Page 1

VSP-V-1080

Issue 3

V-1080 FLEXHORN

THREE WATT ONE-WAY PAGING HORN

INTRODUCTION

The Valcom V-1080 Flexhorn is a one-way

self-amplified paging horn designed to provide voice

paging as well as background music. This horn is

weatherproof and can be used indoors or outside in

environments ranging from -20 to +55°C. A volume

control is accessible on the front of the cone. The horn

is offered in gray, beige and white.

Model V-1080-GY Gray

Model V-1080-BG Beige

Model V-1080-W White

Dimensions/Weight

• 6.80"H x 8.30"W x 3.30"D

(17.27cm H x 21.08cm W x 8.38cm D)

• 2.1 lbs. (0.95 kg)

The V-1080 requires -24VDC, 150mA (3 Valcom

Power Units) and is FCC Part 68 Registered under

BAFUSA-69358-KX-N.

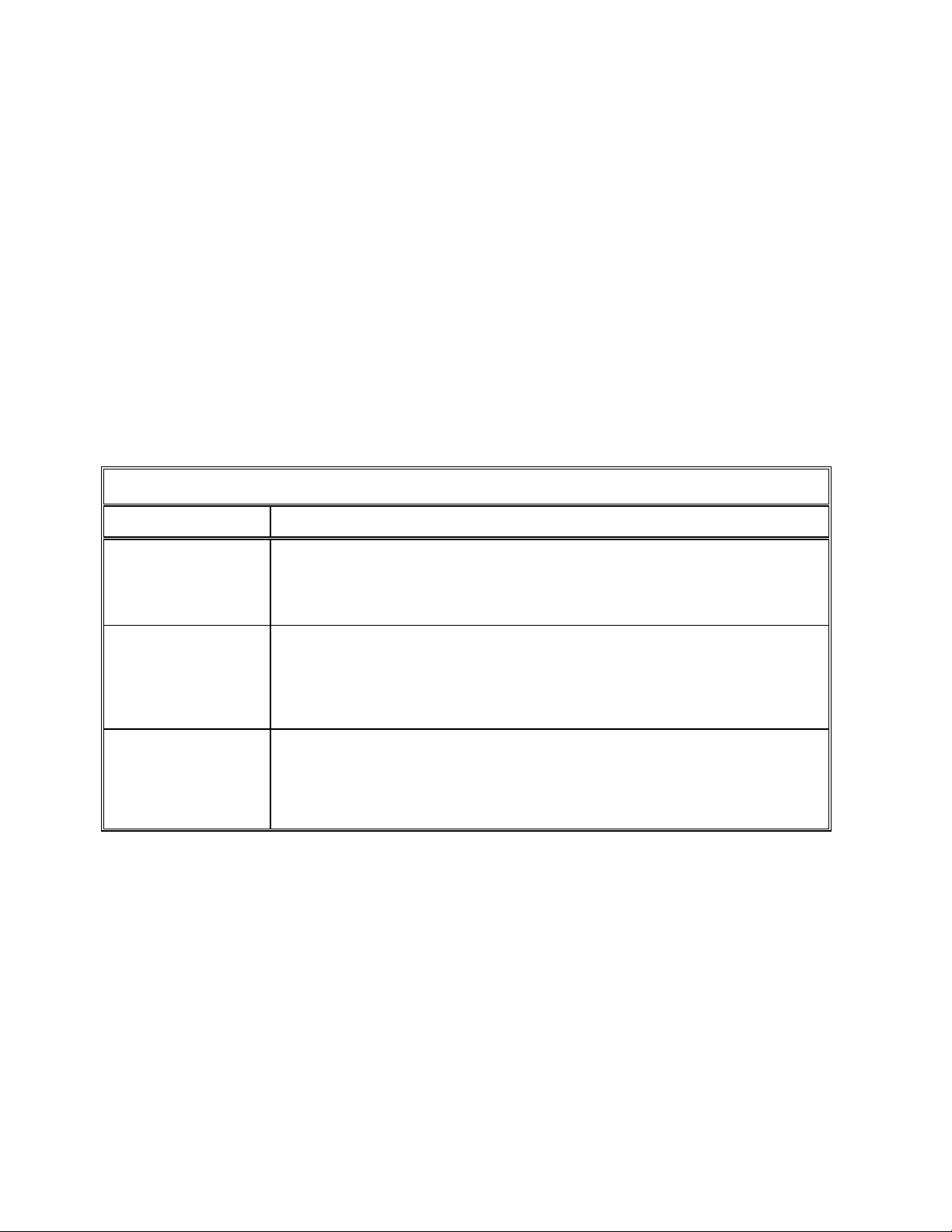

CONNECTIONS

Page

Out

Valcom Page

Control

(Tip/A) Green

(Ring/B) Red

(-24VDC) White

(GND) Black

Valcom -24VDC

Power Supply

One-Way

Amplified

Speaker

NOTE: Do not connect this speaker directly to

a 25/70/100 Volt amplifier as damage to both

the amplifier and speaker may occur. A V-1095

can be used to provide an interface between a

centrally amplified speaker line and Valcom

self-amplified horns.

POWER WIRE RUN

# Horns per

Power Run

V-1080

(3 Watts)

5 250 400

2 500 800

1 760 1200

Wire Run Length (feet)

24 AWG

22 AWG

MOUNTING INSTRUCTIONS

FLUSH MOUNT

Using the template packaged with the speaker, draw the

speaker outline on the wall to be cut. Make appropriate

wiring connections and test the speaker for operation.

Using appropriate mounting screws (not furnished)

drill and mount the flange as shown.

UNIVERSAL BRACKET

Loosen or separate the universal bracket leaves by

loosening or removing the handle and hardware. Using

the back leaf as a template, mark the wall through the

mounting holes, drill and mount to the wall using

appropriate screws (not furnished) or mount directly to

a junction box.

1 947780

Page 2

Mount the T-bracket to the back of the horn as shown

using the (2) ½ inch screws provided.

"C" CLAMP FOR "I" BEAM MOUNTING

A "C" clamp is provided with the horns to allow

mounting to a beam. Place the bolt through the hole in

the bottom of the base to secure the "C" clamp to the

beam. It is suggested that the horn be mounted to the

underside of the "I" beam to provide maximum

positioning adjustments. Mount "C" clamp with (2) ½

inch screws provided.

TECHNICAL ASSISTANCE

When trouble is reported, verify the unit is properly

connected and there are no broken connections leading

to this unit. Ascertain volume control is turned up.

Assistance in troubleshooting is available from the

factory. When calling, you should have a VOM and a

test set and call from the job site. Call (540) 563-2000

for Technical Support or (540) 767-1555 for Valcom

24-hour Automated Support or visit our website at

http://www.valcom.com.

Valcom equipment is not field repairable. Valcom, Inc.

maintains service facilities in Roanoke, VA. Should

repairs be necessary, attach a tag to the unit clearly

stating company name, address, phone number, contact

person and the nature of the problem. Send the unit to:

Repair and Return Dept.

Roanoke, VA 24019-5056

TROUBLESHOOTING CHART

PROBLEM PROBABLE CAUSE AND CORRECTION

Valcom, Inc.

5614 Hollins Road

No Sound - Check volume control turned up (clockwise).

- Check presence and polarity of -24VDC and GND.

- Using a telephone test set, check for the proper audio level on the Tip and Ring

leads and if necessary also at the source.

Low Volume - Check volume control is turned up (clockwise).

- Check voltage at the horn when in use, -20 to -24VDC required.

- Using a telephone test set, check for proper audio level on Tip and Ring leads.

It is possible that some low level audio will be heard with only one side of Tip

and Ring connected.

Loud Squeal - Lower volume of horn.

- Aim horn in different direction.

- Increase the distance between the telephone and horn.

- Install a confidencer on the telephone in severe problem areas.

- Add a V-9964, Stacking Feedback Eliminator.

2

Page 3

UNIVERSAL BRACKET

SURFACE MOUNTED WITH A

UNIVERSAL MOUNTING BRACKET

"C" CLAMP FOR "I" BEAM MOUNTING

ATTACH CLAMP TO HORN ATTACH FLEXHORN TO BEAM

FLUSH MOUNT USING MOUNTING SCREWS:

UNIVERSAL BRACKET WITH CLAMP

USING THE TEMPLATE, MARK LOCATION OF

OPENING AND MOUNTING HOLES ON WALL.

DRILL HOLES APPROPRIATE TO MOUNTING

HARDWARE AND CUT OUT THE OPENING.

PENDANT MOUNTING WITH

OPTIONAL CHAIN AND

'EYE' SCREW

HOLDING FLEXHORN FIRMLY AGAINST A FLAT

SURFACE, DRILL THROUGH EACH MOUNTING BOSS

AS SHOWN.

FLUSH MOUNTING IN A STUD WALL

INSTALLED WITH MOUNTING SCREWS

OR CONSTRUCTION CEMENT.

OTHER MOUNTING OPTIONS:

OPTIONAL V-9805

VANDAL RESISTANT ENCLOSURE

3

Page 4

VALCOM LIMITED WARRANTY

Valcom, Inc. warrants its products to be free from defects in materials and workmanship under conditions of normal use and

service for a period of one year from the date of shipment. The obligation under this warranty shall be limited to the replacement,

repair or refund of any such defective device within the warranty period, provided that:

1. inspection by Valcom, Inc. indicates the validity of the claim;

2. the defect is not the result of damage, misuse or negligence after the original shipment;

3. the product has not been altered in any way or repaired by others and that factory sealed units are unopened (a service

4. freight charges for the return of products to Valcom are prepaid;

5. all units ‘out of warranty’ are subject to a service charge. The service charge will cover minor repairs (major repairs will

This warranty is in lieu of and excludes all other warranties, expressed or implied, anf in no event shall Valcom, Inc. be

liable for any anticipated profits, consequential damages, loss of time or other losses incurred by the buyer in connection

with the purchase, operation or use of the product.

This warranty specifically excludes damage incurred in shipment. In the event a product is received in damaged condition, the

carrier should be notified immediately. Claims for such damage should be filed with the carrier involved in accordance with the

F.O.B. point.

Headquarters: In Canada

Valcom, Inc. CMX Corporation

5614 Hollins Road 35 Van Kirk Drive #11 and 12

Roanoke, VA 24019-5056 Brampton, Ontario L7A 1A5

Phone: (540) 563-2000 Phone: (905) 456-1072

FAX: (540) 362-9800 FAX: (905) 456-2269

charge plus parts and labor will be applied to units defaced or physically damaged);

be subject to additional charges for parts and labor).

4

Loading...

Loading...