Page 1

TECHNICAL MANUAL

VTM-98-006/I

OPERATION AND INSTALLATION

INSTRUCTIONS

HF BROADBAND ANTENNA

MODEL VBBA 2-30

Valcom Manufacturing Group, Inc

175 Southgate Drive, P.O.Box 603, Guelph, Ontario, Canada N1H 6L3 Tel: 519-824-3220 Fax: 519-824-3411

Web Site: www.valcommfg.ca Email: enquiries@valcom-guelph.com

Page 2

RECORD OF CHANGES

VTM-98-006/I

CHANGE NUMBER DATE TITLE OF BRIEF

DESCRIPTION

-- Jan 2001 - Original Issue H.D.

- Added additional cable and connector

- A - May 2002

- B - Sept 2002

- C - Nov 2003 - Added detail to Figure 4-1 J.S.

- D - Aug 2006

- E - Aug 2007 Added Maintenance Section J.Soper

- F- April 2009

information

- Fixed minor typing errors

- Deleted reference to LC-N type and

7/8" Heliax adapters as being included

- They are options to be ordered

separately by the customer

- Change to 7/8 EIA Connector and

related parts

Fixed power rating spec from 2kW to

3kW

ENTERED BY

J.S.

J.S.

HD..

J.Soper

- G - July 2012

- H - September 2013

- I - April 2016

- Added Power vs Frequency Table

- Added improved maintenance

procedures and installation torque

suggestions

- Added cosmetic repair section

- Added contact info section

- Replaced Silicone grease with

Silicone sealant

- Changed p/n of anti-seize

- Added list of basic tools req’d

- Re-worded installation and

maintenance sections

Update new 7/8 EIA Connector and

related parts (replace obsoleted parts)

J.Soper

J.Soper

Haitu Duong

Page 3

VTM-98-006/I

Table of Contents

Section Page

1 GENERAL INFORMATION AND SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 General Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Specific Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-3 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-4 Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-5 Relationship to Other Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-6 Reference Data.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-7 Equipment Accessories, and Documents Supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3 Operating Procedures.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.1 Operator Turn-on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.2 Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.3 Operation Under Interfering Conditions.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.4 Operator Turn-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.5 Emergency Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3.6 Emergency Turn-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 FUNCTIONAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-1 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-1 Site Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-2 Tools and Materials Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-3 Unpacking and Repacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-4 Foundation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-5 Input Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-6 Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4-7 Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4-8 Installation Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-1 Scheduled Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-2 Corrective Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-2.1 General Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-2.2 Cosmetic Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 QUICK REFERENCE DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6-1 General.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6-2 Manufacturer’s Address.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

i

Page 4

VTM-98-006/I

LIST OF ILLUSTRATIONS

Figure Page

1-1 Antenna VBBA2-30.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4-1 Outline Drawing.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LIST OF TABLES

Table Page

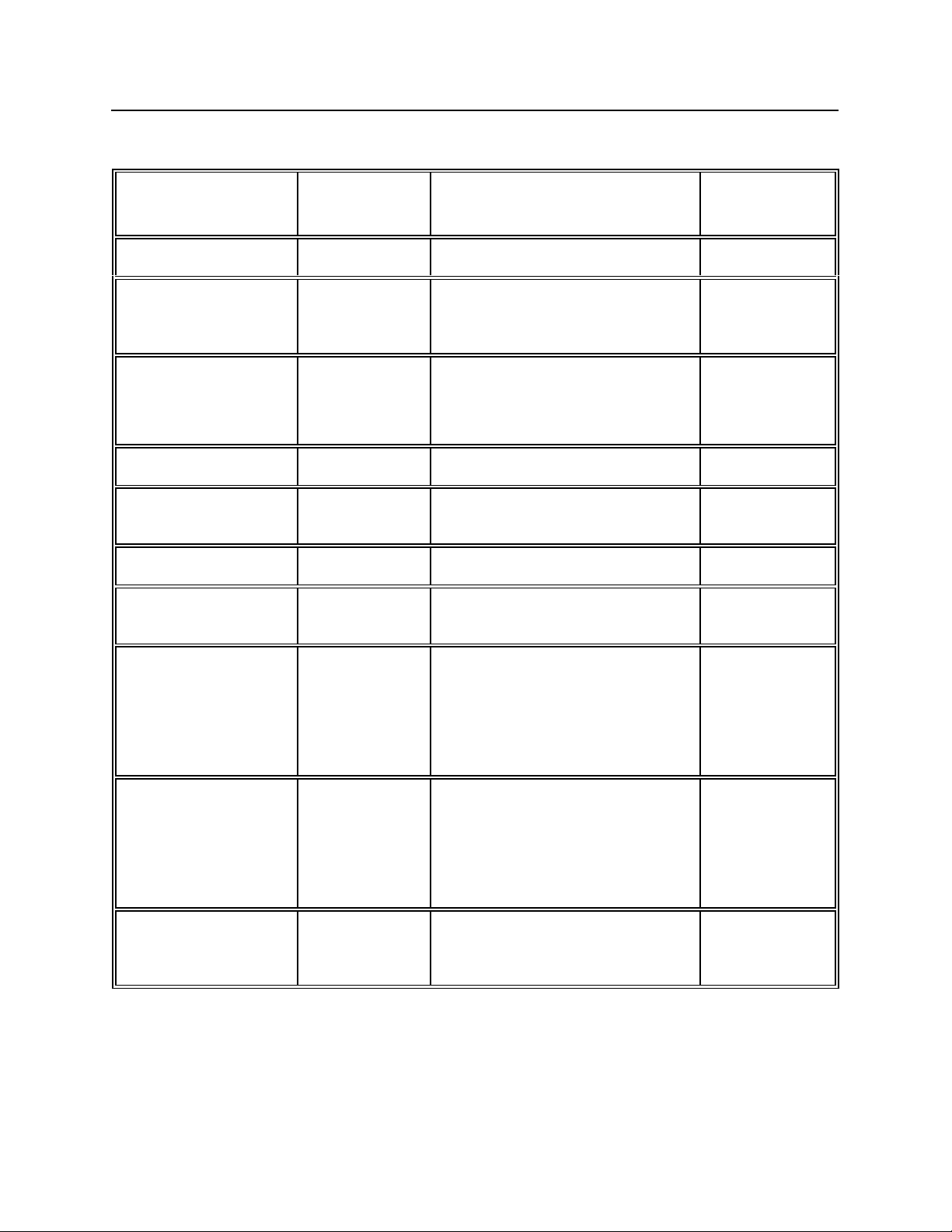

1-1 Reference Data.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 Power Handling vs Frequency Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Equipment, Accessories and Documents Supplied. . . . . . . . . . . . . . . . . . . . . . . . . 5

4-1 Cable and Connector Group Suggestions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ii

Page 5

VTM-98-006/I

SECTION 1

GENERAL INFORMATION AND SAFETY PRECAUTIONS

1-1 GENERAL SAFETY PRECAUTIONS. The following general safety precautions are not

related to any specific procedures and therefore do not appear elsewhere in this publication.

These are recommended precautions that personnel must understand and apply during many

phases of operation and maintenance.

WARNING

Keep away from live circuits. Operating personnel must at all times observe all safety

regulations, to prevent serious injury or death due to electrical shock.

Do not service or adjust alone. Under no circumstances should any person service or adjust

the equipment except in the presence of someone who is capable of rendering aid.

Personnel working with or near high voltages should be familiar with modern methods of

resuscitation.

1.2 SPECIFIC WARNINGS. The following specific precautions are related to inspecting and

removing the antenna.

Ensure that the transmitting equipment is de-energized prior to inspection of the antenna.

Make sure the test equipment is properly grounded, to prevent electric shock.

Make sure the antenna is properly supported before removing its mounting hardware.

Do not coat the insulator with any substance; do not paint with lead base paints.

WARNING

CAUTION

CAUTION

1

Page 6

VTM-98-006/I

1-3 INTRODUCTION. This manual provides general information, operating and functional

description, and installation data for Valcom's VBBA 2-30 broadband antenna.

1-4 EQUIPMENT DESCRIPTION. The VBBA 2-30 Broadband Antenna (see figure 1-1) is a

whip antenna for general use with HF communications equipment. The antenna provides

vertically polarized, omnidirectional azimuth radiation from 2 to 30 MHz when the antenna

is operated with a HF transceiver. It is designed for use under the severe environmental

conditions encountered aboard Naval vessels. It is used for either receiving or transmitting

high frequency signals. The antenna is a two section antenna and is base mounted. The

mounting flange and insulator is a single integral part made from fibreglass.

1-5 RELATIONSHIP TO OTHER EQUIPMENT. The VBBA 2-30 Antenna interfaces with the

HF receiving and transmitting equipment.

1-6 REFERENCE DATA. Table 1-1 lists the reference data for the antenna.

1-7 EQUIPMENT ACCESSORIES, AND DOCUMENTS SUPPLIED. Table 1-3 lists the

equipment and documents supplied.

2

Page 7

VTM-98-006/I

Figure 1-1 Antenna VBBA2-30

3

Page 8

Table 1-1 Reference Data

PARAMETER SPECIFICATION

Nomenclature Antenna, VBBA 2-30

Manufacturer 35736

Frequency Range 2-30 MHz

VSWR 2.0:1 Maximum

Polarization Vertical

Power Rating See Table 1-2 below

Azimuth Coverage Omnidirectional

Input Connection 7/8 EIA Flange (see Note 1)

Temperature -50ºC to 65ºC (-60ºF to 150ºF)

VTM-98-006/I

Wind Velocity 115 mph (185 kph) (51.4 m/s) (100 knots)

Humidity 0 - 100 %

Shock MIL-S-901D Grade A

Vibration MIL-STD-167-1A Type 1

NOTES: 1. For 1 kW operation, an 7/8 EIA to N adapter can be supplied (optional)

Table 1-2 Power Handling vs. Frequency Table

Frequency Range Maximum Power

Continuous-Duty

Maximum Power

Intermittent Duty

1

2.000 to 5.999 MHz 1000 W 3000 W for 5 minutes

6 to 10.999 MHz 1500 W 3000 W for 10 minutes

11 to 20.999 MHz 2000 W 3000 W for 15 minutes

21 to 29.999 MHz 2000 W 3000 W for 30 minutes

1. Duration for continuous-duty transmission, allowing antenna to cool to ambient between

transmissions

4

Page 9

QTY

VTM-98-006/I

Table 1-3 Equipment, Accessories and Documents Supplied

NOMENCLATURE OVERALL DIMENSIONS (INCHES) WEIGHT

CRATED UNCRATED

HEIGHT DIA HEIGHT DIA

(POUNDS)

UNCRATED

1 ANTENNA

VBBA 2-30

P/N VD-97-00061-1

1 TECHNICAL

MANUAL FOR

VBBA 2-30 ANTENNA

VTM-98006

1 SILICONE SEALANT

12 MS24693-C140

3/8-16 X .75 L

FLAT HD SCREW

1 MIL-A-907E

ANTI-SEIZE

COMPOUND

1 GROUND STRAP

P/N VC-97-00069-1

1 7/8-EIA to N-Type

ADAPTER

VC-06-00142-1

(NOTE: Optionally

installed for 1 kW or less

operation)

--- --- 421 13.0

Base

260

- 1/2" HELIAX CABLE

(LDF4-50A)

CONNECTOR

COMMSCOPE

P/N: L4E78-PS

(NOTE: Optionally

supplied for 1kW or

more operation)

5

Page 10

VTM-98-006/I

SECTION 2

OPERATION

2-1 INTRODUCTION. This chapter provides operating instructions for the antenna.

2-2 CONTROLS AND INDICATORS. The antenna contains no controls or indicators.

2-3 OPERATING PROCEDURES.

2-3.1 Operator Turn-On. No operator turn-on procedures apply since no power is required to

operate the antenna. However, the antenna is coupled to RF equipment (transmitter/receiver)

and to associated systems which may require energizing. For operating instructions, consult

the appropriate technical manuals.

2-3.2 Modes of Operation. The antenna operates automatically, and no operator intervention is

required other than interconnecting the associated transmitter or receiver with the antenna.

2-3.3 Operation Under Interfering Conditions. No additional or alternate instructions are necessary

to operate the antenna under interfering conditions.

2-3.4 Operator Turn-off. Since no power is required to operate the antenna, no operator turn-off

is required. However, the specific equipment connected to the antenna may require operator

turn-off. Consult the associated technical manuals for turn-off procedures.

2-3.5 Emergency Operation. No additional or alternate steps are necessary to operate the antenna

under emergency conditions.

2-3.6 Emergency Turn-off. The antenna requires no emergency turn-off. For emergency turn-off

of specific equipment connected to the antenna, consult the associated technical manuals.

6

Page 11

VTM-98-006/I

SECTION 3

FUNCTIONAL DESCRIPTION

3-1 FUNCTIONAL DESCRIPTION. The VBBA 2-30 Broadband Antenna is a base mounted,

high-power antenna which provides omnidirectional coverage for general purpose

communications use from 2 to 30 MHz. The antenna consists of a radiating element, and a

fibreglass base insulator/mounting flange. The radiating element tapers from approximately

8.25 inches in diameter at the insulator to 2.17 inches at the top. The antenna base insulator

electrically isolates the radiating section of the antenna from the ground and physically

supports it. The insulator/mounting base is constructed of high-strength, laminated epoxy

fibreglass material. When assembled, the overall length of the antenna is approximately 35

feet. The antenna disassembles into 2 sections. The broadband feature of the antenna means

no antenna coupler is required. The transmitter or receiver only is required to be connected

to the antenna.

7

Page 12

VTM-98-006/I

SECTION 4

INSTALLATION

4-1 SITE INFORMATION. Valcom's VBBA 2-30 HF Antenna is designed primarily for

shipboard installation. The antenna can also be used at shore installations. The antenna

should be installed in a non-obstructed environment, clear from any contiguous structures,

such as masts, bulkheads, or other metal objects.

4-2 TOOLS AND MATERIALS REQUIRED.

15/16" (normally) wrenches for 5/8" hardware for antenna base bolts (not provided).

7/16" wrenches for EIA-flange connector (nothing for N-type connector)

#4 Phillips screwdriver for joint screws

No other special tools and materials are required for installation.

4-3 UNPACKING AND REPACKING. Table 1-3 gives data on the overall dimensions, volume,

and weight of the un-crated antenna. To unpack, carefully pry off the cover, and remove the

antenna from the container. Save the container to pack the antenna for reshipment. No

special handling procedures are required; observed normal precautions when handling the

antenna.

4-4 FOUNDATION. The antenna should be installed vertically on a mounting plate that has bolt

holes matching those in the antenna base (see figure 4-1).

4-5 INPUT REQUIREMENTS. The antenna has an rf power handling capability of 3 kW in the

2 to 30 MHz frequency range.

4-6 INSTALLATION PROCEDURES. After unpacking the antenna, proceed with its installation

as follows:

a. Examine the exterior of the antenna for damage; make sure that the top of the lower

section and the bottom of the upper section has not been damaged, misaligned, or fractured.

b. Before assembling the two sections together, the sleeve at top of the bottom section must

be coated with a thin layer of electrically conducting nickel-based anti-seize compound MILA-907E (supplied). A small dab of anti-seize in each of the eight threaded holes will assist

with installing the screws later.

c. Place the bottom section of the antenna on two saw horses. After applying the anti-seize

compound to the mating sleeve, carefully slide the antenna top section over the sleeve

making sure the arrows on each section are aligned.

8

Page 13

VTM-98-006/I

d. Ensure the eight holes are in line between the two sections. Install the eight countersink

flat head screws to the two sections. It is recommended to install all eight screws 3 or 4 turns

before tightening any of them.

e. Begin tightening the screws one by one. A minimum torque of 10-20 in-lbs is required

to install the screws. If less than this torque is used, the thread-locking inserts may be

damaged and need to be replaced. Contact the factory for assistance. A final torque between

55-75 in-lbs is acceptable for the screws, providing the screw head sits flush or slightly

below the antenna surface. After installation, seal the screw heads using the RTV sealant.

f. Carefully lift the antenna to its mounting platform. Align the mounting holes of the base

flange with the mounting holes in the platform.

g. Secure the antenna to its mounting plate with using eight 5/8-11 hex head cap screws (not

provided), along with two flat-washers, a split-lock-washer and a nut. Bolt length will need

to be determined by the installing activity. A final torque between 90-100 ft-lbs is acceptable

for the bolts.

h. Make sure the ground strap supplied with the antenna is connected to one of the mounting

bolts directly below the input connector on the antenna as shown in Figure 4-1.

i. The VBBA 2-30 antenna input is an 7/8 EIA Flange and is found on the base insulator

below the drip shields. Prior to connecting the system feedline, ensure the equipment has

been de-energized and proper lock out procedures followed. Once the lockout procedures

have been performed, connect the system feedline to the antenna. For 1 kW operation with

the antenna, an 7/8 EIA to N Adapter can be supplied for connecting to an N type feedline

cable connector. For more than 1 kW operation, a 7/8 EIA Flange can be supplied for the

feedline used. Ensure the ground wire supplied has a secure connection at the input

connector on one end and the other end to the antenna mounting bolt. Seal the ground

connection at both ends using the RTV sealant provided.

4-7 CABLES AND CONNECTORS. Other types of cables and connectors can be used to

connect the antenna’s input connector to the radio equipment. Some suggestions can be

found in table 4-1.

9

Page 14

Table 4-1 Cable and Connector Group Suggestions

VTM-98-006/I

Group 1

(Heliax Cable)

Group 2

(Heliax Cable)

Group 3

(1kW)

4-8 INSTALLATION CHECKOUT. Checkout of the antenna after installation can only be

accomplished by operating the receiving and transmitting equipment that is used with the

antenna.

Cable: LDF4-50A (COMMSCOPE)

(1/2" Dia., 50 ohm, 6.5 kW @ 30 MHz)

Connector: 7/8 EIA Flange L4E78-PS (COMMSCOPE)

Cable: FSJ2-50 (COMMSCOPE)

(3/8" dia., 50 ohm, 3 kW @ 30 MHz)

Connector: N-TYPE MALE F2TNM-PL (COMMSCOPE)

Cable: RG-214/U

Connector: N-type UG-21E/U

10

Page 15

VTM-98-006/I

Figure 4-1 - Outline Drawing

11

Page 16

5-1 Scheduled Maintenance

The antenna is virtually maintenance free. The external finish is a silicone alkyd paint. The

minimum finish life before showing signs of deterioration should be at least six years under

normal climate conditions.

When used in salt-water environments, it is recommended to wash the antenna base with

fresh water to remove any build-up of dried salt residue. This must be performed on a

monthly basis, when exposed to sea-spray.

Use a small wire brush to clear any debris from the drain groove found in the bottom of the

antenna base.

All threaded hardware, including the base mounting bolts, the countersunk screws at the joint

and the input power connector should be inspected for signs of damage and to ensure proper

tightness (suggested torque settings can be found on pages 8 and 9). In most cases a quick

visual inspection is all that is required. This must be performed on a monthly basis or

whenever practical.

VTM-98-006/I

SECTION 5

MAINTENANCE

5-2 Corrective Maintenance

5-2.1 General Repairs

Generally, no corrective maintenance is possible or required. If one section is severely

damaged, it must be replaced by a new section. Workshops having experience in handling

epoxy fibreglass composite structures and/or aluminum construction may attempt the repair

of minor surface damage if practicable.

DO NOT USE LEAD BASE PAINT TO TOUCH-UP OR REPAINT

THE ANTENNA. USE ONLY EPOXY BASE PAINT.

NOTE

12

Page 17

5-2.2 Cosmetic Repairs

The antenna has been designed to meet and tested to pass Naval Shock and Vibration

requirements (MIL-S-901 and MIL-STD-167 respectively). Under and beyond normal

expected environmental stresses onboard ships, this antenna will not suffer mechanical or

electrical failure. However, over the life of the antenna a seam may become visible just

above the top drip shield. This may appear to be a “crack” in the antenna. However, this is

only a surface crack in the paint layers and the filler material. This location is where the

aluminum radiator meets the fibreglass base and since these materials have different

coefficients of expansion, under high mechanical stress(es), the paint may crack under the

normal flexural movement of the materials. An example can be seen in the below

photograph.

IT IS IMPORTANT TO NOTE IN NO WAY WHATSOEVER IS THIS CRACK

RELATED TO A MECHANICAL FAILURE OF THE ANTENNA.

Should this occur, repairing is not considered to be necessary. Otherwise, to restore the

antenna’s cosmetic appearance, it can be refinished as follows:

- use a small scraper to remove all the loose paint flakes;

- lightly sand the area down;

- re-coat with a durable ship-board grade paint;

- if excessive filler material has fallen out, the groove can be filled back in with a

quality acrylic or silicone sealant after painting.

VTM-98-006/I

13

Page 18

6-1 General

Manufacturer’s contact information can be found in Section 6-2.

6-2 Manufacturer's Address

Postal address: Shipping address:

VTM-98-006/I

SECTION 6

QUICK REFERENCE DATA

Valcom Manufacturing Group, Inc

P.O. Box 603

Guelph, Ontario

Canada

N1H 6L3

Or directly at:

Phone : (519) 824 - 3220

Fax : (519) 824 - 3411

e-mail : enquiries@valcom-guelph.com

Internet : www.valcommfg.ca

Valcom Manufacturing Group, Inc

175 Southgate Drive

Guelph, Ontario

Canada

N1G 3M5

14

Loading...

Loading...