Page 1

TECHNICAL MANUAL

VTM-07-007

OPERATION AND INSTALLATION

INSTRUCTIONS

AS-3226C/URC

VHF ANTENNA

Page 2

AS-3226C/URC VTM-07-007

REVISION SHEET

Revision Description Date

- - Original Issue - November 13, 2007

Errors in this publication can be reported to the Manufacturer.

Refer to Section 6 for contact information and address

175 Southgate Drive, P.O. Box 603, Guelph, Ontario, Canada N1H 6L3 Tel: 519-824-3220 Fax: 519-824-3411

Web Site: www.valcom-guelph.com

attention to the Engineering Department.

Valcom Manufacturing Group, Inc.

E-mail: enquiries@valcom-guelph.com

i

Valcom Manufacturing Group, Inc.

Page 3

AS-3226C/URC VTM-07-007

TABLE OF CONTENTS

Section

Page

1 GENERAL INFORMATION AND SAFETY PRECAUTIONS ............... 1

1-1 Safety Precautions ................................................ 1

1-2 Introduction ..................................................... 1

1-3 Equipment Description ............................................ 1

1-4 Relationship to Other Equipment .................................... 1

1-5 Reference Data .................................................. 1

1-6 Equipment and Documents Supplied ................................. 1

1-7 Equipment and Publications Required But Not Supplied .................. 1

2 OPERATION ........................................................ 5

2-1 General ........................................................ 5

3 FUNCTIONAL DESCRIPTION ......................................... 6

3-1 Functional Description .............................................. 6

a. Electrical Balance .......................................... 6

b. Radiation Patterns .......................................... 6

4 SCHEDULED MAINTENANCE ........................................ 7

4-1 Introduction ..................................................... 7

4-2 Scheduled Maintenance Action Index ................................ 7

4-3 Preventive Maintenance Procedures .................................. 7

4-4 Scheduled Performance Tests ....................................... 8

a. Safety Precautions .......................................... 8

b. Tools and Test Equipment ................................... 8

c. Title of Test ............................................... 8

d. Minimum Rating of Technician ............................... 8

e. VSWR Test Setup .......................................... 8

f. Procedures ................................................ 9

g. Test Values ............................................... 9

h. Corrective Actions ......................................... 9

5 TROUBLESHOOTING ............................................... 10

5-1 Introduction .................................................... 10

5-2 Troubleshooting Index ........................................... 10

5-3 Maintenance Turn-On Procedures .................................. 10

5-4 Troubleshooting Procedures ....................................... 10

6 CORRECTIVE MAINTENANCE ...................................... 12

ii

Valcom Manufacturing Group, Inc.

Page 4

AS-3226C/URC VTM-07-007

6-1 Introduction .................................................... 12

6-2 Adjustments and Alignment ....................................... 12

6-3 Repair ........................................................ 12

7 PARTS LIST ........................................................ 13

7-1 Introduction .................................................... 13

a. List of Parts ............................................. 13

b. List of Manufacturers ...................................... 13

8 INSTALLATION .................................................... 14

8-1 Site Information ................................................ 14

8-2 Tools and Materials Required ...................................... 14

8-3 Unpacking and Repacking ........................................ 14

8-4 Foundation .................................................... 14

8-5 Input Requirements .............................................. 14

8-6 Installation Procedures ........................................... 14

8-7 Installation Checkout ............................................ 14

LIST OF FIGURES

Figure Page

1-1 VHF Antenna AS-3226C/URC ...................................... 2

3-1 Balancing Transformer Arrangement ................................. 6

4-1 VSWR Test Setup ................................................ 9

8-1 Installation Data ................................................ 15

LIST OF TABLES

Table Page

1-1 Reference Data ........................................................ 3

1-2 Equipment and Documents Supplied ....................................... 3

1-3 Equipment and Publications Required But Not Supplied ........................ 4

1-4 Field and Factory Changes ............................................... 4

4-1 Scheduled Maintenance Action Index ...................................... 8

5-1 Troubleshooting Index ................................................. 10

5-2 Troubleshooting Procedures ............................................. 11

7-1 List of Parts .......................................................... 13

7-2 List of Manufacturers .................................................. 13

iii

Valcom Manufacturing Group, Inc.

Page 5

AS-3226C/URC VTM-07-007

SECTION 1

GENERAL INFORMATION AND SAFETY PRECAUTIONS

1-1. SAFETY PRECAUTIONS. When working in the vicinity of VHF Antenna AS-

3226C/URC, make sure the antenna is de-energized in accordance with the WARNING in

paragraphs 4-3 and 4-4, and when testing the antenna, make sure the test equipment is properly

grounded in accordance with WARNING in paragraph 4-4.

1-2. INTRODUCTION. This manual provides general information, operating and functional

descriptions, maintenance and troubleshooting instructions, parts list data, and installation data

for VHF Antenna AS-3226C/URC.

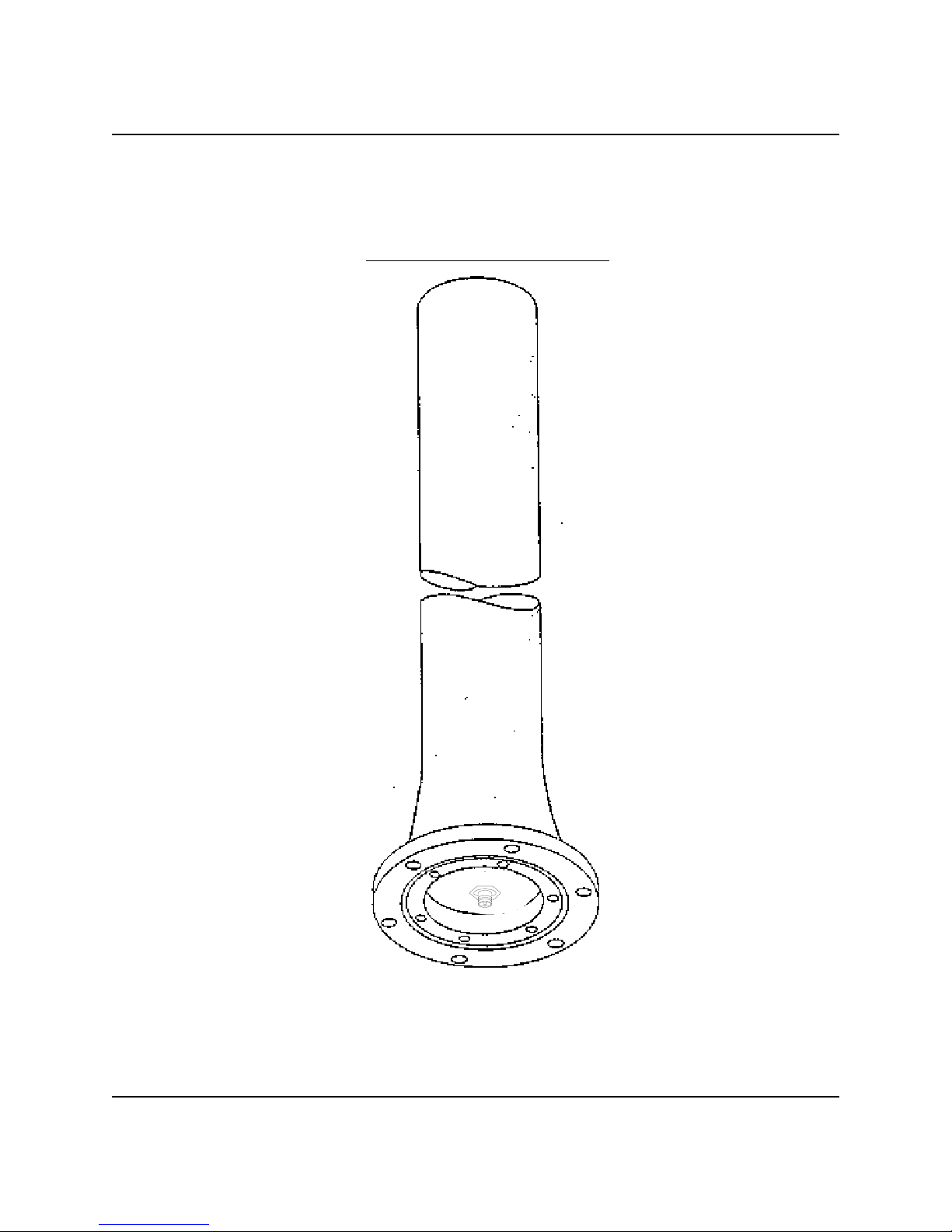

1-3. EQUIPMENT DESCRIPTION. The AS-3226C/URC VHF Antenna (see figure 1-1) is a

general purpose, high performance, reliable, vertically polarized, broadband dipole covering the

30 to 108 MHz frequency range. It is designed for use under the severe environmental conditions

encountered aboard naval vessels. It is used for either receiving or transmitting Very High

Frequency signals. The antenna is a base-mounted light-weight, single piece fiberglass vertical

dipole.

1-4. RELATIONSHIP TO OTHER EQUIPMENT. The AS-3226C/URC VHF Antenna

interfaces with the ship's VHF receiving and transmitting equipment.

1-5. REFERENCE DATA. Table 1-1 lists the reference data for the antenna.

1-6. EQUIPMENT AND DOCUMENTS SUPPLIED. Table 1-2 lists the equipment and

documents supplied.

1-7. EQUIPMENT AND PUBLICATIONS REQUIRED BUT NOT SUPPLIED. Table 1-3

lists the equipment and publications required but not supplied.

1

Valcom Manufacturing Group, Inc.

Page 6

AS-3226C/URC VTM-07-007

Figure 1-1 VHF Antenna AS-3226C/URC

2

Valcom Manufacturing Group, Inc.

Page 7

AS-3226C/URC VTM-07-007

Table 1-1. Reference Data

Parameter Specification

Nomenclature Antenna AS-3226CB/URC

Manufacturer Valcom Mgf Grp, Inc 35736

Frequency Range 30 to 108 MHz

Impedance 50 ohms

VSWR less than 3.0:1

Polarization Vertical

Power Capability 1000 watts

Gain 0 dBi (nominal)

Radiation Pattern Horizontal - omnidirectional

Vertical - figure 8

Temperature Operating: -54°C to +65°C

Non Operating: -62°C to +71°C

Wind Velocity 120 mph

Humidity 95%

Shock Qualified to meet MIL-S-901C, Grade A

Vibration Qualified to meet MIL-STD-167, Type I

Table 1-2. Equipment and Documents Supplied

Overall Dimensions (inches)

Qty Nomenclature

Crated Uncrated

Weight

Uncrated

Length Width (sq) Height Diameter

1

1

VHF Antenna AS3226C/URC

Technical Manual

VTM-07-00?

156 18 149 4.25 47 lbs

-- -- -- -- --

Table 1-3. Equipment and Publications Required But Not Supplied

3

Valcom Manufacturing Group, Inc.

Page 8

AS-3226C/URC VTM-07-007

Category

Power Supply

Modulating

Source

VHF Generator

Recommended

Equipment

General Radio

Type 1203-B

General Radio

Type 1214-A

General Radio

Type 1211-C and

Hewlett

Packard

Generator

Model 608E

Type 1215-C

Impedance

Bridge

Standing Wave

Indicator

Electronic

Counter

PRD Electronic

Type 3302

HP Model 415B

HP Type 5246L

--

General Radio

Type 1234

HP Type

5340A

Megohmmeter Freed Type 1620 --

Alternate

Test

Parameter

VSWR equal to

or less than 3.0:1

Insulation

Resistance

greater than 1

megohm

Application

Scheduled

maintenance

and troubleshooting

Troubleshooting

Table 1-4. Field and Factory Changes

Change Number Nomenclature Description

None -- --

4

Valcom Manufacturing Group, Inc.

Page 9

AS-3226C/URC VTM-07-007

SECTION 2

OPERATION

2-1. GENERAL. The AS-3226C/URC Antenna has no operating controls or indicators. It

operates only when the ship's VHF receiving and transmitting equipment is operated.

5

Valcom Manufacturing Group, Inc.

Page 10

AS-3226C/URC VTM-07-007

SECTION 3

FUNCTIONAL DESCRIPTION

3-1. FUNCTIONAL DESCRIPTION. The AS-3226C/URC VHF Antenna is a general

purpose, high performance, vertically polarized, broadband, balanced dipole covering the 30 to

108 MHz frequency range. It is used for either transmitting or receiving. The antenna is a

cylindrical dipole radiator fed by a conventional coaxial RF line. Integrated into the antenna

structure is a balancing transformer arrangement, which allows the dipole radiator to be fed in a

balanced manner eliminating extraneous line currents. (see figure 3-1).

a. Electrical Balance

. The electrical balance provided for the radiating elements permits

feeding the antenna directly by 50 ohm coaxial cable. The input VSWR is less than

3.0:1 on 50 ohms.

b. Radiation Patterns. Radiation patterns for the antenna correspond to those of a

balanced dipole in free space. Coverage in the plane perpendicular to the radiating

elements is omnidirectional. Figure 8 coverage, with nulls off the ends of the

elements, is provided in the plane of the radiators. The inherent broadband impedance

characteristics make the antenna relatively insensitive to its mounting environment

and minimize azimuth and zenith pattern distortion at any location.

Figure 3-1 Balancing Transformer Arrangement

6

Valcom Manufacturing Group, Inc.

Page 11

AS-3226C/URC VTM-07-007

SECTION 4

SCHEDULED MAINTENANCE

4-1. INTRODUCTION. This section provides preventative maintenance procedures and

scheduled performance tests to be accomplished on a regularly scheduled basis. These

procedures, performed as scheduled, will significantly reduce downtime for corrective

maintenance. The arrangement of the material in this section is a scheduled maintenance action

index with supporting test. The scheduled maintenance instructions in this manual are cancelled

when the Planned Maintenance System (PMS) is implemented for this equipment aboard your

ship or station.

4-2. SCHEDULED MAINTENANCE ACTION INDEX. Table 4-1 lists preventive

maintenance procedures and scheduled performance tests.

4-3. PREVENTATIVE MAINTENANCE PROCEDURES. The following procedures

included the information required for the antenna preventive maintenance:

WARNING

The antenna operates at 1000 watts. Ensure that the transmitting equipment

is de-energized prior to performing the preventive maintenance procedure.

b. Visually inspect the antenna for dirt. Wash dirt off the antenna with soap and water. A

technician with a minimum rating of ETN3 can perform the task.

b. Visually check painted surfaces for wear, chipping, etc. Paint the antenna with grey

epoxy enamel (MIL-P-24441). A technician with a minimum rating of ETN3 can

perform this task.

7

Valcom Manufacturing Group, Inc.

Page 12

AS-3226C/URC VTM-07-007

4-4. SCHEDULED PERFORMANCE TESTS. The following procedures include the

information required for checking the VSWR:

WARNING

The antenna operates at 1000 watts. Ensure that the transmitting equipment

is de-energized when performing the following test. Also make sure the test

equipment is grounded.

a. Safety Precautions. Be sure the transmitting equipment is deenergized and the test

equipment is properly grounded.

Table 4-1. Scheduled Maintenance Action Index

Periodicity Maintenance Action Reference

A Inspect antenna for dirt 4-3.a

A

Check painted surfaces for wear,

chipping, etc.

4-3.b

A Check the VSWR of the antenna 4-4

b. Tools and Test Equipment. No tools are required. The power supply, modulating

source, VHF generator, impedance bridge, standing wave indicator and electronic

counter in table 1-3 are used for this check.

c. Title of Test. The title of the test to be performed is VSWR Test.

d. Minimum Rating of Technician

. A technician with a minimum rating of ETN3 can

perform this task.

e. VSWR Test Setup. Figure 4-1 shows the VSWR test setup for the antenna.

8

Valcom Manufacturing Group, Inc.

Page 13

AS-3226C/URC VTM-07-007

f. Procedures.

(1) Prepare test setup as shown in figure 4-1.

(2) At 10 MHz intervals between 30 MHz and 100 MHz, inclusive, plus 108 MHz,

perform the following steps.

(a) Tune VHF generator to desired frequency as indicated on electronic counter.

(b) Tune impedance bridge for maximum reading as indicated on standing wave

indicator.

(c) Set reference level on standing wave indicator to 1.0 on SWR scale.

(d) Tune impedance bridge for minimum reading as indicated by standing wave

indicator.

(e) Read VSWR on standing wave indicator on SWR scale.

g. Test Values. If VSWR is 3.0:1 or greater, internal damage is indicated.

h. Corrective Action. Refer to table 5-3 for corrective actions.

Figure 4-1 VSWR Test Setup

9

Valcom Manufacturing Group, Inc.

Page 14

AS-3226C/URC VTM-07-007

SECTION 5

TROUBLESHOOTING

5-1. INTRODUCTION. Transmission trouble in the receiving or transmitting system of which

the AS-3226C/URC VHF Antenna is a part may be caused by trouble in the antenna, in another

piece of equipment, or in the transmission line. If trouble occurs, check to determine that the

equipment and the RF transmission line being used with the antenna are functioning properly

before attempting to follow the procedures described in this section. The antenna is essentially a

sealed assembly and as such is non repairable.

5-2. TROUBLESHOOTING INDEX. Table 5-1 lists possible troubles with references to the

appropriate procedures in this section.

5-3. MAINTENANCE TURN-ON PROCEDURE. The AS-3226C/URC VHF Antenna is

turned on when the ship's VHF receiving and transmitting equipment is turned on.

5-4. TROUBLESHOOTING PROCEDURES. Table 5-2 is a troubleshooting procedures

table.

Table 5-1. Troubleshooting Index

Functional

Area

Subnormal antenna

operation

Troubleshooting

Paragraph

5-4 -- 3-1 6-2

Troubleshooting

Diagram

Functional

Description

Paragraph

Alignment

Adjust

Paragraph

Table 5-2. Troubleshooting Procedures

10

Valcom Manufacturing Group, Inc.

Page 15

AS-3226C/URC VTM-07-007

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Low insulation resistance (less

than one megohm as indicated

by megohmmeter connected

between inner and outer

conductors of RF connector

High VSWR (greater than 3.0:1)

as indicated by VSWR test

described in paragraph 4-4.

1. Defective RF connector

or RF gasket.

Replace antenna.

2. Defective internal

assembly in antenna.

1. Defective RF connector

or RF gasket.

Replace antenna.

2. Defective internal

assembly in antenna.

11

Valcom Manufacturing Group, Inc.

Page 16

AS-3226C/URC VTM-07-007

SECTION 6

CORRECTIVE MAINTENANCE

6-1. INTRODUCTION. No corrective maintenance can be performed on the AS-3226C/URC

VHF Antenna.

6-2. ADJUSTMENTS AND ALIGNMENT. No adjustments and alignment are applicable to

the antenna.

6-3. REPAIR. No repair of the antenna or any of its parts is applicable.

12

Valcom Manufacturing Group, Inc.

Page 17

AS-3226C/URC VTM-07-007

SECTION 7

PARTS LIST

7-1. INTRODUCTION. The parts list for the antenna identifies all shipboard, tender, and

shore-based repair parts including attaching hardware. The parts list is arranged in two tables as

follows:

Table 7-1. List of Parts

Table 7-2. List of Manufacturers

a. List of Parts. Table 7-1 lists the parts of the AS-3226C/URC Antenna as shipped.

b. List of Manufacturers

Code for Manufacturers of the manufacturers supply items for the equipment as

referenced in Table 7-1.

UNIT NUMBER

1 VHF Antenna AS-3226C/URC 7-1

Valcom Manufacturing Group, Inc Code : 35736

Postal address: Shipping address:

Valcom Manufacturing Group, Inc

Guelph, Ontario

. Table 7-2 contains the name, address, and Federal Supply

Table 7-1. List of Major Units

Name of Unit Designation Page Number

Table 7-3. List of Manufacturers

P.O. Box 603

Canada

N1H 6L3

NOMENCLATURE

Valcom Manufacturing Group, Inc

175 Southgate Drive

Hanlon Industrial Park

Guelph, Ontario

Canada

N1G 3M5

13

Valcom Manufacturing Group, Inc.

Page 18

AS-3226C/URC VTM-07-007

SECTION 8

INSTALLATION

8-1. SITE INFORMATION. The AS-3226C/URC VHF Antenna is designed primarily for

shipboard installation. The antenna can also be used at shore installations. The antenna should be

installed in a non-obstructed environment, preferably more than 30 feet from any contiguous

structures, such as masts, bulkheads, or other metal objects.

8-2. TOOLS AND MATERIALS REQUIRED. No special tools and materials are required

for installation.

8-3. UNPACKING AND REPACKING. Table 1-2 gives data on the overall dimensions,

volume, and weight of the crated antenna. To unpack, carefully pry off the cover, and remove the

antenna from the container. Save the container to pack the antenna for reshipment. No special

handling procedures are required; observe normal precautions when handling the antenna.

8-4. FOUNDATION. The antenna should be installed vertically on a mounting plate that has

bolt holes matching those in the antenna base (see Figure 8-1). The mounting plate must have a

center hole to accommodate the transmission line to the antenna.

8-5. INPUT REQUIREMENTS. The antenna has an RF power handling capability of 1000

watts in the 30 to 108 MHz frequency range.

8-6. INSTALLATION PROCEDURES. After unpacking the antenna, proceed with its

installation as follows:

a. Examine the exterior of the antenna for damage; make sure that the RF connector is

not deformed, misaligned, or fractured.

b. Perform an insulation resistance test in accordance with step 1 of Table 5-2.

c. Check the voltage standing wave ratio in accordance with paragraph 4-4.

d. Place the antenna on its mounting plate. Tilt the antenna to connect the input cable to

the RF connector.

e. Secure the antenna to its mounting plate with six 1/2 in. bolts.

14

Valcom Manufacturing Group, Inc.

Page 19

AS-3226C/URC VTM-07-007

8-7. INSTALLATION CHECKOUT. Checkout of the antenna after installation can only be

accomplished by operating the ship's receiving and transmitting equipment that is used with the

antenna.

Figure 8-1 Installation Data of the AS-3226C/URC Antenna

15

Valcom Manufacturing Group, Inc.

Loading...

Loading...