Vaillant electronicVED E ../7 INT II Series, VED E 18/7 INT II, VED E 21/7 INT II, VED E 24/7 INT II, VED E 27/7 INT II Installation Instructions Manual

Installation instructions

electronicVED

VED E ../7 INT II

EXP (ar)

Publisher/manufacturer

Vaillant GmbH

Berghauser Str. 40 D-42859 Remscheid

Tel. +49 21 91 18‑0 Fax +49 21 91 18‑2810

info@vaillant.de www.vaillant.de

Contents

2 Installation instructions electronicVED 0020264435_00

Contents

1 Safety .................................................................... 3

1.1 Action-related warnings ......................................... 3

1.2 Intended use.......................................................... 3

1.3 General safety information .................................... 3

1.4 Regulations (directives, laws, standards).............. 4

2 Notes on the documentation .............................. 5

2.1 Observing other applicable documents ................. 5

2.2 Storing documents................................................. 5

2.3 Validity of the instructions...................................... 5

3 Product description............................................. 5

3.1 Overview................................................................ 5

3.2 Function................................................................. 5

3.3 Information on the data plate................................. 5

3.4 CE label ................................................................. 5

4 Set-up.................................................................... 6

4.1 Checking the scope of delivery.............................. 6

4.2 Selecting an installation location ........................... 6

4.3 Installation clearances ........................................... 6

4.4 Installing the product on the wall ........................... 6

5 Installation............................................................ 8

5.1 Connecting the hot and cold water ........................ 8

5.2 Connecting the product to the electricity supply .... 9

6 Start-up ............................................................... 10

6.1 Removing air pockets from the product............... 10

6.2 Fitting the product casing..................................... 10

6.3 Checking the system's functionality..................... 11

6.4 Activating the scald protection function ............... 11

7 Handing over to the operator ........................... 11

8 Recycling and disposal..................................... 11

9 Troubleshooting ................................................ 11

9.1 Detecting and rectifying faults ............................. 11

9.2 Procuring spare parts .......................................... 12

10 Inspection and maintenance ............................ 12

11 Decommissioning.............................................. 12

11.1 Temporarily decommissioning the product.......... 12

11.2 Permanently decommissioning the product......... 12

12 Customer service............................................... 12

13 Technical data.................................................... 13

Safety 1

0020264435_00 electronicVED Installation instructions 3

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning signs and

signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

Vaillant electronicVED electric instantaneous water heaters must only be used to heat

up drinking water.

Vaillant electronicVED electric instantaneous water heaters are suitable for use only

in an enclosed, frost-free room in a domestic

environment.

Vaillant electronicVED electric instantaneous water heaters are not suitable for operation in secondary circulation lines.

Intended use includes the following:

– observance of accompanying operating,

installation and servicing instructions for

the product and any other system components

– installing and fitting the product in accord-

ance with the product and system approval

– compliance with all inspection and main-

tenance conditions listed in the instructions.

Intended use also covers installation in accordance with the IP code.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk caused by inadequate

qualifications

The following work must only be carried out

by competent persons who are sufficiently

qualified to do so:

– Set-up

– Dismantling

– Installation

– Start-up

– Inspection and maintenance

– Repair

– Decommissioning

▶ Observe all instructions that are included

with the product.

▶ Proceed in accordance with current tech-

nology.

▶ Observe all applicable directives, stand-

ards, laws and other regulations.

1.3.2 Risk of material damage caused by

frost

▶ Do not install the product in rooms prone

to frost.

1.3.3 Risk of death from electric shock

There is a risk of death from electric shock if

you touch live components.

Before commencing work on the product:

▶ Disconnect the product from the power

supply by switching off all power supplies

at all poles (electrical partition with a contact gap of at least 3 mm, e.g. fuse or circuit breaker).

▶ Secure against being switched back on

again.

▶ Check that there is no voltage.

1 Safety

4 Installation instructions electronicVED 0020264435_00

1.3.4 Risk of death from electric shock

from live lines and connections

The drinking water that is used must demonstrate a specific resistance of ≥ 900 Ω at

15 °C. Otherwise, the product must not be

used.

▶ Before installing the unit, ask your water

company to inform you about the water

resistance and conductivity.

1.3.5 Risk of being scalded by hot water

The outlet temperatures at the draw-off points

can be up to approx. 60 °C.

▶ When using the product, ensure that you

do not scald yourself.

▶ If you want to be protected from scald-

ing, set the maximum temperature of the

product to 43 °C.

1.3.6 Risk of being scalded by hot water

If a solar thermal energy system is connected

upstream, hot water temperatures of over

43 °C could be generated even if the scald

protection function is set.

If a solar thermal energy system is connected

upstream of the product, the inlet temperature must be limited by including precautionary features in the design (e.g. a mixer valve).

▶ Install a mixer valve to limit the inlet tem-

perature to 25 °C.

1.3.7 Risk of being burned or scalded by

hot components

▶ Only carry out work on these components

once they have cooled down.

1.3.8 Risk of material damage caused by

using an unsuitable tool

▶ Use the correct tool to tighten or loosen

threaded connections.

1.4 Regulations (directives, laws,

standards)

▶ Observe the national regulations, stand-

ards, guidelines and laws.

Notes on the documentation 2

0020264435_00 electronicVED Installation instructions 5

2 Notes on the documentation

2.1 Observing other applicable documents

▶ You must observe all the operating and installation in-

structions included with the system components.

2.2 Storing documents

▶ Pass these instructions and all other applicable docu-

ments on to the system operator.

2.3 Validity of the instructions

These instructions apply only to:

Product article number

VED E 18/7 INT II

0010023714

VED E 21/7 INT II

0010023715

VED E 24/7 INT II

0010023716

VED E 27/7 INT II

0010023717

3 Product description

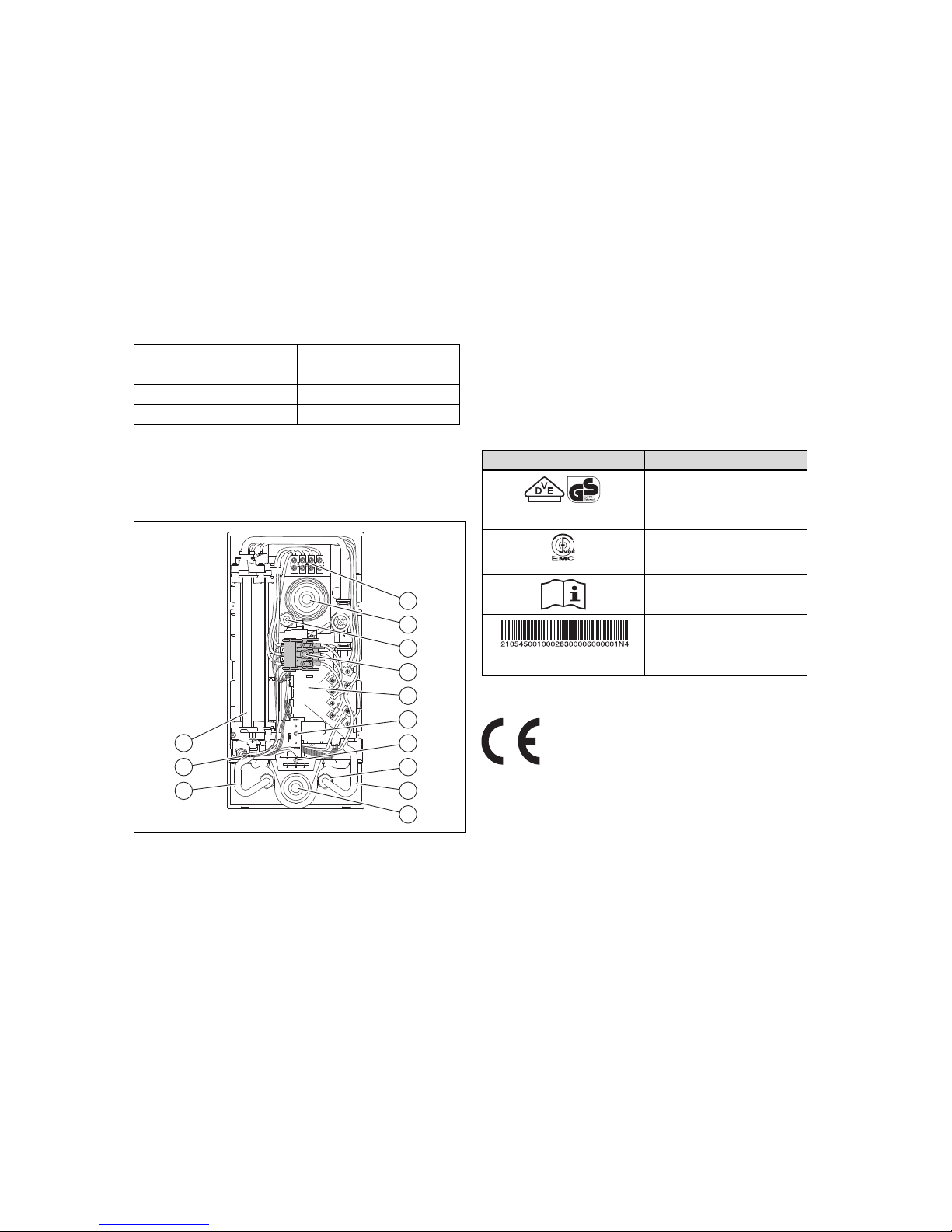

3.1 Overview

10

9

11

12

13

8

7

6

5

4

3

2

1

1 Mains connection ter-

minal

2 Top cable duct

3 Adjustment spindle

4 Safety switch

5 Electronics

6 Temperature selector

(infinitely variable)

7 Optional space under-

neath for the mains

connection terminal

8 Filter

9 Cold water connection

10 Bottom cable duct

11 Hot water connection

12 Safety overheat cut-off

device

13 Heating block

3.2 Function

The product heats up drinking water via a bare wire in the

heating block using the flow-through principle.

The drinking water can be drawn from several draw-off

points.

The electronics measure the temperature of the water in the

cold water supply and the water volume flow. The electrical

performance that is required to heat the water to the required

hot water temperature is calculated using these two values.

The temperature can be set to any value between 30 °C and

60 °C on the product's temperature selector.

The hot water temperature depends on:

– Water inlet temperature

– Water outlet volume

– Performance category of the unit

If the set hot water temperature is not reached, reduce the

water volume.

3.3 Information on the data plate

Symbol Meaning

The VDE GS mark confirms

that the unit complies with

standards and has been

tested for safety.

Symbol confirming conformity

with the electromagnetic compatibility standard

Read all of the instructions.

Barcode with serial number,

The 7th to 16th digits of the

serial number form the article

number

3.4 CE label

The CE label shows that the products comply with the basic

requirements of the applicable directives as stated on the

identification plate.

The declaration of conformity can be viewed at the manufacturer's site.

4 Set-up

6 Installation instructions electronicVED 0020264435_00

4 Set-up

4.1 Checking the scope of delivery

▶ Check that the scope of delivery is complete.

Quantity Description

1

electronicVED electric instantaneous water

heater

1

Operating instructions and installation instructions

1

Bag containing fixing material (2 bolts, 2 rawl

plugs, 3 seals, 1 special fixing screw)

1 R 1/2 cold water connection piece with a

cold water stop valve

1 R 1/2 hot water connection piece

2 Double nipple

1 Installation plate

1 Installation template

4.2 Selecting an installation location

▶ Install the product as close as possible to the draw-off

points that are used most frequently.

Note

The product may also be installed above baths

or in a shower area.

4.3 Installation clearances

_

+

D

C

E

A

C

B

B

A At least 50 mm

B At least 50 mm

C At least 120 mm

D At least 130 mm

E Maximum 22 mm

The bottom section of the product (D) must be level with the

product's bearing area on the wall;.

4.4 Installing the product on the wall

4.4.1 Product and connection dimensions

_

+

240

100

7050

277

481

322

5

16

19

100

7

35 35

1

2

3

4

5

6

1 Top cable duct

2 Central attachment

3 Temperature selector

4 R 1/2 hot water connec-

tion

5 R 1/2 cold water con-

nection

6 Bottom cable duct

7 R 1/2 outside thread

390

277

8585

1

23

1

1 Installation plate

2 Cold water connection

3 Hot water connection

Set-up 4

0020264435_00 electronicVED Installation instructions 7

4.4.2 Removing the product casing

X9

4

2

3 51

1. Grip the two straps (1) on the panel (2).

2. Splay the two straps (pull them away from the product).

3. Remove the panel (2).

4. Undo the two screws (3).

5. Fold up the cover (4).

6. Pull the temperature selector plug from the electronics

(slot X9) in the product (5).

7. Remove the cover (4) from the product.

4.4.3 Installing the product

390

277

8585

1

2

2

1

1. Hold the installation template against the wall and mark

the fixing points.

– Product alignment: Vertically on the wall

Note

When replacing a product, you can use the

drill holes from the previous installation

provided these are compatible with the

additional holes in the installation plate.

2. Use rawl plugs and screws to secure the installation

plate (1) to the fixing points (2).

Danger!

Risk of electric shock caused by penetrat-

ing water

The cable duct prevents water from penetrating along the mains connection cable

and into the product. If the cable duct is completely cut away, water can very easily penetrate and damage the product and may cause

a potentially lethal electric shock.

▶ Never cut off the cable duct completely.

▶ Cut the end of the cable duct in such a

way that the sleeve tightly surrounds the

mains connection cable.

3. Fold the cable duct up or down depending on the location of the mains connection cable.

4. Feed the cable through the cable duct and into the product's interior.

5 Installation

8 Installation instructions electronicVED 0020264435_00

1

2

4

3

5. Fit the product (2) to the retaining screw (1) on the installation plate.

6. Use the adjustment spindle (4) to adjust the product.

7. Use the fixing screw (3) to secure the product.

5 Installation

▶ Flush the cold water pipes thoroughly before installation.

5.1 Connecting the hot and cold water

Caution.

Possible damage caused by unsuitable

plastic pipes.

Damage may be caused by unsuitable plastic

pipes.

▶ Use only plastic pipes that are permitted

for normal operation at 65 °C.

▶ Use only plastic pipes that can withstand

at least one hour at a maximum temperature of 95 °C and a maximum pressure of

1 MPa (10 bar) (check the manufacturer's

specifications).

▶ When using plastic pipes, ensure that they

conform with DIN 16893 and DIN 16892

(check the manufacturer's specifications).

1. Note the water connections for the installation:

– An expansion relief valve on the cold water pipe is

not required.

– All cold and hot water pipes can be made of steel,

copper or plastic.

1

2. To simplify installing the water connection, the bottom

section of product frame can be folded up (1).

– Do not remove the folding frame.

1

2

3

4

7

6

3

5

Caution.

Risk of damage caused by leaks.

Mechanical tension on supply lines may

cause leaks and damage to the product.

▶ Avoid mechanical tension on supply lines.

3. Put hemp on the two double nipples (2) and (6) and use

the connections to screw the double nipples to the wall

(1) and (7).

4. Insert the seals (3) in the cap nuts of the cold (4) and

hot water connections (5).

5. Screw the cold water connection piece (4) to the cold

water connection double nipple (2) in the wall (1).

6. Screw the hot water connection piece (5) to the hot

water connection double nipple (6) in the wall (7).

7. Insert a seal into the cap nut of the unit-side hot water

connection.

Installation 5

0020264435_00 electronicVED Installation instructions 9

Caution.

Risk of damage due to pipes being

blocked by foreign bodies in the water

A water filter that stops foreign bodies entering the product must be fitted to the cold

water flow. The product must not be used

without a water filter. A water filter has been

installed inside the product's cold water pipe

at the factory.

▶ During installation, check that the water

filter is present.

8. After installing the water connection, fold the lower section of the product frame back until it engages.

5.2 Connecting the product to the electricity

supply

1. Note the specifications on the identification plate when

carrying out the electrical installation.

2. Note:

– The product must be installed using a permanent

connection.

– The permanent connection must be equipped with

a customer-supplied partition that has a contact

opening of at least 3 mm on all lines (e.g. via a line

protection switch).

– The product must be connected to the protective

conductor.

– The product is delivered pre-assembled. When car-

rying out the electrical installation, only the electricity

supply line needs to be fed into the product through

one of the two cable ducts and connected.

– The electrical connection must be secured to the up-

per section of the product at the factory. If required,

the connection can be routed in the lower section.

The electrical supply line is then guided through the

lower cable duct.

5.2.1 Carrying out the top electrical connection

4

3

2

1

1. Guide the electrical supply line through the upper cable

duct (2).

2. Connect the individual conductors to L1, L2, and L3 on

the mains connection terminal (1).

3. Connect the protective conductor (4) (3).

5.2.2 Carrying out the bottom electrical

connection

3

2

5

4

6

1

1. Guide the electrical supply line through the lower cable

duct (3).

2. Unscrew the mains connection terminal (1).

3. Route the mains connection terminal (6), including the

internal cable, to the lower position (2) in the product.

4. Screw the mains connection terminal to the lower position (2).

5. Check whether the cables for the mains connection

terminal are routed correctly.

6. Connect the individual conductors to L1, L2, and L3 on

the mains connection terminal (1).

7. Connect the protective conductor (5) (4).

6 Start-up

10 Installation instructions electronicVED 0020264435_00

5.2.3 Installing an optional load-shedding relay

If required, a load-shedding relay that conforms with current

standards can be connected to the product. The role of the

relay is to switch off other power consumers while hot water

is being drawn off via the product so that the house installation is not overloaded. The load-shedding relay must fulfil the

following criteria:

– Pull-in current < 15 A

– Continuous current > 50 A

▶ Install the load-shedding relay in the L2 outer conductor.

▶ If the product is a replacement product, also replace the

load-shedding relay.

6 Start-up

6.1 Removing air pockets from the product

Caution.

Risk of damage from heating wire dry fire

If the air pockets have not been removed

from the product before it is started up, there

is a risk of heating wire dry fire and damage

to the product.

▶ Disconnect all supply lines from the power

supply.

▶ Secure the product against being uninten-

tionally switched back on again.

▶ Check that there is no voltage in the sup-

ply lines and connections.

▶ Check that the product is de-energised.

1. Open the cold water stop valve in the cold water pipe.

2. Open the hot water stop valve for at least one minute.

3. Close and open the hot water draw-off valve several

times.

Note

In normal operating mode, the product will

not need to be purged again.

1

4. Press the safety switch (1).

6.2 Fitting the product casing

X9

2

1

3

4

If the cable for the temperature selector is not plugged into

the electronics, the electronics cannot regulate the power.

The outlet temperature is 30 °C.

▶ Plug the cable (4) for the temperature selector into

slot X9 in the electronics.

▶ Put the product casing (1) on.

▶ Tighten the two screws (3).

▶ Grip the panel (2) using the two straps.

▶ Splay the two straps (slightly pull the panel apart).

▶ Put the panel (2) on.

▶ Close the hot water draw-off valve.

▶ Connect the product to the power mains (switch on the

fuse).

Handing over to the operator 7

0020264435_00 electronicVED Installation instructions 11

6.3 Checking the system's functionality

_

+

1. Connect the product to the power mains (switch on the

fuse).

2. Check the product's power while water is running at a

draw-off point.

3. Turn the temperature selector from hot (left-hand stop =

approx. 30 °C) to hot (right-hand stop = approx. 60 °C).

6.4 Activating the scald protection function

1. Disconnect the product from the power supply.

2. Remove the product casing (→ Page 7).

_

+

3. Turn the temperature selector as far as it will go in an

anti-clockwise direction.

1

4. Move the red lever (1) at the back of the product casing.

◁ This activates the scald protection function and en-

sures that the outlet temperature does not exceed

43 °C.

5. Refit the product casing (→ Page 10).

6. Connect the product to the power mains (switch on the

fuse).

7 Handing over to the operator

1. Provide the operator with all relevant instructions and

unit documentation for safe-keeping.

2. Go through the operating instructions with the operator .

3. Answer any questions they may have.

4. Draw special attention to the safety instructions which

the operator must follow.

5. Inform the operator that there is a risk of scalding when

the hot water temperature exceeds 43 °C.

6. Inform the operator that they must not attempt to repair

the product under any circumstances.

7. Inform the operator that they must not remove the

product casing.

8. Inform the operator of the necessity to ensure that the

system is regularly inspected/maintained and that this

must only be carried out by a competent person (inspection/maintenance contract).

8 Recycling and disposal

Disposing of the packaging

▶ Dispose of the packaging correctly.

▶ Observe all relevant regulations.

9 Troubleshooting

9.1 Detecting and rectifying faults

Fault Possible cause Troubleshooting

Product disconnected from the

power supply

Building's fuse has

been tripped

▶ Replace the electronics system.

The safety switch in

the product has been

triggered

▶ Replace the electronics system.

No hot water; the

water remains

cold

Product is disconnected from the

power supply

▶ Check L1, L2

and L3 against PE

(230 V) and L1, L2

and L3 (400 V).

▶ If there is no

voltage, proceed as

described under

the fault "Product

disconnected from

the power supply".

The measured value

on the heating block

(connection 1

against connection 4) is greater

than 200 Ω

▶ Replace the heating block.

No relay clicking on

the electronics when

the draw-off starts

▶ Replace the impeller.

Other cause ▶ Replace the elec-

tronics system.

The water does

not become hot

enough

The set target temperature or volume

flow are not set correctly

▶ Set the target

temperature to

approx. 40 °C and

the volume flow to

approx. 5 l/min.

10 Inspection and maintenance

12 Installation instructions electronicVED 0020264435_00

Fault Possible cause Troubleshooting

The water does

not become hot

enough

The measured value

on the heating block

(connection 1

against connection 4) is greater

than 200 Ω

▶ Replace the heating block.

The relay only clicks

on the electronics

when there is more

than 4 l/min

▶ Replace the impeller.

Other cause ▶ Replace the elec-

tronics system.

9.2 Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶ If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

10 Inspection and maintenance

▶ Carry out a function check and visual inspection of the

product every three years.

▶ If the water is extremely calciferous, you must de-scale

the product more frequently.

If the water has a large volume of suspended matter, the water filter in the cold water flow must be replaced more frequently. At the same time, the water filter has a sealing function.

Caution.

Risk of damage caused by leaks

After changing the water filter in the cold water flow, leaks may occur due to the new filter

being installed incorrectly.

▶ When installing a new water filter in the

cold water flow, make sure that the filter

is correctly positioned in the pipe and that

the connection is sealed.

▶ Replace the water filter in the cold water flow.

▶ Check for deposits in the hot water pipe between the

heating block and the hot water connection.

▶ When re-assembling the product, insert a new flat seal

into the hot water connection.

▶ Check whether it is necessary to de-scale the product.

▶ De-scale the product as required.

▶ If the product needs to be completely de-scaled, attach a

de-scaling pump between the cold and hot water connection.

▶ After de-scaling the product, flush it thoroughly with wa-

ter.

▶ After de-scaling, remove any air pockets from the product

(→ Page 10).

11 Decommissioning

11.1 Temporarily decommissioning the product

1. Disconnect the product from the power supply.

2. Close the cold water stop valve.

11.2 Permanently decommissioning the product

1. Disconnect the product from the power supply.

2. Close the cold water stop valve.

3. Loosen the cold water and hot water connections.

4. Capture the residual water (up to 0.4 litres) that is left

inside the product using a suitable vessel.

5. Remove the product.

12 Customer service

تجد بيانات الاتصال بخدمة العملاء الخاصة بنا من خلال العنوان

الموضح بأسفل الصفحة الخلفية أو على موقع الإنترنت

www.vaillant.com.

Technical data 13

0020264435_00 electronicVED Installation instructions 13

13 Technical data

Unit E 18/7 INT II E 21/7 INT II E 24/7 INT II E 27/7 INT II

For supplying —

One or more draw-off points

1)

Design — Product for wall-mounting

Equipment — Bare wire heating coil

Capacity l 0.4

Width

Height

Depth

mm

mm

mm

240

481

100

Weight (filled) kg 4.4

Performance characteristics — Electronically regulated output

Water inlet temperature °C 1 ... 25

Minimum start-up flow l/min 3

Switch-off water volume l/min 2.5

Minimum start-up pressure MPa (bar) > 0.015 (> 0.15)

Max. water flow rate l/min 7 9

Rated overpressure MPa (bar) 1 (10)

Rated power kW 18 21 24 27

Minimum water resistance at 15 °C Ω•cm ≥ 900

Measuring voltage — 3/PE ~ 400 V; 50 Hz

Safety — Complies with international safety regulations; radio-shielded;

does not affect the mains supply

IP rating — IP 25 = Sprayed-water protection

1)

Closed product (pressurised)

0020264435_00 22.09.2017

Supplier

Vaillant Group International GmbH

Berghauser Strasse 40 42859 Remscheid

Tel. +49 21 91 18‑0

www.vaillant.info

© These instructions, or parts thereof, are protected by copyright and may be reproduced or distributed only with

the manufacturer's written consent.

We reserve the right to make technical changes.

0020264435_00

Loading...

Loading...