Vaisal OPT100M User Manual

OPT100M Solutions Brochure

www.vaisala.com

AES Indiana uses mobile DGA solution to gain

insight into aging transformers

LISTEN TO ARTICLE

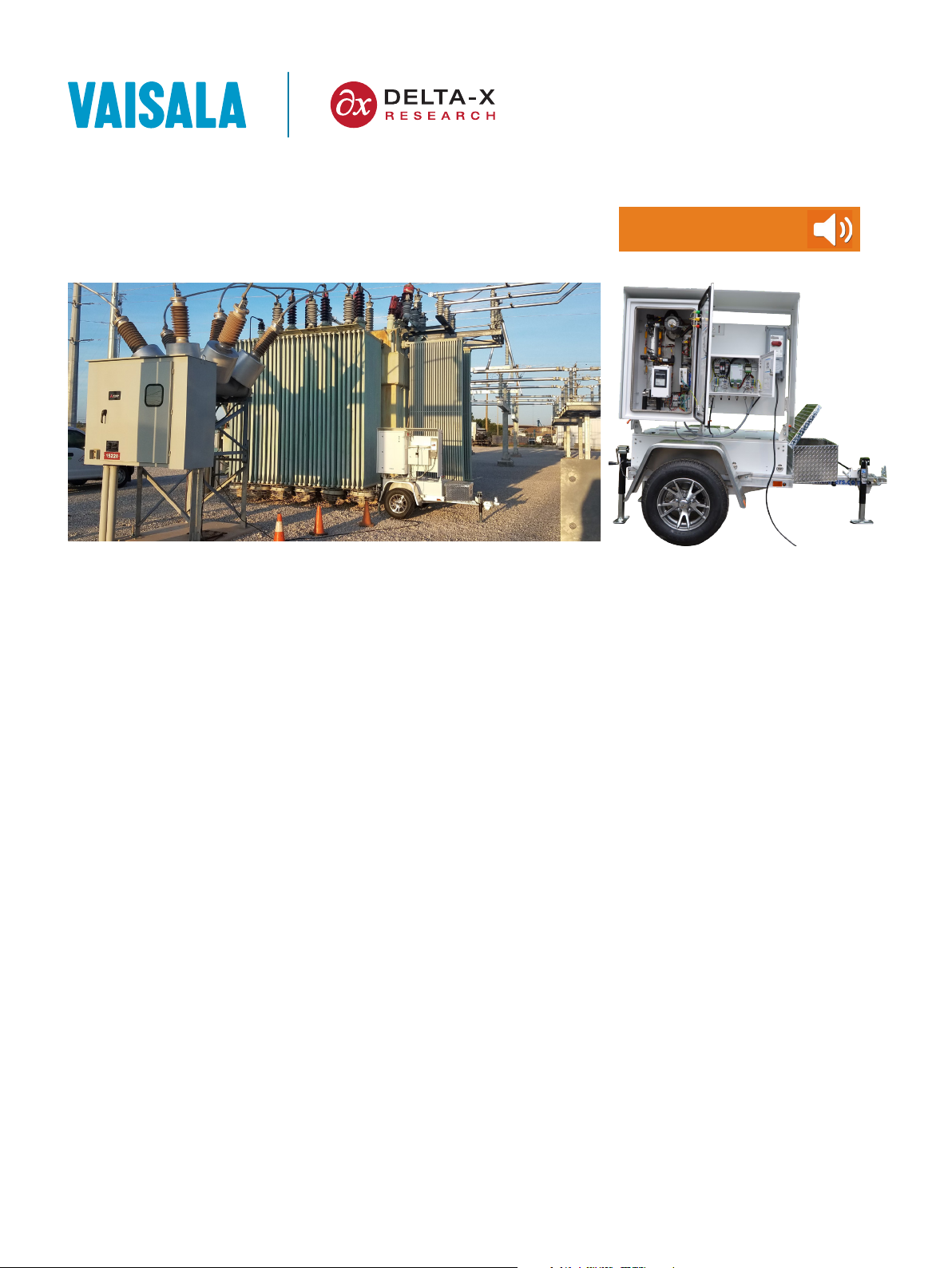

AES Indiana used Vaisala’s Optimus™ Mobile multi-gas DGA Monitor, the OPT100 Mobile and Delta-X

Research’s Transformer Oil Analyst™ software with Monitor Watch™ to detect and identify faults on a

suspect transformer. This was done without taking the transformer oine by using a mobile DGA online

monitor and feeding its information to a cloud-based analytic software tool.

For nearly one hundred years,

AES Indiana has been creating

value for its customers by

moving promptly, anticipating

opportunities, avoiding risk and

changing direction when needed

to best serve its clients. The

Vaisala multi-gas Dissolved Gas

Analyzer (DGA) OPT100 Mobile,

integrated with Delta-X Research’s

Transformer Oil Analyst (TOA)

software with Monitor Watch,

ensure AES Indiana’s tradition is

met.

To maintain service delivery

commitments, AES Indiana

has implemented Vaisala’s

revolutionary mobile online

Dissolved Gas Analyzer (DGA)

monitoring solution to stay

ahead of unforeseen outages

and failures. All maintenance

and asset managers know that

faulty transformers can cause

unplanned outages leading to

catastrophic events with impact

to the community, the bottom

line, and of course, you and your

maintenance teams. Upon learning

of the Vaisala OPT100 Mobile

solution, AES Indiana wanted to

run a pilot, as they immediately

saw how this technology could

be used for responding to DGA

gassing alarms/reports.

Traditionally, standard oil

sampling procedures are carried

out only once or twice a year. If

a transformer is not “healthy”

and shows signs of dysfunction

based on DGA measurements,

software tools, or lab consultants,

the frequency of testing is then

increased to almost every two

weeks. What is really needed

in these cases is an online DGA

monitor that provides real time

data that can be compared to

operating conditions.

Here an online DGA monitor with

capability to provide real time

data for comparison to operating

conditions is a traditional fix.

However, not every transformer

is worth the cost. A mobile online

solution to gather true DGA

analysis and fault determination

was the fix. Vaisala developed a

DGA monitor technology platform

to be mounted on a trailer and

deployed temporarily – no

onerous maintenance or manual

calibration between deployments.

Understanding this challenge,

Vaisala developed its OPT100

Mobile DGA platform and leak

detection solution to provide the

first truly mobile online solution on

the market - significantly improving

the ability of substation managers

to manage their assets and

drastically reduce unintended labor

costs and unplanned outages.

Scenario and challenge

Currently, AES Indiana owns

350 transformers, 3 fixed DGA

monitors, and 15 single gas

monitors. As expected, monitoring

transformer performance and

gas condition across the entire

portfolio can be rather time

consuming and extremely costly.

AES Indiana has been using

traditional DGA sampling from

existing laboratories, but those

can take days before AES Indiana

has access to any data at all.

After lab sampling and

further analysis from Delta-X

Research’s TOA software, AES

Indiana identified a 50-year-old

transformer showing signs of

active gassing and potentially

degrading health. Continuous

monitoring with the OPT100

Mobile became the primary

analytical tool to assess the

current condition of this particular

transformer.

In order to investigate the

scenario described further, Vaisala

provided AES Indiana with an

OPT100 Mobile multi-gas DGA

monitor. It measures 7 key fault

gases, moisture in transformer

oil and utilizes total gas pressure

for air leak detection. The unit

has zero-maintenance and no

consumables, partly due to its

non-dispersive infrared (NDIR)

technology and patented gas

extraction system. It also has

internal mechanisms to selfcalibrate the NDIR measurement

system as well as systems for

calibrating based on the local oil

condition.

AES Indiana also leveraged

Transformer Oil Analyst (TOA)

diagnostic software from Delta-X

Research (www.deltaxresearch.

com) to interpret both the

lab and the monitor data. As

well as supporting standardsbased interpretation methods,

TOA provides Reliabilitybased DGA interpretation

that compares a transformer’s

performance against that of a

statistically large population of

transformers, including failures,

to more correctly identify atrisk transformers and quantify

the risk of continuing operation.

With Reliability-based DGA, the

Monitor Watch option of TOA

correctly assesses transformer

health while avoiding the spurious

alarms that are common with

limits-based solutions typically

applied to monitor data. With TOA

providing correct and consistent

interpretation of both lab and

monitor data, AES Indiana relies

on TOA as a key decision support

tool for maintaining, refurbishing

and replacing critical assets while

optimizing capital budgets.

AES Indiana then uses the results

from TOA to prioritize problematic

transformers for further

investigation. Once identified,

these transformers are connected

to Vaisala’s OPT100 Mobile and

the continuously monitored online

data merges with the historical

lab data kept in TOA. In this case,

the results provided AES Indiana

with the missing pieces of data to

truly understand this problematic

transformer’s condition and

develop a proactive maintenance

plan.

The obstacle

AES Indiana wanted

to closely monitor the

gassing transformer to

make informed decisions

regarding its maintenance

or replacement. Moreover,

AES Indiana wanted to

avoid unpredicted outages,

but needed to do so

without having to commit

to a hefty investment for

a DGA monitor system

for the problematic

transformer before knowing

its true health. Therefore,

AES Indiana needed

factual and reliable data

to properly understand

this transformer’s status,

including the potential need

to adjust power loads across

other assets in their fleet.

The solution(s)

In this case, AES Indiana used a single gas monitor (e.g. MHT410) for alarming and lab sampling to qualify the

transformer with the help of the TOA software. AES Indiana then connected Vaisala’s Optimus™ OPT100 Mobile

to the 1967 transformer (GE step-up transformer, 69-280 kVA) and started the online measuring process.

Once connected to the transformer, the OPT100 Mobile began communicating with the Delta-X Research

Transformer Oil Analyst (TOA) software with Monitor Watch by interfacing with a Digi modem integrated into

the OPT100 Mobile platform. By combining the real-time online measurements of the key fault gases data from

the OPT100 Mobile with the interpretation and analysis of the DGA data by the TOA software, AES Indiana was

able to validate the health and confirm there was no active internal arcing or overheating and take the correct

preventative measures on the transformer.

Once the maintenance plan was completed and verified, the OPT100 Mobile and TOA software were

implemented on another transformer. The mobility of the OPT100 Mobile was crucial to the value of this project,

allowing AES Indiana to immediately deploy this online monitor to another problematic transformer needing

analysis, allowing for maximum return on investment in the equipment. This was only possible because of the

OPT100 Mobile design and functionality.

Loading...

Loading...