Valco baby HEATRITE ES Series, HEATRITE ES-60, HEATRITE ES-40, HEATRITE ES-80, HEATRITE ES-100 Installation, Operation & Service Manual

...Page 1

FOR YOUR SAFETY

WARNING

Installation must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment or your gas supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or

property damage. Read the Installation, Operation

and Service Manual thoroughly before installing or

servicing this equipment.

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Extinguish any open flame.

6. Leave the building.

7. Immediately call your local gas

supplier after leaving the building.

Follow the gas supplier’s

instructions.

8. If you cannot reach your gas

supplier, call the Fire Department.

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to combustibles away from

heater.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

ES

Gas Fired, Low Intensity

Unitary Heater

Installation, Operation &

Service Manual

ES-40

ES-60

ES-80

ES-100

ES-125

ES-150

ES-175

© 2018 Roberts-Gordon LLC

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your service technician with necessary information.

Val -Co

210 E. Main Street

P.O. Box 117

Coldwater, OH 45828 USA

Telephone: 800.998.2526

Fax: 419.678.2200

www.val-co.com

P/N VES36100NA Rev D 05/18

Page 2

Page 3

© 2018

Roberts-Gordon LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon LLC.

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... 1

1.1 Manpower Requirements ............................................. 1

1.2 Safety Labels and Their Placement ............................. 1

1.3 California Proposition 65 .............................................. 1

SECTION 2: Installer Responsibility ..................................... 4

2.1 Wall Tag ....................................................................... 4

2.2 Corrosive Chemicals.................................................... 4

2.3 National Standards and Applicable Codes .................. 4

SECTION 3: Clearances to Combustibles............................. 5

3.1 Required Clearances to Combustibles......................... 5

SECTION 4: National Standards and Applicable Codes .....8

4.1 Gas Codes................................................................... 8

4.2 Aircraft Hangars ........................................................... 8

4.3 Public Garages ............................................................8

4.4 Electrical ...................................................................... 8

4.5 Venting.........................................................................8

4.6 High Altitude ................................................................ 8

SECTION 5: Major Components ............................................9

5.1 Standard Parts List .................................................... 11

SECTION 6: Heater Installation............................................ 14

SECTION 7: Optional Heater Accessories..........................24

7.1 U-Tube Configuration..................................................24

7.2 Elbow Package Configuration..................................... 27

7.3 Reflector Side Extension ............................................29

7.4 Lower Clearance Shield Installation...........................30

SECTION 8: Venting..............................................................31

8.1 Venting.......................................................................31

8.2 Unvented Operation...................................................32

8.3 Horizontal Venting......................................................32

8.4 Vertical Venting..........................................................32

8.5 Unvented Operation Tube Termination ...................... 32

8.6 Length Requirements ................................................ 32

8.7 Vent Material Recommendations............................... 32

8.8 Horizontal Ventilation 4'' (10 cm) Pipe........................ 33

8.9 Vertical Ventilation 4'' (10 cm) Pipe............................33

8.10 Common Side Wall Venting ..................................... 34

8.11 Common Vertical Venting ........................................35

8.12 Outside Combustion Air Supply ...............................36

SECTION 9: Gas Piping........................................................39

SECTION 10: Wiring ..............................................................41

10.1 Line Voltage Thermostat Wiring...............................41

10.2 Low Voltage Thermostat with One Burner ............... 41

10.3 Low Voltage Thermostat Wiring with

ultiple Burners ....................................................... 42

M

10.4 Internal Wiring..........................................................43

10.5 Ladder Diagram ....................................................... 43

SECTION 11: Operation and Maintenance.......................... 44

11.1 Sequence of Operation ............................................ 44

11.2 To Shut Off Heater.................................................... 44

11.3 To Start Heater ......................................................... 44

11.4 Pre-Season Maintenance and Annual Inspection..... 44

11.5 Maintenance Checklist ............................................. 45

SECTION 12: Troubleshooting............................................. 47

12.1 Troubleshooting Flow Chart ..................................... 48

12.2 Manifold Gas Pressure Setting ................................ 50

SECTION 13: Replacement Parts ........................................ 51

SECTION 14: General Specifications .................................. 53

14.1 Material Specifications............................................. 53

14.2 Heater Specifications............................................... 53

14.3 Suspension Specifications....................................... 53

14.4 Controls Specifications ............................................ 53

Prin ted in U.S.A.

Page 4

Page 5

SECTION 1: HEATER SAFETY

SECTION 1: HEATER SAFETY

Your Safety is Important to Us!

This symbol is used throughout

the manual to notify you of

possible fire, electrical or burn

hazards. Please pay special

attention when reading and

following the warnings in these

sections.

Installation, service and annual inspection of heater

must be done by a contractor qualified in the

installation and service of gas-fired heating

equipment.

Read this manual carefully before installation,

operation or service of this equipment.

This heater is designed for heating nonresidential

indoor spaces. Do not install in residential spaces.

This heater is not certified to meet the requirements

of NFPA30A-2012 Section 7.6.6. (maximum tube

temperature of 750 °F (399 °C)). Do not install this

heater in facilities where compressed natural gas

(CNG) or liquid natural gas (LNG) are present. These

instructions, the layout drawing, local codes and

ordinances, and applicable standards that apply to

gas piping, electrical wiring, venting, etc. must be

thoroughly understood before proceeding with the

installation.

Protective gear is to be worn during installation,

operation and service in accordance to the

Occupational Safety and Hazard Administration

(OSHA). Gear must be in accordance to NFPA 70E,

latest revision when working with electrical

components. Thin sheet metal parts have sharp

edges. To prevent injury, the use of work gloves is

recommended. The use of gloves will also prevent

the transfer of body oils from the hands to the surface

of the reflector.

Before installation, check that local distribution

conditions, nature of gas and pressure, and

adjustment of the appliance are compatible.

This heater must be applied and operated under the

general concepts of reasonable use and installed

using best building practices.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instr

uction concerning use of the appliance by a

person responsible for their safety. Children should

be supervised to ensure that they do no play with the

appliance.

For additional copies of the Installation, Operation

and Service Manual, please contact Val-Co.

1.1 Manpower Requirements

To prevent personal injury and damage to the heater,

two persons will be required for installation.

1.2 Safety Labels and Their Placement

Product safety signs or labels should be replaced by

the product user when they are no longer legible.

Please contact Val-Co or your VAL-CO independent

distributor to obtain replacement signs or labels. See

Page 2, Figure 1 through Page 3, Figure 2.

1.3 California Proposition 65

In accordance with California Proposition 65

requirements, a warning label must be placed in a

highly visible location on the outside of the

equipment (i.e., near equipment’s serial plate). See

label placement drawing on Page 3, Figure 2 for label

location. Avoid placing label on areas with extreme

heat, cold, corrosive chemicals or other elements. To

order additional labels, please contact Val-Co or your

VAL-CO independent distributor.

1 of 53

Page 6

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 1: Top and Bottom Panel Label Placement

Description Part Number

Logo Label 91013205

Vent Length Label 91039500

Gas Connection Label 91018122

Burner Status Light Label 91033301

2 of 53

Page 7

FIGURE 2: Side and Back Panel Label Placement

SECTION 1: HEATER SAFETY

Description Part Number

Rating Plate Label 91010405

Lighting Instruction Plate Label 91029602

Wiring Label 91030308

Clearances to Combustibles Label 91013430

Proposition 65 Label 91070016

Thermostat Connection Label (not shown) 91037902

3 of 53

Page 8

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

CAUTION

Product Damage Hazard

Do not use heater in area containing

corrosive chemicals.

Refer to appropriate Material Safety Data

Sheets (MSDS).

Failure to follow these instructions can result

in product damage.

SECTION 2: INSTALLER RESPONSIBILITY

The installer is responsible for the following:

• To install the heater, as well as the gas and

electrical supplies, in accordance with applicable

specifications and codes. Val-Co recommends

the installer contact a local Building Inspector or

Fire Marshal for guidance.

• To use the information given in a layout drawing

and in the manual together with the cited codes

and regulations to perform the installation.

• To install the heater in accordance with the

clearances to combustibles.

• To furnish all needed materials not furnished as

standard equipment.

• To plan location of supports.

• To provide access on all sides for burner servicing

and removal.

• To provide the owner with a copy of this

Installation, Operation and Service Manual.

• To never use heater as a support for a ladder or

other access equipment and never hang or

suspend anything from heater.

• To ensure there is adequate air circulation around

the heater and to supply air for combustion,

ventilation and distribution in accordance with

local codes.

• To safely and adequately install heater using

materials with a minimal working load of 75 lbs

(33 kg).

• To ensure the heater is placed in an approved

application.

2.1 Wall Tag

A laminated wall tag is available for the heater as

a permanent reminder of the safety instructions and

the importance of the required clearances to

combustibles. Please contact Val-Co or your VAL-CO

independent distributor to obtain the wall tag. Affix

the tag by peeling off the backing of the adhesive

strips on the rear surface and position the tag on a

wall near the

heater (e.g. thermostat or VAL-CO Controller).

A copy of the wall tag (P/N 91037912) is illustrated on

the back cover. For an immediate solution, you may

affix this copy on the wall near the heater.

Know your model number and installed configuration.

Model number and installed configuration are found on

the burner and in the Installation, Operation and

Service Manual. See Page 6, Figure 3 through Page

7, Figure 8. Write the proper clearance dimensions in

permanent ink according to your model number and

configuration in the open spaces on the tag.

2.2 Corrosive Chemicals

Val-Co cannot be responsible for ensuring that all

appropriate safety measures are undertaken prior to

installation; this is entirely the responsibility of the

installer. It is essential that the contractor, the subcontractor, or the owner identifies the presence of

combustible materials, corrosive chemicals or

halogenated hydrocarbons* anywhere in the

premises.

* Halogenated Hydrocarbons are a family of

chemical compounds characterized by the

presence of halogen elements (fluorine, chlorine,

bromine, etc.). These compounds are frequently

used in refrigerants, cleaning agents, solvents, etc.

If these compounds enter the air supply of the

burner, the life span of the heater components will

be greatly reduced. An outside air supply must be

provided to the burners whenever the presence of

these compounds is suspected. Warranty will be

invalid if the heater is exposed to halogenated

hydrocarbons.

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with

the latest revision of the applicable standards and

national codes. This refers also to the electric, gas

and venting installation. Note: Additional standards

for installations in public garages, aircraft hangars,

etc. may be applicable.

4 of 53

Page 9

SECTION 3: CLEARANCES TO COMBUSTIBLES

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

3.1 Required Clearances to Combustibles

Clearances are the required distances that

combustible objects must be away from the heater to

prevent serious fire hazards. Combustibles are

materials that may catch on fire and include common

items such as wood, paper, rubber, fabric, etc.

Maintain clearances to combustibles at all times

for safety.

Clearances for all heater models are located on the

burner of the heater and on Page 6, Figure 3 through

Page 7, Figure 8 in this manual. Check the

clearances on each burner for the model heater

being installed to make sure the product is suitable

for your application and the clearances are

maintained. Read and follow the safety guidelines

below:

• Keep gasoline or other combustible materials

including flammable objects, liquids, dust or

vapors away from this heater or any other

appliance.

• The stated clearances to combustibles represents

a surface temperature of 90 °F (32 °C) above

room temperature. Building materials with a low

heat tolerance (s

canvas, tri-ply, etc) may be subject to degradation

at lower temperatures. It is the installer’s

responsibility to assure that adjacent materials

are protected from degradation.

• Maintain clearances from heat sensitive

equipment and workstations.

• Maintain clearances from vehicles parked below

the heater.

• Maintain clearances from swinging and overhead

doors, overhead cranes, vehicle lifts, partitions,

storage racks, hoists, building construction, etc.

• In locations used for the storage of combustible

materials, signs must be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the

combustibles. Signs must be posted adjacent to

the heater thermostat. In the absence of a

thermostat, signs must be posted in a

conspicuous location.

• Consult local Fire Marshal, Fire Insurance Carrier

or other authorities for approval of proposed

installation when there is a possibility of exposure

to combustible airborne materials or vapors.

• Hang heater in accordance to the minimum

suspension requ

uch as plastics, vinyl siding,

irements on Page 15, Figure 11.

SECTION 3: CLEARANCES TO COMBUSTIBLES

• If the radiant tubes must pass through the building

structure, be sure that adequate sleeving and fire

stop is installed to prevent scorching and/or fire

hazard.

5 of 53

Page 10

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

FIGURE 3: LEVEL REFLECTOR

Model ABCDABCD

ES-40 6 27 53 27 16 69 135 69

ES-60 6 356335168916189

ES-80 6 38 66 38 16 97 168 97

ES-100 6 40 71 40 16 102 181 102

ES-125 6 46 77 46 16 117 196 117

ES-150 6 50 80 50 16 127 204 127

ES-175 8 52 82 52 21 133 209 133

FIGURE 4: LEVEL SIDE REFLECTOR

Model ABCDABCD

ES-40 6 9 53 44 16 23 135 112

ES-60 6 9 63 47 16 23 161 120

ES-80 6 9 70 54 16 23 178 138

ES-100 6 9 77 59 16 23 196 150

ES-125 6 9 83 65 16 23 211 166

ES-150 6 9 86 69 16 23 219 176

ES-175 8 9 88 73 21 23 224 186

(inches) (centimeters)

(inches) (centimeters)

FIGURE 5: TWO SIDE REFLECTORS

Model ABCDABCD

6 of 53

(inches) (centimeters)

ES-40 6 15 53 15 16 39 135 39

ES-60 6 23 66 23 16 59 168 59

ES-80 6 25 72 25 16 64 183 64

ES-100 6 27 78 27 16 69 199 69

ES-125 6 32 84 32 16 82 214 82

ES-150 6 35 88 35 16 89 224 89

ES-175 8 40 91 40 21 102 232 102

Page 11

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings and elbows.

Radiant Tubes

Vent

Pipes

Unvented

Vented

A

E

F

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream

from where the burner and burner tube connect.

FIGURE 6: U-TUBE, LEVEL REFLECTOR

(inches) (centimeters)

Model ABCDABCD

ES-40

ES-60 6 35 63 30 16 89 161 77

ES-80 6 38 69 37 16 97 176 94

ES-100 6 40 76 39 16 102 194 100

ES-125 6 46 79 43 16 117 201 110

ES-150 6 50 84 47 16 127 214 120

ES-175 8 54 87 51 21 138 221 130

- UNAPPROVED -

FIGURE 7: 2-FOOT DECO GRILLE AND PROTECTIVE GRILLE

(inches) (centimeters)

Model ABCDABCD

ES-40 6 27 53 27 16 69 135 69

ES-60 6 35 63 35 16 89 161 89

ES-80 6 38 66 38 16 97 168 97

ES-100 6 40 71 40 16 102 181 102

ES-125 6 46 77 46 16 117 196 117

ES-150 6 50 80 50 16 127 204 127

ES-175 8 52 82 52 21 133 209 133

SECTION 3: CLEARANCES TO COMBUSTIBLES

- UNAPPROVED -

FIGURE 8: VENTING

(inches) (centimeters)

Model A E F A E F

ES-40 14 18 18 36 46 46

ES-60 141818364646

ES-80 20 24 18 51 61 46

ES-100 20 24 18 51 61 46

ES-125 20 24 18 51 61 46

ES-150 20 30 18 51 77 46

ES-175 20 30 18 51 77 46

7 of 53

Page 12

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

SECTION 4: NATIONAL STANDARDS AND

APPLICABLE CODES

4.1 Gas Codes

Type of gas appearing on the nameplate must be

the type of gas used. Installation must comply

with national and local codes and requirements

of the local gas company.

United States: Refer to National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

4.2 Aircraft Hangars

Installation in aircraft hangars must be in

accordance with the following codes:

United States: Refer to Standard for Aircraft

Hangars, NFPA 409 - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

In aircraft storage and servicing areas, heaters

shall be installed at least 10' (3 m) above the

upper surface of wings or of engine enclosures

of the highest aircraft which may be housed in

the hangar. The measurement shall be made

from the wing or engine enclosure (whichever is

higher from the floor) to the bottom of the heater.

• In shops, offices and other sections of aircraft

hangars communicating with aircraft storage or

servicing areas, heaters shall be installed not

less than 8' (2.4 m) above the floor.

• Suspended or elevated heaters shall be so

located in all spaces of aircraft hangars that they

shall not be s

ubject to injury by aircraft, cranes,

movable scaffolding or other objects. Provisions

shall be made to assure accessibility to

suspended heaters for recurrent maintenance

purposes.

4.3 Public Garages

Installation in garages must be in accordance

with the following codes:

United States: Refer to Standard for Parking

Structures NFPA 88A - latest revision or the

Code for Motor Fuel Dispensing Facilities and

Repair Garages, NFPA 30A - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

• Heaters must not be installed less than 8'

(2.4 m) above the floor. Minimum clearances to

combustibles must be maintained from vehicles

parked below the heater.

• When installed over hoists, minimum

clearances to combustibles must be maintained

from the upper most point of objects on the hoist.

4.4 Electrical

Heater must be electrically grounded in

accordance with the following codes:

United States: Refer to National Electrical Code

NFPA 70 - latest revision. Wiring must conform to

the most current National Electrical Code

®

, local

ordinances and any special diagrams furnished.

Canada: Refer to Canadian Electrical Code,

CSA C22.1 Part 1 - latest revision.

4.5 Venting

Venting must be installed in accordance with the

requirements within this manual and the

following codes:

United States: Refer to National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

®

,

8 of 53

4.6 High Altitude

These heaters are approved for installations up

to 2000' (610 m) (US), 4500' (1370 m) (Canada)

without modification. Consult factory if US

installation is above 2000' (610 m) or Canadian

installation is above 4500' (1370 m).

Page 13

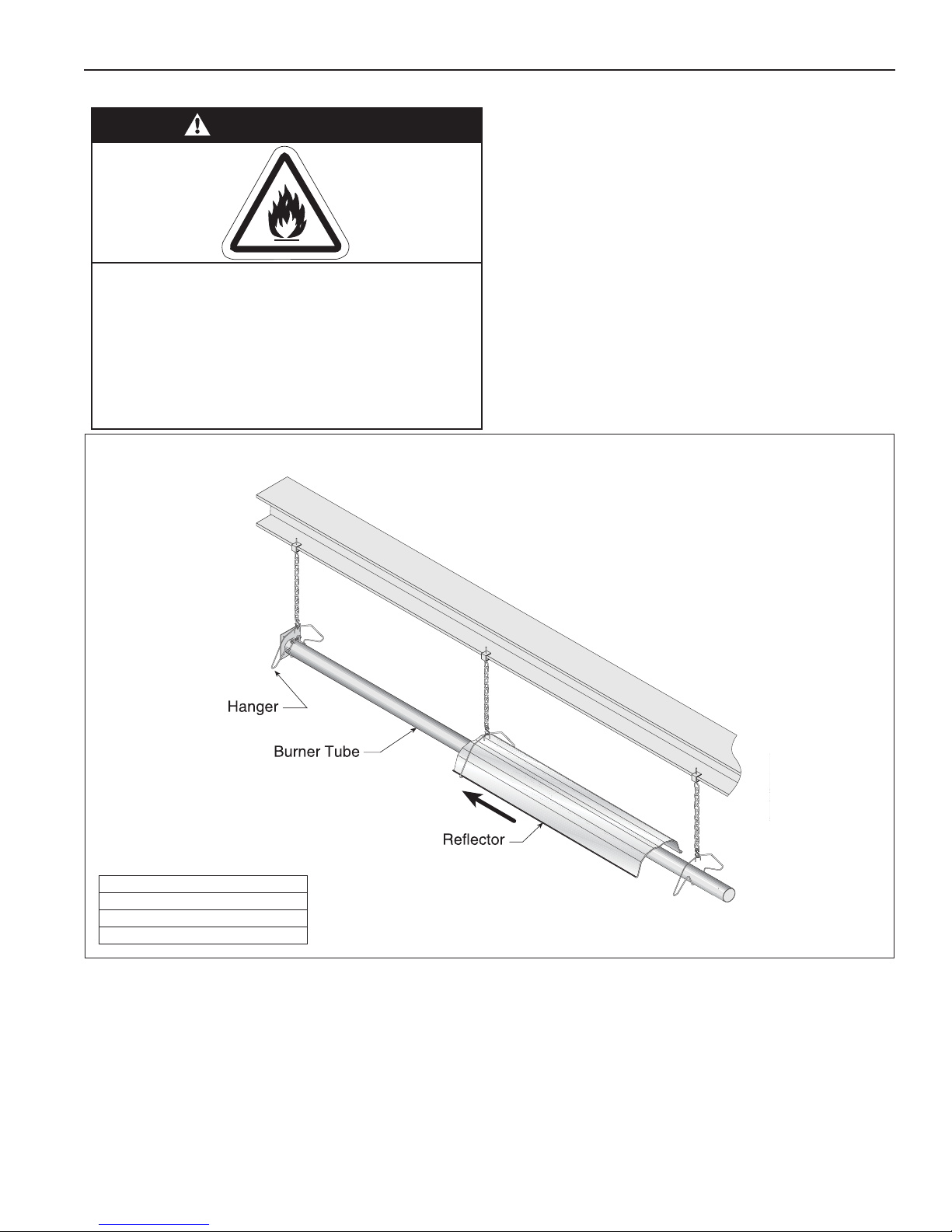

SECTION 5: MAJOR COMPONENTS

FIGURE 9: Major Component Descriptions - Standard Reflector

SECTION 5: MAJOR COMPONENTS

Burner with Tube

Gasket

Must be installed with

the flame observation

window facing down.

Burner Tube

Supplied in 10' (3 m) lengths.

Burner tube is always the first

tube after the burner.

Tube and Reflector Hanger

with Clamp Package

Position this hanger no more

than 4" (10 cm) away from the

burner.

Tube and Reflector Hanger

Suspend system from these

hangers.

Standard

Reflector

(Aluminum or

Stainless

Steel)

Alternate overlap as

shown on overview and on

Page 22, Figure 6.5.1.

Minimum overlap is 6" (16 cm).

Tube

Hot rolled or heat

treated aluminized tube

supplied in 10' (3 m) lengths.

Coupling Assembly

with Lock

Reflector End Cap

Punch out center

section to

accommodate tube.

Vent Adapter

Reflector Support Strap &

Wire Form

Flex Gas Line with

Shut Off Cock

Turbulator

Install turbulator

as specified in the

"Turbulator Installation" chart.

See Page 20, Step 6.4.

Turbulator is not required on the

ES-175.

9 of 53

Page 14

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 10: Major Component Descriptions - High Efficiency Reflector

Burner with Tube

Gasket

Must be installed with

the flame observation

window facing down.

Burner Tube

Supplied in 10' (3 m) lengths.

Burner tube is always the first

tube after the burner.

Tube and Reflector Hanger

with Clamp Package-EF

Position this hanger no more

than 4" (10 cm) away from the

burner.

Tube and Reflector Hanger-EF

Suspend system from these

hangers.

High Efficiency Reflector

(Aluminum only)

Alternate

overlap as

shown on

overview

and

on Page 22, Step 6.5.1.

Minimum overlap is 6" (16 cm).

Tube

Hot rolled or heat

treated aluminized tube

supplied in 10' (3 m) lengths.

Coupling Assembly

with Lock

Reflector End Cap-EF

Punch out center

section to

accommodate tube.

Vent Adapter

Reflector Support Strap &

Wire Form

Flex Gas Line with

Shut Off Cock

10 of 53

Turbulator

Install turbulator

as specified in the

"Turbulator Installation" chart.

See Page 20, Step 6.4.

Turbulator is not required on the

ES-175.

Page 15

SECTION 5: MAJOR COMPONENTS

5.1 Standard Parts List

Table 1: Contents of the Burner Carton

Part No. Description ES-40 ES-60 ES-80 ES-100 ES-125 ES-150 ES-175

47481X Burner Assembly (Rate and Fuel Varies) 1 1 1 1 1 1 1

92700025 Gasket (Burner to Burner Tube) 1 1 1 1 1 1 1

VES36100NA Installation, Operation and Service Manual 1 1 1 1 1 1 1

92113900 Hex Head Nuts 5/16" - 18 Rolok 4 4 4 4 4 4 4

96411600 Split Lock washer 4 4 4 4 4 4 4

91201708 Pipe Nipple (Black) 1/2” NPT x 4” 1 1 1 1 1 1 1

91317300 1/4" Quick Disconnect (Wire) 2 2 2 2 2 2 2

*91412200 Flexible Stainless Steel Gas Hose - 1/2" NPT (US Models Only) 1 1 1 1 1

*91412204 Flexible Stainless Steel Gas Hose - 3/4" NPT (US Models Only) - - - - - 1 1

03051503 Turbulator Adapter 1 1 1 1 1 1 -

03051504 Turbulator Aluminized Steel 3 4 5 4 2 1 -

03051505 Turbulator Stainless Steel 1 - - - - - -

*Canadian Models: Rubber (Type 1) Gas Hoses available as an accessory.

See Page 39, Section 9

.

Table 2: Contents of Standard Core and Extension Packages

Core Packages Extension Packages

Aluminized Aluminized

Part No. Description

91409408

03051105

474833

Tube, HT Aluminized, 10

'

(3 m)

Burner Tube ST, ALUMI-THERM® Steel, 10' (3 m)

Burner Tube ST, HT ALUMI-THERM® Steel, 10' (3 m)

01312700 Coupling Assembly - 1 2 3 1234

02750303

Standard Reflector, 8

'

(3.5 m)

02750800End Cap 2222- - - -

03090101Tube and Reflector Hanger, Wide Pattern 23451234

91907302S-Hook 23451234

03050011 Reflector Support Package (Strap, Wire Form, Screws), Wide Pattern 12352346

91107720 U-Clip Package 11111111

03090101Vent Adapter 1111- - - -

01318901 Tube Clamp Package 1111- - - -

Part Number

10

'

20

'

30

'

40

'

10

'

20

'

30

(3m)

(6m)

(9m)

(12m)

(3m)

(6m)

(9m)

'

(12m)

-1231234

--11----

11------

23462346

40

'

474828

CPWST10ALUM

474829

472830

EXPW10ALUM

EXPW20ALUM

EXPW30ALUM

EXPW40ALUM

11 o f 5 3

Page 16

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Table 3: Contents of High Efficiency Core and Extension Packages

Part No. Description

91409408

Tube, HT Aluminized, 10' (3 m)

'

10

(3m)

-1231234

Core Packages Extension Packages

Aluminized Aluminized

20

'

30

'

40

'

10

'

20

'

30

(6m)

(9m)

(12m)

(3m)

(6m)

'

(9m)

40

(12m)

'

03051105

474833

Burner Tube ST, ALUMI-THERM® Steel, 10' (3 m)

Burner Tube ST, HT ALUMI-THERM® Steel, 10' (3 m)

--11----

11------

01312700 Coupling Assembly - 1 2 3 1 2 3 4

02750313

High Efficiency Reflector, 8

'

(3.5 m)

23462346

02750802 End Cap, High Efficiency 2 2 2 2 - - - -

03090102 Tube and Reflector Hanger, High Efficiency 2 3 4 5 1 2 3 4

91907302 S-Hook 2 3 4 5 1 2 3 4

03050012 Reflector Support Package (Strap, Wire Form, Screws) 1 2 3 5 2 3 4 6

91107720 U-Clip Package 1 1 1 1 1 1 1 1

90508701 Vent Adapter 1 1 1 1 - - - -

01318902 Tube Clamp Package - EF 1 1 1 1 - - - -

Part Number

EXP10ALUMEF

EXP20ALUMEF

CPST10ALUMEF

CPST20ALUMEF

CPST30ALUMEF

CPST40ALUMEF

EXP30ALUMEF

EXP40ALUMEF

12 of 53

Page 17

Table 4: Component Package Guide

Model

ES-40 10’ (3m) CPWST10ALUM

ES-60 20’ (6m) 474828

ES-80 20’ (6m) 474828

ES-100 30’ (9m) 474829

ES-125 40’ (12m) 474830

ES-150 50’ (15m) 474829 + EXPW20ALUM

ES-175 60’ (18m) 474829 + EXPW30ALUM

Table 5: Component Package Guide

Model

ES-40 10’ (3m) CPST10ALUMEF

SECTION 5: MAJOR COMPONENTS

Tubing Length Standard Core Packages-Wide Pattern

Minimum Aluminized

Tubing Length High Efficiency Core Packages

Minimum Aluminized

ES-60 20’ (6m) CPST20ALUMEF

ES-80 20’ (6m) CPST20ALUMEF

ES-100 30’ (9m) CPST30ALUMEF

ES-125 40’ (12m) CPST40ALUMEF

ES-150 50’ (15m) CPST30ALUMEF + EXP20ALUMEF

ES-175 60’ (18m) CPST30ALUMEF + EXP30ALUMEF

Although not recommended, additional tube lengths may be added to the heater. Tubing must be aluminized

(heat-treated or non-heat-treated), or porcelain coated. Additional tube lengths beyond the specified

minimum tubing length are considered vent pipe for length determination. Maximum vent length allowed is

45' (13.7 m) total.

13 of 53

Page 18

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 6: HEATER INSTALLATION

WARNING

Severe Injury Hazard

Secure burner to burner tube with nuts and

lockwashers.

Hang heater with materials with a minimum

working load of 75 lbs (33 kg).

Failure to follow these instructions can result

in death, injury or property damage.

Expansion and contraction of the tube dictates that

the minimum suspension lengths must be

maintained. See table on Page 15, Figure 11.

To ensure your safety and comply with the terms of

the warranty, all units must be installed in

accordance with these instructions.

The gas or the electrical supply lines must not be

used to support the heater.

Do not locate the gas or electric supply lines directly

over the path of the flue products from the heater.

The heater must be installed in a location that it is

readily accessible for servicing.

The heaters must be installed in accordance with

clearances to combustibles as indicated on the rating

plate and in this instruction manual.

The minimum and maximum gas inlet pressures

must be maintained as indicated on the rating plate.

Typical installation configurations are shown on

Page 15, Figure 11.

14 of 53

Page 19

FIGURE 11: Critical Hanger Placement

SECTION 6: HEATER INSTALLATION

Description

S-Hook

Tube/Reflector Hanger

Run Length Typical Expansion Minimum “X” Length

10' (3 m) - 50' (15.2 m) ±1" (3 cm) 12" (30.5 cm)

51' (15.5 m) - 60' (18.3 m) ±2" (5 cm) 18" (45.7 cm)

61' (18.6 m) - 80' (24.4 m) ±3" (8 cm) 24" (61 cm)

15 of 53

Page 20

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 12: Linear Heater Assembly Overview

16 of 53

Page 21

FIGURE 13: Linear Heater Layout Overview

SECTION 6: HEATER INSTALLATION

17 of 53

Page 22

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Step 6.1 Burner Tube Installation

Description

Burner Tube

S-Hook

Tube/Reflector Hanger

Step 6.2 Tube Clamp Package Installation

Description

Tube Clamp Package

18 of 53

Page 23

Step 6.3 Coupling and Tube Assembly

A

Close coupling and slide

opposite end into tab.

Position tab underneath

guide rail.

B

Insert wide end of slide bar/coupling lock into

guide rail on opposite end of tabs. Slide the slide

bar/coupling lock up the guide rail until snug

(approximately 3" (8 cm) to 4" (10 cm)).

C

Insert tubes into coupling

until end of each tube rests

against internal pins.

D

Strike slide bar/coupling lock with mallet or hammer

until tight.

Description

Coupling

Slide Bar/Coupling Lock

Tube

SECTION 6: HEATER INSTALLATION

Step 6.3.1 Coupling and Tube Assembly (Continued)

Tighten slide bar as shown below.

• Repeat Step 6.3 A - D until all tubes are assembled. See Page 20, Step 6.3.2.

19 of 53

Page 24

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

7' 6" ± 1'

(2.3 m ± .25 m)

Step 6.3.2 Coupling and Tube Assembly (Continued)

10' ± 1'

(3 m ± .25 m)

Total Overall

Tube Length

Model

ES-40 10’ (3 m)

ES-60 20 (6 m)

ES-80 20' (6 m)

ES-100 30' (9 m)

ES-125 40' (12 m)

ES-150 50’ (15 m)

ES-175

Tub e Len gth

Mi nimum

Step 6.4 Turbulator Installation

Description

Turbulator Adapter 2.5' (76.2 cm)

Turbulator Section 2' (61 cm)

Turbulator Section 2.5' (76.2 cm) (Stainless)

Tube

Install turbulator as specified in the

“Turbulator Installation” chart below.

Turbulator is not required on the ES-125/150

Turbulator Installation

Model Tube Section

ES-40 1st 10' (3 m) Section

ES-60 2nd 10' (3 m) Section

ES-80 2nd 10' (3 m) Section

ES-100 3rd 10' (3 m) Section

ES-125 4th 10' (3 m) Section

ES-150 5th 10' (3 m) Section

ES-175 N/A

20 of 53

Page 25

Step 6.5 Reflector Installation

WARNING

Fire Hazard

Support reflector with reflector hanger

and support strap.

Reflector must not touch tube.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 6: HEATER INSTALLATION

Description

Tube/Reflector Hanger

Burner Tube

Reflector 96" (244 cm)

21 of 53

Page 26

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Step 6.5.1 Reflector, U-Clip and Reflector Support Installation

The pictorial drawings of the heater construction in

Section 6 are schematic only and provide a general

guideline of where hangers, reflector supports and

U-clips are to be installed.

To ensure proper expansion and contraction

movement of the reflectors, a combination of U-clips

reflector supports and U-clips depend on the

individual installation. Use either pop rivets or sheet

metal screws instead of u-clips when installing end

caps and joint pieces in areas where impact and high

wind may be a factor. The following rules must be

observed.

and reflector supports are used. The positioning of

1. Slide first reflector after burner a minimum 2” (4 cm) through first hanger and

ensure reflector end cap is securely fastened via U-clips, pop rivets, or sheet

metal screws. Position reflector support with tight screws in middle of first

reflector.

Description

Reflector Support Package

Wire Form

Reflector Support Strap, Wide Pattern

Screw #8 x 3/4"

U-Clip Package

Reflector End Cap

22 of 53

NOTE: High efficiency

reflectors should NOT

be used in applications

exposed to wind.

Page 27

Step 6.6 Burner Installation

SECTION 6: HEATER INSTALLATION

Description

Burner

Lock Washer

Nut

Gasket

NOTE: To ensure proper orientation,

attached burner tube with tube weld

facing downward

23 of 53

Page 28

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 7: OPTIONAL HEATER ACCESSORIES

7.1 U-Tube Configuration

Heaters (except ES-40) are approved for optional Utube configurations.

The U-tube may be installed in a standard horizontal

position. When using a U-tube configuration, the

following additional rules must be adhered to:

• A minimum of 10' (3 m) on ES-60/80 and a

'

minimum of 15

required between the burner and the U-tube.

• The correct turbulator (See Page 20, Step 6.4)

must be installed in the last standard section of

the tube.

• The burner must never be operated in a tilted

position.

• The heater must be properly supported at all

locations. See Page 27, Figure 7.2.

(4.5 m) on ES-100/125/150/175 is

24 of 53

Page 29

FIGURE 14: U-Tube Heater Assembly Overview

Secure overlap

with six #8

sheet metal screws.

Reflector Junctions

SECTION 7: OPTIONAL HEATER ACCESSORIES

FIGURE 15: U-tube reflector kit (optional)

Description

Kit, U-tube reflector kit

Reflector Joints

25 of 53

Page 30

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 16: U-Tube Heater Layout Overview

a = 14” (36 cm)

Reflector Width (Not Shown)

b = 2” (5 cm)

End Cap to Burner

c = 2” (5 cm)

End Cap Hanger

d = 7’ 6” (2.3 cm)

Distance Between First and

Second Hangers

e = 10’ (3.0 m)

Distance Between Next Hangers

f = 5’ (1.5 m)

Distance Between Last Full Tube

Hanger and Half Tube Hanger

g = 11.5” (29.2 cm) Burner Length

h = 8” (21.6 cm) Burner Height

* Requires the last reflector

before the u-tube to be cut in

half for use on both sides.

** Requires the last tube before

the u-tube to be cut in half for

use on both sides.

26 of 53

Page 31

7.2 Elbow Package Configuration

Step 7.2.1 Elbow Installation

Description

Elbow Package

90° Elbow

Coupling

Reflector End Cap

Reflector Joint Piece

U-Clip Package

Step 7.2.2 Elbow Installation

SECTION 7: OPTIONAL HEATER ACCESSORIES

Minimum Distance Required

Between Burner and Elbow

Model

ES-40 N/A

ES-60 10' (3 m)

ES-80 10' (3 m)

ES-100 15' (4.5 m)

ES-125 15' (4.5 m)

ES-150 15' (4.5 m)

ES-175 15' (4.5 m)

Minimum

Distance

Step 7.2.3 Reflector Joint Installation

27 of 53

Page 32

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Step 7.2.4 Reflector Joint Installation

Step 7.2.5 Reflector Joint Detail

FIGURE 17: Reflector Joint Detail

28 of 53

Page 33

7.3 Reflector Side Extension

Step 7.3.1 Bracket Installation

Description

Reflector Side Extension Package

Reflector Side Extension

96" (244 cm)

Retainer Clips

Sheet Metal Screws

SECTION 7: OPTIONAL HEATER ACCESSORIES

Order Separately

Reflector Side Extension Bracket

Step 7.3.2 Side Reflector Installation

29 of 53

Page 34

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Lower Clearance Shield

17"

(43 cm)

Washers

Screws

Locknuts

7.4 Lower Clearance Shield Installation

Step 7.4.1 Shield Support Strap Assembly

12"

(30 cm)

Align Pilot Holes

Reflector

Description

Lower Clearance Shield Package

Shield Support Strap

Lower Clearance Shield 8' (2.4 m)

Locknut #8

Flat Washer #8

Screw #8 x 3/8''

30 of 53

Page 35

SECTION 8: VENTING

WARNING

Carbon Monoxide Hazard

Heaters installed unvented must be interlocked

with sufficient building exhaust.

Heaters must be installed according to the

installation manual.

Failure to follow these instructions can result

in death or injury.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

SECTION 8: VENTING

Any portion of vent pipe passing through a

combustible wall must have an approved thimble

to conform with the above listed codes.

Vent pipe must be sloped downward away from the

heater 1/2'' (1 cm) for every 20' (6 m).

The heater may be individually vented or common

vented. When venting horizontally, a maximum of

two heaters can be commonly vented. See Page 34,

Section 8.10. When venting vertically, a maximum of

four heaters can be commonly vented. See Page 35,

Section 8.11.

The heater may also be installed unvented in certain

circumstances according to building ventilation

codes. Refer to the above codes and Page 32,

Section 8.2 for further information. Unvented

operation also requires compliance with the

clearances to combustibles given on Page 7, Figure

8.

8.1 Venting

This heater must be vented in accordance with the

rules contained in this manual and with the following

national codes and any state, provincial or local

codes which may apply:

United States: Refer to National Fuel Gas Code

NFPA 54/ANSI Z223.1 - latest revision.

Canada: Refer to Natural Gas and Propane

Installation Code CSA B149.1 - latest revision.

Exhaust end of heater will accept a 4'' (10 cm) vent

pipe using the vent adapter. To prevent leakage of

condensation, install the vent adapter with the seam

on top and seal the joint using a high temperature

silicone sealant.

The bottom of the vent or air intake terminal shall not

be located less than 1' (0.3 m) above grade level.

The vent shall not terminate less than 7' (2.1 m)

above grade where located adjacent to public

walkways.

Vent terminal must be installed at a height sufficient

to prevent blockage by snow, and building materials

protected from degradation by flue gases.

Secure all joints with #8 x 3/8 sheet metal screws.

Seal all joints with high temperature silicone sealant.

Vent terminal must be beyond any combustible

overhang.

8.1.1 United States Requirements

Vent must terminate at least 3' (0.9 m) above any

forced air inlet located within 10' (3.1 m).

Vent must terminate at least 4' (1.2 m) below, 4'

(1.2 m) horizontally from, or 1' (0.3 m) above any

door, operable window, or gravity air inlet into any

building.

8.1.2 Canadian Requirements

The vent shall not terminate within 6' (1.8 m) of a

mechanical air supply inlet to any building.

The vent shall not terminate within 3' (0.9 m) of a

window or door that can be opened in any building,

any non-mechanical air supply inlet to any building,

or of the combustion air inlet of any other appliance.

31 of 53

Page 36

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

8.2 Unvented Operation

Sufficient ventilation must be provided in the amount

of 4 cfm per 1000 Btu/h firing rate (United States); 3

cfm per 1000 Btu/h firing rate (Canada).

Use of optional outside combustion air is not

recommended with unvented heaters.

If exhaust fans are used to supply ventilation air, an

interlock switch must be used to prevent the heater

from coming on when the fans are off. This may be

done using a pressure switch.

8.3 Horizontal Venting

In noncombustible walls only, vent terminal may be

used.

For 4" (10 cm) vents in either combustible or

noncombustible walls, use Tjernlund VH1-4 or

equivalent, insulated vent terminal. Follow the

manufacturer's instructions for proper

installation.

For 6" (15 cm) common vents in either combustible

or noncombustible walls, use Tjernlund VH1-6 or

equivalent, insulated vent terminal. Follow the

manufacturer's instructions for proper installation.

8.4 Vertical Venting

For 4'' (10 cm) common vent, an approved vent cap

must be used.

For 6'' (15 cm) common vent, an approved vent cap

must be used.

For common vertical venting of more than two

heaters, See Page 35, Section 8.11.

8.6 Length Requirements

The maximum vent length allowed is 45' (13.7 m).

The maximum outside air supply duct length allowed

is 45' (13.7 m).

The total vent length, plus outside air duct length,

plus any extensions to minimum heat exchanger

lengths, cannot exceed 65' (19.8 m).

Vent length should be limited to less than 20' (6 m).

If using vent lengths greater than 20' (6 m),

condensation will form in the vent pipe. Insulation

and additional sealing measures (high temperature

silicone at all seams) are required. Optional heat

exchanger beyond minimum lengths is considered

as vent length for length determination.

Subtract 15' (4.6 m) of maximum allowed vent or

duct length per vent elbow if more than two are

used.

8.7 Vent Material Recommendations

Vent recommendations:

1. Porcelain coated tubing 4'' (10 cm) O.D.

2. Heat treated aluminized tubing 4'' (10 cm) O.D.

Heat treated aluminized tubing 6'' (15 cm) O.D.

3. Single wall flue pipe - minimum 26 ga.

(Supplied by others)

NOTE: 4" (10 cm) O.D. Porcelain coated tubing, 4"

(10 cm) O.D. Heat treated aluminized tubing, and 6"

(15 cm) O.D. Heat treated aluminized tubing are

equivalent to single wall flue pipe.

A vent shall not extend less than 2' (0.6m) above the

highest point where it passes through a flat roof of a

building.

8.5 Unvented Operation Tube Termination

Turndown type vent terminal with a screen must be

installed at the exhaust end of the tube. Vent

terminal design shall not incorporate backdraft flap.

FIGURE 18: Tube Termination

32 of 53

Page 37

8.8 Horizontal Ventilation 4'' (10 cm) Pipe

4" (10 cm)

Single Wall Pipe

Vent Adapter

Vent Terminal

Combustible or

Non-Combustible Wall

Vent Adapter

18" (46 cm)

Min.

Vent Terminal

4" (10 cm) Single Wall Pipe

Non-Combustible Wall Only

SIDE VIEW

Description

Vent Terminal (Comb. Wall)

Vent Terminal

8.9 Vertical Ventilation 4'' (10 cm) Pipe

SECTION 8: VENTING

Description

Vent Cap 4" (10 cm)

33 of 53

Page 38

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

8.10 Common Side Wall Venting

Description

Vent Terminal 6" (15 cm)

Requirements:

• Maximum of two heaters can be commonly

vented through a side wall.

• Heaters must be of the same BTU output.

• Heaters must be controlled by a common

thermostat.

34 of 53

Page 39

8.11 Common Vertical Venting

SECTION 8: VENTING

Requirements:

• Maximum of four heaters can be commonly

vented through the roof.

• Heaters must be of the same BTU output.

• Heaters must be controlled by a common

thermostat.

• Connections to a common stack must be

positioned to avoid direct opposition between

streams of combustion gases.

35 of 53

Page 40

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

8.12 Outside Combustion Air Supply

IMPORTANT: If the building has a slight negative

8.12.1 Length Requirements

Follow the constraints listed on Page 32, Section 8.6.

pressure or corrosive contaminants, such as

halogenated hydrocarbons, are present in the air, an

outside combustion air supply to the heater is

required. Seal all combustion air pipe joints.

Use of optional outside combustion air is not

recommended with unvented heaters.

The air supply duct may have to be insulated to

prevent condensation on the outer surface. The

outside air terminal must not be more than 1' (31 cm)

above the vent termination while maintaining a

minimum distance of 3' (93 cm) for both vertical and

horizontal venting.

8.12.2 Vertical Outside Air Supply for Single Heater Installation

Description

Vent Cap 4" (10 cm)

36 of 53

Page 41

8.12.3 Horizontal Outside Air Supply for Single Heater Installation

Band Clamp

(Recommended)

Flex Hose

(Recommended)

Vent Cap

Wall

Burner

4" (10 cm)

Single Wall Pipe

Description

Vent Cap 4" (10 cm)

SECTION 8: VENTING

8.12.4 Vertical Outside Air with Outside Air Inlet Kit

Description Part Number

Outside Air Inlet Kit 4" 90502401

Bird Screen 01365400

Hose Clamp - 4" 93901300

Vent Pip - 4" OD 90507200

Flange - 4" 90507001

Flexible Vent Pipe - 4" OD 91409603

Screw #12 Hex hd (Self tap) 13404

Description Part Number

Outside Air Inlet Kit 5" 90502403

Bird Screen 01397400

Hose Clamp - 5" 90901301

Vent Pip - 5" OD 90507201

Flange - 5" 90507002

Flexible Vent Pipe - 5" OD 91409604

Screw #12 Hex hd (Self tap) 13404

37 of 53

Page 42

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

8.12.5 Vertical Outside Air Supply for Double Heater Installation

Description

Vent Cap 6" (15 cm)

Requirements:

• Heaters must be controlled by a common thermostat.

8.12.6 Horizontal Outside Air Supply for Double Heater Installation

Description

Vent Cap

6" (15 cm)

30

Requirements:

• Heaters must be controlled by a common thermostat.

38 of 53

Page 43

SECTION 9: GAS PIPING

WARNING

Fire Hazard

Tighten gas hose fittings to connect gas

supply according to Figure 23.

Gas hose can crack when twisted.

Gas hose moves during normal operation.

Use only 36" (91 cm) long connector of 1/2" or

3/4" nominal ID.

Connector supplied with heater for U.S.

models (not with Canadian models).

Failure to follow these instructions can result

in death, injury or property damage.

WARNING

Explosion Hazard

Leak test all components of gas piping

before operation.

Gas can leak if piping is not installed

properly.

Do not high pressure test gas piping with

heater connected.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 9: GAS PIPING Install the gas hose as shown on Page 40, Figure 19.

The gas hose accommodates expansion of the

heating system and allows for easy installation and

service of the burner. Before connecting the burners

to the supply system, verify that all high pressure

testing of the gas piping has been completed.

There is an expansion of the tube with each firing

cycle; this will cause the burner to move with respect

to the gas hose. This can cause a gas leak resulting

in an unsafe condition if the gas connection is not

made strictly in accordance with Figure 19 on Page

40.

Meter and service must be large enough to handle all

the burners being installed plus any other connected

load. The gas hose which feeds the system must be

large enough to supply the required gas with a

maximum pressure drop of 1/2" w.c. When gas piping

is not included in the layout drawing, the local gas

supplier will usually help in planning the gas piping.

Gas lines must meet applicable codes:

United States: The Flexible Stainless Steel Gas

Hose (US models) supplied with the heater is certified per the Standard for Connectors for Gas Appliances, ANSI Z21.24/CSA 6.10 - latest revision.

Canada: The Rubber Type 1 Gas Hose (Canadian

models) optional with the heater is certified as being

in compliance with the Standard for Elastomeric

Composite Hose and Hose Couplings for Conducting

Propane and Natural Gas, CAN/CGA 8.1 - Latest

revision.

• Check the pipe and tubing ends for leaks

before placing heating equipment into

service. When checking for gas leaks, use a

soap and water solution; never use an open

flame.

39 of 53

Page 44

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 19: Gas Connection with Flexible Gas Hose

See Page 53, Section 14

Description

High gas pressure regulator ½” – 2 PSI

High gas pressure regulator ¾” – 5 PSI

Description

1/2" Flexible Stainless Steel Gas Hose (US Models)

3/4" Flexible Stainless Steel Gas Hose (US Models)

1/2" Rubber Type 1 Gas Hose (Canadian Models)

3/4" Rubber Type 1 Gas Hose (Canadian Models)

40 of 53

Page 45

SECTION 10: WIRING

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly earthed.

Failure to follow these instructions can result

in death or electrical shock.

Line Voltage

Thermostat

Gnd.

Gnd.

120 V-60 Hz

Supply Circuit

HN HN

Gnd.

L1

L2

T

Low Voltage

Terminal Detail

On All Burners

10.1 Line Voltage Thermostat Wiring

SECTION 10: WIRING

Heaters can be controlled using several methods.

Normally thermostats are used to control the heaters

but they can also be controlled by an energy

management system. Section 10.1 illustrates the

connection for heaters controlled by a line voltage

thermostat.

For heaters on a low voltage thermostat, See Page

41, Section 10.1. Heaters must be grounded in

accordance with applicable codes: United States:

®

Refer to National Electrical Code

NFPA 70 - latest

revision; Canada: Refer to Canadian Electrical Code

CSA C22.1 Part I - latest revision.

If any of the original internal wiring must be replaced,

it must be replaced with wiring materials having a

temperature rating of at least 105 °C and 600 volts.

10.2 Low Voltage Thermostat with One Burner

120 V-60 Hz

Supply Circuit

L1

L2

Gnd.

Low Voltage

Thermostat

T

HN

Gnd.

Low Voltage

Terminal Detail

41 of 53

Page 46

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

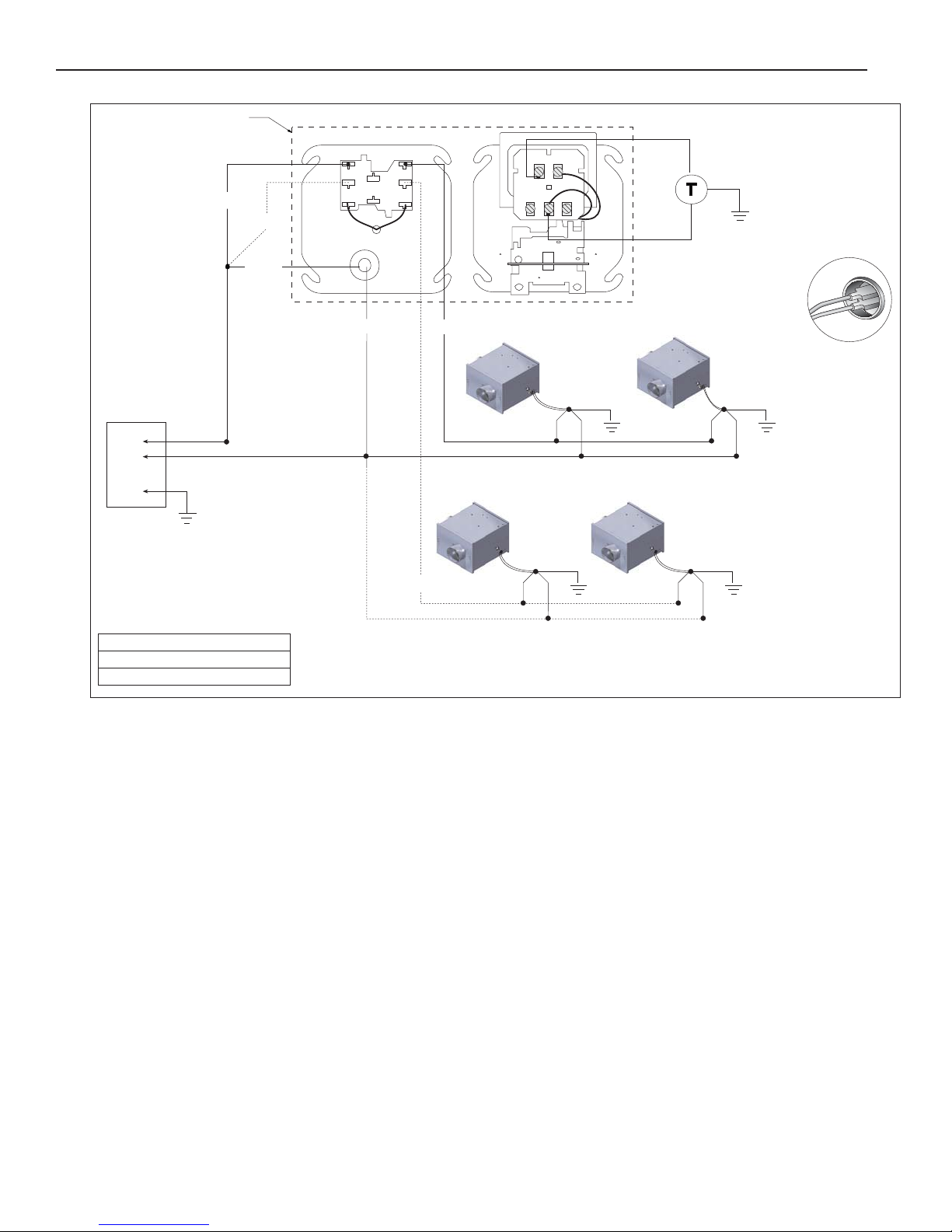

NH

Gnd.

NH

Gnd.

L1

L2

Gnd.

120V-60 Hz

supply circuit

Low Voltage Thermostat

RC

W

G

Y

1

2

3

4

5

6

COIL COIL

Black

Black

White Red

Transformer Relay

FRONT VIEW BACK VIEW

Burner 1 Burner 2

NH

Gnd.

Burner 3

NH

Gnd.

Burner 4

Purple

Red/Yellow

When using 1-2 burners, use SPST

Transformer Relay.

When using 3-4 burners, use DPDT

Transformer Relay.

Low Voltage

Terminal Detail

on all Burners

10.3 Low Voltage Thermostat Wiring with Multiple Burners

Description

Thermostat Relay-SPST

Transformer Relay-DPDT

42 of 53

Page 47

10.4 Internal Wiring

SECTION 10: WIRING

BLK

MOTOR/BLOWER

BLK

BLK

VALVE

10.5 Ladder Diagram

POWER SUPPLY

120V 60 HZ

GAS

BLUE

R1

BLUE

PRESSURE SWITCH

TH

C1

V1

C2

S1

V2

GND

IGNITION

MODULE

PLUG

1

3

TERMINAL

BUSHING

YEL

5

4

NUETRAL

BLK

(L2)

GRN

YEL

BLUE

THERMOSTAT

TO

R1

BLK

GRN

GRN

WHT

YEL

WHT

YEL

BURNER ON LED

FLAME SENSE

IGNITER

LINE

(L1)

1

3

TRANSFORMER

BRN

120VAC

GND

L2

L1

BLK

TRANSFORMER

24V

THERMOSTAT

PRESSURE

SWITCH

GAP

ELECTRODE

R1

BLOWER

GAS VALVE

120VAC

24VAC

RELAY

TH

S1

SPARK

C2

R1

V2

BURNER ON

43 of 53

Page 48

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

SECTION 11: OPERATION AND MAINTENANCE

DANGER

Electrical Shock Hazard

Disconnect electric

before service.

Heater must be

connected to a properly

grounded electrical

source.

Failure to follow these instructions can result in death, electric shock, injury or property damage.

This heater is equipped with a direct spark ignition

system.

11.1 Sequence of Operation

4. Turn the thermostat up. When the thermostat

calls for heat, the blower motor will energize.

5. When the motor approaches nominal running

RPM, the pressure switch closes and activates

the ignition module.

6. After a 45 second prepurge, the ignition module

then opens the gas valve and energizes the

spark igniter.

7. When the flame is established, the sparking

sequence ceases.

Explosion Hazard

Turn off gas supply to

heater before service.

WARNING

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

11. When thermostat is satisfied, all power to the

unit is shut off.

11.2 To Shut Off Heater

Set thermostat to lowest setting.

Turn OFF electric power to heater.

Turn OFF manual gas valve in the heater supply line.

11.3 To Start Heater

Turn gas valve and electric power OFF and wait five

minutes for unburned gases to vent from heater.

Turn ON main gas valve.

Turn ON electric power.

Set thermostat to desired temperature.

Burner should light automatically.

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

8. If the flame is not established during the ignition

sequence, the ignition module closes the gas

valve and purge begins. Module will try 2

additional times for ignition (with purges in

between trials). If ignition is not established, the

module will lockout.

9. If the flame extinguishes during operation, the

ignition module will attempt the multiple trial

sequence described in step 5. If ignition is not

re-established, the module w

hour or until reset.

10.After lockout, the control can be reset by turning

down thermostat for five seconds, and then

raising it again to desired temperature, or by

disconnecting power and then reconnecting.

overall heater condition should be thoroughly inspected.

44 of 53

ill lockout for one

11.4 Pre-Season Maintenance and Annual

Inspection

To ensure yo

operation of the heating system, service and annual

inspections must be done by a contractor qualified in

the installation and service of gas-fired heating

equipment.

Turn off gas and electric supplies before performing

service or maintenance. Allow heater to cool before

servicing.

Before every heating season, a contractor qualified in

the installation and service of gas-fired heating

equipment must perform a thorough safety

inspection of the heater.

For best performance, the gas, electrical, thermostat

connections, tubing, venting, suspensions and

ur safety and years of trouble-free

Page 49

SECTION 11: OPERATION AND MAINTENANCE

NOTE: Gas flow and burner ignition are among the

first things that should be throughly inspected.

Please see Page 45, Section 11.5 for suggested

items to inspect.

set forth in the VAL-CO manuals and all applicable

governmental authorities pertaining to the

installation, service, operation and labeling of the

equipment.

To help facilitate optimum performance and safety,

11.5 Maintenance Checklist

Installation Code and Annual Inspections:

All installation and service of VAL-CO equipment

must be performed by a contractor qualified in the

installation and service of equipment sold and

Val-Co recommends that a qualified contractor

conduct, at a minimum, annual inspections of your

VAL-CO equipment and perform service where

necessary, using only replacement parts sold and

supplied by Val-Co.

supplied by Val-Co and conform to all requirements

The Vicinity of the Heater Do not store or use flammable objects, liquids or vapors near the heater.

Immediately remove these items if they are present.

See Page 5, Section 3.

Vehicles and Other

Objects

Maintain the clearances to combustibles.

Do not hang anything from, or place anything on, the heater.

Make sure nothing is lodged underneath the reflector, in between the tubes or

in the decorative or protective grilles (included with select models).

Immediately remove objects in violation of the clearances to combustibles.

See Page 5, Section 3.

Reflector Support reflector with reflector hanger and support strap.

Reflector must not touch tube.

Make sure there is no dirt, sagging, cracking or distortion.

Do not operate if there is sagging, cracking or distortion.

Make sure reflectors are correctly overlapped. See Page 22, Section 6.5.1.

Clean outside surface with a damp cloth.

Vent Pipe Venting must be intact. Using a flashlight, look for obstructions, cracks on the

pipe, gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Remove any carbon deposits or scale using a wire brush.

See Page 31, Section 8.

Outside Air Inlet Inlet must be intact. Look for obstructions, cracks on the pipe, gaps in the

sealed areas or corrosion.

The area must be free of dirt and dust. Clean and reinstall as required.

Tubes Make sure there are no cracks.

Make s

ure tubes are connected and suspended securely.

See Page 14, Section 6.

Make sure there is no sagging, bending or distortion.

Clean or replace as required.

Gas Line Check for gas leaks. See Page 39, Section 9.

Burner Observation

Window

Blower Scroll, Wheel and

Make sure it is clean and free of cracks or holes.

Clean and replace as required.

Compressed air or a vacuum cleaner may be used to clean dust and dirt.

Motor

45 of 53

Page 50

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Burner Cup and Orifice Clear of obstructions (even spider webs will cause problems).

Carefully remove any dust and debris from the burner.

Electrode Replace if there are cracked ceramics, excessive carbon residue, or erosion

of the electrode.

The electrode gap should be 1/8" (3.2 mm).

Thermostat There should be no exposed wire or damage to the thermostat.

See Page 41, Section 10.

Suspension Points Make sure the heater is hanging securely. Look for signs of wear on the chain

or ceiling.

See Page 15, Figure 11.

Lower Clearance Shield

(optional)

The lower shield must be securely attached. Inspect shield support straps

and lower clearance shield anchor points.

See Page 30, Section 7.4.

Make sure shield is installed correctly and secured in place if necessary.

See Page 30, Section 7.4.

Wall Tag If wall tag is present, make sure it is legible and accurate. Please contact Val-

Co or your VAL-CO independent distributor, if you need a wall tag. See Page

4, Section 2.1

Safety Labels Product safety signs or labels shou

ld be replaced by the product user when

they are no longer legible. Please contact Val-Co or your VAL-CO independent distributor to obtain replacement signs or labels. See Page 2, Figure 1

through Page 3, Figure 2.

46 of 53

Page 51

SECTION 12: TROUBLESHOOTING

Fire Hazard

Keep all flammable

objects, liquids and

vapors the minimum

required clearances to

combustibles away

from heater.

Some objects will catch

fire or explode when

placed close to heater.

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly earthed.

Failure to follow these instructions can result

in death or electrical shock.

SECTION 12: TROUBLESHOOTING

47 of 53

Page 52

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

Module Diagnostic Codes:

LED Problem Solution

4 second steady

flash at start of cycle Normal Wait for valve to open

Steady on Microprocessor failure Replace module

within module

Three flashes Ignition lockout Recycle unit: check for

Lockout of module spark and valve opening and

after 3 tries replace:if none, replace module

12.1 Troubleshooting Flow Chart

48 of 53

Page 53

SECTION 12: TROUBLESHOOTING

49 of 53

Page 54

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

12.2 Manifold Gas Pressure Setting

50 of 53

Page 55

SECTION 13: REPLACEMENT PARTS

Carbon Monoxide Hazard

WARNING

Use only genuine ROBERTS GORDON® replacement parts per this installation, operation and

service manual.

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Explosion Hazard

DANGER

Electrical Shock Hazard

Fire Hazard

SECTION 13: REPLACEMENT PARTS

See warnings and important information before removing or replacing parts. After any maintenance or repair

work, always test fire the heater in accordance with the start-up instructions on Page 44, Section 11 to help

ensure all safety systems are in working order before leaving the heater to operate. Minor faults may be

traced by using the troubleshooting charts on Page 47, Section 12 through Page 50, Figure 12.2.

51 of 53

Page 56

ES-SERIES INSTALLATION, OPERATION AND SERVICE MANUAL

FIGURE 20: Burner Exploded View

2

3

12

4

6

11

5

Description

1 Gas Valve (Natural)

1 Gas Valve (LP)

Tube Gasket (Not Shown)

Blower Inlet Gasket (Not Shown)

2 Motor and Blower Assembly

Air Adapter Collar (Not Shown)

3 Burner Cup Assembly

4 Igniter

5 Mica Window Assembly

6Flame Sensor

7 Transformer

8 Thermostat Connection

9 Jumper Wire

10 Pressure Switch:

(80, 100, 125, 150, 175)

(40)

(60)

LED Burner Status Light (Not Shown)

11 24 Vac Relay

12 DSI Ignition Module

8

9

10

7

1

Val-Co Part Number

474834

474835

474820

03050900

90708600-P

91911700

474828

474822

02553203

90439300

90436900K

91317900

03090900

90439803K

90439807K

90439805K

474826

474836

474094

52 of 53

Page 57

SECTION 14: GENERAL SPECIFICATIONS

8.5

(21.6 cm)

12

(30.7)

11.5

(29.2 cm)

14.1 Material Specifications

14.1.1 Reflectors

.024 Aluminum

(Optional .024 Stainless Steel Type 304)

14.2 Heater Specifications

14.2.1 Ignition

Fully automatic, three-try, direct spark, electronic

14.3 Suspension Specifications

Hang heater with materials with a minimum working

load of 75 lbs (33 kg). See Page 15, Figure 11.

14.4 Controls Specifications

Time switches, thermostats, etc. can be wired into

the electrical supply. External controls supplied as an

optional extra.

ignition control, 100% safety shut-off.

General Specifications for ES-Series heaters are as follows:

Heat Input Rate Length “A”

Model (Btu/h) x (1000) Minimum Space Spot

ES-40 40 10' (3 m) 8'-10' (2.4-3 m) 8' (2.4 m)

ES-60 65 20' (6 m) 10'-12' (3-3.6 m) 9' (2.7 m)

ES-80 80 20' (6 m) 12-15' (3.6 - 4.5 m) 11' (3.3 m)

ES-100 100 30' (9 m) 12-15' (3.6 - 4.5 m) 12' (3.7 m)

ES-125 125 40' (12 m) 15-20' (4.5 - 6 m) 15' (4.6 m)

ES-150 150 50' (15 m) 20-25' (6 - 7.6 m) 20' (6.1 m)

ES-175 175 60' (18 m) 25' (7.6 m) 23' (7 m)

*See Page 5, Section 3 for clearances to combustibles.

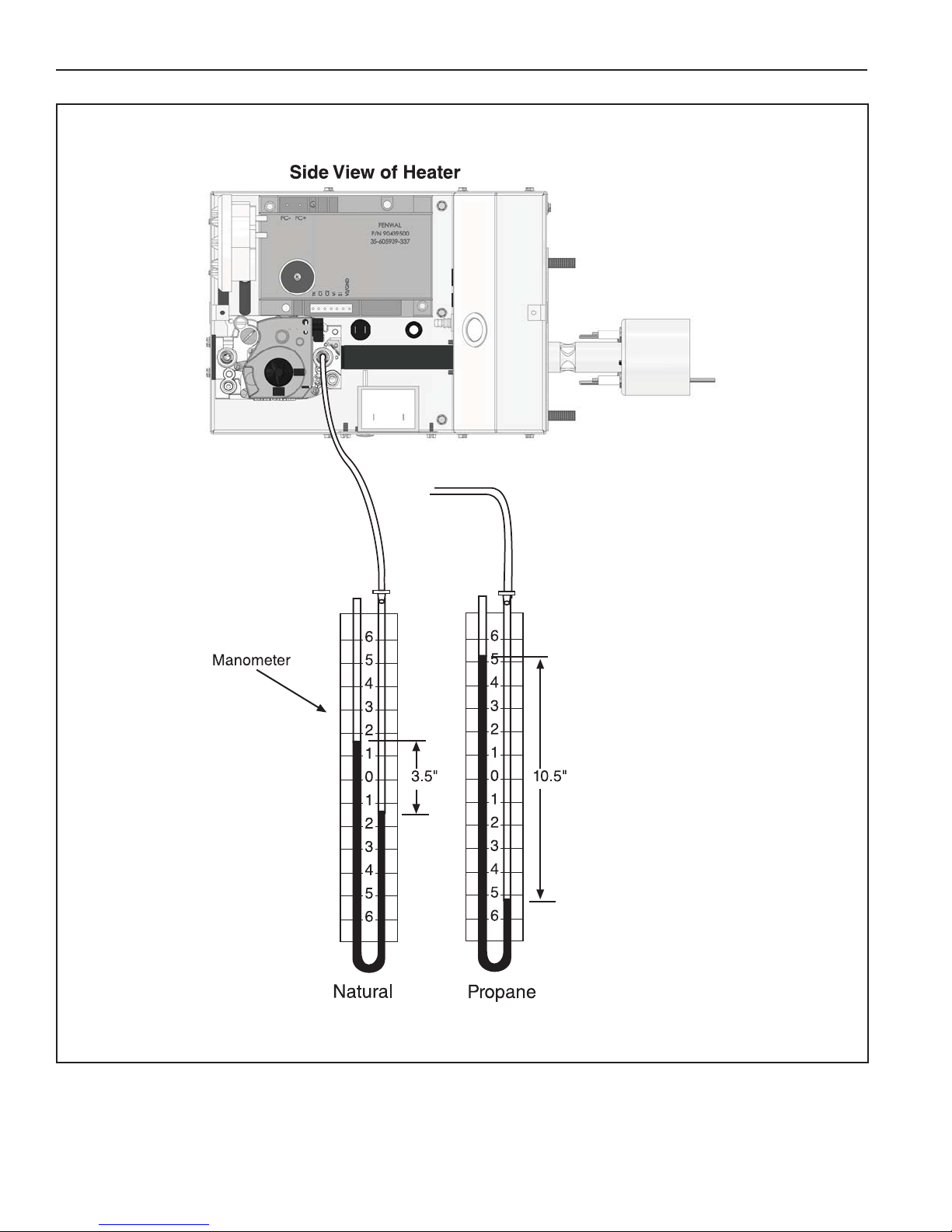

GAS PRESSURE AT MANIFOLD:

Natural Gas: 3.5" wc

LP Gas: 10.5" wc

PIPE CONNECTION:

1/2" NPT (for ES-40, 60, 80, 100 & 125)

3/4" NPT (for ES-150 and 175)

DIMENSIONS:

Vent Connection Size: 4" (10 cm)

Outside Air Connection Size: 4" (10 cm)

Refer to figure above for dimensional information.

Recommended

Minimum Mounting Height*

GAS INLET PRESSURE:

Natural Gas:

for ES-40, 60, 80, 100, 125, 150 4.6" wc Minimum

for ES-175 5.0" wc Minimum

14.0" wc Maximum

LP Gas: 11.0" w c M i ni m um

14.0" wc Maximum

ELECTRICAL RATING (ALL MODELS):

120 V - 60 Hz, 1 A (run)

Page 58

Page 59

Page 60

Loading...

Loading...