Page 1

Installation and maintenance instructions

For the competent person

Installation and maintenance instructions

ecoLEVEL

Condensed water pump

GB, IE

Page 2

Table of contents

Table of contents

1 Notes on the documentation .....................................3

1.1 Attaching and storing documents ...............................3

1.2 Applicability of the instructions ...................................3

1.3 CE label ...............................................................................3

1.4 Identification plate ...........................................................3

2 Safety information and regulations ......................... 3

2.1 Intended use ......................................................................3

2.2 General safety information ............................................4

3 Installation .......................................................................6

3.1 Scope of delivery .............................................................6

3.2 Required tools ...................................................................6

3.3 Selecting the installation site .......................................6

3.4 Dimensions and installation clearances .....................7

3.5 Installing the wall bracket ..............................................7

4 Hydraulic connection ....................................................8

4.1 Removing the ecoLEVEL ................................................8

4.2 Install the inlet hose ........................................................9

4.3 Connecting and positioning the drain hose ..............9

4.4 Connecting the drain hose to the

existing discharge pipe ................................................. 10

4.5 Connecting the condensed water pump

to the boiler ......................................................................11

5 Electrical connection ...................................................12

5.1 Overview of the electrical connections .....................12

5.2 Preparing the electrical connection ...........................12

5.3 Connecting the condensed water pump

to the 230 V mains voltage ..........................................12

5.4 Connecting the condensed water pump

to the safety cut-out switch .........................................13

11 Recycling and disposal ................................................19

12 Technical data .............................................................. 20

6 Operation and troubleshooting .................................15

6.1 LED display of operating status or faults .................15

6.2 Faults ..................................................................................15

6.3 Fault diagnostics and elimination ...............................15

7 Handing over to the operator ...................................16

8 Maintenance ....................................................................17

8.1 Cleaning the non-return valve .....................................17

8.2 Cleaning the pump ........................................................ 18

9 Spare parts ..................................................................... 18

10 Guarantee and Customer Service............................19

10.1 Vaillant guarantee ...........................................................19

10.2 Vaillant Service ................................................................19

2 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 3

Notes on the documentation

11

1 Notes on the documentation

The following information is intended to help you throughout the entire documentation.

Further documents apply in combination with these operating, installation and maintenance instructions.

We accept no liability for any damage caused by failure

to observe these instructions.

Other applicable documents

When installing the condensed water pump, you must

observe all the installation instructions for the assemblies

and components of the system. These instructions are

enclosed with the various system parts and supplementary

components.

1.1 Attaching and storing documents

Please pass these operating, installation and maintenance

instructions on to the system operator, who is responsible

for storing the instructions so that they are available whenever required.

1.2 Applicability of the instructions

These installation and maintenance instructions apply

exclusively to units with the following article number:

– 0020030797

The article number of the unit can be found on the identification plate.

1.3 CE label

CE labelling shows that the ecoLEVEL condensed water

pump complies with the basic requirements of the following

applicable directives as stated on the identification plate:

> Permissible voltages (Directive EN 60 335-1 and

EN 60 335-2-41)

> Electromagnetic compatibility (Directive EN 55 014-1 and

EN 55 014-2)

1.4 Identification plate

The identification plate with the serial number, the protection rating classification, the supply voltage, the frequency,

and the CE label is situated on the underside of the

ecoLEVEL condensed water pump.

2 Safety information and regulations

Classification of warnings

The warnings are classified in accordance with the severity

of the possible danger using the following warning signs

and signal words:

Warning

symbol

a

e

Signal word Explanation

Danger!

Danger!

Warning. Risk of minor personal injury

Imminent danger to life or risk

of severe personal injury

Risk of death from electric

shock

a

Caution.

b

2.1 Intended use

The Vaillant condensed water pump is constructed using

state-of-the-art technology in accordance with the recognised safety rules and regulations. Nevertheless, there is

still a risk of injury or death to the user or others or of

damage to the unit and other property in the event of

improper use or use for which it is not intended.

The ecoLEVEL condensed water pump is intended for use

only in conjunction with Vaillant system components in

which the condensed water is produced as a by-product of

operation. This includes all Vaillant condensing boilers.

The ecoLEVEL condensed water pump is only approved for

individual units up to 45 kW. The pump and all of its components are designed for delivering condensed water from

heating installations. The introduction of rainwater into the

system as a result of the flue gas system is taken into

account in terms of the permitted volume, the composition,

and also the content of solids in the condensate.

This unit is not designed to be used by persons (including

children) with limited physical, mental or sensory capabilities or by persons who do not have enough experience and/

or knowledge, unless they are supervised by a person who

is responsible for their safety or have been instructed by

him/her about how to use the unit.

Children must be supervised to ensure that they do not

play with the unit.

Risk of material or environmental damage

ecoLEVEL installation and maintenance instructions 0020029316_01 3

Page 4

Safety information and regulations

2

The condensed water pump is not suitable for the pumping

of other fluids or solid media. In particular, waste water of

all types, chemicals and emulsions that contain oil must not

be fed into the condensed water pump. Using the condensed water pump in vehicles is regarded as improper use.

Units that are not classed as vehicles are those that are

installed in a fixed and permanent location (known as "fixed

installation").

Any other use, or use beyond that specified, shall be considered improper use. Any direct commercial or industrial

use is also deemed to be improper. The manufacturer/supplier is not liable for any claims or damage resulting from

improper use. The user alone bears the risk.

Intended use includes observance of the operating and

installation and maintenance instructions and all other

applicable documents, as well as adherence to the maintenance and inspection conditions.

Caution.

Improper use of any kind is prohibited.

2.2 General safety information

Working on the ecoLEVEL condensed water pump

The ecoLEVEL condensed water pump must only be

installed and started up by a competent person. The existing regulations, rules and guidelines must be observed

when doing so. Inspection/maintenance and repairs must

also be carried out by this skilled tradesman.

Only competent persons who have acquainted themselves

with all the safety information provided in these installation

instructions, and the fitting, operating and maintenance

instructions, may work on this unit.

Risk of electric shock when opening the unit and

carrying out maintenance work.

When operating this unit, certain components must inevitably be under dangerous voltages which can lead to severe

bodily injury or to death.

> Ensure that the unit is only opened by a company oper-

ating a recognised competent persons scheme.

> Only open the bottom cover plate if all electrical connec-

tions to the pump have been isolated.

> Before carrying out any visual inspections and mainte-

nance work, ensure that the power supply is switched off

and secured against being switched back on again.

Risk of electric shock when the unit is switched on.

When operating this unit, certain components must inevitably be under dangerous voltages which can lead to severe

bodily injury or to death.

> If measurements need to be made with the power supply

switched on, never touch the electrical connections.

> Remove all jewellery from wrists and fingers.

> Make sure that the test equipment is in a good, safe

operating condition.

> When working on the unit when it is switched on, ensure

that it is standing on an insulated base, in other words

make sure that there is no earth connection.

Risk of burns and explosion when unsuitable

liquids are used.

Pumping out flammable and explosive liquids such as petrol, heating oil, etc., poses a risk of burns and explosions.

> Do not use the pump to pump out flammable or explo-

sive liquids.

Risk of explosions in explosive atmospheres.

Operating the pump in explosive atmospheres could trigger

an explosion.

> Do not use the pump in an explosive atmosphere.

Risk of injury due to condensate.

The condensate pumped by the pump poses a risk to the

eyes if they come into contact with it.

> Avoid any contact of the condensed water with the eyes.

> Make sure that the ecoLEVEL condensed water pump is

only operated out of the reach of children.

> In case of eye contact with the condensate, rinse the

eyes thoroughly with clean water and seek medical

advice.

Danger of poisoning by flue gas leaks.

If you connect the condensate drain hose of the pump with

the waste water piping, the internal siphon of the boiler

may be completely emptied.

> Do not connect the water condensate hose of the pump

with a sealed connection to the waste water piping ('free

outlet').

Malfunctions and material damage due to

instability.

If the pump is not in a stable position during operation, this

can lead to malfunctions of the pump. This may result in

damage to the pump or boiler.

> During operation, ensure that the pump has a stable

base or is attached to the wall.

Risk of damage due to improper modifications.

Modifications to the ecoLEVEL condensed water pump may

damage the unit and are therefore generally prohibited.

> Under no circumstances should you ever attempt to make

alterations to the pump or other parts of the system.

> Consult an approved heating specialist company to make

such alterations.

Material damage caused by leaking condensed

water

In the event of a defect in the condensed water pump, leaking condensed water may cause material damage or damage to the boiler.

> Connect a current interrupter or an alarm to the safety

cut-out switch.

4 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 5

Material damage caused by unsuitable discharge

pipes

If you use discharge pipes that are not acid-resistant, this

can lead to leaks and damage caused by leaking condensed

water.

> If you need to extend the condensed water discharge

pipe during installation, use only acid-resistant discharge

pipes.

Earthing, conductor dimensioning, short-circuit

protection

> The pump connection has a protective connection. Make

sure that the power supply is earthed in accordance with

legal requirements.

Regulations and standards

IEC 60364-7-712 Electrical installations of buildings Part 7-712

EMC test procedure in accordance with EN 50081-1:1992,

EN 50082-1:1997

Interference emission: EN 55014-1: 1993

Immunity: EN 55014-2: 1997

Safety information and regulations

2

Rules of engineering

The installation must suit the conditions at the site of the

customer and comply with local regulations and engineering rules. In particular, this includes:

– Electrical connection

– VDE 0100 Erection of power installations with rated

voltages below 1000 V,

– VDE 0105, part 100 Operation of electrical systems

DIN 18382 Electrical cable and wiring systems in

buildings

ecoLEVEL installation and maintenance instructions 0020029316_01 5

Page 6

Installation

3

3 Installation

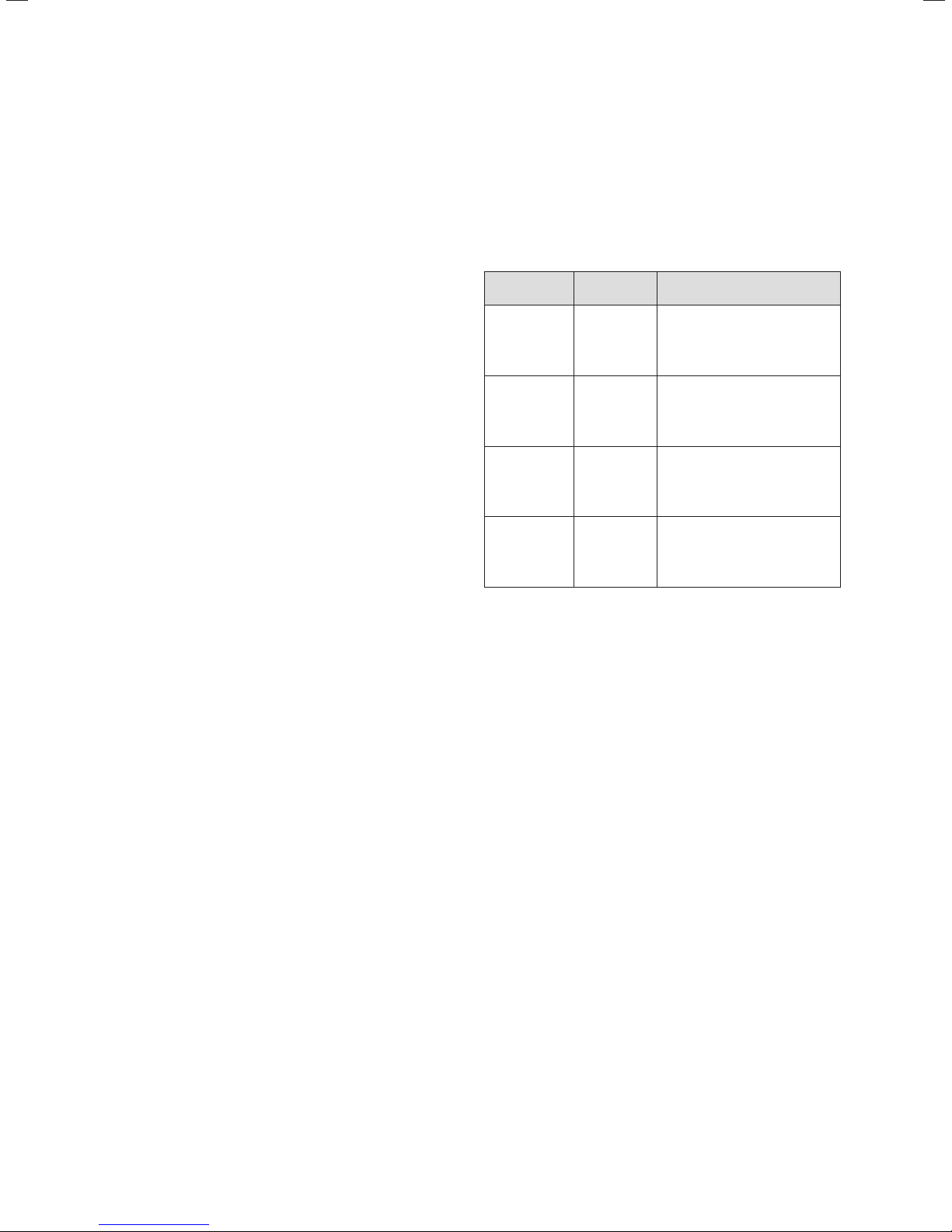

Item Component Dimensions Number

3.1 Scope of delivery

10

9

Für den Betreiber

Betriebs anleitung

ecoLEVEL

Kondenswasserpumpe

Betriebs anleitung

DE, AT, BEDE, CH

1 Condensed water pump

(H x W x L)

150 x 175 x 100 mm

1

2 Fixing plugs 6 mm 2

1

3 Bolts 4 x 35 mm 2

4 Wall bracket - 1

2

3

5 Drain hose dia. 10 mm x 6 m 1

Installation and mainte-

6

nance instructions

-1

7 Socket screw connection 15 x 22 mm 1

Stainless steel pipe

8

insert

4

9 Coupling piece 22 mm x 3/4" imperial 1

-1

10 Inlet hose dia. 24 mm x 1.15 m 1

Wall bracket for drain

hose

5

3.1 Scope of delivery

-6

3.2 Required tools

6

DE

The following tools are required for installation:

– Drill

– Drill bit (6 mm)

7

– Flat blade screwdriver

8

– Spirit level

– Cutting blade

– Tools for electrical connection

3.1 Scope of delivery

6 ecoLEVEL installation and maintenance instructions 0020029316_01

3.3 Selecting the installation site

The ecoLEVEL condensed water pump is designed for

installation in the room housing the boiler.

The ambient temperature must be between 5 °C and 60 °C.

The condition of the walls in the installation room must

allow the connecting elements supplied to be used without

any problems.

> If the walls are not in a suitable condition, a suitable

installation surface must be prepared before starting the

installation.

The ecoLEVEL condensed water pump must not be used as

a storage surface for objects.

Page 7

Installation

3

3.4 Dimensions and installation clearances

min. 5 mm min. 5 mm

min. 200 mm

150 mm

115 mm

165 mm

175 mm

min. 5 mm min. 5 mm

min. 200 mm

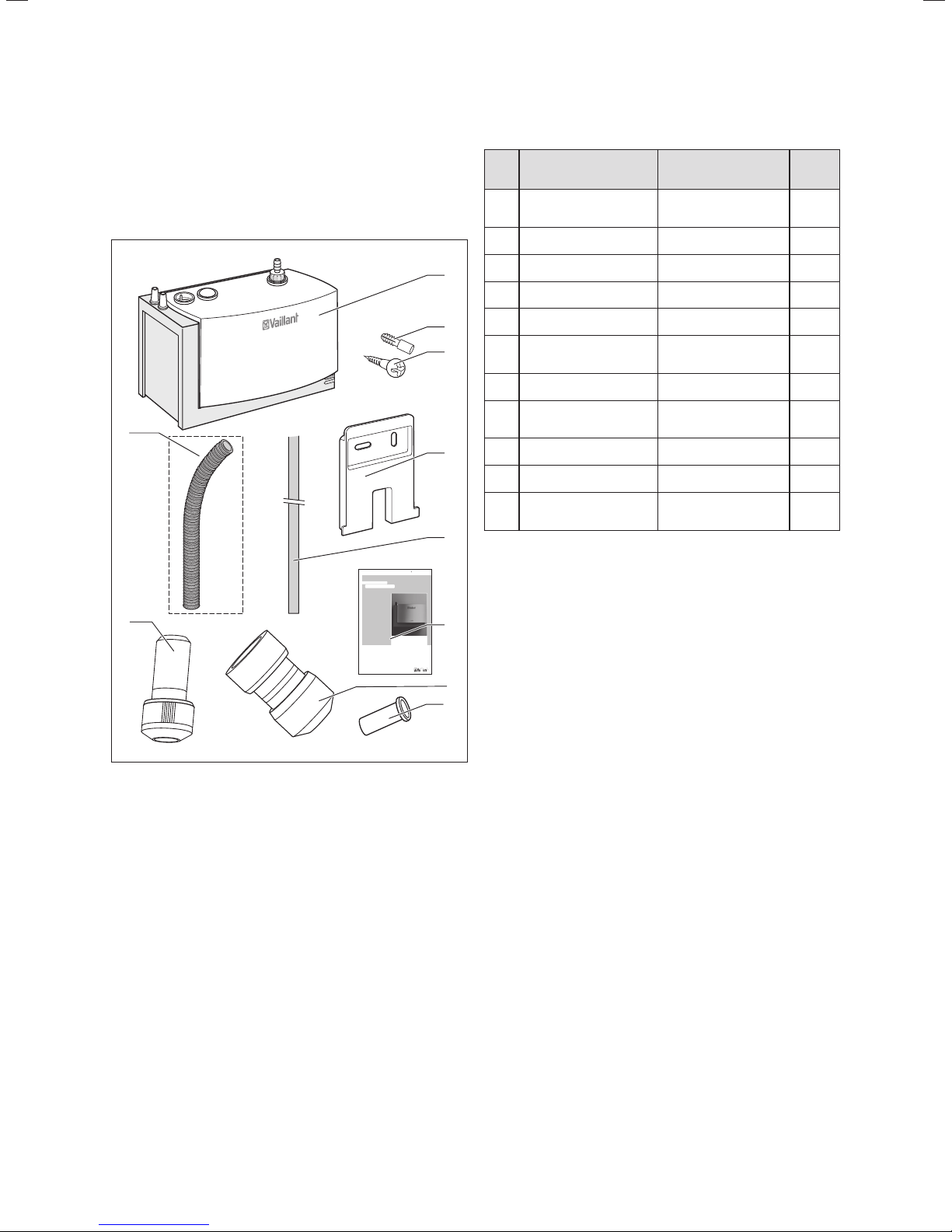

3.5 Installing the wall bracket

90 mm

100 mm

3.2 Dimensions and installation clearances

> During installation, adhere to the appropriate dimensions

and installation clearances.

A

B

3.3 Installing the wall bracket

> Push the pre-assembled wall bracket downwards out of

the casing for the condensed water pump.

> Install the wall bracket in a suitable position underneath

the condensate drain point of the boiler.

The wall bracket must be installed horizontally. Use a

spirit level.

ecoLEVEL installation and maintenance instructions 0020029316_01 7

Page 8

Hydraulic connection

4

> Push the condensed water pump from above onto the

guide surfaces of the wall bracket.

A small hook retains the pump on the bracket in the lowest position.

The condensed water pump can be secured in

the bracket either on the wide rear surface (A)

i

or on the narrow side (B) (¬ fig. 3.3).

4 Hydraulic connection

Caution.

Material damage.

b

b

The pump and the wall bracket can be damaged during fitting if excessive force is

used.

> Do not connect the hoses until you have

removed the non-return valve and the

cover.

Caution.

Material damage.

If the inlet hose is not connected correctly,

the condensed water cannot flow freely into

the pump.

> Route the inlet hose at a constant down-

ward gradient from the boiler to the

ecoLEVEL condensed water pump.

> Lay the inlet hose as straight as possible,

avoiding any bends or kinks.

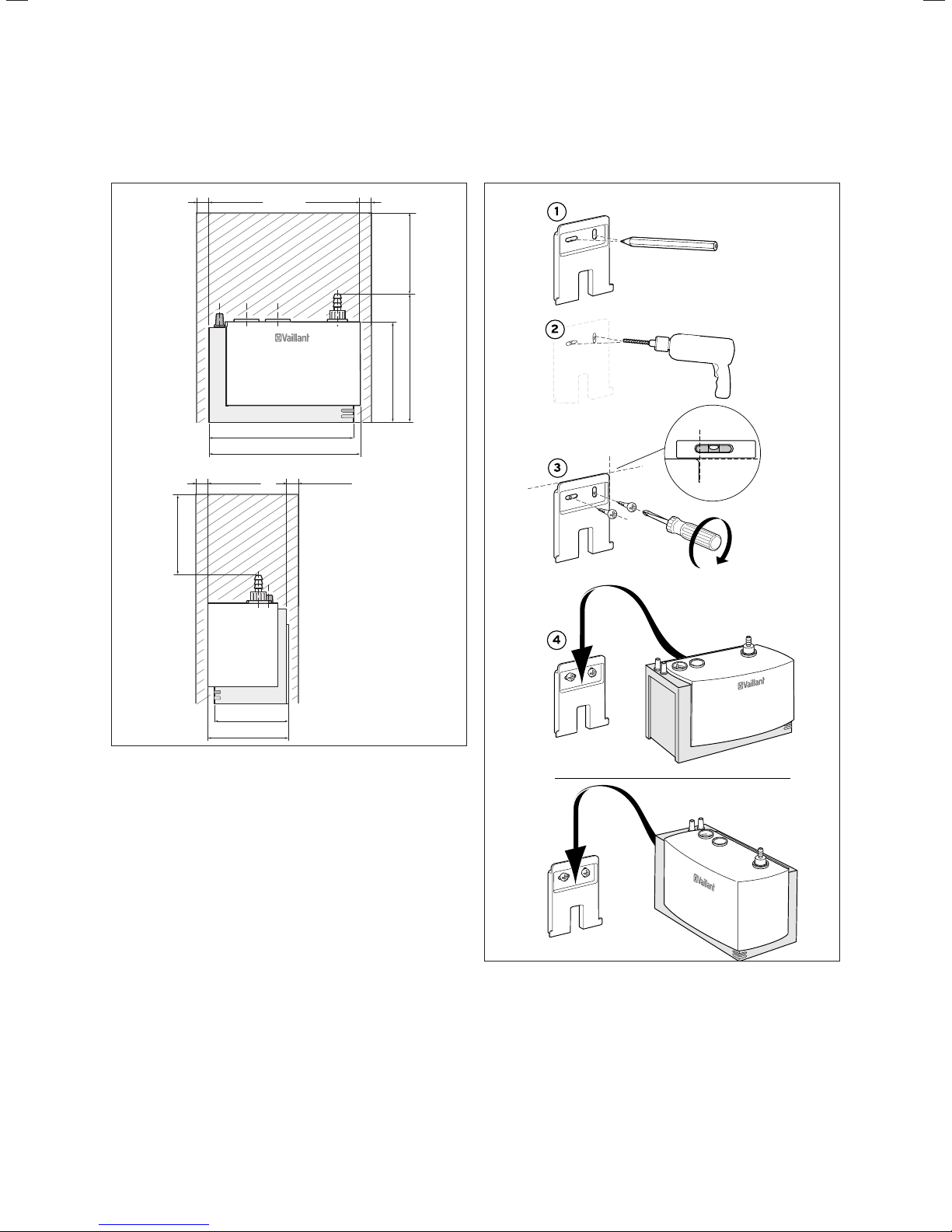

4.1 Removing the ecoLEVEL

5

1

3

4

4.1 Removing the non-return valve and cover, and installing the

inlet hose

2

8 ecoLEVEL installation and maintenance instructions 0020029316_01

Key

1 Non-return valve

2 Cover

3 Opening for the inlet hose

4 Additional opening for the inlet hose

5 Inlet hose

Removing the cover and the non-return valve

> To open the cover of the pump (2), turn the non-return

valve (1) a quarter turn to the left.

Both the cover and the non-return valve are then unlocked.

> Remove the cover (2) and the non-return valve (1) by

pulling upwards.

Page 9

Hydraulic connection

4

4.2 Install the inlet hose

Shortening and plugging in the inlet hose

> Determine the required length of the inlet hose.

> Shorten the hose so that it clicks a maximum of

3 notches into the cover.

> Ensure that the hoses do not protrude into the water

when the pump is at its maximum fill level.

> Push the inlet hose into the inlet opening (3) or (4) of

the removed cover until the inlet hose clicks into position

(max. 3 notches).

Install the second inlet hose

> If you need to connect a second hose, remove the plug

from the second inlet opening (4).

> Shorten the hose so that it clicks a maximum of

3 notches into the cover.

> Ensure that the hoses do not protrude into the water

when the pump is at its maximum fill level.

> Note that the hoses must be pushed no more than

3 notches into the inlet openings (3) and (4).

Replacing the cover

> Place the cover onto the ecoLEVEL condensed water

pump from above.

Positioning the drain hose

ca 3°

max. 4 .0 m

4.3 Connecting and positioning the drain hose

Connecting the drain hose

> Push the drain hose (¬ fig. 3.1), item 5) onto the

removed non-return valve (¬ fig. 3.3), item 1) until it

stops.

> Insert the non-return valve into the cover and lock it into

position by turning a quarter turn to the right.

4.2 Positioning the drain hose

> When routing the drain hose, note the following

(¬ fig. 4.2):

The drain hose of the pump must connect into the wastewater system of the building housing the installation. The

drain hose must lead upwards from the pump,

– in order to compensate for the height difference

between the pump outlet and the drain point

– so that the drain hose can be laid at a gradient to the

drain point after the diversion.

> Lay the drain hose far enough upwards directly from the

pump.

ecoLEVEL installation and maintenance instructions 0020029316_01 9

Page 10

Hydraulic connection

4

Caution:

Material damage caused by unsuitable

a

discharge pipes

If you use discharge pipes that are not acidresistant, this can lead to leaks and damage

caused by leaking condensed water.

> If you need to extend the condensed water

discharge pipe during installation, use only

acid-resistant discharge pipes.

> Note that the maximum feed height of the pump is 4 m.

> Run the drain hose at a steady downward gradient to a

suitable drain location.

> At its highest point, lay the drain hose in a U-shape to

form a non-return device.

4.4 Connecting the drain hose to the existing

discharge pipe

Note!

If a 21.5 mm discharge pipe is already present,

i

you can use the supplied pipe connecting elements.

1

1

4.4 Drain hose and stainless steel pipe insert (installed)

> Hold the cut end of the drain hose (1) in hot water for a

moment. Then insert the stainless steel pipe insert (2)

into the end of the drain hose (¬ fig. 4.4).

1

4.5 Installed drain hose in socket screw connection

2

2

4.3 Drain hose and stainless steel pipe insert (not installed)

> Shorten the end of the drain hose (1). For this, ensure

that the cut on the hose is at a right angle and is free

from burrs (¬ fig. 4.3).

10 ecoLEVEL installation and maintenance instructions 0020029316_01

> Push the drain hose (1) tightly into the socket screw con-

nection (2). Pull on the drain hose to make sure that the

snap-on connection has engaged (¬ fig. 4.5).

> Ensure that the end of your discharge pipe in the build-

ing housing the installation is at a right angle.

Page 11

Hydraulic connection

4

1

4.6 Complete installation at the discharge pipe

> Push the end of the white 3/4" coupling piece (3) tightly

onto the discharge pipe (4).

> Pull on the drain hose (1) to make sure that the snap-on

connections have engaged (¬ fig. 4.6).

> Push the socket screw connection (2) and the coupling

piece (3) together (¬ fig. 4.6).

2

3

4

4.5 Connecting the condensed water pump to

the boiler

The ecoLEVEL condensed water pump can be connected to

the siphon of all Vaillant condensing boilers using the inlet

hose provided.

> If the boiler's condensed water drain hose is long

enough, it can be connected directly to the pump

(¬ fig. 4.1)/(¬ fig. 4.2).

If the boiler hose is too short, replace it with the inlet hose

provided.

> Connect the inlet hose to the condensed water outlet on

the boiler.

> Connect the inlet hose to the ecoLEVEL condensed

water pump.

ecoLEVEL installation and maintenance instructions 0020029316_01 11

Page 12

Electrical connection

5

5 Electrical connection

Before you begin the electrical connection of the unit, the

installation (¬ section 3) and the hydraulic connection

(¬ section 4) for the ecoLEVEL condensed water pump

must be completed.

Danger!

Risk of death from electric shock!

a

5.1 Overview of the electrical connections

a

If the electrical installation is not carried

out properly, there is a risk of electric

shock and damage to the unit.

> Ensure that only competent persons are

permitted to perform the electrical connection.

Caution:

Error functions due to improper use of

the plugs.

Using X40 and Pro-E plugs at the same

time leads to error functions.

> Only use one of the connection types

mentioned here to connect the safety

cut-out switch.

3

Key

1 230 V connection cable (if necessary: plug can be connected)

2 Main line from ecoLEVEL

3 Connection cable for the safety cut-out switch with Pro-E plug

and X-40 plug

The 230 V connection cable (1) with the free cable end provides the power supply to the pump.

The connection cable of the safety cut-out switch (3) is

used for the electrical connection of the safety cut-out

switch to the boiler.

5.2 Preparing the electrical connection

Before you establish the electrical connection to the condensed water pump:

> Switch off the condensed water pump.

> Switch off the boiler.

> Secure the condensed water pump and the boiler against

being switched back on again.

All electrical and water condensate carrying con-

nections to the pump must be routed so that no

i

5.3 Connecting the condensed water pump to

The pump can be connected to the 230 V mains voltage in

two different methods:

> Connect the line (1) to the 230 V mains voltage via the

mains voltage output of the boiler.

Or:

> Install a mains plug on the cable (1) and connect the

pump via a mains socket (the plug is not included in the

scope of delivery).

mechanical tension is present.

the 230 V mains voltage

2

1

5.1 Overview of the electrical connections

12 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 13

Electrical connection

5

5.4 Connecting the condensed water pump to

the safety cut-out switch

The type of connection on the printed circuit board (PCB)

depends upon the individual boiler.

The table (¬ tab. 5.1) shows which boiler must be connected in accordance with connection type C.

Country Boiler

GB/IE ecoMAX pro

5.1 Connection types for different boilers

Connection for safety cut-out

switch

Connection type C:

(Mains voltage of the boiler is

switched via a relay in the

ecoLEVEL condensed water

pump)

All other boilers can be connected using connection type A

or B.

Connection type A

For connection type A, you can connect the safety cut-out

switch to the extra-low voltage circuit of the boiler using

variants I., II. or III.

> Instead, plug the Pro-E plug on the connection cable of

the safety cut-out switch into the blue socket which is

labelled as either "Anl-Therm" (I.) or "Burner off" (B.Off)

(II.)(2).

1

2

BUSRTB. off

5.3 Connecting the safety cut-out switch, connection type A

3

Anl -

Therm

24V

RT

BUS

1

2

Burner

off

24V

RT

BUS

5.2 Connecting the safety cut-out switch, connection type A

Variants I. and II.

> Open the electronics box on the boiler.

> On the boiler PCB, remove the plug from the blue socket

which is labelled as either "Anl-Therm" (I.) or "Burner

off" (B.Off) (II.) (1).

2

Variant III.

> Open the electronics box on the boiler.

> Remove the cable bridge from the plug on the PCB of

the boiler (1).

> Remove the Pro-E plug from the connection cable of the

safety cut-out switch (2).

> Instead, connect the free cable ends of the connection

cable to the "Burner off" (B. off) terminal block (3).

ecoLEVEL installation and maintenance instructions 0020029316_01 13

Page 14

Electrical connection

1

1

X35

X90

Display

X21

5

Connection type B

For connection type B, you can connect the safety cut-out

switch to the extra-low voltage circuit of the boiler using

variants I., or II.

If a flue non-return flap is connected to the multi-functional

module 2 in 7 and you want to use the function of the flue

non-return flap, you must not use the X40B connection:

> In this case, use the connection type A "Anl-Therm"/

"Burner off" (B.off).

Connection type C

Connect the safety cut-out switch to the boiler in the following way:

> Use a suitable tool to cut both plugs from the cable

(¬ fig. 5.1), item 3) and insulate the cable ends.

> Connect the boiler mains voltage line accordingly

(¬ fig. 5.5).

> Connect the 230 V mains voltage for the ecoLEVEL con-

densed water pump in accordance with (¬ section 5.3).

Boiler

PE L1 N

230 V ~

5.4 Connecting the safety cut-out switch, connection type B

Variants I. and II:

> Open the electronics box on the boiler.

> Select variant I. or II., depending on where the X40 plug

is located on the PCB.

> Plug the X-40 plug into the peripheral plug location X40.

Connection type B if connection X40 is occupied

If the boiler has a multi-functional module 2 of 7 (article

number 00 2001 7744) fitted, connection X40 is already

occupied. If this is the case, connect the safety cut-out

switch as follows:

> Insert the plug in the connection X40B of the multi-func-

tional module 2 of 7.

> Also refer to the instructions for the multi-functional

module.

230 V ~

5.5 Connecting the safety cut-out switch, connection type C

14 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 15

Operation and troubleshooting

6

6 Operation and troubleshooting

Once the installation and the hydraulic and electrical connections are completed, the ecoLEVEL condensed water

pump is ready for operation. The green LED lights up. The

operation is self-regulating and does not require any further manual control.

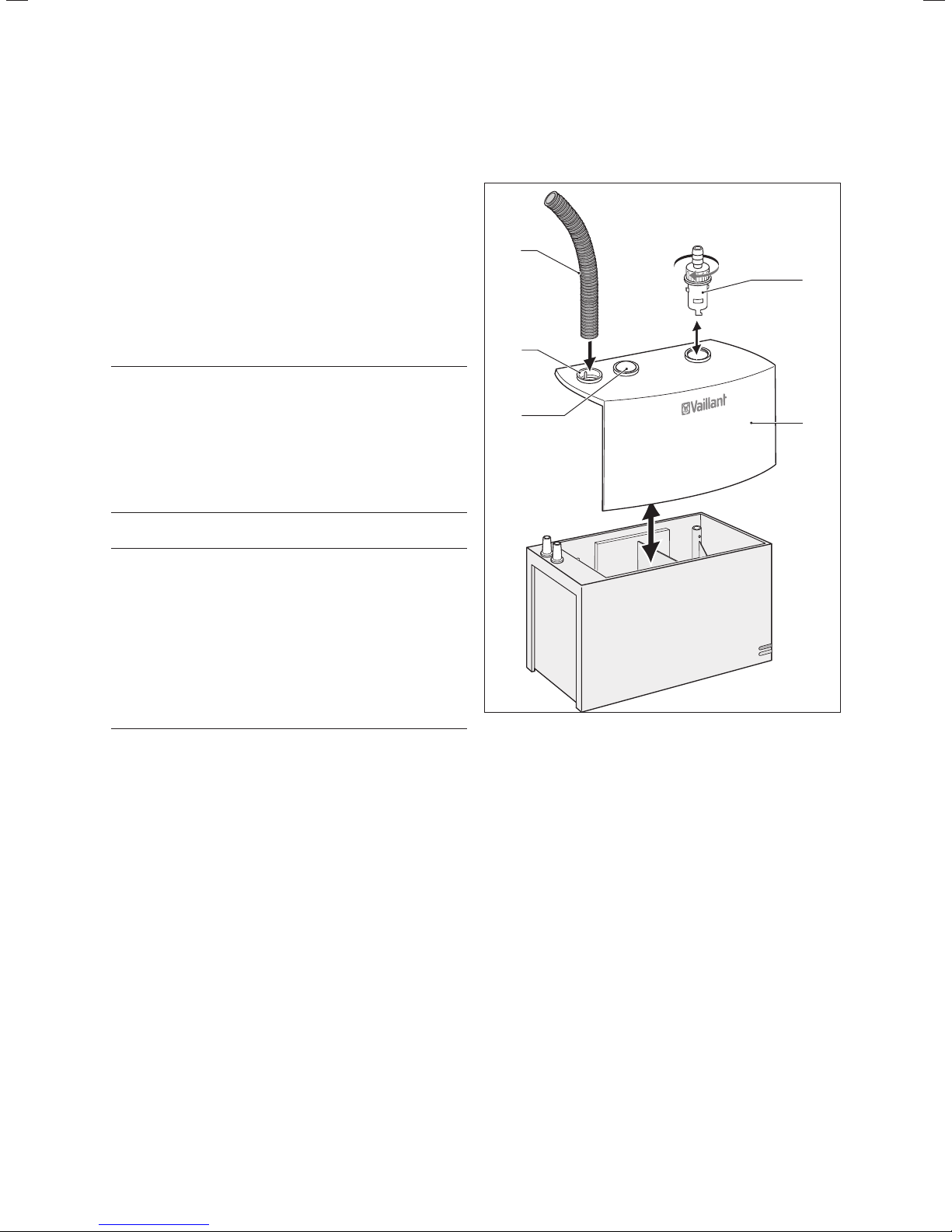

6.1 LED display of operating status or faults

On the front of the ecoLEVEL condensed water pump casing, there are two LEDs (¬ fig. 6.1), items 1 and 2) which

indicate the operating status or faults of the ecoLEVEL

condensed water pump.

1

2

6.1 Display of operating status

Key

1 Top LED

2 Bottom LED

Which operating status or fault is displayed by the light signals of the LEDs can be taken from the following table.

Bottom LED (2)

Lights up

1

green

Lights up

2

green

3 Flashes green Lights up red

4 Flashes green Flashes red

5 Flashes green

6.1 Display of operating status

Top LED (1) Operating status/Fault

The pump is supplied with

-

Flashes green

Flashes red

(> 1 min)

230 V mains voltage. The

pump is ready for operation.

The pump is in operation

and is pumping.

The water level has

exceeded the maximum

permitted value. The

safety cut-out switch is

triggered if this condition

is prolonged.

If a connection between

the safety cut-out switch

and the boiler has been

installed, the boiler is

switched off. Switching off

prevents further condensed water from forming.

The pump is at rest for a

defined time period and

then starts up again on its

own.

> Follow the fault diag-

nostics (¬ section 6.3)

6.2 Faults

The ecoLEVEL condensed water pump can automatically

resolve short-term faults in the normal function sequence.

When the maximum permitted water level is reached, both

LEDs flash. If the water level cannot be reduced by pumping, the red LED flashes. As a consequence, the safety cutout switch is triggered after approx. 10 seconds. A potential-free contact or the current circuit opens to switch off

the boiler.

If a corresponding connection to the boiler has been

installed, the boiler is switched off to prevent any further

condensed water from being formed.

ecoLEVEL installation and maintenance instructions 0020029316_01 15

6.3 Fault diagnostics and elimination

If the red LED flashes or remains lit for longer than

1 minute, there is a fault in the installation or a defect in

the pump.

> To eliminate this fault, check the following points:

Page 16

Handing over to the operator

7

Cause Troubleshooting

Pump not pumping:

Kink in the drain hose

Motor blocked

Motor defective Replace condensed water pump

Pump is not being filled

Auxiliary float blocked Release blocked auxiliary float

6.2 Fault diagnosis and elimination

Remove kink

Visual inspection of the motor inlet:

Check for foreign bodies and remove

if necessary

Check inlet hoses for routing, blockage and seating in the pump, and

resolve the fault, if required

Fault messages on the boiler or system controller

You will also find fault messages on the display of your

boiler or system controller. The messages differ depending

on the country, boiler, and connection type. The following

table shows which message is displayed on your unit.

> To eliminate the fault, refer to the installation instruc-

tions for your boiler or system.

7 Handing over to the operator

The operator must be instructed in the handling and functions of the ecoLEVEL condensed water pump.

> Provide the operator with all relevant instructions and

unit documentation for safe-keeping.

> Go through the operating instructions with the operator

and answer any questions the operator may have.

> Draw special attention to the safety information which

the operator must follow.

> Inform the operator of the necessity to ensure that the

system is regularly inspected/maintained (inspection and

maintenance contract).

> Make the operator aware of the need to keep the instruc-

tions near the ecoLEVEL condensed water pump.

Connection for

safety cut-out

switch

Connection type A Status message on unit display (S.39)

Connection type B

6.3 Fault messages, divided according to the connection type

Message if fault occurs

Status message on unit display (S.42);

approx. 15 min fault message (F.77)

16 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 17

Maintenance

8

8 Maintenance

Danger!

Risk of death from electric shock!

a

> Make sure that the infeeds and drains are free from

blockage.

> Clean the non-return valve, as described in (¬ sec-

tion 8.1).

> Remove the cover from the pump and check the conden-

sate vessel for contamination. If necessary, clean the

condensate vessel with warm water and a mild cleaner

(¬ section 8.2)

> Check the inlet and drain lines and clean these if neces-

sary.

> Check that the lines are not kinked to ensure that the

flow rate is unhindered.

i

8.1 Cleaning the non-return valve

There is a risk of electrical shock from live connections.

> Always switch off the power supply to the

pump and to the boiler before performing

maintenance work.

The maintenance of the pump can be based

upon the maintenance intervals of the boiler.

The pump should be maintained at least once

a year.

Removing the non-return valve

> Remove the drain hose.

In doing so, protect against leaking condensed water. For

more information, see the "Safety" section (¬ section 2)

> Remove the non-return valve (1) from the pump cover by

turning it anti-clockwise.

1

4

2

3

3

8.2 Removing the sealing insert

Removing the sealing insert from the non-return

valve

> Proceed carefully when removing the sealing insert.

Ensure that the sealing insert is not damaged.

> To remove the sealing insert (2) from the casing of the

non-return valve, use a screwdriver to carefully push in

the four protruding burls (3).

The sealing insert becomes loose from the casing.

Cleaning the non-return valve

> Remove the ball (4) from the non-return valve.

> Flush the casing of the non-return valve thoroughly with

warm water.

> Clean the ball from the non-return valve with warm

water.

Reinstalling the non-return valve

> If required, clean the pump first before you reinstall the

1

8.1 Removing the non-return valve

ecoLEVEL installation and maintenance instructions 0020029316_01 17

non-return valve (¬ section 8.2)

> Proceed with the installation carefully. Ensure that the

sealing insert is not damaged.

> Place the ball (¬ fig. 8.2), item 4) into the non-return

valve.

> Position the burls (¬ fig. 8.2), item 3) of the sealing

insert (¬ fig. 8.2), item 2) at the designated position.

> Carefully push the sealing insert into the non-return

valve.

Page 18

Spare parts

9

8.2 Cleaning the pump

2

8.3 Cleaning the pump

1

Removing the internal component

> Remove the cover of the pump.

> Press the clip on the internal component (1) inwards and

hold.

> Remove the internal component (1) from the condensate

vessel.

9 Spare parts

Procuring spare parts

The original components of the unit were also certified as

part of the CE declaration of conformity. If you do not use

certified Vaillant genuine spare parts, this voids the CE conformity of the unit. We therefore strongly recommend that

you fit Vaillant genuine spare parts.

You can find information about available Vaillant genuine

spare parts from the contact address provided on the

reverse of this document.

> If you require spare parts for servicing or repair work,

use only Vaillant genuine spare parts.

Removing the O-ring

> Ensure that the O-ring (2) does not remain in the pump.

> Should the O-ring (2) remain in the nut on the base of

the pump, remove it using tweezers.

Cleaning the pump

> Clean the condensate vessel and the internal component

(1) using a soft brush, warm water and some soap. Do

not use scouring or cleaning agents which could damage

the plastic casing.

Reassemble the unit

> Place the O-ring (2) onto the internal component (1) as

shown.

> Place the internal component (1) back into the conden-

sate vessel.

> Ensure that the clips click into place.

> Replace the pump cover on the unit.

18 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 19

Guarantee and Customer Service

10

10 Guarantee and Customer Service

10.1 Vaillant guarantee

Vaillant provides a full parts and labour guarantee for this

appliance for the duration as shown on the enclosed registration card which must be fully completed and returned

within 30 days of installation. All appliances must be

installed by a suitably competent person fully conversant

and in accordance with all current regulations applicable to

the appliance type installation. In the case of gas appliances

the Gas Safety (Installation and Use) Regulations 1998, and

the manufacturer’s instructions. In the UK competent persons approved at the time by the Health and Safety Executive undertake the work in compliance with safe and satisfactory standards. Installers should also be fully conversant

with and competent with all necessary electrical and building regulations that may apply to the installation.

In addition all unvented domestic hot water cylinders must

be installed by a competent person to the prevailing building regulations at the time of installation (G3).

All appliances shall be fully commissioned in accordance

with our installation manual and Benchmark commissioning

check list (this will be included within the installation manual). These must be signed and given to the user for safe

keeping during the hand over process. Installers should also

at this time advise the user of the annual servicing requirements and advise of appropriate service agreement.

Terms and conditions do apply to the guarantee, details of

which can be found on the registration card included with

this appliance. In order to qualify for guarantee after one

year the appliance must be serviced in accordance with our

installation manual servicing instructions. The benchmark

service history should be completed.

Note - all costs associated with this service are excluded

from this guarantee. Failure to install and commission this

appliance in compliance with the manufacturer’s instructions will invalidate the guarantee (this does not affect the

customer’s statutory rights).

11 Recycling and disposal

Both the pump and its transport packaging are made

mainly of recyclable raw materials.

Unit

Faulty pumps and all the accessories must not be disposed

of in the household waste.

> Make sure that the old unit and any accessories are dis-

posed of properly.

If your Vaillant unit is labelled with this symbol, it

does not belong with your household waste at the

end of its useful life.

> In this case, make sure that the Vaillant unit and any

accessories present are properly disposed of at the end

of their useful life.

As this Vaillant appliance is covered by the law regarding

the marketing, return and environmentally friendly disposal

of electrical and electronic equipment (ElektroG in Germany), the unit can be disposed of at no cost at a municipal

collection point.

Packaging

> Leave the disposal of the transport packaging to the

approved competent person who installed the unit

10.2 Vaillant Service

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement.

Please contact Vaillant Service Solutions (0870 6060 777)

for further details.

ecoLEVEL installation and maintenance instructions 0020029316_01 19

Page 20

Technical data

12

12 Technical data

Technical data Units ecoLEVEL

Design Appliance for wall-mounted installation

Nominal capacity l 0.5

Supply voltage V 230

Max. current consumption A 1

Frequency Hz 50

Max. nominal output W 25

Max. feed height m 4

Dimensions Height mm 150

Width mm 175

Depth mm 100

Weight when filled with water kg 1.8

Inlet hose (max. outside diameter) mm 24

Drain hose (min. inner diameter) mm 10

Water inlet temperature °C 1 - 60

Ambient temperature °C 5 - 60

Safety Radio-shielded, non-interacting with the mains supply

Safety cut-out switch 5 mA - 4 A; 230 V

Level of protection in accordance with EN 60529 IP 44

Approved for individual units kW up to 45

12.1 Technical data

20 ecoLEVEL installation and maintenance instructions 0020029316_01

Page 21

Page 22

Page 23

Page 24

Supplier

Manufacturer

0020029316_01 GBIE 102012 – Subject to change

Loading...

Loading...