Page 1

PagePac

®

by

40 WATT EXPLOSION PROOF HORN

V-5331215A

INTRODUCTION

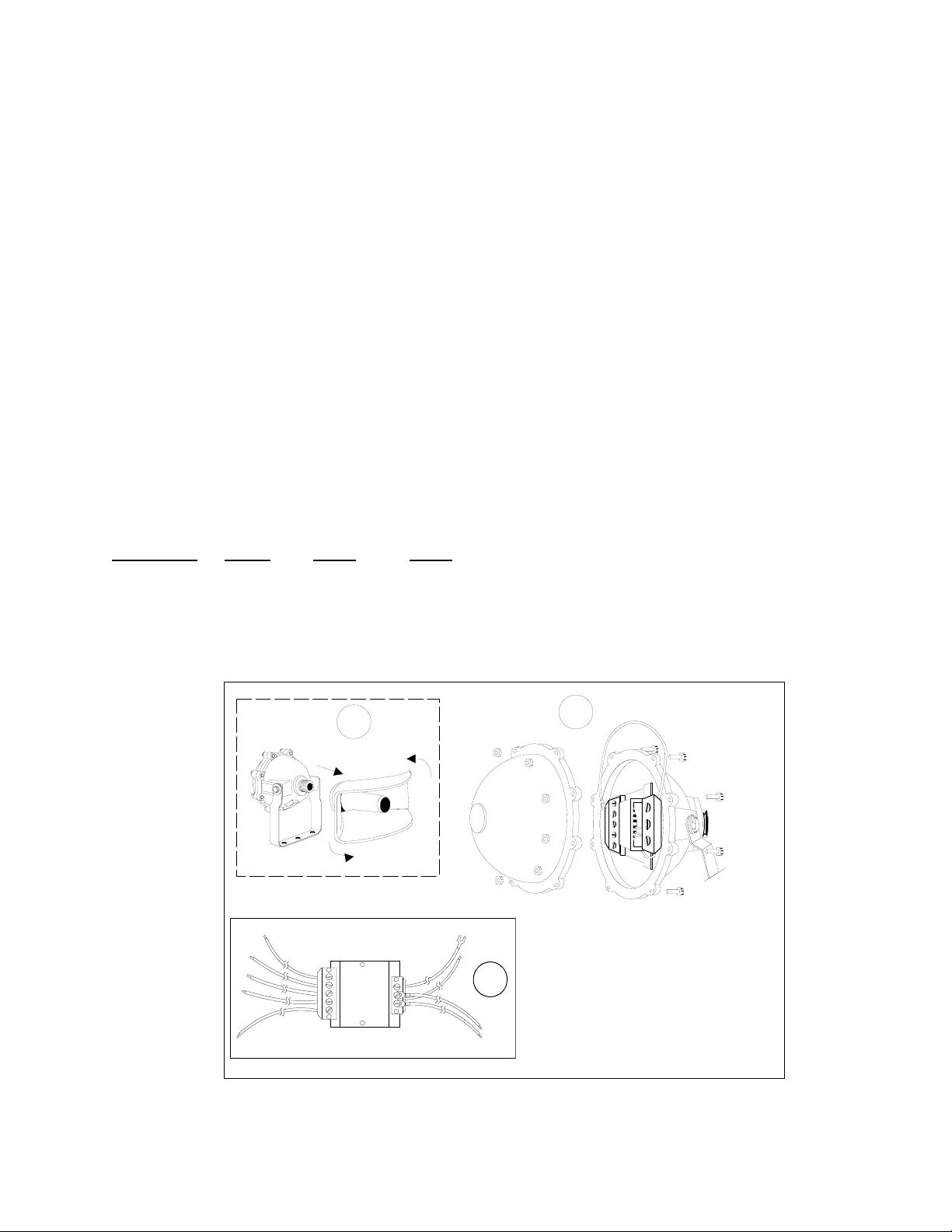

Explosion Proof Horn Speakers are constructed

so that all electrical components are sealed from

the atmosphere and may be used in areas where

flammable substances are present. The exp losion

proof speakers require some assembly before

installation (see Figure 1).

Explosion proof speakers are mounted, using the

U-shaped mounting bracket (attach ed to each

speaker). These brackets are intended primarily

for mounting on flat surfaces, and each bracket

has three holes which may be used for installing

mounting hardware. Speaker position in the vertical axis may be adjusted by loosening the bolts

that secure the bracket to the speaker body

(see Figure 1).

SPECIFICATIONS

FEATURES

• UL/CSA Approved

• Heavy Duty Construction

• Omni-Directional Mounting Bracket

• 5 Tap Settings (2.5W, 5W, 10W, 20W , 40W)

Nominal Specifications

• Dispersion: Wide Angle

• Input: 70.7V Line

• Output: 101dB - 113dB

Dimensions/Weight

• 16.5”Dia. x 21.5”D

(41.9cm x 54.6cm)

• 27 lbs. (12.2 kg)

Environment

• Temperature: -4 to 131° F (-20 to 55° C)

• Humidity: 0 to 95%

Issue 1

INSTALLATION

MOUNTING

Separate the horn and the b ase of the speaker by

holding the base of the speaker tightly and turning

the horn counterclockwise (see Figure 1, View 1).

Separate the two halves of the speaker base by

removing the eight bolts (see Figure 1, View 2).

Make the conduit entry into the speaker as

required by local ordinances f or the class and type

of speaker used (see Figure 1, View 3).

On the speaker cable, separa te the inner wires f or

a distance of 3 or 4 inches by stripping away insulation from the main cable. If us ing shielded cable ,

the inner wire without insulation is the shield wire.

Str ip appr oximately 1/2 inch of insulation from the

end of each of the smaller insulated wires.

Note: The cable must enter t he speaker thr ough a

conduit that has been installed according to local

ordinances for the class and type of speaker

used.

Connect the wires on terminals 1 and 2. If

shielded cable is used, either splice the shield

wire to provide a continuous shield to the next

speaker, or clip the shield wire at the point where

it emerges from the main cable, as appropriate.

The shield wire should not be terminated on the

speaker.

1947190

Page 2

POWER ADJUSTMENTS

If necessary, remove the power tap selection wire

(white wire) and reattach it to the desired power

tap. The numbers on the terminal strip indicate the

output in watts for a 70-volt pagi ng system (on a

25-volt paging system, the output wil l be approximately 1/8 of that indicated (see Table 1)).

Reassemble the two halves of the speaker case

by reinstalling the eight bolts.

CONNECTION TO AMPLIFIER

Exercise special care in removing back cover of

explosion proof driver enclosure (Part 1) to avoid

damaging machined surfaces. Prior to reassembly, make certain that joining surfaces of enclosure are free of dirt. Tighten all cover bolts

completely. To provide the specified protection in

hazardous locations, please note that no compound of any type is to be applied on machined

flange.

TABLE 1. 40-Watt Explosion Proof

Impedance 70V Power 25V Power

Tap Setting

1 2K 2.50 0.330

2 1K 5.00 0.650

3 500 10.0 1.30

4 250 20.0 2.60

5 125 40.0 4.80

Ohms Watts Watts

TECHNICAL ASSISTANCE

When calling, have a VOM and a telephone test

set available and call from the job site. Call (540)

427-3900 and ask for PagePac Technical Support, or call (540) 427-6000 for Valcom 24-hour

Automated Support. Visit our websites at

http://www.pagepac.com and www.valcom.com.

Should repairs be necessary, attach a tag to the

unit clearly stating company name, address,

phone number , contact person, and the nature of

the problem. Send the unit to:

Valcom, Inc.

PagePac

5614 Hollins Road

Roanoke, VA 24019-5056

®

Repair Dept.

1

CONNECT TO DESIRED POWER TAP

CONNECT TO DESIRED

12

3

3 2 1

40W 20W 10W 5W 2.5W

40W 20W 10W 5W 2.5W

POW ER TAP

FROM ADAPTER

FROM AMPLIFIER

3

3

2

Each explosion proof speaker has a one-

Each explosion-proof speaker has

half-inch conduit access into the sealed

a one-half-inch conduit access into

case. Conduit entry into the speaker must

the sealed case. C onduit entry into

be made in accordance with local codes

the speaker m ust be m ade in

accordance w ith lo cal cod es for th e

for the Class and Group of speaker being

C lass and G roup of speaker being

used. See Connection Procedures.

u s e d . S e e C o n n e c tio n P ro c e d u re s .

Figure 1

2947190

Loading...

Loading...