Page 1

y

Camera and Electronic Products for Integrators

Installation and User Guide

WALLVIEW™ PRO HD1 WITH HSDS™

Vaddio™ PRO Series Cable System with

High Speed Differential Signaling for the

Sony® EVI-HD1 High Definition PTZ Camera

OVERVIEW

The Vaddio WallVIEW PRO HD1 (Figure 1) is built

around the Sony EVI-HD1 2-megapixel CMOS high

definition PTZ Camera. The WallVIEW PRO HD1 uses

high speed differential signaling (HSDS), an active

transmission system that delivers low-loss, high

definition or standard definition video over Cat. 5 cabling

distances up to 500 feet.

The WallVIEW PRO HD1 system is capable of 1080i or

720p HD resolution in a 16:9 format or standard

definition (SD) resolutions – using the optional SD

Break-out cable – in a variety of screen configurations to

fit most monitors. The HD1 camera offers both NTSC

and PAL video standards.

The WallVIEW PRO system also has many new features, including a unique IR forwarding system which

allows the user to forward IR commands from third party IR remote controls, through the WallVIEW system to

a third party device such as a videoconference codec (see Figure 2). Other new features include video

outputs on BNC connectors (Y,Pb, Pr or Y-C and composite), a four position distance adjustment for Cat. 5

cabling, Y-Gain adjustment, and the EZ Interface Module (EZIM). Like all Vaddio WallVIEW systems, the

Thin Profile Wall Mount and mounting hardware is included.

INTENDED USE

Before installing the Vaddio WallVIEW PRO HD1 Camera System, please read the entire manual thoroughly.

All Vaddio camera systems are designed for use indoors. Outdoor operation is not recommended, has not

been tested, and could damage the camera and/or create a potentially unsafe operating condition. Use only

the Vaddio PowerRite power supply provided.

SAVE THESE INSTRUCTIONS

The information contained in this manual will help you install the Vaddio WallVIEW PRO system. For

reference, Vaddio keeps copies of Specifications, Installation and User Guides and most pertinent product

drawings for the Vaddio product line on the website. These documents can be downloaded from

www.vaddio.com

free of charge.

IMPORTANT SAFEGUARDS

Read and understand all instructions before using. Do not operate the any electrical device if it has been

dropped or damaged. In this case, a Vaddio technician must examine the product before operating. To

reduce the risk of electric shock, do not immerse in water or other liquids and avoid extremely humid

conditions.

Use only the power supply provided with the Vaddio WallVIEW products.

Use of an

unauthorized power supply will void any and all warranties.

INFORMATION

For RS-232 control information, please see the full-length Technical Manual for the SONY EVI-HD1 model.

This manual can be found either on the Vaddio or Sony website. Vaddio has also prepared a number of

TechNotes, specifications and drawings designed to inform and educate integrators’ of the value and the

specific uses of Vaddio products.

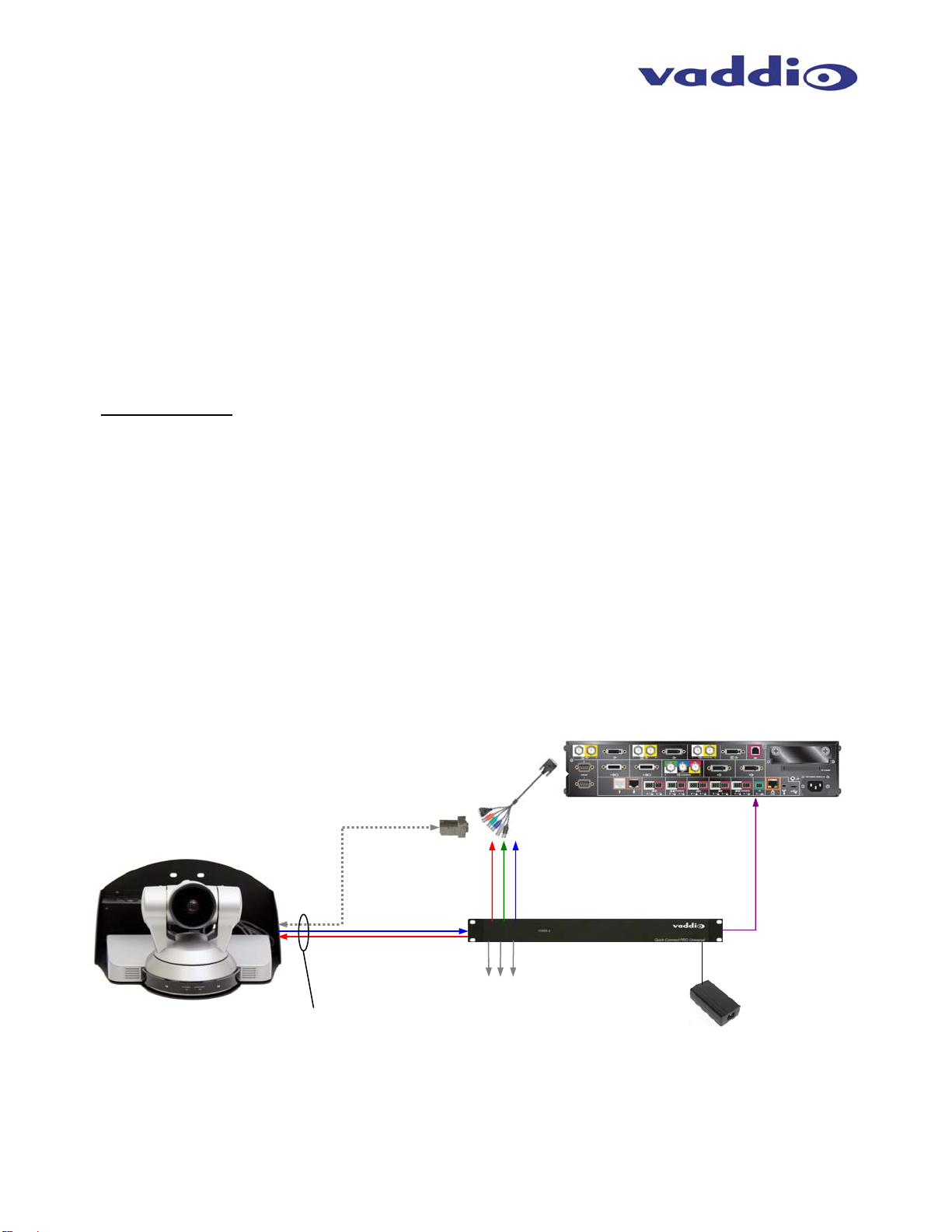

Figure 1:

WallVIEW PRO HD1 System with Camera,

Wall Mount and EZIM

©2008 Vaddio - All Rights Reserved. Reproduction in whole or in part without written permission is prohibited. Specifications and pricing subject to change. Vaddio,

WallVIEW, HSDS, Quick-Connect, EZIM and PowerRite are registered trademarks of Vaddio, Inc. All other trademarks are property of their respective owners.

Document Number 341-661 Rev D.

Page 2

UNPACKING:

Carefully remove all of the parts from the packaging and identify the following parts:

• One (1) - Sony EVI-HD1 High Definition PTZ Camera

• One (1) - Vaddio EZ Interface Module (EZIM)

• One (1) - Vaddio EZIM to HD Break-out Cable

• One (1) - Vaddio Quick-Connect PRO (1-RU Rack Mountable)

• One (1) - Vaddio Thin Profile PRO HD1 Wall Mount

• One (1) - Sony IR Remote Control

• One (1) - EZCamera Control Adapter 998-1001-232 (RJ-45 to DB-9F)

• One (1) - 36V PowerRite™ HD Power Supply with AC Cord Set

• One (1) - 2-position Phoenix Connector for IR

• Mounting Hardware

• Documentation

Vaddio Manual

Sony EVI-HD1 Manual

Optional Accessories: SD Break-out cable (for SD video configurations) - Part # 440-6204-000

TANDBERG Codec RJ-45 to DB-9 Adapter – Part # 998-1002-232

RS-232 and IR Adapter for Polycom 8000 & 7000 Series Codecs - Part # 998-1006-232

INSTALLATION

All WallVIEW products are specifically designed for installation on a vertical wall surface with Cat. 5 cable

connectivity for Power, Video and Control signaling. Installation is simplified in that no custom 8-Pin mini-din

cables or expensive S-Video plenum cables are needed and power outlets are not required near the camera

bracket. All cabling is routed to the head-end using Cat.5 cables. NOTE: All RJ-45 connectors need to be

terminated TIA/EIA 568B or A. The use of RJ-45 “EZ” connectors is not recommended.

Before Installing

• Locate the camera mounting position paying close attention to camera viewing angles, lighting conditions,

possible line of site obstructions, and checking for in-wall obstructions. Pick a location to optimize the

performance of the camera.

• Pre-wire all cabling from the camera location to the equipment head-end.

• The Thin Profile Wall Mount for the WallVIEW HD1 can be mounted directly to a 2-gang wall box or can

be mounted to the drywall using four dry wall anchors.

Wiring Diagram with HDX 9000 Series Codec:

WallVIEW HD1 with Camera,

Wall Mount and EZIM

Up to 500’ (152.4m) of Cat. 5

for Power, Video and Control

Figure 2: The WallVIEW HD1 connected to an HDX 9000 series codec uses the standard RJ-45 to DB-9 adapter

supplied with the system and DB9 M-M gender changer (not supplied) for control between the camera and codec

breakout cable. IR is fed out of the Quick-Connect rack mount unit to the IR port on the back of the HDX 9000 series

codec for IR forwarding from the camera. The Power, Video and Control Cat. 5 cables can be run up to 500’

(152.4m) from the Quick-Connect box to the EZ Interface Module, which connects to the camera. See Step 9 for

additional information on HDX 9000 IR wiring.

RS-232 DB-9F Adapter with

Gender Changer

Video Cat. 5

Power Cat. 5

Y-C and Composite SD video outputs

(using optional SD break out cable – will

not output simultaneous HD and SD video)

Polycom HDCI

Adapter Cable

Component Video (Y, Pb, Pr)

to HD codec or other device

IR Output

(See page 7)

Quick-Connect Pro

36 VDC

Power Supply

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 2 of 14

Page 3

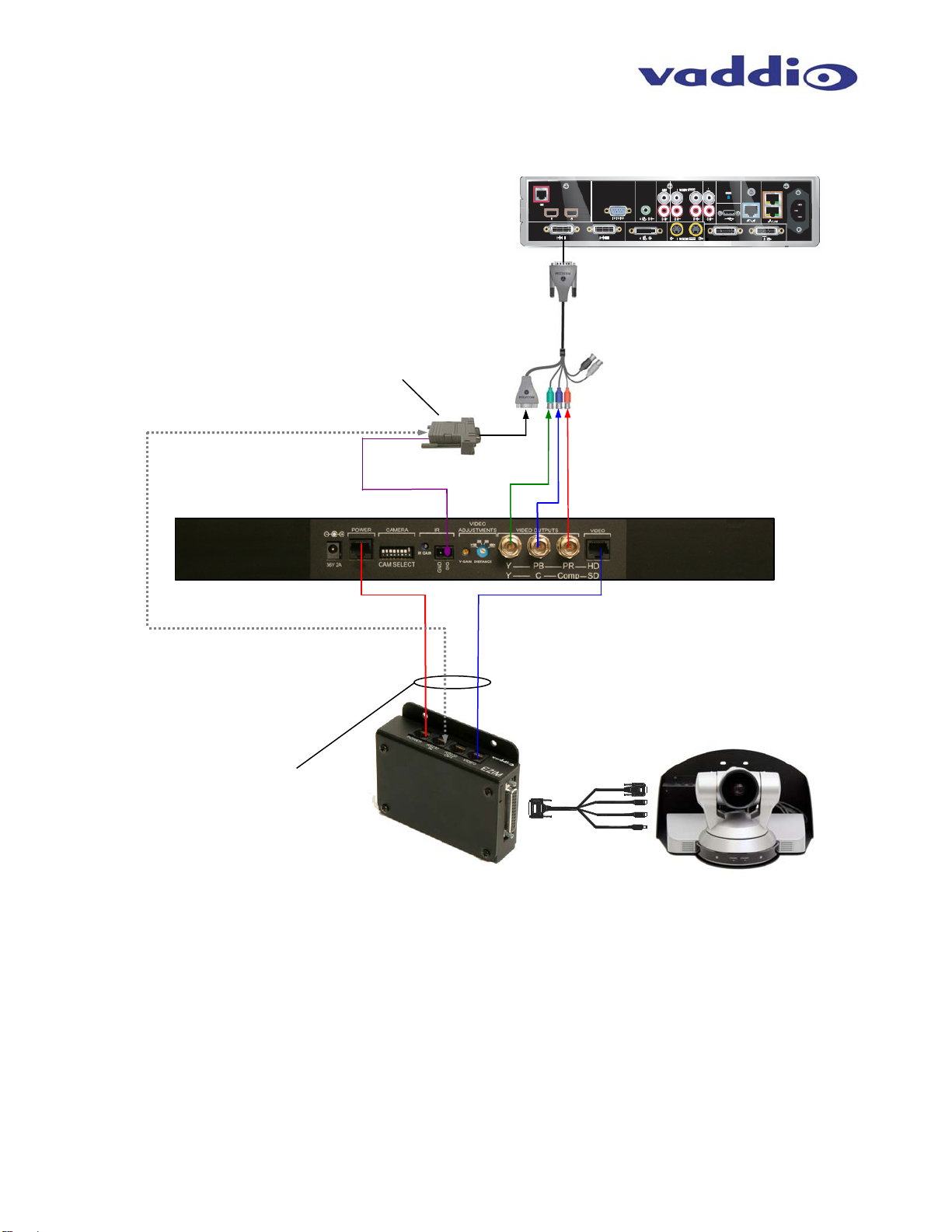

Wiring Diagram Example for HDX 7000 and 8000 Series Codecs:

Requires optional DB-9M to RJ-45 Adapter – Part # 998-1006-232

Optional 998-1006-232

RS-232 and IR Adapter

(see Page 7)

RS-232 Cat. 5

Up to 500’ (152.4m) of Cat. 5

for Power, Video and Control

Figure 3: The WallVIEW HD1 connected to an HDX 7000 / 8000 series codec uses an Optional RJ-45 to DB-9M adapter

(998-1006-232) for PTZ and IR control between the HD1 and codec. IR signals are fed from the HD1 camera, to the

Quick-Connect rack mount unit – see Step 9 for additional information on wiring the HDX 7000 / 8000 codecs. The Power,

Video and Control Cat. 5 cables can be run up to 500 from the Quick-Connect box to the EZ Interface Module, which

connects to the camera.

Polycom HDX-8000

Series Codec

IR Signal Wire

Power Cat. 5

Video Cat. 5

Vaddio HD

Interface Cable for

WallVIEW HD1

Polycom

Breakout

Cable

Component Video (Y, Pb, Pr)

to breakout cable

Quick-Connect PRO

Rack Mount Interface

HD1 on Mount with EZIM

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 3 of 14

Page 4

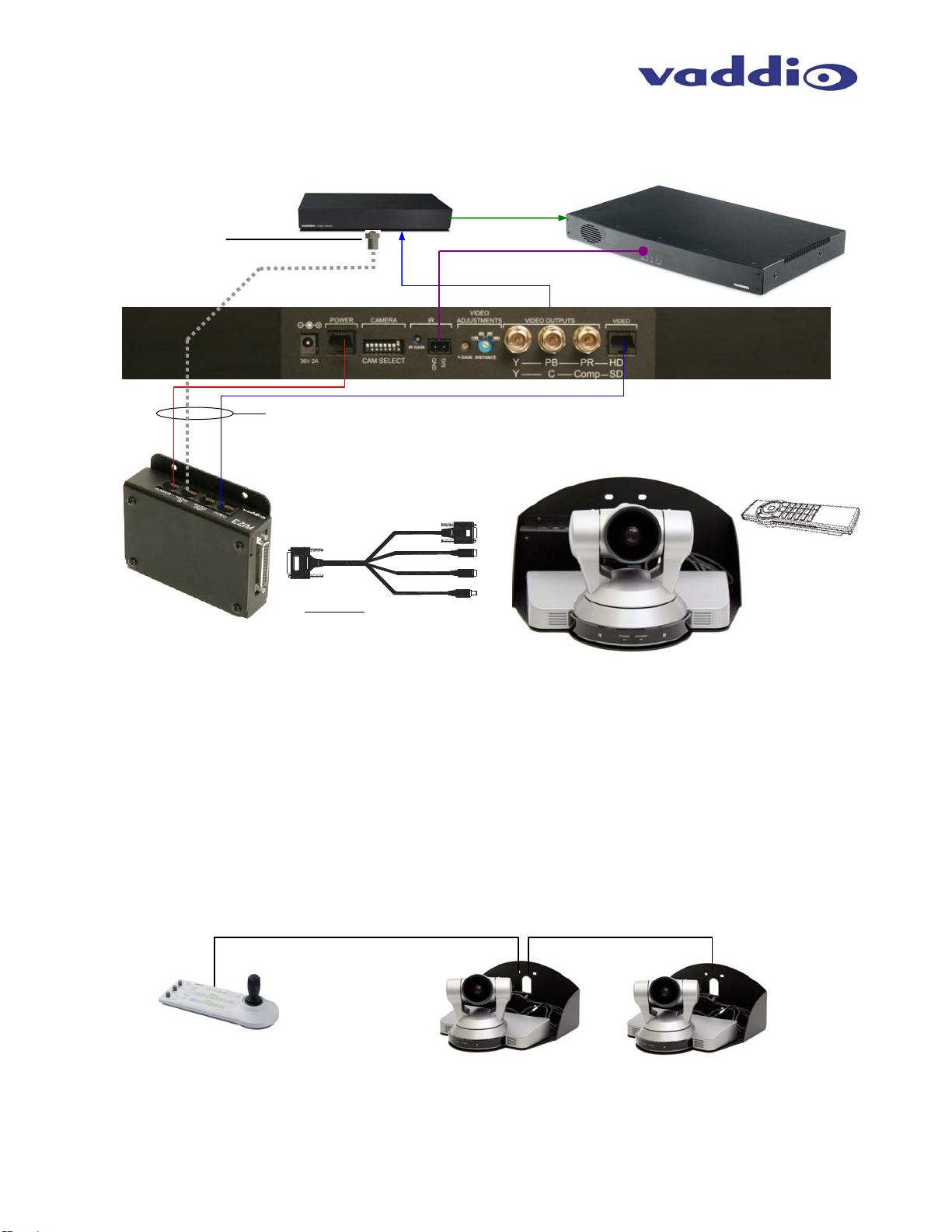

Wiring Diagram Example* for Interfacing with TANDBERG Video Switch:

Requires optional TANDBERG DB-9 to RJ-45 Adapter – Part # 998-1002-232

Daisy Chain Control Configuration:

The WallVIEW PRO HD1 has provisions for daisy chaining control signals when using an RS-232 controller

with only one (1) RS-232 output. Each EZIM has a RS-232 input and a RS-232 output (Figure 3).

Vaddio/Sony Joystick

* Optional TANDBERG

RJ-45 Adapter

Quick-Connect

PRO

TANDBERG

TVS

RS-232

Cat. 5 Cables Up to 500’

Vaddio HD Interface

Cable for WallVIEW HD1

DB-25M

Proprietary

LVDS Signal

IR Probe

HD Video

①

TANDBERG 6000 MXP

TANDBERG IR codes

sent through the camera,

EZIM and Quick-Connect

PRO to HDX Codec

②

③

EZIM

Connector List

① DB-15HD (Y,PB,PR)

② RS-232 IN (8-Pin Min Din)

③ RS-232 OUT (8-Pin Mini Din)

④ POWER (EIAJ4)

Figure 4: Basic connectivity of the WallVIEW PRO HD1 with TANDBERG Video Switch. The WallVIEW HD1 connected to a

TANDBERG 6000 MXP codec and utilizes an Optional RJ-45 to DB-9 adapter for PTZ control between the HD1 and codec.

IR signals are fed from the HD1 camera, to the Quick-Connect rack mount unit to the TANDBERG codec via an IR probe (not

supplied) – see Step 7 for additional information. The Power, Video and Control Cat. 5 cables can be run up to 500 from the

Quick-Connect box to the EZ Interface Module, which connects to the camera. NOTE: See TANDBERG Step 9 for

additional information on IR Probe Wiring and compatible probes.

RS-232 Out via Cat. 5

Cable

-

-

Figure 5:

Daisy chain control configuration using two (2) WallVIEW PRO HD1 systems and a

single RS-232 output control device. See Appendix 1 for wiring and pin-out information.

④

HD1 on Mount with EZIM mounted

under camera and inside camera mount

RS-232 Out RS-232 Input RS-232 Input

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 4 of 14

Page 5

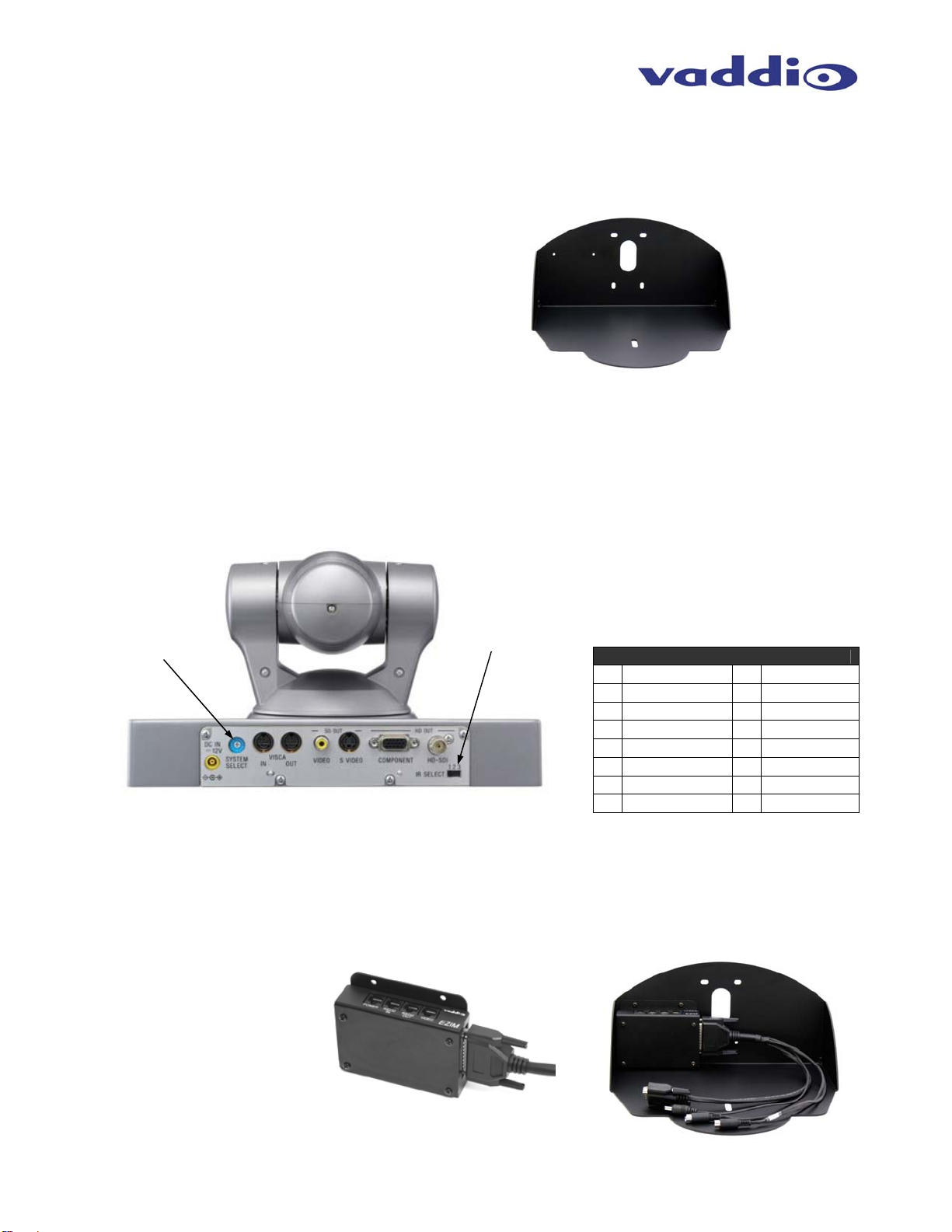

MOUNTING INSTRUCTIONS

Step 1:

After determining the optimum location of the camera system, mark locations for the four screw holes and

cable pass-thru (vertical oval). Install the drywall mounts and cut the hole for the cable pass-thru. At this

point, do not install the Wall Mount.

Step 2:

Set the camera output resolution. The resolution of the camera can be set to HD (high definition) or SD

(standard-definition). The EVI-HD1 cannot output both HD and SD concurrently, so a choice must be made

with the rotary SYSTEM SELECT switch (Figure 5 and Table 1). Also, if an IR Remote is going to be used to

control the camera, chose the IR frequency with the IR SELECT switch. NOTE: SD break-out cable sold

separately.

Figure 7:

Rear panel of EVI-HD1

System Select

Switch

Step 3:

Connect the 25-pin cable to the EZIM. Next, mount the EZIM and break out cable to the back of the wall

mount, using the two tapped screw holes (see Figure 6).

Figure 8:

25-pin connector mounted to

EZIM (left) and EZIM

mounted to the back of the

Wall Mount (right)

Figure 6:

Thin Profile Wall Mount with oval cable feedthrough hole. The wall mount may be mounted

directly to a 2-gang wall box or to drywall with

wall anchors.

System Select

1080i/59.94 8 1080i/50

1 1080p/29.97 9 1080p/25

720p/59.94 A 720p/50

720p/29.97 B 720p/25

4 480i/59.94 (LB) C 576i/50 (LB)

5 480i/59.94 (CR) D 576i/50 (CR)

6 480i/59.94 (SQ) E 576i/50 (SQ)

7 F

Note: If IR forwarding is to be used turn dip switch

#1 on the bottom of the camera to the ON position

IR Select

Switch

Table 1:

System Select switch settings supports

both NTSC and PAL formats, LB = Letter

Box, CR = Cropped, SQ = Squeezed.

Note: See Sony Manual for switch setting

definitions.

System Select

0 1080i/59.94 8 1080i/50

1 1080p/29.97 9 1080p/25

2 720p/59.94 A 720p/50

3 720p/29.97 B 720p/25

4 480i/59.94 (LB) C 576i/50 (LB)

5 480i/59.94 (CR) D 576i/50 (CR)

6 480i/59.94 (SQ) E 576i/50 (SQ)

7 F

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 5 of 14

Page 6

Step 4:

Place the wall mount, without the EZIM installed, against the drywall anchors or 2-gang wall box, making

sure to pull the Cat. 5 cables through the oval hole at the back of the mount. Finger-tighten the screws to the

mount and confirm that the base is level. Tighten the screws firmly. If the bracket is to be mounted on a 2gang wall box, use screws supplied with the electrical box.

Step 5:

Place the EZIM onto the wall mount and with the supplied screws, mount the EZIM to the Wall Mount (see

Figure 6, right photo). Connect the cables to the back of the HD1 PTZ camera, and then secure the camera

to the mount and using the ¼”-20 screw.

Step 6:

Connecting the Quick Connect PRO. The Quick Connect PRO is a 1-RU rack mount interface that breaks

out the signals from the Cat. 5 cables back to the standard connectors. The basic system connectivity is

illustrated in Figures 2 & 3.

Step 7:

Check all Cat. 5 cables for proper continuity in advance of final connection. Attach the Cat. 5 cables for

Power, Video and Control to the Quick-Connect PRO rack mount interface. Connect the BNC video output

connectors – either HD or SD – depending on where the SYSTEM SELECT rotary switch was set in Step 2.

Connect the PowerRite 36 VDC power supply to the Quick-Connect PRO power input.

Note: Plugging the POWER Cat. 5 Cable into the wrong RJ-45 may cause damage to the camera system and void the warranty.

Step 8:

The Quick-Connect PRO interface has an 8-position dip switch on the rear panel to allow the selection of IR

Forwarding Mode for Polycom® and TANDBERG® codecs. The following table defines the dip switch

settings:

DIP Switch Example

WallVIEW Universal PRO back panel

Description Dip Switch (Up = ON) 1 2 3 4 5 6 7 8

*

IR Forwarding through main camera for use with Polycom

* * * * * UP UP

HDX-9000 Series Codecs

• 2-wire signal & GND connection only to IR spring cage connector on the

back panel of the codec

*

IR Forwarding through main camera for use with Polycom

* * * * * DN UP

HDX-8000/7000 Series Codecs

• Single wire from RJ-45 to DB-9 adapter to “SIG” pin on IR Port of the

back of the Quick-Connect PRO

* * * * * UP DN

IR Forwarding through main camera for use with TANDBERG

*

MXP (using the TANDBERG TVS) Codecs

• Modulated IR signal from Quick-Connect PRO to IR probe attached to the

front panel IR window of the codec

o Compatible IR Emitters

Xantech 282MRP

Xantech 283M

UP

DN

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 6 of 14

Page 7

Step 9: For HDX 9000 Series Installs Requiring IR Pass-Thru

Connect a two-conductor wire to the connectors of both the

Polycom HDX codec and Quick-Connect Universal PRO rack

mount box. Ground from the Universal PRO should be

terminated to the “-“ port on the HDX 9000 Series codec’s IR input.

The SIG port on the Universal PRO should be terminated to the

square wave symbol. See adjacent drawing for additional detail

Connect the IR output from the Quick-Connect Universal PRO to

either the IR spring cage IR input on an HDX series codec (where

available) or a Xantech™ IR probe (compatible models: 282MRP

or 283M). The white striped wire on the IR Probe is the Signal

and the black wire is Ground.

Step 9: For HD1 IR Pass-Thru on HDX 7000 and 8000 Series Codecs

Using the Optional RJ-45 to DB-9 adapter (998-1006-232) with the system, strip and terminate the single wire

coming out of the back of the adapter, and connect it to the Phoenix-type connector supplied with the QuickConnect PRO. The wire needs to be terminated to the Signal “SIG” pin on the back of the Quick-Connect

PRO.

Figure 10: Required wiring configuration

for IR Forwarding from the camera IR

port to codec. Note: There is no IR port

on the front of the HDX 7000 and 8000

series codecs. The IR receiver on these

codecs is imbedded in the camera.

Step 9: For TANDBERG Video Switch IR Pass-Thru

If connecting a Xantech IR Probe to the IR output of the QuickConnect Pro, the white striped wire on the probe should be

connected to the signal “SIG” terminal and the ground, or black

wire to “GND”. Attach the probe over the IR window of the codec.

Make sure the dipswitch is in the correct position

Figure 9: Wiring Configuration for

IR Forwarding feature

(optional)

Figure 11: Terminating Xantech

Probe cable to 2-position Phoenix

type connector

RS-232 Cat. 5

Single wire from the back of the Optional

RJ-45 to DB-9 adapter (998-1006-000),

connected to the IR “SIG” (signal) port via a

Phoenix-type connector

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 7 of 14

Page 8

COMPLETING THE INSTALLATION:

Connect the Vaddio 36 VDC power supply to an AC outlet. Power will travel down the Power Cat. 5 cable to

the EZIM, powering the camera. The camera will “Home” to a centered position ready for control information

from the provided IR Remote Control or RS-232 Camera controller of the integrators’ choice. To insure

proper continuity of control and operation of the cameras, the RS-232 controller (control system or joystick)

should be powered on after the camera.

Step 10: Setting the IR Pass-Through Adjustment (optional)

The PRO system is capable of transmitting IR signal frequencies between 25 to 45 kHz. Connect the IR

output from the Quick-Connect PRO to either the IR input on a third party device or a Xantech™ IR probe

(compatible models: 282MRP or 283M). See Figure 8 for terminating the Xantech probe. NOTE: Vaddio has

tested compatibility of the IR forwarding with Sony, Vaddio, Polycom and TANDBERG remote controls.

IMPORTANT NOTE:

(91.4 meters), and should not have to be adjusted unless the Cat. 5 cabling distance is

over this length. For cable runs above 300 feet, slowly adjust the gain level up while

pressing functions on the remote control, pointed at the HD1 camera using the WallVIEW

PRO system. Once all remote control functions are operating from the remote, through the

camera’s IR sensor, the IR gain is adjusted properly.

CARE AND CLEANING

• Do not attempt to take the products in the system apart. There are no user-serviceable components.

• Keep the devices away from food and liquid, and do not spill liquids on the products

• For smears or smudges on the lens, wipe with a clean, soft cloth. Do not use any abrasive chemicals on

the camera body at any time.

OPERATING AND STORAGE CONDITIONS

Do not store or operate the WallVIEW PRO System under the following conditions:

• Temperatures above 40°C (104°F) or below 0°C (32°F), for Indoor Use Only

• High humidity, condensing or wet environments

• Dusty environments

• In inclement weather

• Under severe vibration

The IR Gain adjustment is factory set for distances below 300 feet

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 8 of 14

Page 9

GENERAL SPECIFICATIONS

WallVIEW HD1 System

System Part Numbers 999-6305-000 NTSC

999-6305-001 PAL

Quick-Connect Interface

Connectors Power Connector: 5.5mm OD x 2.5mm ID

Camera Select Switch 8-Position DIP switch loads camera profiles and IR Forwarding for Polycom and TANDBERG Codecs

Video Adjustments Y-Gain (luminance gain) for fine tuning over longer cable distances

Compatible Cameras Sony BRC-H700, BRC-Z700, EVI-HD1, BRC-300, (EVI-D70, EVI-D100 also in SD Mode)

Max. Cat. 5 Cable

Distance

Power Supply 36 VDC, 2.78 Amp

Dimensions 1-RU Rack Mount (1.75” H x 19” W x 6” D)

Power RJ-45: Supplies 36V to EZCamera Interface Module Regulator

IR: 2-Pin Phoenix type spring cage connector

Video Outputs: BNC Connectors for HD Analog Component (Y,PB,PR) or SD

Video RJ-45: Transports HD or SD video from camera depending on camera selection switch position

Distance Compensation: 100’, 200’, 300’, 400’+

Polycom EagleEye

Up to 500’ (152.4m) for Video Power and Control

EZCamera Interface Module

Connectors Four (4) RJ-45 Connectors

Cable Assemblies For Sony HD Cameras: DB-25M to DB-15HD/8-Pin Mini Din x 2/EIAJ4 Power Connector

Power Regulator Supplies 12VDC to Cameras

Dimensions Approx. (3.035” H x 4.46” W x 1.242” D)

One DB-25 for Power, Video, Control & IR

For Sony SD Cameras: DB-25M to RCA-M/4-Pin Mini Din/8-Pin Mini Din x 2/EIAJ4 Power Connector *

* SD Break-out cable

CAMERA SPECIFICATIONS

Sony EVI-HD1 Camera Basic Specifications

Camera Part Number EVI-HD1

Image Sensor 1/3-type CMOS

Effective Pixels Approx 2-Mill Pixels (16:9)

Signal Systems NTSC and PAL

Video Resolutions HD: 1080i (59.94/50), 720p (59.94/50),

Lens 10X Optical, 4X Digital, 40X total

Horiz. Viewing Angle 8° tele to 70° wide (16:9)

Weight Approx. 4 lbs 7 oz (2kg)

Dimensions Approx 10.25” W x 6” H x 6.75” D

SD: 480i, 576i

(259mm x 150mm 169mm)

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 9 of 14

Page 10

Appendix 1: Cable Pin-outs for the WallVIEW PRO System

EZCamera Interface Module Pin-outs:

Power Connector

Pin Signal

1 Power +

2 Power 3 Power +

4 Power 5 Power +

6 Power 7 Power +

8 Power -

RS-232 IN Connector

Pin Signal

1) DTR (Sony® Daisy chain to DSR)

2) DSR (Sony Daisy chain from DTR)

3) Unused

4) Unused

5) Unused

6) Digital GND

7) RXD (from TXD of control source)

8) TXD (to RXD of control source)

RS-232 OUT Connector

Signal

Pin

1) DSR (Sony Daisy chain from DTR)

2) DTR (Sony Daisy chain to DSR)

3) Unused

4) Unused

5) Unused

6) Digital GND

7) TXD (to RXD of control source)

8) RXD (from TXD of control source)

Video Connector

Pin Signal

SD HD

1) IR+ IR+

2) IR GND IR GND

3) Y+ Y+

4) C+ PB+

5) C- PB-

6) Y- Y-

7) Comp. Video + PR+

8) Comp. Video - PR-

DB-25 Connector

Signal

Pins

1 GND Out

14 RXD Out

2 TXD Out

15 DTR Out

3 DSR Out

16 GND IN

4 TXD IN

17 RXD IN

5 DTR IN

18 DSR IN

6 IR

19 GND

7 GND

20 CVBS/PR

8 GND

21 C/PB

9 GND

22 Y/Y

10 GND

23 GND

11 GND

24 12V

12 12V

25 12V

13 12V

EZIM

EZIM

12345678

12345678

12345678

RS-232

IN

RS-232

OUT

RS-232

IN

VIDEOPOWER

RS-232

OUT

VIDEOPOWER

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 10 of 14

Page 11

Quick-Connect Pin-outs:

POWER

CAMERA

36V 2A

CAM SELECT

Power Connector

Signal

Pin

1 Power +

2 Power 3 Power +

4 Power 5 Power +

6 Power 7 Power +

8 Power -

Sony HD & SD Camera Control Pin-outs:

RS-232 IN Connector (8-Pin Mini Din)

Signal

Pin

1 DTR

2 DSR

3 TXD

4 GND

5 RXD

6 GND

7 IR OUT

8 Unused

RS-232 IN Connector (8-Pin Mini Din)

Signal

Pin

1 DTR

2 DSR

3 TXD

4 GND

5 RXD

6 GND

7 Unused

8 Unused

Sony HD Video (analog component) Pin-outs:

Video Output Connector (DB-15HD)

Pin Signal

1 PR

2 Y

3 PB

4 GND

5 GND

6 GND

7 GND

8 GND

9 NC

10 Unused

11 Unused

12 Unused

13 Unused

14 Unused

15 Unused

IR

IR GAIN

5 8 4

5 8 4

5

10

VIDEO ADJUST VIDEO OUTPUTS VIDEO

300

200

400+

>100

Y-GAIN

DISTANCE

SIG.

GND

YPB

Y

PR HD

COMP

C

Video Connector

Pin

SD HD

1) IR+ IR+

2) IR GND IR GND

3) Y+ Y+

4) C+ PB+

5) C- PB-

6) Y- Y-

7) Comp. Video + PR+

8) Comp. Video - PR-

6

7

3

2 1

6

7

3

2 1

1

6

15

11

SD

Signal

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 11 of 14

Page 12

FCC, ICES-003 Compliance and CE Declaration of Conformity

For Vaddio Quick-Connect and EZIM products

FCC Part 15 Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his/her own expense.

Operation is subject to the following two conditions: (1) This device may not cause interference, and (2) This

device must accept any interference including interference that may cause undesired operation of the device.

Changes or modifications not expressly approved by Vaddio can affect emission compliance and could void

the user’s authority to operate this equipment.

ICES-003 Compliance

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques dépassant les limites applicables aux

appareils numeriques de la classe A préscrites dans le Règlement sur le brouillage radioélectrique édicte par

le ministère des Communications du Canada.

European Compliance

This product has been evaluated for Electromagnetic Compatibility under the standards for Emissions and

Immunity and meets the requirements for E4 environment. This product complies with Class A (E4

environment). In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

Standard(s) To Which Conformity Is Declared:

EMC Directive 89/336/EEC

EN 55022A Conducted and Radiated Emissions

EN 55024 Electromagnetic Compatibility - Immunity

EN 61000-4-2 Electrostatic Discharge Requirements

EN 61000-4-3 Radiated Electromagnetic Field Requirement

EN 61000-4-4 Electrical Fast Transients / Burst Requirements

EN 61000-4-5 Surge Requirements

EN 61000-4-6 Conducted Immunity Requirements

EN 61000-4-8 Power Frequency Magnetic Field Requirements

EN 61000-4-11 Voltage Dips, Interrupts and Fluctuations Requirements

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 12 of 14

Page 13

WARRANTY INFORMATION

Hardware* Warranty - One year limited warranty on all parts. Vaddio warrants this product against defects

in materials and workmanship for a period of one year from the day of purchase from Vaddio. If Vaddio

receives notice of such defects during the warranty period, they will, at their option, repair or replace

products that prove to be defective.

Exclusions - The above warranty shall not apply to defects resulting from: improper or inadequate

maintenance by the customer, customer applied software or interfacing, unauthorized modifications or

misuse, operation outside the normal environmental specifications for the product, use of the incorrect power

supply, improper extension of the power supply cable or improper site operation and maintenance.

Vaddio Customer service – Vaddio will test, repair, or replace the product or products without charge if the

unit is under warranty and is found to be defective. If the product is out of warranty, Vaddio will test then

repair the product or products. The cost of parts and labor charge will be estimated by a technician and

confirmed by the customer prior to repair. All components must be returned for testing as a complete unit.

Vaddio will not accept responsibility for shipment after it has left the premises.

Vaddio Technical support - Vaddio technicians will determine and discuss with the customer the criteria for

repair costs and/or replacement. Vaddio Technical Support can be contacted through one of the following

resources: e-mail support at support@vaddio.com or online at www.vaddio.com

Return Material Authorization (RMA) number - Before returning a product for repair or replacement,

request an RMA from Vaddio’s technical support. Provide a technician with a return phone number, e-mail

address, shipping address, and product serial numbers and describe the reason for repairs or returns as well

as the date of purchase and proof of purchase. Include your assigned RMA number in all correspondence

with Vaddio. Write your assigned RMA number on the shipping label of the box when returning the product.

Please see Vaddio’s website for current RMA policies and procedures.

Voided warranty – The warranty does not apply if the original serial number has been removed or if the

product has been disassembled or damaged through misuse, accident, modifications, or unauthorized repair.

Cutting the power supply cable on the secondary side (low voltage side) to extend the power to the device

(camera or controller) voids the warranty for that device.

Shipping and handling - Vaddio will not pay for inbound shipping transportation or insurance charges or

accept any responsibility for laws and ordinances from inbound transit. Vaddio will pay for outbound shipping,

transportation, and insurance charges for all items under warranty but will not assume responsibility for loss

and/or damage by the outbound freight carrier. If the return shipment appears damaged, retain the original

boxes and packing material for inspection by the carrier. Contact your carrier immediately.

Products not under warranty - Payment arrangements are required before outbound shipment for all out of

warranty products.

*Vaddio manufactures its hardware products from parts and components that are new or equivalent to new in accordance with industry standard practices.

.

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 13 of 14

Page 14

Toll Free: 800-572-2011 ▪ Phone: 763-971-4400 ▪ FAX: 763-971-4464

©2008 Vaddio - All Rights Reserved. Reproduction in whole or in part without written permission is prohibited. Specifications and pricing

subject to change. Vaddio, WallVIEW, HSDS, Quick-Connect, EZIM and PowerRite are registered trademarks of Vaddio. All other trademarks

are property of their respective owners. Document Number 341-661 Rev D.

WallVIEW PRO HD1 Installation and User Guide 341-661 Rev. D Page 14 of 14

9433 Science Center Drive, Minneapolis, MN 55428

www.vaddio.com

Loading...

Loading...