TAMPERING WITH THE ABOVE-MENTIONED SAFETY DEVICES IS

PROHIBITED.

ENGLISH 11 / 74 CAP. 3 - SAFETY CONDITIONS

ClimFill Maxi

CAP. 4 - LAYOUT AND USE OF THE MANUAL

4.1 USE OF THE MANUAL

• This manual shall accompany the equipment in case this is passed on to a new

user.

• The content of this manual has been drawn up in compliance with the guide

lines of the UNI standard 10893:2000.

• Diffusion, modification or use of this manual for own aims is forbidden.

• The manual uses symbols which call the reader's attention to specific points to

facilitate its use.

It includes all technical, operating, shutdown, maintenance, spare parts and safety

information.

• In case of doubts on the correct interpretation of the instructions, please contact

our technical service to obtain the required clarifications.

4.2 SYMBOLS

This paragraph describes the safety symbols which may be posted on the service

equipment.

This manual is an integral part of the equipment and must be kept

near the equipment by the purchaser

Operations which are potentially hazardous for the operator are

highlighted with this symbol.

Such operations can cause serious injury.

Operations requiring special attention are highlighted with this symbol.

Such operations shall be carried out correctly to avoid causing

damage to objects or to the surrounding environment. This symbol also

highlights information to which special attention must be paid.

Operations which require careful reading of the manual's instructions

are highlighted with this symbol.

4.2.1 Safety

ALTERNATING CURRENT

CONSULT THE INSTRUCTIONS MANUAL

SAFETY GROUNDING

ATTENTION! ELECTROCUTION HAZARD

CAUTION !: DO NOT REMOVE THE COVER

(maintenance technicians only)

USE PROTECTIVE GLOVES

WEAR PROTECTIVE GOGGLES

USE ANTI-SMASH SAFETY SHOES

CAP. 4 - LAYOUT AND USE OF THE MANUAL 12 / 74

ENGLISH

ClimFill Maxi

4.3 GLOSSARY

To make the reading of this manual easier, we have prepared the list of the most

important technical terms used in the manual.

Refrigerant: Refrigerant fluid used in advanced motor vehicle A/C systems.

The following refrigerant fluids may be used:

o R-134a C2H2F4 - 1,1,1,2-Tetrafluoroethane

A/C system: air conditioning system.

Equipment: ClimFill® Maxi service station for recovering, recycling, draining and

charging the A/C system.

External tank: Refrigerant bottle used to fill the internal vessel.

Internal vessel: vessel for refrigerant storage.

Phase: Performance of a single function.

Cycle: Sequence of steps.

Recovery: Extraction of refrigerant from the vehicle.

Recycling: Cleaning of refrigerant, includes: separating out oils, removal of non-

condensable gas and single/multiple pass through filters to reduce the humidity,

acidity and particulate content of the fluid.

Disposal: disposal of refrigerant for storage followed by destruction/scrapping by an

authorised waste management centre.

Vacuum cycle: Draining out of a motor vehicle A/C system and separation out of

condensed matter and humidity, using only the vacuum pump.

Oil injection: Injection of oil into an A/C system to ensure the correct charge as

specified by the vehicle's manufacturer.

Charge: filling of refrigerant into the A/C system in the amount specified by the

manufacturer.

System flushing: Cleaning phase for the removal of possible polluting substances from

the A/C system or parts of it.

Non condensable gases: Gas stored in the gaseous phase, including air and nitrogen.

ENGLISH 13 / 74 CAP. 4 - LAYOUT AND USE OF THE MANUAL

ClimFill Maxi

4.4 GUIDELINES FOR HANDLING REFRIGERANT

4.4.1 Precautions for refrigerant storage

The refrigerant removed from the A/C system must be handled with care to prevent or

minimise the risk of mixing with other refrigerants.

This equipment is designed to handle refrigerant R134a.

The external vessels used to store the refrigerants must be clearly marked to prevent

mixing different refrigerants.

The vessels must be free of oil and other contaminants.

ATTENTION: when handling, using and storing R-134a gas and dealing

with emergency situations, MAKE SURE to refer to the product's safety

sheet.

GET THE SAFETY SHEET FROM YOUR REFRIGERANT SUPPLIER AND FOLLOW

ITS INSTRUCTIONS

Fac-Simile

4.4.2 Refrigerant conditions

The condition of the refrigerant is critical to the operation of the vehicle's A/C system.

Running repairs properly following failure or damage ensures the quality of the

refrigerant itself (particulates, acids and water).

4.4.3 Recycling capacity

The service equipment's filtering systems must be replaced regularly (see maintenance

messages) to ensure effective recycling.

CAP. 4 - LAYOUT AND USE OF THE MANUAL 14 / 74

ENGLISH

ClimFill Maxi

CAP. 5 - GENERAL DESCRIPTION

The advanced technology and innovative concept employed in designing and

fabricating ClimFill® Maxi makes it extremely simple and reliable in operation.

With its vessel holding up to 32 kg of refrigerant, ClimFill® Maxi has been specifically

designed for the maintenance and service of vehicle A/C systems containing large

amounts of refrigerant, particularly buses.

However, it can also be used to recharge vehicles with smaller amounts, such as cars.

ClimFill® Maxi is assembled by the manufacturer according to established EU standards

and undergoes service trials on completion.

The ClimFill® Maxi as recharge methods uses two modes, the Q-Mode (Quick Mode) or

S-Mode (Suction Mode).

The Q-Mode for this model ClimFill® Maxi is based on the patented technology

Supercharge which allows for increasing the refrigerant injection speed by charging

an A/C loop from the HP side while recovering, at the same time, from LP (if available).

The S-Mode (Suction Mode) assure to complete the refrigerant recharge, but needs

always to turn on the vehicle engine and the A/C system to recharge refrigerant from

LP side.

ENGLISH 15 / 74 CAP. 5 - GENERAL DESCRIPTION

ClimFill Maxi

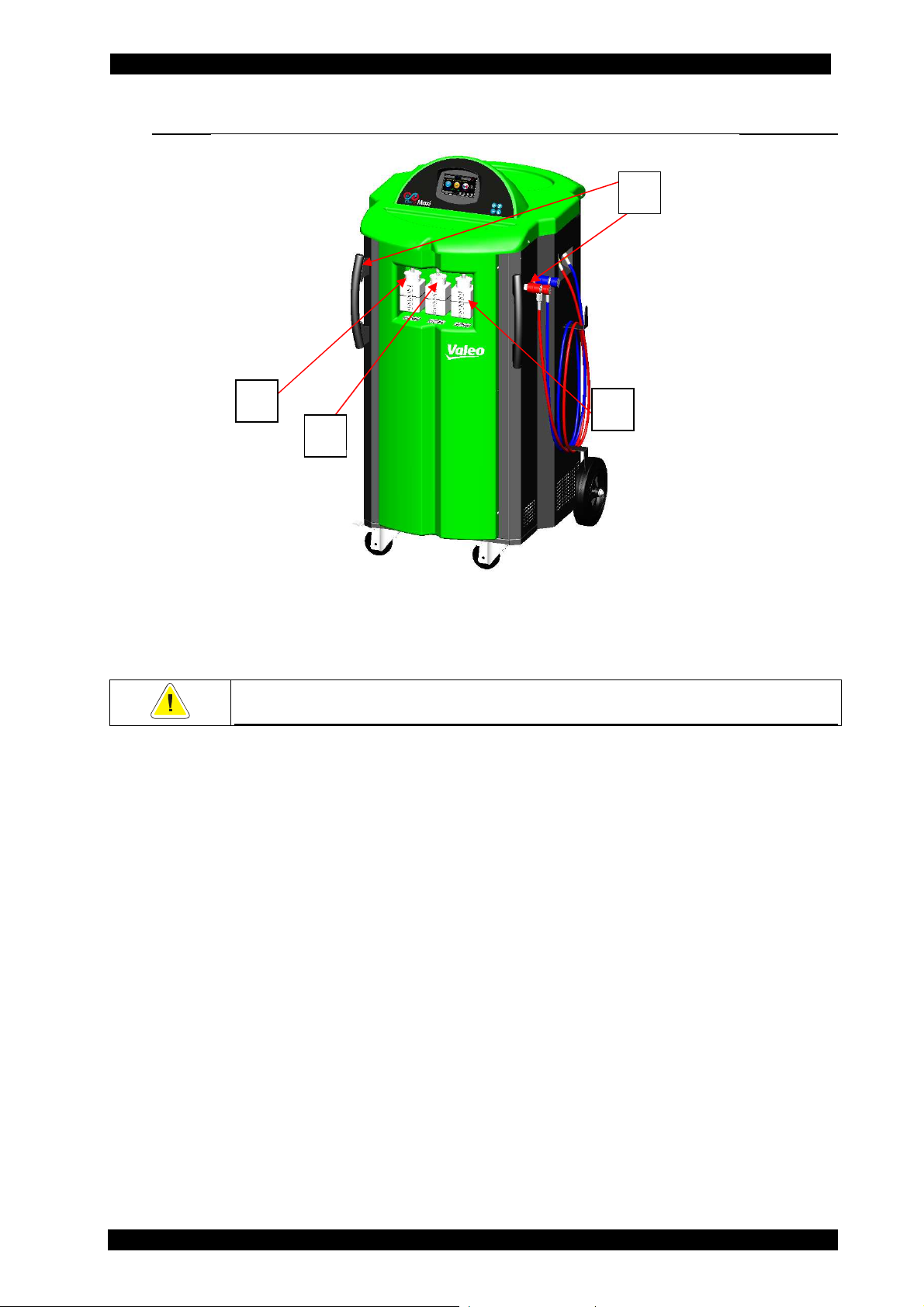

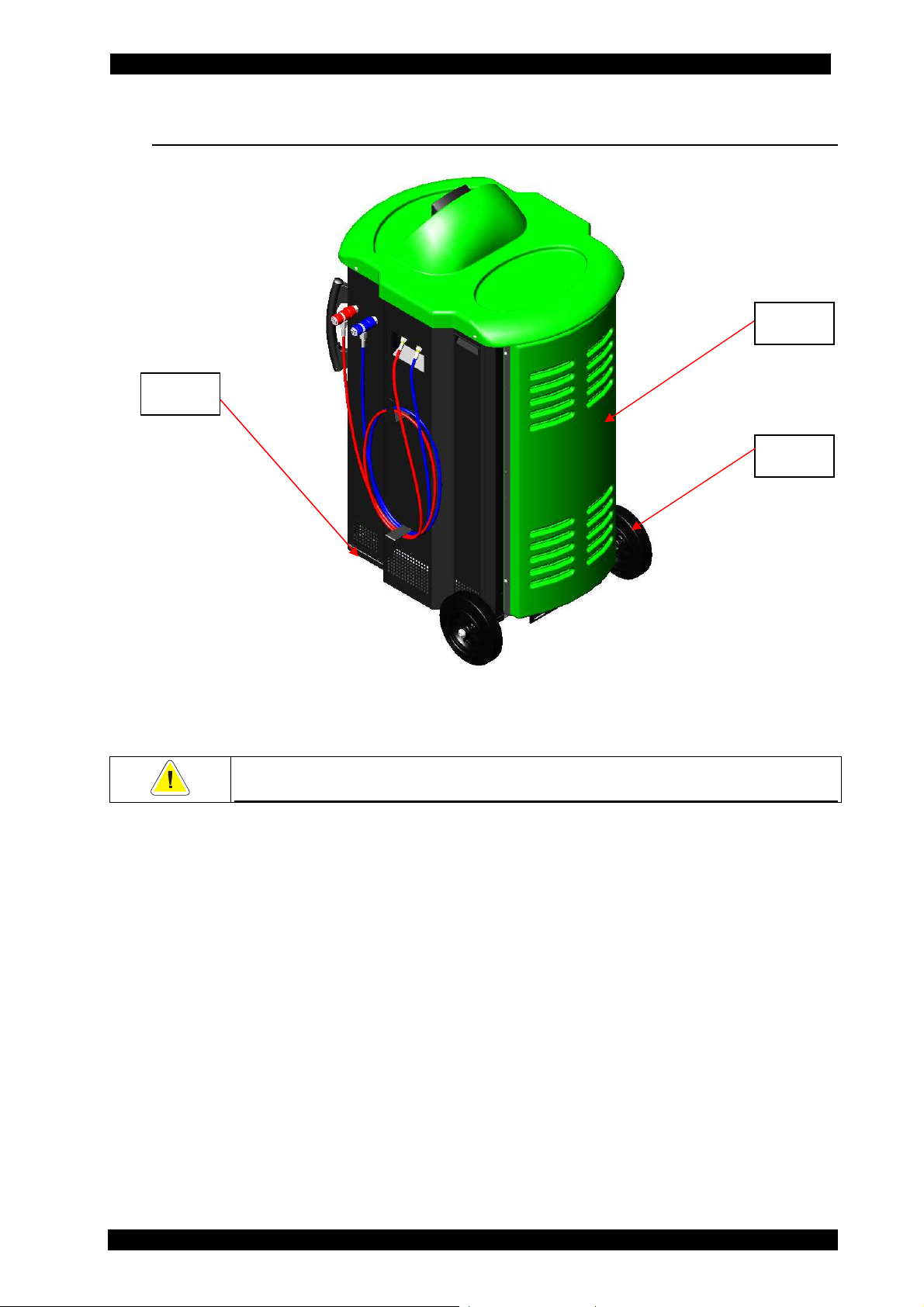

5.1 FRONT VIEW (EXTERIOR)

4

1

2

1. New PAG oil container 250 cc

2. Exhausted oil container 250 cc

3. UV contrast fluid container 250 cc

4. Handles

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

3

CAP. 5 - GENERAL DESCRIPTION 16 / 74 ENGLISH

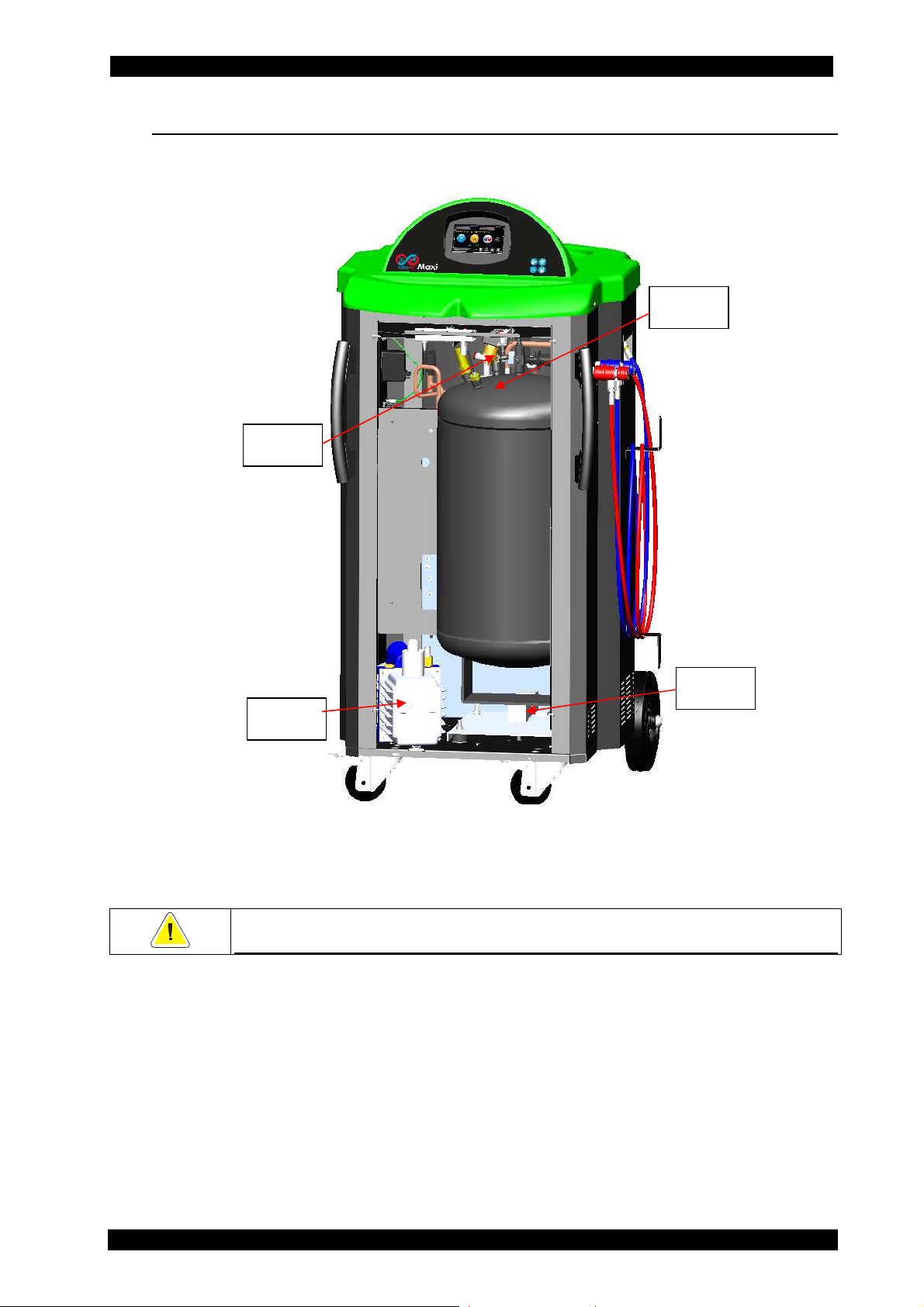

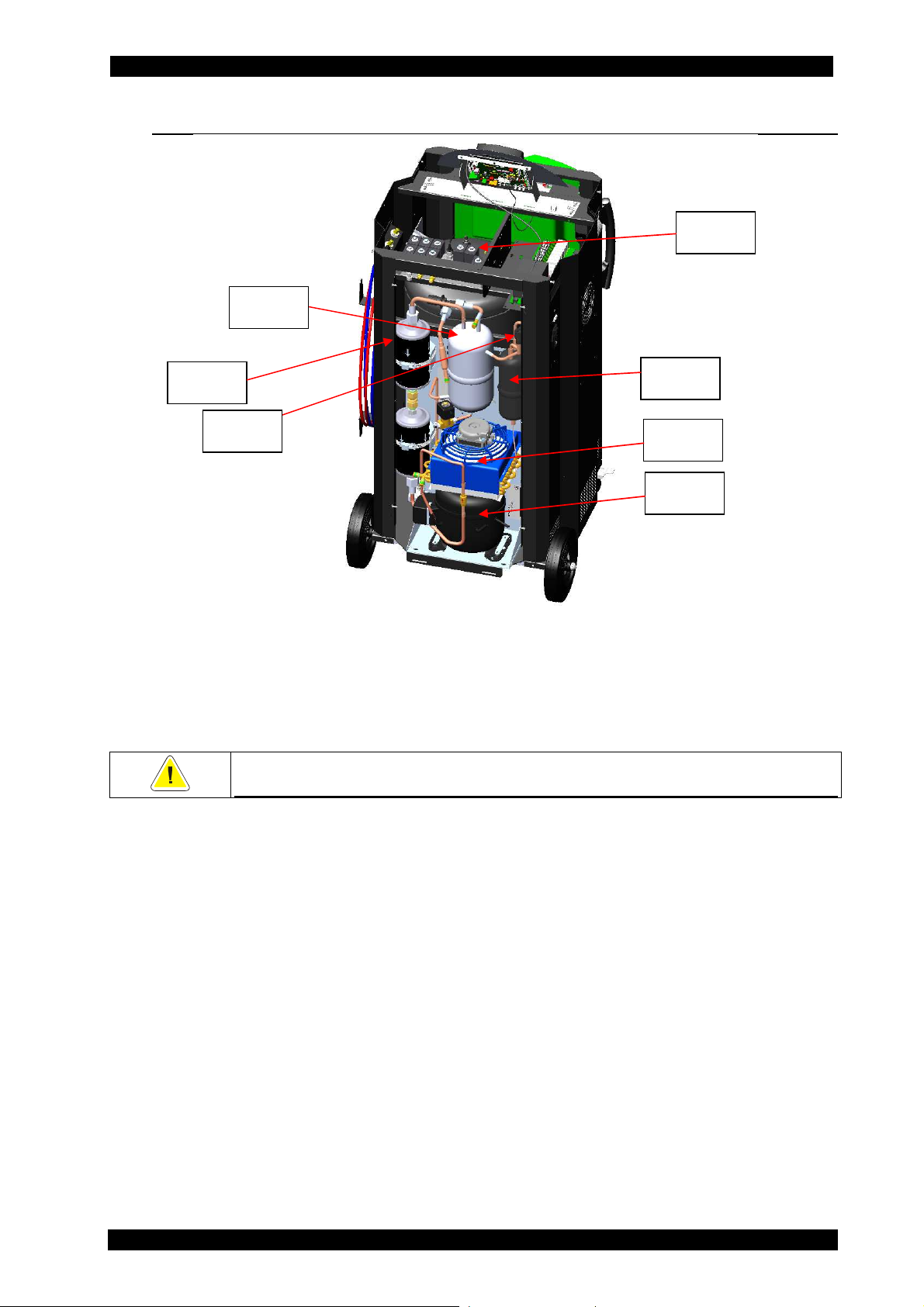

5.2 FRONT VIEW (INTERIOR)

8

ClimFill Maxi

6

5

5. Vacuum pump

6. Refrigerant tank 40 L

7. Load cell

8. Non-condensable gas vent valve (automatic)

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

7

ENGLISH 17 / 74 CAP. 5 - GENERAL DESCRIPTION

ClimFill Maxi

5.3 REAR VIEW (EXTERIOR)

9

11

10

9. Caster wheels, with brakes

10. Handling wheels

11. Rear door

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

CAP. 5 - GENERAL DESCRIPTION 18 / 74 ENGLISH

5.4 REAR VIEW (INTERIOR)

13

ClimFill Maxi

12

14

15

12. Manifold

13. Distiller

14. Dryer filter

15. Safety pressure switch

16. Oil separator

17. Vented condenser

18. Compressor

ONLY MAINTENANCE TECHNICIANS MAY REMOVE THE FRONT AND REAR

DOORS OR THE TOP COVER

16

17

18

ENGLISH 19 / 74 CAP. 5 - GENERAL DESCRIPTION

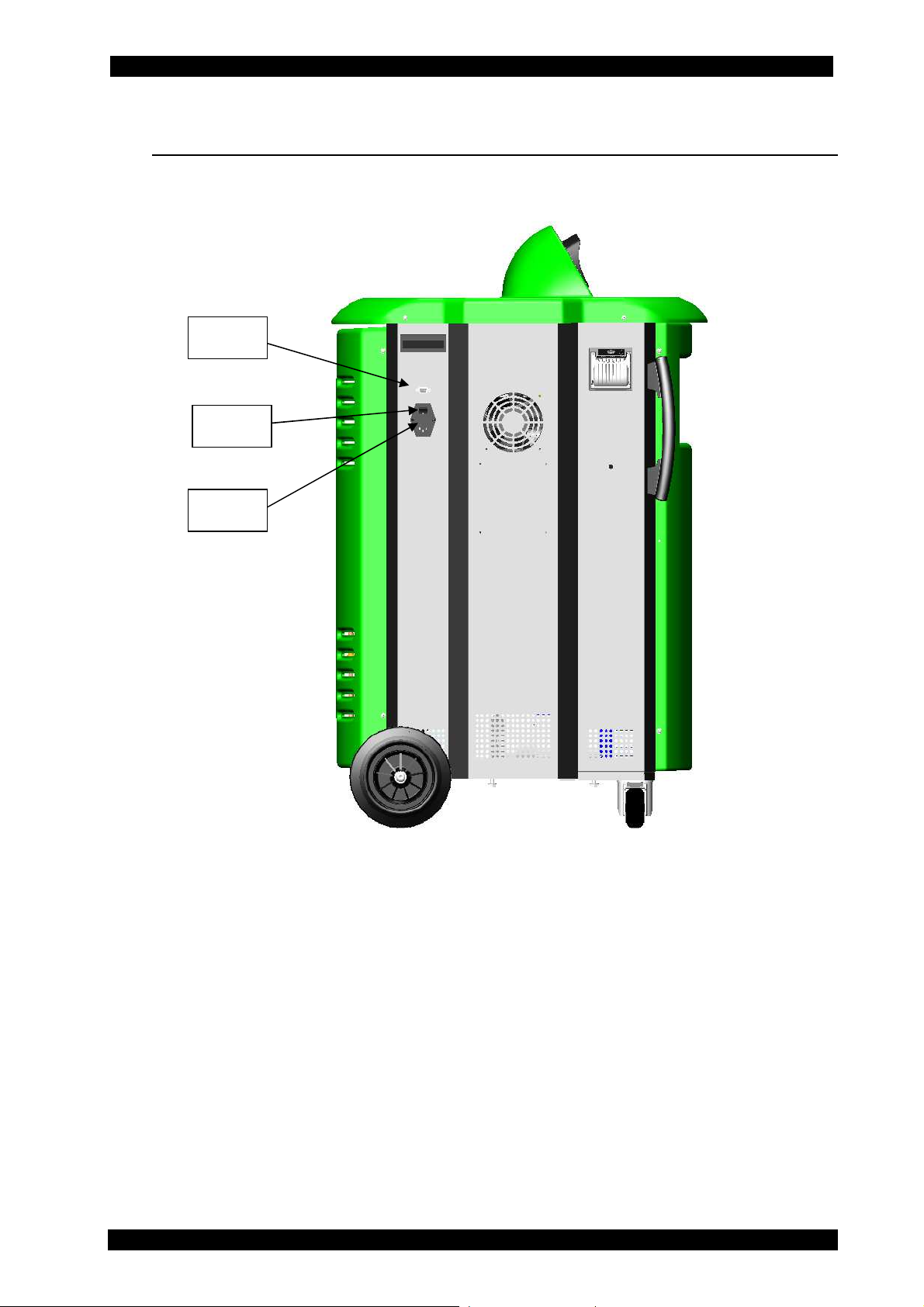

ClimFill Maxi

5.5 RIGHT SIDE VIEW

19

20

19. HP hose and quick coupling

20. LP hose and quick coupling

DO NOT USE THE UNIT UNLESS THE CHARGING HOSES (HP – LP) ARE

CAP. 5 - GENERAL DESCRIPTION 20 / 74 ENGLISH

CORRECTLY CONNECTED

5.6 LEFT SIDE VIEW

21

22

23

ClimFill Maxi

21. RS232 serial port (updating software installation interface)

22. Main switch

23. 230 VAC MAINS SUPPLY FUSES (5x20 T 10A 250V)

ENGLISH 21 / 74 CAP. 5 - GENERAL DESCRIPTION

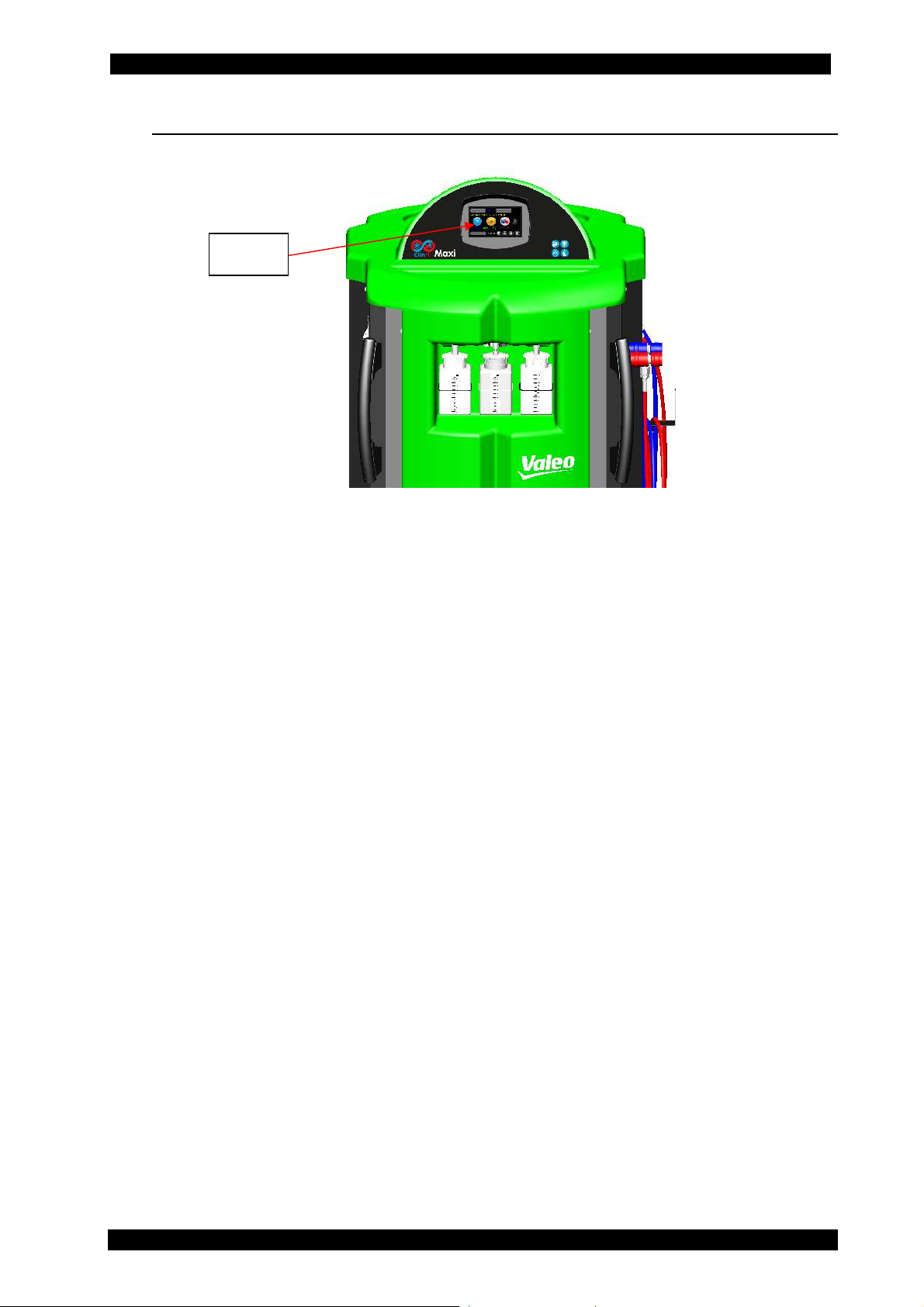

ClimFill Maxi

5.7 FRONT SIDE VIEW

24

24. Touch Screen graphic display

CAP. 5 - GENERAL DESCRIPTION 22 / 74 ENGLISH

ClimFill Maxi

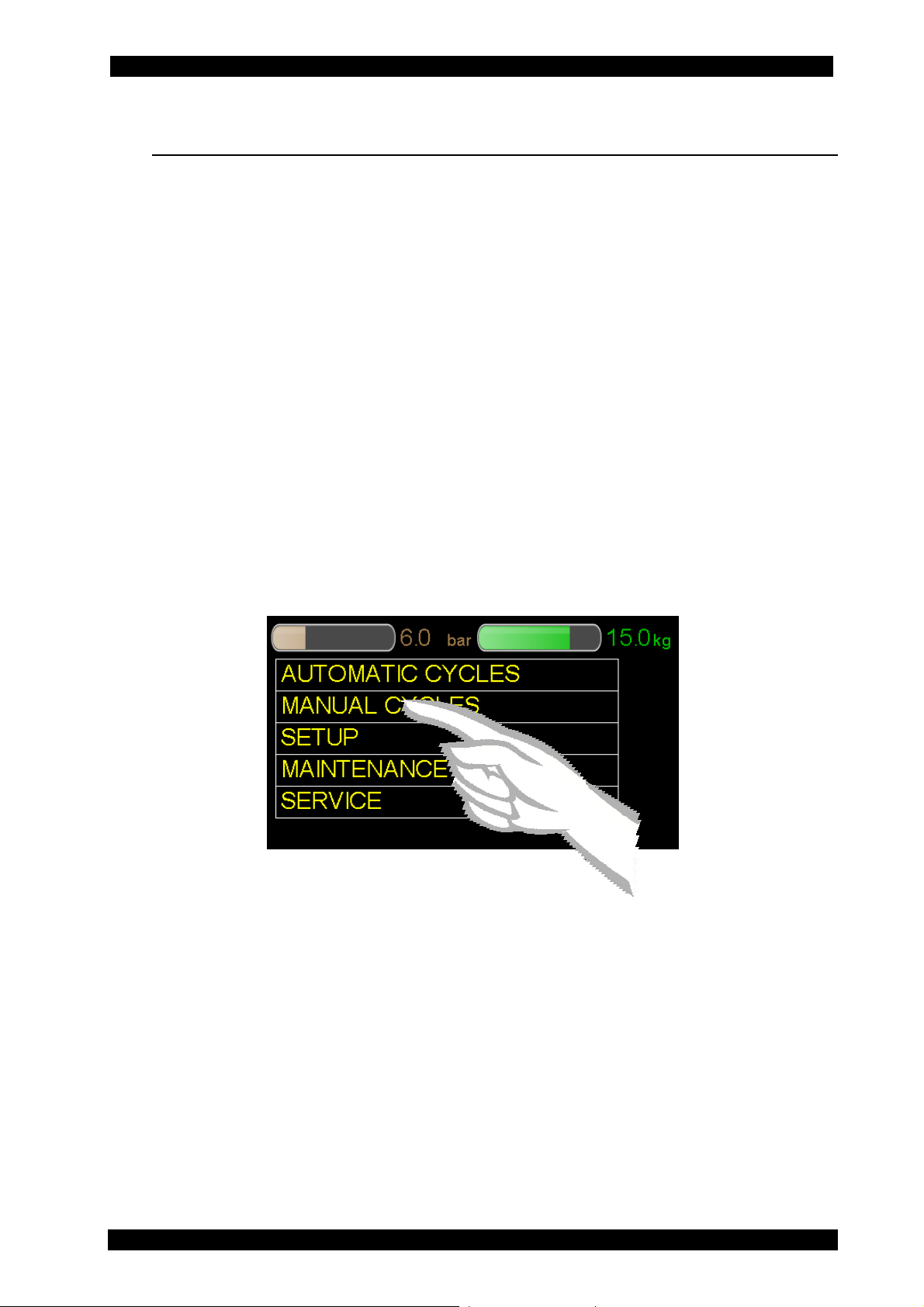

5.8 TOUCHSCREEN

All settings, controls and service functions are available on the touchscreen display. It

also displays the service equipment’s status, the progress of A/C system service and any

alarms and error messages.

The touchscreen is the basic operator interface and can be operated with the fingers

or some other object, such as a pen.

When a button is pressed, a beep sounds.

The following functions are available:

scroll left: previous menu

scroll up: top menu

scroll down: lower menu

press: confirm / enter

press and hold: open the function to change it or press the ''home'' button

double press: supplementary functions

To select a MENU (e.g. MANUAL CYCLES), press the text MANUAL CYCLES: the selection

occurs when the finger is released, the selected entry is pointed out with a different

colour and the menu screen page changes.

If there are descriptions that need more space on the screen page, for example the

manual cycles list (see the screen page below), or in case of setup, it is possible to

display the different entries by moving the scroll bar to the side. For this reason, it is

necessary to touch the grey point on the scroll bar and slide up or down with the finger.

Lift the finger when you are on the desired position.

By touching the scroll bar once, the menu moves one line up or down depending on

whether it is touched over or under the grey dot.

The “home” icon is the button to “interrupt/return to the main menu’’.

To access to the main menu you have to touch it for 2 seconds. Sliding to the left with

the finger you can access to the previous menu.

ENGLISH 23 / 74 CAP. 5 - GENERAL DESCRIPTION

Loading...

Loading...