Page 1

Installation and User Guide

P

R

O

D

U

R

O

P

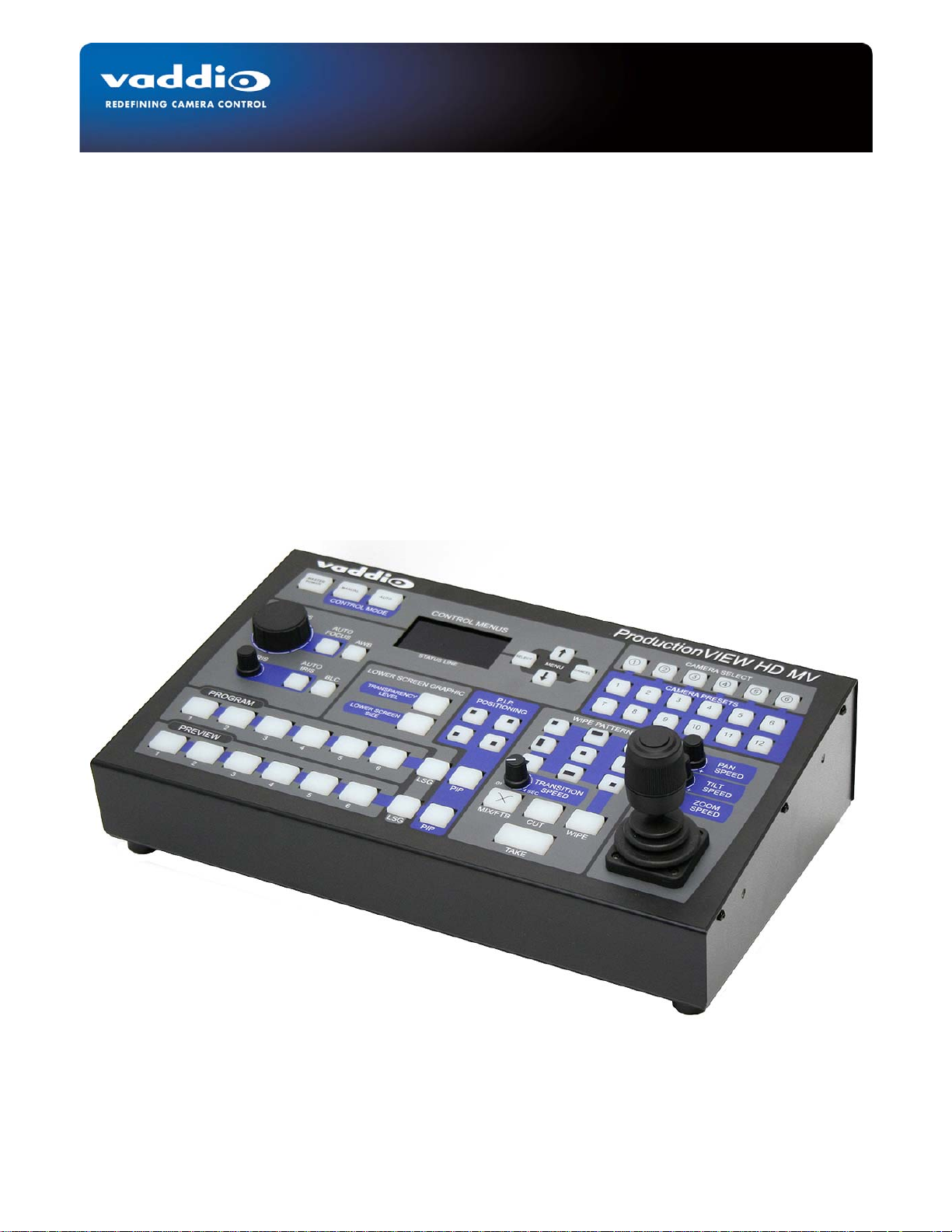

High Definition Camera Control Console with Multiviewer, Digital Inputs

and Outputs, Camera Preset Video Thumbnails and Optional TeleTouch™

Touch Screen Controller

Part Number 999-5625-000 North America

Part Number 999-5625-001 International

D

U

CTTII

C

O

O

N

N

VII

V

E

E

W

W

™

™

H

H

D

D

M

M

V

V

©2011 Vaddio - All Rights Reserved ● ProductionVIEW HD MV ● Document Number 342-0241 Rev. A

Page 2

ProductionVIEW HD MV

Inside Front Cover - Blank

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 2 of 32

Page 3

ProductionVIEW HD MV

Overview:

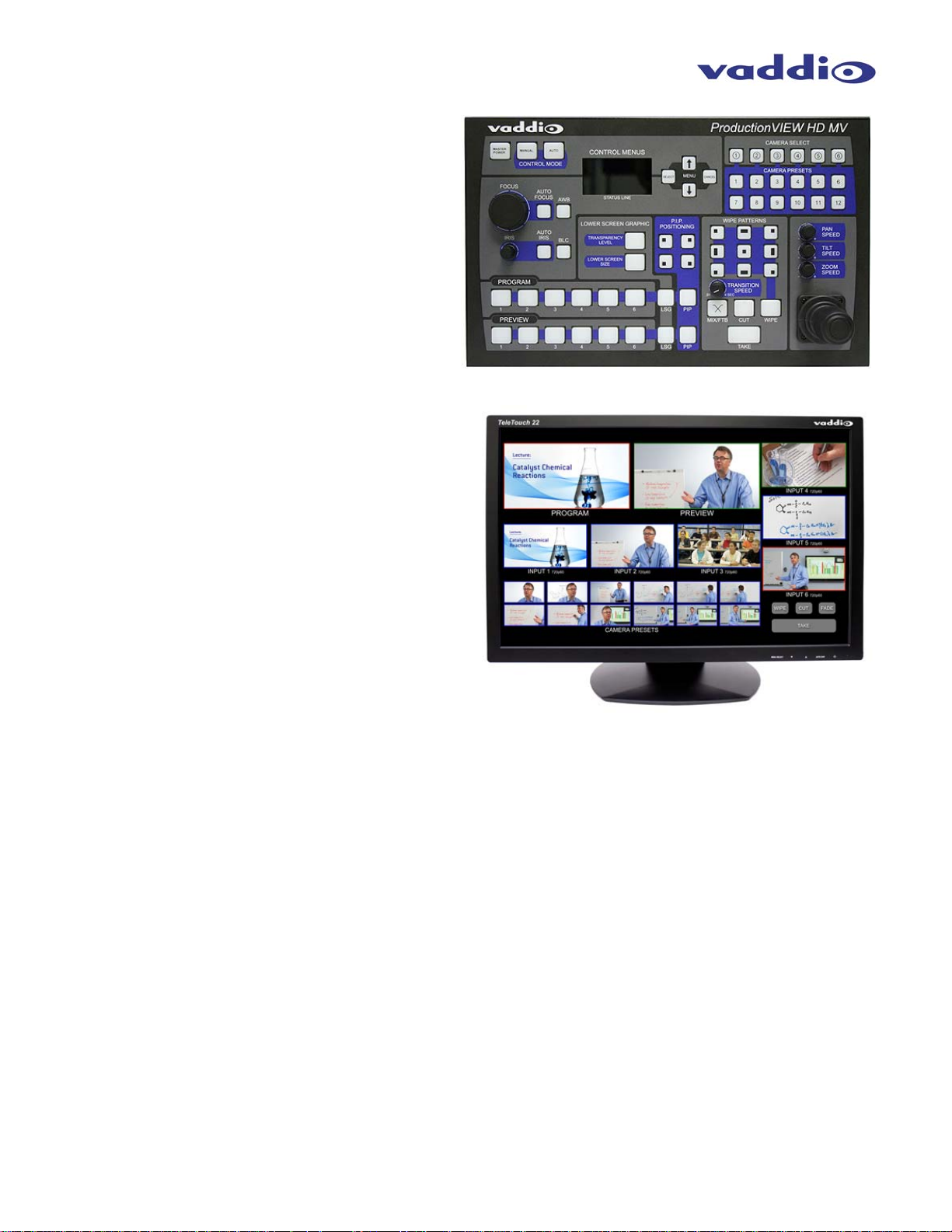

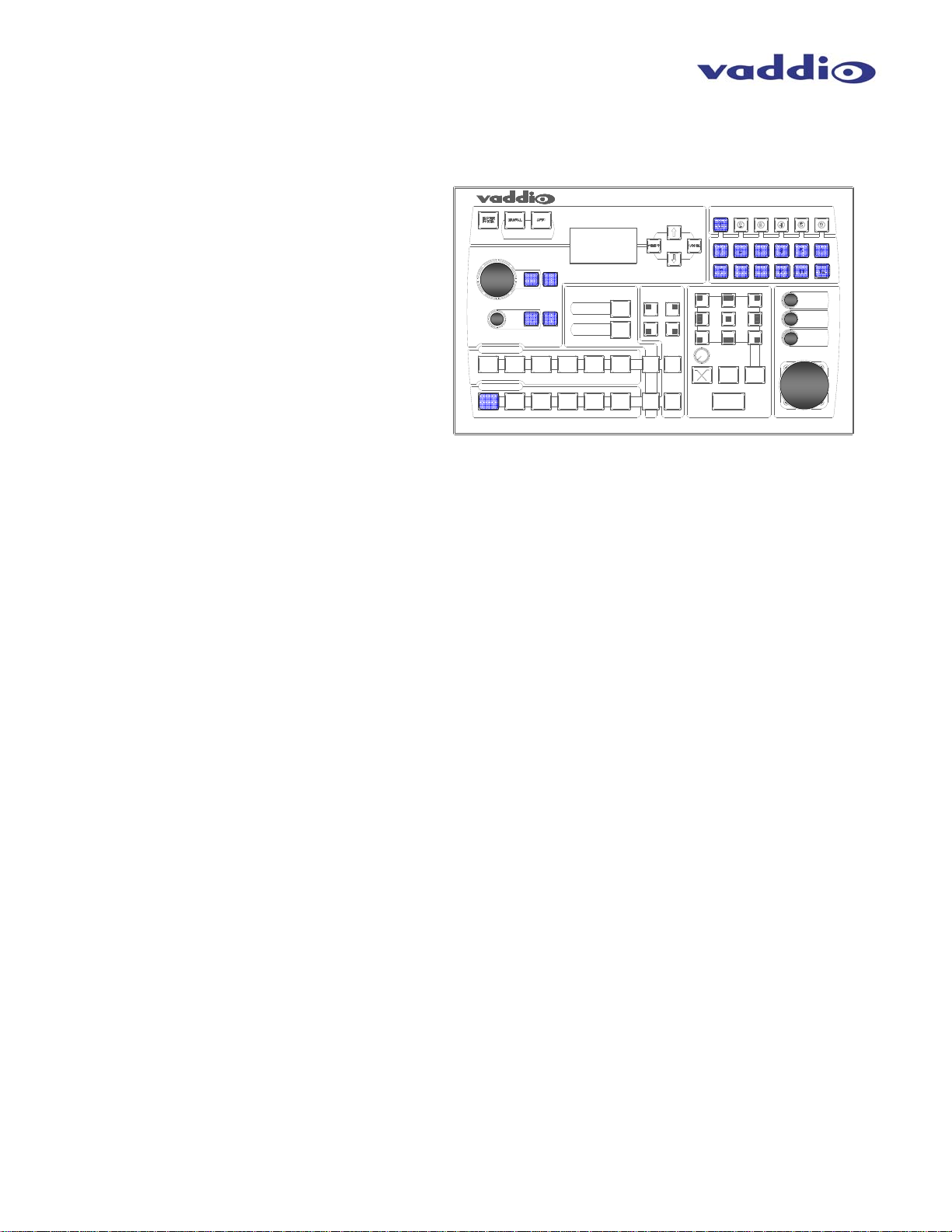

The Vaddio™ ProductionVIEW HD MV Production

Switcher with integrated camera controller and

multiviewer is a powerful, cost effective and easy

to operate platform for live presentation

environments. With Vaddio’s revolutionary

TeleTouch™ Multiviewer Touch Screen Control

Panel (optional, sold separately), production

operators can easily see and switch all live video

feeds and create “video thumbnails” of preset

camera shots with the touch of their finger.

ProductionVIEW HD MV is a broadcast quality 6 x

2 multi-format, seamless video mixer that also

provides two discrete outputs for dual bus program

feeds (two independent 6 x 1 switchers/mixers).

Accepting any combination of input signals from

ProductionVIEW HD MV

Camera Control Console

analog HD YPbPr video, RGBHV, SD (Y/C and

CVBS) video with Input 6 providing a DVI-I input,

the ProductionVIEW HD MV supports HD

resolutions up to and including 1080p/60fps.

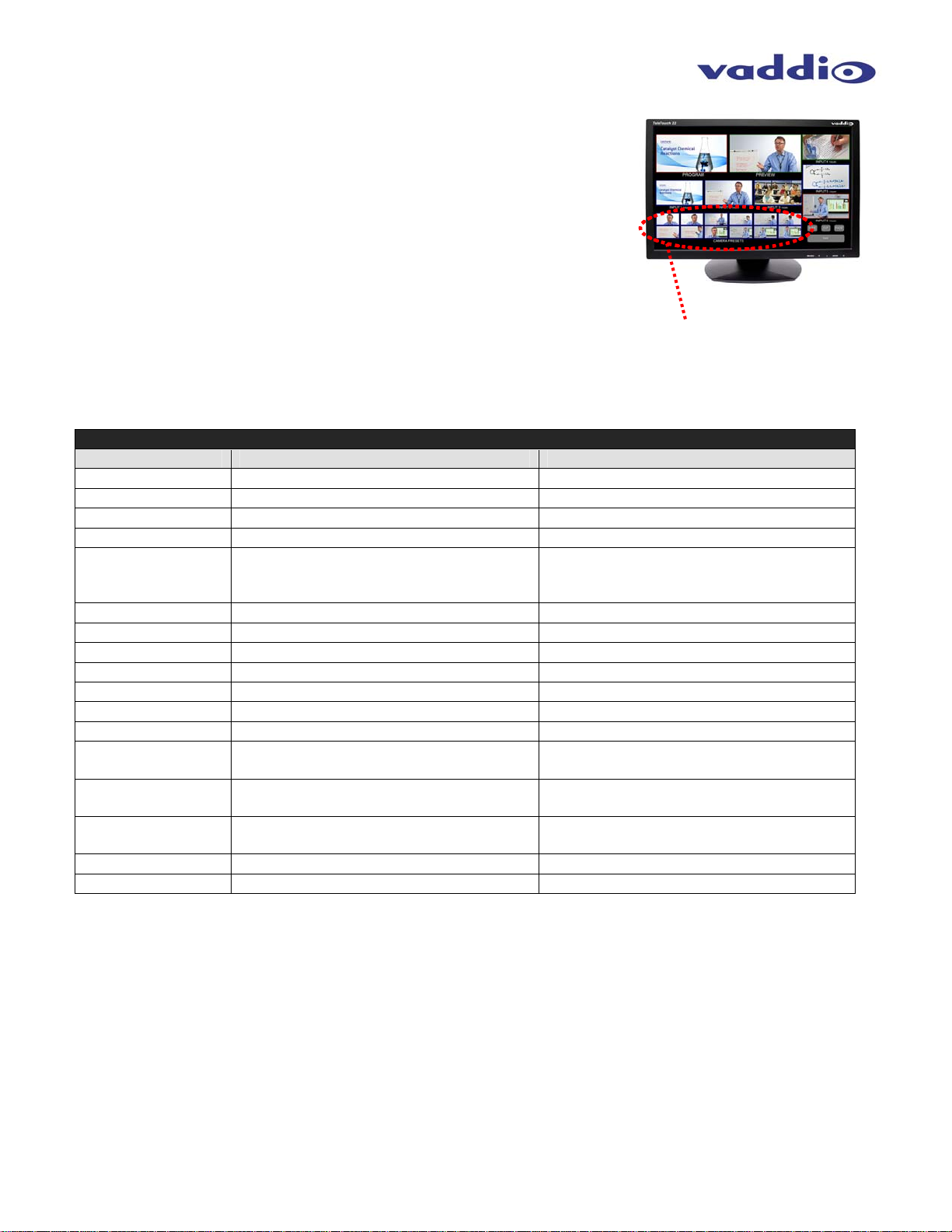

The TeleTouch Multiviewer Touch Screen Control

Panel can be user configured to display four, five

or six input windows as well as two larger preview

and program windows with red and green tally

window borders, which indicate the current output

selections. The outputs have been configured for

analog (YPbPr, RGBHV and SD) and digital (DVID) video support allowing for either a standard

preview output or multiviewer preview output with

support for two monitors or the multiviewer output

supporting a Vaddio TeleTouch Touch Screen

Control Panel. The Vaddio TeleTouch multiviewer

touch screens are available in two sizes; 18.5”

rack-mount (7-RU) version or a standard 22” with

ProductionVIEW HD MV TeleTouch 22”

Multiviewer Touch Screen Control Panel

base.

The TeleTouch Multiviewer Touch Screen Control Panel also eliminates the need for individual preview monitors

and allows the camera operator to see and switch all the live video feeds by simply touching the windows that they

want controlled. Each camera input can have up to 12 stored “video thumbnails” of each preset camera shot.

These video thumbnail images provide an easy way to identify and recall preset camera positions on a per input

basis in the preview window that greatly simplifies overall console operation.

The ProductionVIEW HD MV control surface is laid out to allow even a novice to operate the system with minimal

training. ProductionVIEW HD MV is unmatched in today’s camera control, video mixing and video switching

market.

Key Technical Features:

Video Switcher: The internal video switcher can be configured as a traditional video switcher, using the

TAKE button, or DUAL BUS mode (essentially two 6 x 1 video switchers).

Dual Bus Mode: Dual Bus allows users to switch two separate programs (i.e. IMAG for live presentations on

the Program output, and a secondary program for a recording of the live event on the Preview output). The

Program output can be a discrete resolution setting from the Preview outputs.

Anything In, Anything Out: The inputs auto-detect the video resolution and the outputs have user

configurable discrete video resolution settings. See the specifications on page 23 for additional information

on all of the resolutions supported.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 3 of 32

Page 4

ProductionVIEW HD MV

Vaddio TeleTouch Touch Screen Controller: The ProductionVIEW HD MV outputs can provide either a

standard preview output or a multiviewer preview output with support for two monitors, one of the outputs

supporting a Vaddio touch screen controller. The Vaddio TeleTouch Multiviewer Touch Screens are available

in two sizes; 18.5” (P/N: 999-5520-185) rack-mount or a standard 22” (P/N: 999-5520-022) with base.

Graphic Insertion: Graphics may be inserted as “lower-thirds” using the Lower Screen Graphics (LSG)

feature. LSG can be set up to cover the bottom

¼, ⅓, ½ or full screen, with 10 adjustable steps of

transparency levels between the graphic and the video image behind it.

Graphic Templates: A variety of graphic templates are included on a DVD supplied with the

ProductionVIEW HD MV in both Keynote and PowerPoint, to help guide users in creating professional Lower

Screen Graphics quickly and easily.

3-Axis, 1-Button, Hall Effect Joystick: The ProductionVIEW HD MV includes a 3-Axis Hall Effect joystick

controller to smoothly operate up to six (6) PTZ cameras directly (without daisy chaining). Vaddio, Sony®,

Canon® and Panasonic® PTZ cameras are compatible with ProductionVIEW HD MV (see the list below of

specific models).

Camera Presets: Each input can store up to12 preset PTZ camera preset positions for 72 total presets.

Transitions: On the control surface, buttons for the type of effect; (dissolve, wipe or cut) as well as wipe

patterns are selectable. The transition time is adjustable through a knob on the console, from zero (0.1) to

four (4) seconds.

Automatic Mode: The ProductionVIEW HD MV console is equipped with an automatic camera switching

mode (for compatible PTZ cameras on inputs 1 & 2), and when combined with Vaddio’s StepVIEW™ Mats,

MicVIEW™, PresenterPOD™ or other trigger devices, allows ProductionVIEW HD MV to be set up for use

without an operator present.

Tally Outputs/External Triggers: The ProductionVIEW HD MV can be configured for six Program tally

outputs and six Preview tally outputs for controlling tally lights on external sources. It can also be configured

for up to twelve external trigger inputs.

Additional Features: Other features include auto/manual focus, auto/manual iris, backlight compensation

and automatic white balance for compatible PTZ cameras.

Camera Auto-Sensing: The ProductionVIEW HD MV is capable of auto-sensing each PTZ camera

attached. Control codes for the following cameras are built-in:

Vaddio ClearVIEW HD-Series PTZ Cameras

Vaddio WallVIEW, CCU and PRO Series Cameras

Vaddio CeilingVIEW 70 PTZ Series Cameras

Vaddio HideAway Series Cameras

Vaddio CeilingVIEW Document Cameras

Vaddio Model Series and PTZCam Series Cameras

Sony EVI and Sony BRC Series

Panasonic AW-HE100

Canon VC-C50i & VC-C50iR

Video Transitions:

Video transitions are seamless with exceptional video quality. Transition time is adjustable from zero (0) to

four (4) seconds and include:

Cross Fades (one image fades into another)

Wipes (9 different patterns)

Straight Cuts

Fade To Black (by pressing and holding the MIX/FTB button)

Important Note: When using the Multiviewer output (technically still the Preview output), the

transitions are not visible. The multiviewer gives a representation of the Program bus, but without

transitions. Please use a separate Program monitor to view the actual Program feed.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 4 of 32

Page 5

ProductionVIEW HD MV

p

Intended Use:

Before operating the device, please read the entire manual thoroughly. The system was designed, built and

tested for use indoors, and with the provided power supply and cabling. The use of a power supply other than the

one provided or outdoor operation has not been tested and could damage the device and/or create a potentially

unsafe operating condition.

Save These Instructions:

The information contained in this manual will help you install and operate your product. If these instructions are

misplaced, Vaddio keeps copies of Specifications, Installation and User Guides and most pertinent product

drawings for the Vaddio product line on the Vaddio website. These documents can be downloaded from

www.vaddio.com free of charge.

Important Safeguards:

Read and understand all instructions before using. Do not operate any device if it has been dropped or damaged.

In this case, a Vaddio technician must examine the product before operating. To reduce the risk of electric shock,

do not immerse in water or other liquids and avoid extremely humid conditions.

Use only the power supply provided with the system. Use of any unauthorized

power supply will void any and all warranties.

Please do not use “pass-thru” type RJ-45 connectors. These pass-thru type connectors do not

work well for professional installations and can be the cause of intermitten t connections which

can result in the RS-232 control line failing and locking up, and/ or compromising the HSDS™

signals. For best results please use standard RJ-45 connectors and test all cables for proper

in-outs prior to use and connection to Vaddio product.

UNPACKING:

Carefully remove the device and all of the parts from the packaging.

For 999-5625-000 for North America, unpack and identify the following parts:

One (1) ProductionVIEW HD MV Camera Control Console

One (1) Vaddio PowerRite 18 VDC, 2.75A Switching Power Supply

One (1) AC Power Cable

One (1) Laird 100 ohm ¼” Snap-On Rectangular Ferrite (for DC cable of the Power Supply)

One (1) DVD ROM with templates and sample graphics for Lower Screen Graphics*

Documentation

For 999-5625-001 for International use, unpack and identify the following parts:

One (1) ProductionVIEW HD MV Camera Control Console

One (1) Vaddio PowerRite 18 VDC, 2.75A Switching Power Supply

One (1) Euro Power Cable and UK Power Cable

One (1) Laird 100 ohm ¼” Snap-On Rectangular Ferrite (for DC cable of the Power Supply)

One (1) DVD ROM with templates and sample graphics for Lower Screen Graphics*

Documentation

Notes:

*User must supply their own compatible version of Keynote or PowerPoint to display and modify templates on the DVD ROM.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 5 of 32

Page 6

ProductionVIEW HD MV

ProductionVIEW HD MV with Feature Call-outs:

⑩

⑨

⑧

①

②

③ ④

⑤

⑥ ⑦

1. Focus and Iris Controls: Focus and Iris can be adjusted from knobs on the console for real-time control of

these critical functions when in manual mode. Auto White Balance (AWB) and Backlight Compensation

(BLC) functions are available for compatible cameras.

2. Single Bus or Dual Bus Switching: ProductionVIEW HD MV can be configured as Program and Preview

buses or as discrete video outputs (i.e. one for high resolution IMAG and the other for delivery to a recording

or streaming device).

3. Lower Screen Graphics: Insert “lower third” and other graphics, through our unique LSG function. A variety

of sizes and transparency levels are available through buttons on the console.

4. Picture-In-Picture: Insert video in any quadrant of the program video output to add impact to your live

production. The PIP can be adjusted to three different sizes.

5. Wipe, Fade, Cut, Transition Speed and Fade to Black: Select from a variety of wipe patterns, mix or cut

from buttons on the control console. The fade to black (FTB) feature allows the Program output to fade to

black. Transition Speed allows a wipe or crossfade (mix) to be adjusted up to 4 seconds in duration.

6. Take Button: Pressing the Take button switches the input selected from Preview to Program in single bus

mode. In dual bus mode, it switches the input to the input that is flashing.

7. 3-Axis Hall Effect Joystick PTZ Camera and Speed Controls: Sony, Canon and Vaddio PTZ cameras can

be controlled via the 3-axis Hall-Effect Joystick built into ProductionVIEW HD MV. When the button on top of

the joystick is pressed, it will reposition the selected camera to its home position. Located above the joystick,

adjustable knobs for Pan, Tilt and Zoom speeds allow the operator extremely fine real-time camera control.

8. Camera Selector and Presets: Select a camera from the top row of buttons, and program (or recall) up to

12 preset shots per camera, using the camera preset control buttons.

9. 8-Line LCD Screen (for Menus and Status): The internal menu allows the user to configure the resolution

on the outputs, as well as other parameters built into the console. The LCD screen will also provide status to

current settings. See pages 15 to 19 for the menu structures and programmable functions.

10. Manual and Automatic Modes: In addition to a manual or “operator” mode there is an automatic camera

switching mode for PTZ camera presets assigned to Vaddio input triggers like the StepVIEW™ mats,

AutoVIEW™ IR or PresenterPOD.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 6 of 32

Page 7

ProductionVIEW HD MV

ProductionVIEW HD MV, Rear View with Feature Call-outs:

②

①

⑧

⑦

⑥

1. Power Input: Use only the 18 VDC, 2.75A power supply provided with the ProductionVIEW HD MV.

2. Camera Control Ports on RJ-45 connectors: One camera control port per camera (no daisy-chaining

required). Compatible with Sony, Canon, Panasonic and Vaddio PTZ cameras. See page 4 for details on

cameras and camera systems compatible with ProductionVIEW HD MV.

3. Video Inputs 1-5: Each input 1 through 5 will accept either an HD (YPbPr) or RGBHV or SD (CVBS or Y/C,

with adapter cable) video signals selectable via internal menu on the DE-15-F connector. See the Video

Resolutions table on page 23 for all signals and resolutions supported.

4. Video Input 6: Input 6 is a DVI-I Input (DVI-D and DVI-A). See page 23 for supported resolutions.

5. Program Outputs: The Program outputs are on DE-15-F (HD-15) and DVI-D Connectors. The DVI-D

connector uses a HDMI 1.3 compliant transmitter, so with an adapter cable (DVI-D-M to HDMI) HDMI is also

output. The DE-15-F outputs HD (YPbPr) or RGBHV or SD (CVBS or Y/C, with adapter cable). The DVI-D

outputs DVI-D with sRGB color space and HDMI in YCbCr color space depending on the resolution chosen in

the menu. See page 23 for supported resolutions.

6. Preview/Multiviewer Outputs: The Program outputs are on DE-15-F (HD-15) and DVI-D Connectors. The

DVI-D connector uses a HDMI 1.3 compliant transmitter, so with an adapter cable (DVI-D-M to HDMI) HDMI

is also output. The DE-15-F outputs HD (YPbPr) or RGBHV or SD (CVBS or Y/C, with adapter cable). The

DVI-D outputs DVI-D with sRGB color space and HDMI in YCbCr color space depending on the resolution

chosen in the menu. When using the optional TeleTouch Touch Screen Controller, use the DVI-D Connector

and set the output to 1080p/60 HZ or 1080p/50 for best results. Both Preview/Multiviewer connectors will be

the same resolution. See page 23 for supported resolutions.

7. Tally Outputs/External Triggers: Allows for connecting ProductionVIEW HD MV to up to six Program

external Tally outputs and up to six Preview Tally Outputs when in Manual Mode. Pressing the “Auto” Control

Mode button on activates External Input Triggers such as Vaddio AutoVIEW IR, StepVIEW, TouchVIEW or

MicVIEW triggering devices. ProductionVIEW HD MV recalls the Camera Switching and Camera Presets

automatically as the triggers are received. In this mode, an operator is not required.

8. Control Port: DB-9 for RS-232 control of internal functions (Pin 2 = TX, Pin 3 = RX, Pin 5 = GND).

③

Note: Transitions and effects will only appear on the Program output.

④

⑤

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 7 of 32

Page 8

ProductionVIEW HD MV

First Time Set-up with the ProductionVIEW HD MV:

ProductionVIEW HD MV is designed to be exceptionally easy to use and operate right out of the box. All of the

Vaddio standards for using video, power and control over Cat. 5 cabling are well documented and are in the

manual and available free of charge from the Vaddio website.

Getting Started:

Connect all of the cameras, monitors and peripheral devices to ProductionVIEW HD MV. The back panel has

five-standard DE-15-F (HD-15) connectors and one-DVI-I connector. Vaddio offers several different break out

cables including one for SD video inputs (either Y/C or composite) and two cables (3 ft. or 6 ft.) for high resolution

video (YPbPr or RGBHV). See accessory cables below.

Once you have connected all of your inputs, outputs and the PowerRite power supply, plug the AC cord into an

outlet. ProductionVIEW HD MV will boot up and scan for cameras. As ProductionVIEW HD MV boots up, it will

automatically scan each input to confirm which ports have compatible PTZ cameras connected. After boot up, a

menu will appear on the blue LCD screen.

Configuring Output Resolutions:

On the LCD screen, a chevron (>) will be

displayed next to the menu item that is currently

selected. Press the arrow down button (↓)

adjacent to the LCD screen, until the chevron is

next to “VIDEO OUTPUT MENU” and then press

the SELECT Button. Select PROGRAM OUTPUT,

which will display your options for video output

resolution for the PROGRAM OUTPUT.

Press the arrow down button to the appropriate resolution that is compatible with your video monitor and press the

SELECT Button. Press the CANCEL Button to exit out to the previous menu.

Repeat the process for your Preview Output. Once you have selected the Program and Preview output

resolutions, press the CANCEL Button to get back to the Main Menu. For additional information on the menu

structure, see pages 17 to 21 for additional information.

To set up the Preview out to be a multiviewer output, go to menu item “MULTIVIEWER” and select “ON”. If you

are using the optional Vaddio TeleTouch touch screen controller, go to the System Menu and go to the menu item

“TOUCH SCREEN” and select the 22” or the 18.5” monitor, which sets up the touch screen coordinates. Use

1080p/60 Hz or 1080p/50 Hz output resolution for the multiviewer and TeleTouch Monitor.

Auto Configured Input Resolutions:

The ProductionVIEW HD MV automatically configures and matches the input resolution for each camera

video output connected (with active video output) to an Input Port.

For Inputs 1 through 5, it will scan and select from 1080p/60 Hz (1920x1080) to 640x480@60 Hz. (including

SD 480i/29.97 NTSC and PAL 576i/25 Composite and S-Video).

Input 6 (DVI-I Port) will scan and select from 1080p/60 to 640x480@60 Hz.

Additional Programming: Review the ProductionVIEW HD Menu Structure for additional information on

programming specific parameters. For API and Programming Language, see information in the Appendix.

Vaddio Accessory Cables and Part Numbers:

440-5600-000 – 15-pin to SD (Y-C / CVBS) breakout cable (female BNCs - 1’ / 308.4mm)

440-5600-001 – 15-pin to HD Component (YPbPr/RGBHV) breakout cable (male BNCs - 3’ / .914m)

440-5600-002 – 15-pin to HD Component (YPbPr/RGBHV) breakout cable (male BNCs - 6’ / 1.83m)

440-5600-003 – 15-pin to HD Component (YPbPr/RGBHV) breakout cable (female BNCs - 7” / 177.8mm)

440-5600-00\: Optional SD Accessory

Cable (Y-C & Composite) Required for

SD signals into ProductionVIEW HD MV

Optional HD Accessory Cable

(3’ or 6’ length)

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 8 of 32

Page 9

ProductionVIEW HD MV

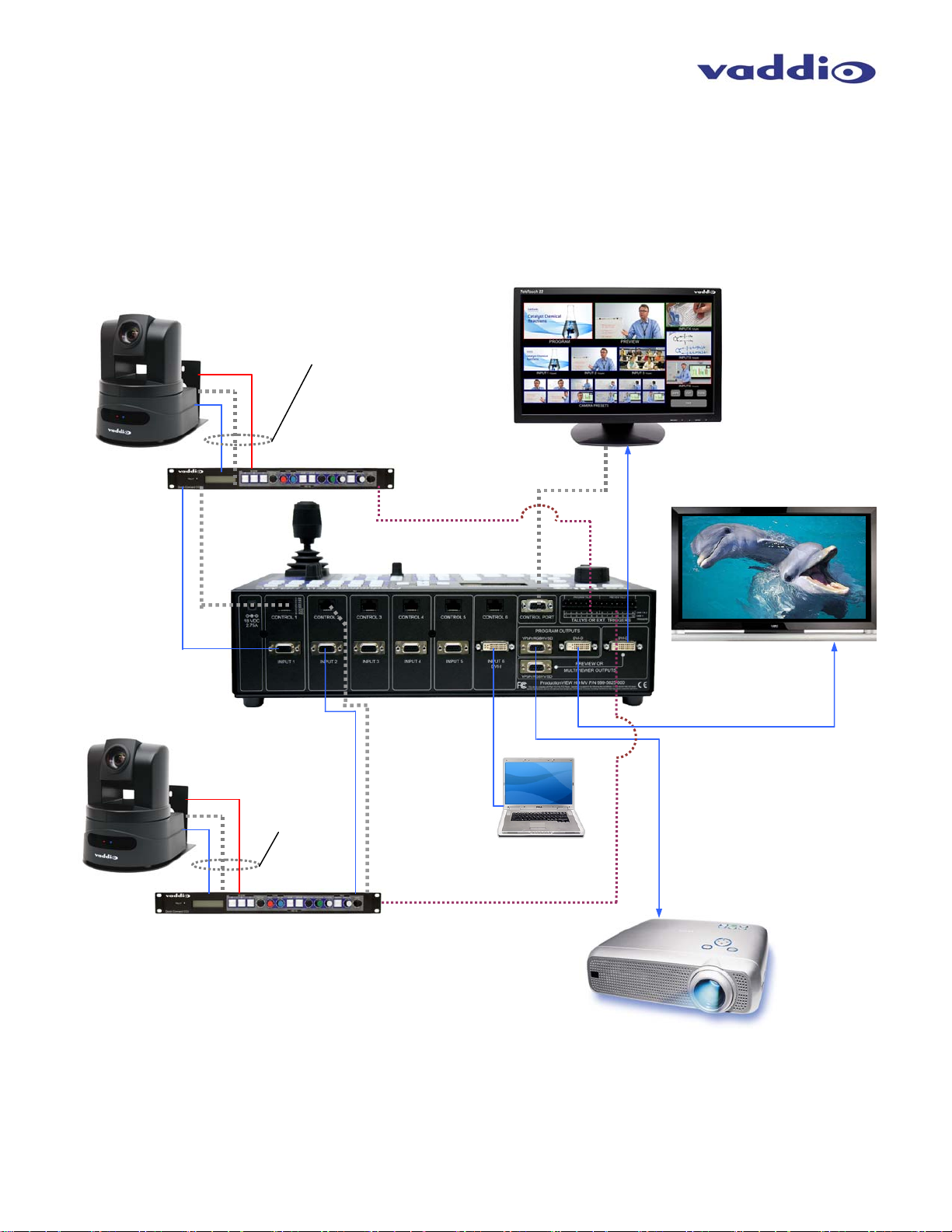

Basic System Configuration:

ProductionVIEW HD MV connected to two (2) Vaddio Quick-Connect™ HD-18 CCU Systems, PC, TeleTouch 22”

Touch Screen Controller and room projector. The TeleTouch Multiviewer Touch Screen Controller eliminates the

need for individual preview monitors and the touch screen greatly simplifies overall console operation. The

TeleTouch Multiviewer Touch Screen can be configured to display up to six input windows and two larger

Program bus and Preview bus windows with red and green tally window borders. It also displays video

thumbnails for up to 12 camera presets per camera input.

TeleTouch 22” Touch Screen

LCD Monitor with Base

Vaddio HD-18

PTZ Camera

Power

Video, Control and

Power Cat-5e up to

500’ (152.4m)

Multiviewer Out

at 1080/60p

RS-232

CAM 1

Quick-Connect CCU

ProductionVIEW HD MV

TALLY

RS-232 on

DB-9

DVI-D HD Video

Program Feed with Transitions

YPbPr

HD Video

Vaddio HD-18

PTZ Camera

Power

Quick-Connect CCU

Video, Control

and Power Cat5e up to 500’

(152.4m)

YPbPr

HD Video

DVI-D

DVI-A

RS-232 CAM 2

OR

3-LCD Projector

Program Out

with Transitions

PC/MAC

TALLY

Simulated Video Feed

Program Out

DVI-D to HDMI with

Adapter Cable 1080/60p

YPbPr

HD Video

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 9 of 32

Page 10

ProductionVIEW HD MV

Operating the ProductionVIEW HD MV:

Most of the console functions and controls are easy and intuitive. Over the next few pages there are details on

how the different functions operate.

Camera Controls:

The controls that can be used to adjust a PTZ

camera are highlighted in the diagram to the right

(mechanical functions are in gray, and electronic

in blue). See notes below for additional

information.

ProductionVIEW HD MV is shipped with “Select

Follow Preview” as the default setting. In this

configuration, the camera that is selected on the

Preview bus will automatically choose the

appropriate Camera Select button in the upper

right corner. In this example, Input 1 is a PTZ

camera on the Preview bus and the Camera

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

TRANSPARENCY

BLC

LOWER SCREEN

STATUS LINE

LEVEL

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

Select is illuminated on Input 1 (“1” with a circle

around the number).

3-Axis Hall Effect Joystick: Within the menus, the 3-axis joystick is programmable for pan, tilt and zoom

direction control. The zoom-in/zoom-out, tilt-up/tilt-down and pan-left/pan-right commands can be inverted on all

3-axis to customize control of the PTZ cameras attached to ProductionVIEW HD MV. Pan, tilt and zoom speeds

can be adjusted on controls above the joystick. The PTZ speeds are set on a per camera basis. The top button

on the joystick will return the camera to its HOME position.

Preset Location Storage Options: This feature allows the user to store 12 camera presets in the

ProductionVIEW HD MV or have the option of storing 6 camera presets (1 through 6) in the camera and 6 presets

(7 through 12) in the ProductionVIEW HD MV. When storing the presets in the camera, the user is allowed to

speed switch camera presets. Please see the ProductionVIEW HD MV Menu Structure, System Menu for access

to the Preset location parameter.

Setting Camera Presets: To program a PTZ camera preset, press and hold the Camera Select button for three

(3) seconds. The Camera Preset button (1 thru 12) will begin to flash. Move the camera to the desired PTZ

position, and select one of the Camera Presets buttons to store the position. Repeat the process for each preset

position that is required to be stored, up to 12 total positions per PTZ camera. A non-flashing preset button has a

location stored, but can be overwritten.

Select Follows Preview: When “Select Follows Preview” is activated, the camera selected for control is the

camera selected by the Preview bus selection. The operator selects the camera to be previewed, and control

(joystick and camera control) is transferred to that camera. The default position for this feature from the factory is

‘on’.

Focus, Iris, Auto White Balance and Backlight Compensation: When the Auto Focus or Auto Iris buttons are

turned off, the manual focus and iris knobs can be used to adjust these functions on compatible PTZ cameras that

are connected to the system. Auto White Balance (AWB) automatically adjusts the camera’s color settings based

on lighting and other factors. Backlight Compensation (BLC) opens the iris to allow objects in front of windows

and other bright backgrounds to be more visible.

Dual Bus Mode: Select Follow Preview is disabled when the system is set for Dual Bus mode.

NOTES:

1) Camera presets contain all the camera information besides the Pan/Tilt/Zoom position including brightness, focus,

backlight, zoom speed etc….

2) The particular control saved under each camera preset is a function of the parameters available on the camera only.

3) Camera presets will not save specific settings of a Quick-Connect CCU.

4) Backlight Compensation can only be used when the Auto White Balance is turned on.

5) Auto White Balance will not operate with the Panasonic AW-HE100, as well as the WallVIEW HE100 cameras.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 10 of 32

Page 11

ProductionVIEW HD MV

Wipe, Cut or Mix Transitions:

To set up the switcher to transition from the current

input selected as the Program output to another

input, select a different video signal on the Preview

bus. In the example to the right, Program is on

Input 1 and Preview is on Input 3.

Select the type of effect (wipe, cut or mix) that the

switcher will use to transition from one input to the

other. Pressing the Take button will execute the

transition from one input to the other, using the

selected transition (wipe, cut or mix).

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

TRANSPARENCY

BLC

LOWER SCREEN

STATUS LINE

LEVEL

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

Changing Effect: To change the type of transition, Wipe, Cut or Mix, select that effect above the Take button.

Changing Transition Speed: Both the Mix and Wipe effects can be adjusted from .01 to 4 seconds, by adjusting

the Transition Speed knob, which is located above the Mix button.

Transitions in Dual Bus Mode: Both Program and Preview will allow for transitions (the same type of transition

will occur on both outputs). To select the input that will replace the current output on each bus, press the input

that will become the next signal sent to the output for either buses, or one bus. The signal that each bus will

switch to, will flash. Press the Take button, and the transition will occur from the current output to the next one on

each bus, one after the other. The other option for making a transition is to press the flashing button a second

time, which will execute the switch from the current (solid lit button) video signal, to the next video signal (flashing

button).

Fade To Black:

The Fade to Black feature allows a user to fade

the Program and Preview outputs to black, and

then fade the outputs up from black. To have

the outputs fade to black, press and hold the

MIX/FTB button for more than one second. The

outputs will start fading to black.

At the point where it is appropriate to fade up

from black, press and hold the MIX/FTB button

again, and the Preview and Program outputs will

return to their selected video inputs that were

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

TRANSPARENCY

BLC

LOWER SCREEN

STATUS LINE

LEVEL

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

selected prior to pressing FTB.

FTB Speed: The speed at which the signal fades in and out can be adjusted through the internal menu of

ProductionVIEW HD MV. Speed ranges from 0.1 to 4.0 seconds (01 to 40 in the menu). See the

ProductionVIEW HD MV Menu Structure section of this manual for the location of the internal menu that adjusts

FTB timing.

Dual Mode FTB: Pressing and holding FTB in Dual Mode allows both the Preview and Program outputs to fade

to black, just as it will in Single Mode operation.

Note: FTB transition time is adjusted via the internal menu of ProductionVIEW HD MV, not from the Transition

Speed knob

.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 11 of 32

Page 12

ProductionVIEW HD MV

Lower Screen Graphics:

Preparing to display Lower Screen Graphics on

ProductionVIEW HD MV, first select your

“background” video input (typically a live camera)

on the Program bus, and then select the input

that has the computer graphics that are to be

displayed, on the Preview bus. In the example to

the right, the background is Input 1 on Program,

and the computer is on Input 6.

To initiate the Lower Screen Graphic, press one

of the LSG buttons on either bus, and the graphic

will appear.

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

BLC

STATUS LINE

TRANSPARENCY

LEVEL

LOWER SCREEN

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

Transparency Level: To increase or decrease the transparency of the graphic overlay, press and hold the

Transparency Level button down. The system will toggle through the levels to allow the user to select the level

that is appropriate for the graphics.

Lower Screen Size: To increase or decrease the size of the graphic overlay, press and hold the Lower Screen

Size button. The system will toggle through the sizes (bottom ¼, ⅓, ½ or full screen), to allow the user to select

the level that is appropriate for the graphics that have been created.

Increasing/Decreasing Transparency Level and Lower Screen Size: When LSG is activated; pressing the

PIP upper left button will allow both Transparency Level and Lower Screen Size to increase when either button is

pressed. Pressing the lower left PIP button will allow the LSG controls to decrease when either button is pressed.

Note: This feature does not work in Dual Bus mode.

LSG in Dual Bus Mode: In Dual Bus Mode, where seamless switched outputs with effects and transitions can

be delivered out of both the Preview and Program outputs, select the Input on each bus that will be the

“background” image. Next, select the input that has the computer graphics that will be displayed (the second

button that is pressed on each bus will flash). Press the LSG buttons on the Program and Preview buses. The

graphics will be placed on each output seamlessly.

LSG Presets: Preset configurations for LSG can be set up utilizing the Camera Preset buttons in the upper right

of the console. Up to 12 preset configurations of lower screen size and transparency level can be programmed.

To do this, with LSG mode turned on, simply set a Lower Screen Size and Transparency Level. Next, press and

hold one of the 12 Camera Preset buttons for approximately 4 seconds. The Lower Screen Size and

Transparency Level will be stored in that preset position, much like a camera preset can be stored in the system.

Change the Transparency Level and/or Size and store the new preset in one of the other 12 Camera Preset

selector buttons. A total of 12 LSG presets can be stored in the system. The last LSG preset position displayed

will be the one recalled when LSG is turned back on. Currently, the preset positions for the LSG can only be

changed when LSG is turned on.

Note: A DVD containing sample graphics in both Keynote and PowerPoint is supplied with ProductionVIEW HD

MV. The sample graphics provide users with an easy way of getting started creating graphics for their own live

productions.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 12 of 32

Page 13

ProductionVIEW HD MV

PIP Display:

To set up and display a Picture-In-Picture on the

Program output, select the input that will be the

“background” on the Program bus. Select the

video input that will be the picture-in-picture, or in

the “window” on the screen. In the example to

the right, the background is Input 1 on the

Program bus and Input 3 is the window on the

Preview bus.

Next, select the corner that the PIP window will

show up in, using the P.I.P. Positioning buttons

(upper left, upper right, lower left and lower right).

In the illustration to the right, the lower left is

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

TRANSPARENCY

BLC

LOWER SCREEN

STATUS LINE

LEVEL

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

selected.

To display the PIP, press either of the PIP buttons, and the PIP will appear on the screen. Input 3 will now be

displayed in a window in the lower left corner of the screen.

Changing PIP Size: To change the size of the PIP (small, medium or large), press and hold the PIP Positioning

button and ProductionVIEW HD MV will toggle through the sizes.

PIP In Dual Mode: If ProductionVIEW HD MV is set up for Dual Mode (independently switched live feeds on

Preview and Program buses) select the background source. Next, select the PIP source, which will flash. Press

the PIP button for that specific bus, and the window will be displayed. Press the PIP button to remove the window

from the screen. PIP is discrete for the Program and Preview buses when the system is in Dual Mode.

Master Power, Manual and Auto Modes:

If ProductionVIEW HD MV is to be used with an

operator at the console, the Manual mode button

will need to be illuminated.

Pressing the Auto button will activate the Auto

mode, which is a configuration when

ProductionVIEW HD MV is used in conjunction

with Vaddio’s StepVIEW mats, MicVIEW system

and AutoVIEW IR sensors or other trigger

devices. These triggers allow ProductionVIEW

HD MV to automatically switch between camera

inputs and preset camera positions. In this mode,

CONTROL MODE

FOCUS

AUTO

FOCUS

AUTO

IRIS

IRIS

PROGRAM

123456

PREVIEW

123456

CONTROL MENUS

AWB

LOWER SCREEN GRAPHIC

TRANSPARENCY

BLC

LOWER SCREEN

STATUS LINE

LEVEL

SIZE

POSITIONING

LSG

LSG

ProductionVIEW HD MV

MENU

P. I. P.

WIPE PATTERNS

TRANSITION

SPEED

.01 4 SEC

PIP

MIX / FTB

CUT

PIP

TAKE

CAMERA SELECT

CAMERA PRESETS

-

-

-

WIPE

PAN

SPEED

+

TILT

SPEED

+

ZOOM

SPEED

+

no operator is required.

The mats and sensors can be placed in locations, such as podiums, white boards, etc. to allow the system to be

run in “Presenter” or Auto mode. No operator needs to be present when the system is set up in Auto mode.

ProductionVIEW HD MV handles camera switching and PTZ movements automatically.

Master Power Switch

When the Master Power Switch is powered down, all of the attached cameras will be placed in standby.

Press and hold the power switch for 3 seconds to initiate power down sequence. This is a safeguard to

prevent accidental shutdown.

When the Master Power Switch is powered up, all attached cameras will activate and select default camera

and preset information as defined in the menu. The ProductionVIEW HD MV will scan the inputs for camera

type and video signal type and auto-configure accordingly. This can take up to one minute and is normal

operation.

Note: When the camera control ports are changed or reconfigured, the “Rescan Cameras” option in the menu

must be selected and started to rescan the cameras and reload the proper control codes. If only the video

inputs are changed, then activate the Rescan Video function in the Main Menu to reset the video input

priorities.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 13 of 32

Page 14

ProductionVIEW HD MV

(

)

(

)

r

Using the Multiviewer and Control modes with the Optional TeleTouch™ HD Touch Screen LCD Monitors:

Vaddio has the optional TeleTouch 22” and 18.5” Resistive Touch Technology, Full HD LCD Monitors available

for use with the ProductionVIEW™ HD MV and ProductionVIEW HD-SDI MV Multiviewer Video Consoles.

TeleTouch 18.5” Rack Mount HD Touch Screen LCD Monitor

Simulated ProductionVIEW Multiviewer Output

The Vaddio TeleTouch LCD touch screen monitors for the ProductionVIEW MV series consoles use 5-wire

resistive touch technology, which allows the operator to control the consoles with the simple touch of a finger,

gloved hand or stylus. The TeleTouch monitors can be configured to display up to six (6) input windows and two

(2) larger Preview and Program windows with green and red tally borders. In addition, each PTZ camera input

can store up to 12 video thumbnail preset camera shots.

Unlike retail/consumer grade monitors, the TeleTouch LCD panels are high-end, industrial quality and are

designed for durability when used in demanding control environments.

Connecting the TeleTouch Touch Screen LCD Monitors to the ProductionVIEW HD MV:

Step 1: To use the Multiviewer and TeleTouch Touch Screen Controller, connect the main RS-232 port (DB-9-F)

of the ProductionVIEW HD MV to the RS-232 port of the TeleTouch monitor with the cable provided. Connect the

provided DVI-D cable from the multiviewer output (preview DVI-D Connector) to the DVI-D input of the TeleTouch

Monitor.

RS-232

Port on

DB-9-F

RS-232 (Cable Supplied)

DVI-D OUT from Multiviewer

(Cable Supplied)

22” TeleTouch Touch Screen LCD Monito

Step 2: In the menus, go to the menu item “MULTIVIEWER” and select “ON”. Then go to the System Menu and

go to the menu item “TOUCH SCREEN” and select the 22” or the 18.5” monitor, which sets up the touch screen

coordinates. Use 1080p/60/50 Hz output resolution for the multiviewer.

to Monitor IN

TeleTouch 22” HD Touch Screen LCD Monitor with Base

Simulated ProductionVIEW Multiviewer Output

RS-232

Port on

DB-9-F

ProductionVIEW HD MV with Built-in Multiviewer

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 14 of 32

Page 15

ProductionVIEW HD MV

TeleTouch LCD Monitor Touch Screen Software,

Hardware and how it Works.

➀

Details:

1) Program video output window with red tally border.

2) Preview video output window with green tally border.

3) Video window name and output resolutions listed under Program and Preview windows.

4) Up to 6 input windows, labeled INPUT 1 through INPUT 6, with input resolutions listed. These smaller input

5) Up to 12 preset video thumbnails (still shots) allow the user to see a still image of the camera position before

6) Standard base for the 22” monitor. The base can be removed and a 100mm x 100mm VESA mount can be

7) Standard control features with the Take button and choice of fade, cut or wipe transitions. Transitions will not

8) One (1) of six (6) standard video windows with blue borders (blue indicates that the window has not been

To operate the ProductionVIEW HD MV with the Touch Screen:

Plug in all the sources (PTZ Cameras, Video Whiteboard, PC etc…). Try to get the sources at the same

For simple switching, touch any of the six (6) standard video input widows. This touch will elevate that input

Touch the larger Preview screen with the green tally border (or touch the TAKE button) to “take” the Preview

The TAKE can be performed 2-ways; by touching the large Preview window with the green tally border or by

➂

➃

➄

➅

windows also have Program and Preview tally borders.

calling up a preset into the input windows.

used instead of the base.

appear on the TeleTouch multiviewer preview monitor. Transitions appear on the Program output only.

chosen for Program or Preview).

resolution or close, as this enhances switching speed. Once the sources are plugged in and Steps 1 & 2 were

performed on the previous page then move on.

window to the larger Preview screen and both the standard input screen and Preview screen are given green

tally boarders and are cued up for the Program shot.

shot to the Program output. The Preview shot will move to Program and both the Program output and the

standard input window will be given red tally borders. Meanwhile, back at the ranch, the previous Program

window and standard input window will be moved to the Preview position and given the green tally boarders.

use of the large grey TAKE button (#7 above). Other buttons allow the operator to switch between fades,

wipes or cuts. The time for these transitions is still controlled by the console.

1080p/60 1080p/60

➁

➇

➆

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 15 of 32

Page 16

ProductionVIEW HD MV

2

2

How to Create Presets and Video Thumbnails:

To set up still video thumbnails of preset camera positions, touch and

hold a standard video input window with a PTZ camera, for our example

input window #2. The size of the widow will reduce to about ¼ its size

(same size as the video thumbnail) and is ready to be positioned. With

the ProductionVIEW HD MV’s joystick, position the camera where it can

be easily recalled for later use. These areas will be lectern positions,

whiteboard areas, podium areas, choir areas, center aisle for entrances,

close ups and distant shots and anywhere in between. The presets will

be still shots of those areas.

After the camera 2 is positioned, touch one of 12 video thumbnails below

to store the still shot of that position. Move the camera again and touch

a second thumbnail window and so on. Do this for every PTZ camera

that you desire presets for future recall.

12 Video Thumbnails

(stills) used for PTZ

Camera Presets

To exit, touch (and don’t hold) a video input window,

General Specifications

TeleTouch™ HD Touch Screen LCD Monitors

Feature TeleTouch 22” TeleTouch 18.5”

Part Numbers 999-5520-022 (Worldwide) 999-5520-185 (Worldwide)

LCD Panel 22” TFT Color LCD 18.5” TFT Color LCD

Touch Screen Type 5-Wire Resistive Touch 5-Wire Resistive Touch

Control Interface RS-232 (DB-9F) RS-232 (DB-9F)

Resolutions for

ProductionVIEW

HD MV (Optimized)

Video Format DVI-D DVI-D

Aspect Ratio 16:10 16:9

Brightness 300 nit (cd/m

Contrast Ratio 1000:1 1000:1

Pixel Pitch 0.282mm 0.3mm

Display Colors 16.7 Million 16.7 Million

Viewing Angle 170° (H) x 160° (V) 170° (H) x 160° (V)

Power Supply 12VDC, 5.0A

with NA, Euro and UK Power Cord Set

Mounting Standard Base or 100mm x 100mm

Dimensions

20.1” (510.5mm) W x 13.3” (387.82) H

(W x H x D)

Weight 13.4 lbs (607813 kg) 11.0 lbs (4.98951 kg)

Supplied Cables DVI and RS-232 (DB-9 M to F) DVI and RS-232 (DB-9 M to F)

1080/60p & 1080/50p 1080/60p & 1080/50p

) 300 nit (cd/m

)

12VDC, 5.0A

with NA, Euro and UK Power Cords

7-RU Metal Rack Mount

VESA Hole Pattern

Monitor Enclosure

19” (482.6mm) W x 12.2” (309.9mm) H

x 2.4” (60.1mm) D

x 2.1” (53.3mm) D

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 16 of 32

Page 17

ProductionVIEW HD MV

ProductionVIEW HD MV Menu Structure

The ProductionVIEW HD MV has an 8-line LCD that displays the system menus. The menus are traversed with

the up/down arrows, select and cancel buttons. The menu structure is as follows:

1st Screen ProductionVIEW HD MV

V01.00.XX (software version)

Main Menu

Rescan Cameras

Rescan Video

Video Output Menu

DVI Input Mode

SD Video Format

Default Camera

Default Preset

Default Idle Return

Pan Dir Menu

Tilt Dir Menu

Zoom Dir Menu

Preset Pan Speed

Preset Tilt Speed

Preset Zoom Speed

External Triggers

Select Follow Prv

Multiviewer

Cam Search Menu

CCU Mode Menu

System Menu

Rescan Cameras

>Select (Note: Rescans all RS-232 ports for camera inputs)

>Start

Rescan Video

>Select (Note: Resets all inputs, outputs and video processor)

>Start

Video Output Menu

>Select

>Video Output Menu

>Program Output

HD 1080p/60/59.94 Hz

HD 1080p/50 Hz

HD 1080i/59.94 Hz

HD 1080i/50 Hz

HD 720p/59.94 Hz

HD 720p/50 Hz

HV 640 x 480 - 60 Hz

HV 640 x 480 - 75 Hz

HV 800 x 600 - 60 Hz

HV 1024 x 768 - 60 Hz

HV 1024 x 768 -75 Hz

HV 1280 x 1024 -60 Hz

HV 1280 x 800 - 60 Hz

HV 1280 x 768 - 60 Hz

HV 1280 x 720 - 60 Hz

HV 1360 x 768 - 60 Hz

HV 1400 x 1050- 60 Hz

HV 1600 x 1200 - 60 Hz

HV 1680 x 1050 - 60 Hz

HV 1920 x 1200 - 60 Hz

SD 480i /29.97Hz

SD 576i/25Hz

Menu Section

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 17 of 32

Page 18

ProductionVIEW HD MV

>Preview Output

HD 1080p/60/59.94 Hz*

HD 1080p/50 Hz*

HD 1080i/59.94 Hz

HD 1080i/50 Hz

HD 720p/59.94 Hz

HD 720p/50 Hz

HV 640 x 480 - 60 Hz

HV 640 x 480 - 75 Hz

HV 800 x 600 - 60 Hz

HV 1024 x 768 - 60 Hz

HV 1024 x 768 - 75 Hz

HV 1280 x 1024 - 60 Hz

HV 1280 x 800 – 60 Hz

HV 1280 x 768 – 60 Hz

HV 1280 x 720 – 60 Hz

HV 1360 x 768 – 60 Hz

HV 1400 x 1050 – 60 Hz

HV 1600 x 1200 – 60 Hz

HV 1680 x 1050 – 60 Hz

HV 1920 x 1200 – 60 Hz

SD 480i/ 29.97Hz

SD 576i/ 25Hz

MV 1080p/ 59.94Hz*

MV 1080p/ 50Hz*

MV 1080i/ 59.94Hz

MV 1080i/ 50Hz

DVI Input Mode

>Select

High Res (1440 x 900 @ 60 Hz and resolutions above)

SD Video Format

>Select

>Squeeze

>Letter Box

>Squeeze

>Letter Box

Video Input Note: ProductionVIEW HD MV Auto Configures each Input Port for each camera connected.

Default Camera (Automatic and Start-up Modes – the default input selected on the Program bus when the system is turned on)

>Select

> 00 – 06

Default Preset (Automatic Mode – the default preset that the camera is sent to when the system is in Auto Mode. Only reverts to the

configured default position after a trigger has been activated in Auto Mode)

>Select

> 01 – 12

Assigns camera preset 1 through 12 as Default Preset on the default camera (default is 01)

Def Idle Rtn (Default Idle Return Position - Automatic Mode only using an external trigger such as a StepVIEW Mat)

Pan Dir Menu (Pan Direction Menu)

>Select

>All Ports: Normal or Invert (default is Normal) Inverts the Joystick Pan Direction (Inverted - left = right)

>Port 01: Normal or Invert

>Port 02: Normal or Invert

>Port 03: Normal or Invert

>Port 04: Normal or Invert

>Port 05: Normal or Invert

>Port 06: Normal or Invert

>Select Returns to Main Menu

>DVI Input Mode Menu

Low Res (1360 x768 @60 Hz and resolution below)

> Program Output

>Crop

>Preview Output

>Crop

Selects inputs 1 through 6 as the default camera (default is 01)

>Select

>00 – 60

Default Camera Idle Return Timer - with no other trigger input, the system returns to the Default Camera and Default

Preset after this time elapses (The default setting is 10 or roughly 10 seconds. To disable function, set to 00. )

*NOTES:

MV settings for the multiviewer bypass the video

processing engine. For best results, use the HD

1080p/60/59.94/50 Hz for the multiviewer output for

fully adaptive deinterlacing, adaptive 3D noise

reduction, mosquito noise reduction, block artifact

reduction, adaptive detail enhancement featuring

sharpness and texture enhancement with overshoot

control, and adaptive contrast enhancement.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 18 of 32

Page 19

ProductionVIEW HD MV

Tilt Dir Menu (Tilt Direction Menu)

>Select

>All Ports: Normal or Invert (default is Normal) Inverts the Joystick Tilt Direction (Inverted - up = down)

>Port 01: Normal or Invert

>Port 02: Normal or Invert

>Port 03: Normal or Invert

>Port 04: Normal or Invert

>Port 05: Normal or Invert

>Port 06: Normal or Invert

>Select Returns to Main Menu

Zoom Direction

>Select

>Normal or Invert (default is Normal)

Inverts the Joystick Zoom Direction (Inverted - Clockwise twist = zoom out)

Preset Pan Speed

>01 – 24 (default is 18)

Sets the Pan Speed on all cameras between camera presets (24 is fastest)

(This parameter does not affect the Pan Speed or sensitivity of the Joystick)

Preset Tilt Speed

>Select

>01 – 20 (default is 15)

Sets Tilt Speed on all cameras between camera preset changes (20 is fastest)

(This parameter does not affect the Tilt Speed on the Joystick)

Preset Zoom Speed

>Select

>00 – 07 (default is 04)

Sets Zoom Speed on all cameras between camera presets

Ext Triggers (Automatic Mode)

>Select

>6 Cam 1, 6 Cam 2

>Select

>All 12 Cam 1

External Trigger Assignment - 6 triggers each for cameras 1 and 2, or all 12 triggers for camera 1 presets

Select Follow Preview

>Select

>On or Off

Multiviewer

>Select

>On or Off

Note: When activated, you must go to Touch Screen Menu and select either the 22” or 18.5” Vaddio TeleTouch Touch

Screen.

Cam Search Menu

>Select

>All Ports: (select search method – Auto, Sony, Canon, Panasonic)

>Port 01: (select search method – Auto, Sony, Canon, Panasonic)

>Port 02: (select search method – Auto, Sony, Canon, Panasonic)

>Port 03: (select search method – Auto, Sony, Canon, Panasonic)

>Port 04: (select search method – Auto, Sony, Canon, Panasonic)

>Port 05: (select search method – Auto, Sony, Canon, Panasonic)

>Port 06: (select search method – Auto, Sony, Canon, Panasonic)

CCU Mode

>Select

>All Ports: (Select method – Direct Cam Ctrl or CCU)

>Port 01: (Select method – Direct Cam Ctrl or CCU)

>Port 02: (Select method – Direct Cam Ctrl or CCU)

>Port 03: (Select method – Direct Cam Ctrl or CCU)

>Port 04: (Select method – Direct Cam Ctrl or CCU)

>Port 05: (Select method – Direct Cam Ctrl or CCU)

>Port 06: (Select method – Direct Cam Ctrl or CCU)

When activated, camera selection switching follows the Preview bus selection, immediately transferring joystick and

camera control directly to the camera selected on the Preview bus (On is default). NOTE: This function only works in

Single Bus Mode – and not in Dual Bus Mode.

NOTE: When using the Panasonic HE-100 cameras, it is required to select Panasonic.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 19 of 32

Page 20

ProductionVIEW HD MV

NOTE: When Vaddio Quick-Connect CCUs are used with ProductionVIEW HD MV, the CCU mode disables Iris

functions, AWB and BLC on the ProductionVIEW HD MV console, allowing the user to control these functions from the

Quick-Connect CCU only.

System Menu

>Select

>Serial Input

>Select

>On or Off

Turns on or off serial input (default is on)

>Serial Echo

>Select

>On or Off

Turns Serial Echo on or off (default is on)

>Serial Info

>Select

>On or Off

Reports button pushes on front panel out the serial port (default is off)

(Does not report joystick position)

>Panel Lights

>Select

>00 through 50

Panel Light Brightness (all lights - 50 is the brightest) (default is 25, off is 00)

>Clear Memory

>Select

>Start

Clears the camera preset memories and sets all parameters to default settings

>Clear Presets

>Select

>Start

Clears the camera preset memory only

>Power Up Preset

>Select

>Home Camera

>Select - Upon power up, all cameras will go to their home position

>Preset 12

> Select - Upon power up, all cameras will go to Preset 12

>Preset Location

>Local

>6 InCam 6 Local

In “Local” mode, the ProductionVIEW stores all 12 presets internally

In “6 InCam 6 Local” mode, the presets 1 through 6 will be stored in the cameras.

Presets 7 through 12 will be stored in the ProductionVIEW.

Note: The “6 InCam 6 Local” mode allows for switching video sources when cameras are moving to preset

locations. Since Presets are stored in Camera, the system does not have to wait for position feedback before

allowing another command to be entered.

>Switching Mode

>Select

>Single Mode (Default)

>Dual Mode

NOTE: See page 2 for additional information on Dual Bus mode, as well as pages 11 – 14.

>Transition Swap (Default is on)

>On

>Off

>Settle Time (Default is 20)

>Select

>01 to 90

Note: Settle time allows the user to set up the time delay between pressing the Take button and when the

next button can be selected on the console. With a lower settle time, there is a greater chance that a

blue screen will appear on the Program output, when the video is switched quickly, and repeatedly.

In most applications this will not be an issue. In Single Bus Mode, a faster Settle Time will also create

a video roll on the Preview output, which again in most situations will not be an issue.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 20 of 32

Page 21

ProductionVIEW HD MV

>FTB Time (Default is 10)

>Select

>10 to 40

>Program Lockout (Default is on)

>Select

>On

>Off

>Tally Level (Use Active Low)

>Active High

>Active Low

>Save Config

>Save Config Now

>Touch Screen

>22 Inch

>18.5 Inch

Note: Once you select the TeleTouch Touch Screen you are connecting to the ProductionVIEW HD MV, you must go to

the Multiviewer Menu and select On to activate the Touch Screen Control.

>Home Button

>On

>Off

>Init Triggers

>Start

>Lock Program

>On

>Off

Selecting On will lock the Program until you select Off.

>Select

Returns to Main Menu

Note: FTB Time allows the user to set up a length of time that a fade to black on the Program Output will

occur. 10 is equal to 1.0 second, 11 is equal to 1.1 seconds, etc. FTB is executed on

ProductionVIEW HD by pressing and holding the Mix/FTB button for more than 2 seconds.

Note: Program Lockout prevents a user from selecting a different source on the Program bus of the

switcher.

Note: All changes are saved as they occur in the switcher. The Save Config allows the user to save all

parameter changes, if multiple changes have been made.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 21 of 32

Page 22

ProductionVIEW HD MV

ProductionVIEW HD MV Back Panel Connectors:

Power:

18 VDC, 2.75A (5.5mm OD x 2.5mm ID), Positive Center

Inputs 1-5:

Analog Component Video - YPbPr, RGBHV, Y/C and CVBS (DE-15 female x 5)

RS-232C Port (RJ-45 Jack x 5)

Input 6:

DVI-I Female x 1

RS-232C Port (RJ-45 Jack x 1)

Preview/Multiviewer Out:

Analog Component Video - YPbPr, RGBHV, Y/C and CVBS (DE-15 female x 1)

DVI-D Female x 1 (Use with TeleTouch Multiviewer Touch Screen LCD Monitor at 1080p/60 for North

America and 1080p/50 for International installations)

Program Out:

Analog Component Video - YPbPr, RGBHV, Y/C and CVBS (DE-15 female x 1)

DVI-D Female x 1

Control Port:

RS-232 - DE-9-F (DB-9-F)

Triggers/Tally:

14-pin Molex 5.0mm Euro connector (two 7-pin mating connectors)

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 22 of 32

Page 23

ProductionVIEW HD MV

General Specifications:

Automatically Accepted Input Resolutions:

Analog Component (YPbPr)

1080p/60/59.94/50/30/25Hz

1080i/60/59.94/50 Hz

720p/60/59.94/50 Hz

480i/29.97Hz NTSC (Y/C or CVBS)

576i/25 Hz PAL (Y/C or CVBS)

RGBHV

640 x 480 @ 60Hz - VGA

640 x 480 @ 75Hz - VGA

800 x 600 @ 60Hz - SVGA

1024 x 768 @ 60Hz - XGA

1024 x 768 @ 75Hz - XGA

1280 x 768 @ 60Hz - WXGA

1280 x 1024 @ 60Hz - SXGA

1360 x 768 @ 60Hz - WXGA

1400 x 1050 @ 60Hz - SXGA+

1600 x 1200 @ 60Hz - UXGA

Input 6 - DVI-D

1080p/60/59.94/50/30/25Hz

1080i/60/59.94/50 Hz

720p/60/59.94/50 Hz

1920 x 1200 @ 60Hz - WUXGA

1600 x 1200 @ 60Hz - UXGA

1400 x 1050 @ 60Hz - SXGA+

1440 x 900 @ 60HZ -WXGA+

1360 x 768 @ 60Hz - WXGA

1280 x 1024 @ 60Hz - SXGA

1280 x 800 @ 60 Hz - WXGA

1280 x 768 @ 60Hz - WXGA

1152 x 720 @ 60Hz - XGA+

1024x 768 @ 75 Hz - XGA

1024 x 768 @ 60Hz - XGA

800 x 600 @ 60Hz - SVGA

640 x 480 @ 75Hz - VGA

640 x 480 @ 60Hz - VGA

Notes:

Support of 1080p component video (YPbPr) required on

third-party equipment for 1080/60p.

Certain equipment may not supply appropriate resolutions,

and therefore may not function properly.

Assignable Program Output Resolutions

(On DE-15 and DVI-D Connectors)

Analog Component (YPbPr)

1080p/60/59.94 Hz

1080p/50 Hz

1080i/59.94 Hz

1080i/50 Hz

720p/59.94 Hz

720p/50 Hz

SD 480i /29.97Hz (No DVI-D)

SD 576i/25Hz (No DVI-D)

RGBHV

640 x 480 @ 60 Hz

640 x 480 @ 75 Hz

800 x 600 @ 60 Hz

1024 x 768 @ 60 Hz

1024 x 768 @75 Hz

1280 x 720 @ 60 Hz

1280 x 768 @ 60 Hz

1280 x 800 @ 60 Hz

1280 x 1024 @ 60 Hz

1360 x 768 @ 60 Hz

1400 x 1050 @ 60 Hz

1600 x 1200 @ 60 Hz

1680 x 1050 @ 60 Hz

1920 x 1200 @ 60 Hz

Assignable Preview Output Resolutions

Analog Component (YPbPr)

1080p/60/59.94 Hz

1080p/50 Hz

1080i/59.94 Hz

1080i/50 Hz

720p/59.94 Hz

720p/50 Hz

480i/ 29.97Hz (No DVI-D)

576i/ 25Hz (No DVI-D)

MV 1080p/60/59.94/50 Hz

MV 1080i/59.94/50Hz

RGBHV

640 x 480 @ 60 Hz

640 x 480 @75 Hz

800 x 600 @ 60 Hz

1024 x 768 @60 Hz

1024 x 768 @ 75 Hz

1280 x 1024 @ 60 Hz

1280 x 800 @ 60 Hz

1280 x 768 @ 60 Hz

1280 x 720 @ 60 Hz

1360 x 768 @ 60 Hz

1400 x 1050 @ 60 Hz

1600 x 1200 @ 60 Hz

1680 x 1050 @ 60 Hz

1920 x 1200 @ 60 Hz

480i/ 29.97Hz

576i/ 25Hz

MV 1080p/ 60/59.94/50 Hz

MV 1080i//59.94/50 HZ

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 23 of 32

Page 24

ProductionVIEW HD MV

General Specifications (continued):

ProductionVIEW HD MV

Part Numbers:

Compatible Cameras:

Video Formats Supported:

Video Switcher:

Video Transitions:

999-5625-000 (NTSC)

999-5625-001 (PAL)

Vaddio, Panasonic, Sony & Canon (See Manual for Specific Models)

NTSC and PAL

6 x 2 (or Two 6 x 1)

Cross Fade, 9 Wipe options and Straight Cuts, Fade to Black

Five (5 - DE-15): RGBHV, HD Component (YPbPr), or Y-C &

Video Inputs:

Composite using adapter cables

One (1-DVI-I)

One (1 - DE-15) Preview or Multiviewer Output: RGBHV, HD

Component (YPbPr), or Y-C & Composite using adapter cables -

Preview or Multiviewer Output:

Same resolution on both Preview outputs

One (DVI-D/HDMI) Preview or Multiviewer Output: RGBHV, HD

Component (YPbPr), or Y-C & Composite using adapter cables Same resolution on both Preview outputs

One (1 - DE-15) Program Output: RGBHV, HD Component (YPbPr),

or Y-C & Composite using adapter cables - Same resolution on both

Program Output:

Program outputs

One (DVI-D/HDMI) Program Output: RGBHV, HD Component

(YPbPr), or Y-C & Composite using adapter cables - Same resolution

on both Program outputs

Camera Control Ports:

Control Interface:

LCD Display:

Power Requirements:

Trigger Inputs (Inputs 1 & 2):

Tally Output:

Weight:

Dimensions (H x W x D):

Accessory Cables:

440-5600-000

440-5600-001

440-5600-002

440-5600-003

Six (6) RS-232 on RJ-45F

One (1) RS-232 on DB-9

8-line backlit LCD display

PowerRite 18 VDC, 2.78 Amp

Cameras 1 & 2 have 6 presets each or Camera 1 can have 12

Tally outputs for each of the six inputs

9.5 lbs. (4.32kg) – approximate weight

4” (10.16cm) x 16” (40.64cm) x 10” (25.4cm)

HD-15M to SD (Y-C / CVBS w/female BNCs - 1’ / 308.4mm)

HD-15M to HD (YPbPr/RGBHV w/male BNCs - 3’ / .914m)

HD-15M to HD (YPbPr/RGBHV w/male BNCs - 6’ / 1.83m)

HD-15M to HD (YPbPr/RGBHV w/female BNCs - 7” / 177.8mm)

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 24 of 32

Page 25

ProductionVIEW HD MV

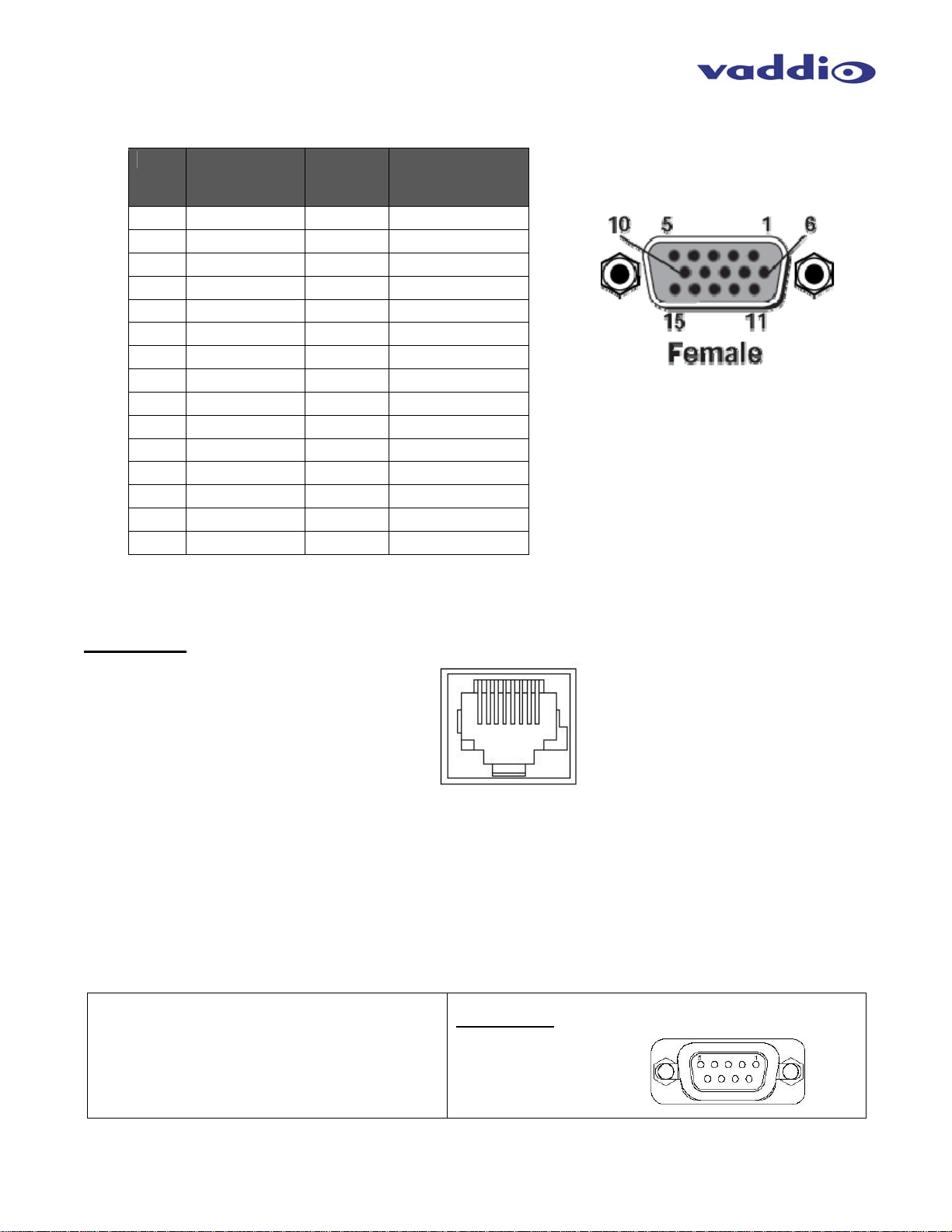

Appendix 1: Video and Control Pin-out Table for ProductionVIEW HD MV

Pin RGBHV YPbPr Y/C &

Composite

Adapter Cable

1 Red Pr

2 Green Y

3 Blue Pb

4 ID -

5 N/C -

6 Red GND Pr GND

7 Green GND Y GND

8 Blue GND Pb GND

9 No Pin -

10 GND - GND

11 ID - Y - Luminance

12 ID - C - Chrominance

13 H-Sync -

14 V-Sync -

15 N/C - Composite

Camera Control Ports 1 through 6 - RS-232 on RJ-45 Connectors:

PIN# Signal

1) Unused

2) Unused

3) Unused

4) Unused

5) Unused

12345678

6) GND

7) TXD (to RXD of camera)

8) RXD (from TXD of camera)

Appendix 2: RS-232 Control

The ProductionVIEW HD MV has six (6) discrete camera control ports which eliminates the need for daisychaining control cabling. With ProductionVIEW HD MV, all cabling configurations are home run wiring

configurations. Each Channel will auto-configure the input channel for control of the camera attached.

Vaddio uses simple control protocols to accomplish custom programming with the ProductionVIEW HD MV. The

Communication Specification, API and Programming Language are listed below and definitions are listed on the

next page. Note: All commands must be followed by a carriage return.

Communication Specification

Communication Speed: 9600 bps (default)

Start bit: 1

Stop bit: 1

Data bits: 8

Parity: None

No Flow control

Control Port - RS-232 on DB-9F Connector

PIN# Signal

2) TXD

3) RXD

5) GND

All other pins - Unused

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 25 of 32

Page 26

ProductionVIEW HD MV

API and Programming Language

+--------------------------------------------------------------------------+

| Vaddio ProductionVIEW HD MV |

+--------------------------------------------------------------------------+

| |

+------------------------ System Access -----------------------------------+

|Power x- Power(On/Off) |SysMode x- (Manual/Auto) |

|ProgIn x- Program (1-6,7-LSG,8-PIP)|Mix - Mix/FTB Button |

|PrevIn x- Preview (1-6,7-LSG,8-PIP)|Cut - Cut Button |

|Camera x- Switch to Camera(1-6) |Take - Take Button |

|Preset x- Go to Preset(1-12) |Wipe - Wipe Button |

|Store x- Store Preset(1-12) |lsgSize x- Lsg Size(0-3) |

|WipeSel x- Effect select:(0-8) |lsgDen x- Lsg Density(0-9) |

|0:Wipe UL>LR,1:Wipe Top>Bot, |BLC x-BacklightComp(On,Off)|

|2:Wipe UR>LL,3:Wipe L>R,4:Wipe Cnt>Out,|AWB x- AutoWhiteBal(On,Off)|

|5:Wipe R>L,6:Wipe LL>UR,7:Wipe Bot>Top,|PipLoc x,x- Location,size(0-2) |

|8:Wipe LR>UL | 0:UL,1:UR,2:LL,3:LR |

+--------------------- Joystick Pan, Tilt, Zoom----------------------------+

|JPanDir x,x-Port(0-6)Invert/Normal |JPanSpd x,x-Port(0-6),Spd(1-24)|

|JTiltDir x,x-Port(0-6)Invert/Normal |JTiltSpd x,x-Port(0-6),Spd(1-20)|

|JZoomDir x,x-Port(0-6)Invert/Normal |JZoomSpd x,x-Port(0-6),Spd(0-7) |

+--------------------- Preset Pan, Tilt, Zoom------------------------------+

|PanSpeed x- Preset Pan Speed (1-24) |TiltSpeed x-Preset Tilt Spd(1-20)|

|ZoomSpeed x- Preset Zoom Spd (0-7) |Home - Home Camera |

|PresetLoc x- Store Preset (InCam/Lcl) |OnCamInit x- (Home/Preset12) |

+--------------- Camera ----------------+----------------------------------+

|Move x,x- (Up/Down/Stop/Left/Right),Value |

|Zoom x,x- (In/Out/Stop),Value |

|Iris x,x- (Up/Down/Auto/Manual),Value |

|Focus x,x- (Up/Down/Auto/Manual),Value |

+--------------------- System Setup and Utilties---------------------------+

|SetDefault x- Set Default Preset(1-12) |Tally - Idle Tally(High/Low)|

|DefaultCam x- Set Default Camera(1-6) |IdleRtn x- Default Timer(0-60) |

|ExtTrigger x- Combine (AllCam1/Cam1&2) |SerialEcho x- Echo Serial (On/Off)|

|FTB x- Fade U/D/(10-40) |SerialInfo x- Status (On/Off) |

|Reset - 'CPU'Reset |SwMode x- Switch(Single/Dual) |

|DspCams - List connected cameras |Version - Firmware Version |

|ClearAll - Clear all presets |Config - List Config Settings|

|SaveConfig - Manual Config Save |ResetVideo - Re-Load Video config|

|Rescan - Rescan cameras | |

+--------------------------------------------------------------------------+

+--------------------- Touch Screen Configuration--------------------------+

WBtn xxddvvvvVVVVHHHH-Set button touch screen limits

xx-Button Index (0x00-ox2f)

dd-Button ID 0x3c:take,0x16-0x1b:preview 1-6,0x24-02f:preset 1-12

0x39:wipe,0x3a:cut,0x3b:fade

vvvv-Vertical coordinate lower limit

hhhh-Horizontal coordinate lower limit

VVVV-Vertical coordinate upper limit

HHHH-Horizontal upper limit

RBtn xx- Read button touch screen limits record

xx-Button Index (0x00-0x2f)

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 26 of 32

Page 27

ProductionVIEW HD MV

Appendix 3: Command Structure Definitions

Command Parameters Description

AWB AWB On/Off(cr) Auto White Balance On/Off

BLC BLC On/Off(cr) Backlight Compensation On/Off

Camera Camera [9](cr) Select indicated camera (1-6)

CamFolPrv CamFolPrv On/Off(cr) Set Select follows Review selection On/Off

ClearAll ClearAll(cr) Clear all presets

Config Config(cr) Display system configuration

Cut Cut(cr) Select Cut Transition

DefaultCam DefaultCam [9](cr) Set default camera (1-6)

DspCams DspCams(cr) Display cameras connected(and Port)

ExtTrigger ExtTrigger AllCam1/Cam1_2(cr) Set trigger mode all on cam 1 for 6 on each

Focus Focus Up/Dn/Auto/Manual,[9] (cr) Focus Up/Dn/Auto/Manual, Value

FTB

Home Home(cr) Home Camera

IdleRtn IdleRtn [9](cr) Idle Return 0-60 seconds

Iris Iris Up/Dn/Auto/Manual,[9] (cr) Iris change Up/Dn/Auto/Manual, Value

JPanDir JPanDir [9],[9](cr) Set Pan Direction by Port(0,1-6), Dir(Normal/Invert)

JPanSpd JPanSpeed [9],[9](cr) Set Pan Speed by Port (0,1-6), Speed(1-24)

JTiltDir JTiltDir [9],[9](cr) Set Tilt Direction by Port(0,1-6), Dir(Normal/Invert)

JTiltSpd JTiltSpeed [9],[9](cr) Set Tilt Speed by Port(0,1-6), Speed(1-20)

JZoomDir JZoomDir [9],[9](cr) Set Zoom Direction by Port(0,1-6), Dir(Normal/Invert)

JZoomSpd JZoomSpeed [9],[9](cr) Set Zoom Speed by Port(0,1-6), Speed(0-7)

lsgDen lsgDen [9](cr) Set LSG density (0-9)

LSgSize LsgSize [9](cr) LSG Size (0-3)

Mix Mix(cr) Select Mix/FTB mode

Move Move(Up/Down/Left/Right/Stop)(cr) Move camera

OnCamInit OnCamInit Home/Preset12(cr) Set initialization preset Home camera or content of preset12

PanSpeed PanSpeed [9](cr) Set Preset Pan Speed

PipLoc PipLoc [9], [9](cr) Select Pip location (0-3), Size (0-2)

Power Power On/Off(cr) Power system On/Off

Preset Preset [9](cr) Select indicated preset (1-12)

PresetLoc PresetLoc Local/InCam (cr) Set Preset location 6 in cam 6 in system, All in system

PrevIn PrevIn [9](cr) Select Preview input(1-6)

ProgIn ProgIn [9](cr) Select Program input(1-6)

Rescan Rescan(cr) Initiate Camera scan

Reset Reset(cr) Soft System reset

ResetVideo ResetVideo(cr) Re-Load Video Configuration

Save Config SaveConfig(cr) Saves configuration of all console settings

SerialEcho SerialEcho On/Off(cr) Serial Echo On/Off

SerialInfo SerialInfo(On/Off)(cr) Serial Information mode on/off

SetDefault SetDefault [9](cr) Set default Preset (1-12)

Store Store [9](cr) Store indicated preset on the current camera(1-12)

SwMode SwMode Single/Dual(cr) Select operating mode Single/Dual switcher(s)

SysMode SysMode Auto/Manual(cr) System Access automatic/Manual

Take Take(cr) Initiate Transition

Tally Tally High/Low(cr) Non-selected(Idle) tally level

TiltSpeed TiltSpeed [9](cr) Set Preset Tilt Speed

Version Version(cr) Display System Version information

Wipe Wipe(cr) Select Wipe Transition

WipeSel WipeSel [9](cr) Select Wipe (0-11)

Zoom Zoom (in/Out/Stop)(cr) Zoom Camera

ZoomSpeed ZoomSpeed [9](cr) Set Preset Zoom Speed

Fade U/D/(10-40)

Fade To Black

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 27 of 32

Page 28

ProductionVIEW HD MV

Compliance and CE Declaration of Conformity

Compliance testing was performed to the following regulations:

FCC Part 15, Subpart B Class A

ICES-003, Issue 4: 2004 Class A

CISPR 22: 2009 Class A

European Standard EN 55103-1: 2009 Class A

European Standard EN 55103-2: 2009 Class A

EN 5502: 2006 + A1: 2007 (CISPR 22:2005/A1: 2005) Class A

EMC Directive 2004/108/EC Class A

FCC Part 15 Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15, Subpart

B, of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his/her own expense.

Operation is subject to the following two conditions: (1) This device may not cause interference, and (2) This device must

accept any interference including interference that may cause undesired operation of the device.

Changes or modifications not expressly approved by Vaddio can affect emission compliance and could void the user’s

authority to operate this equipment.

ICES-003 Compliance

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numeriques de la classe A préscrites dans le Règlement sur le brouillage radioélectrique édicte par le ministère des

Communications du Canada.

European Compliance

This product has been evaluated for Electromagnetic Compatibility under the EMC Directive for Emissions and Immunity and

meets the requirements for a Class A digital device. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Standard(s) To Which Conformity Is Declared:

EMC Directive 2004/108/EC

EN 55022: 2006 + A1: 2007 (CISPR 22: 2005/A1:2005) Conducted and Radiated Emissions

EN 55103-1: 2009 Electromagnetic Compatibility

EN 55103-2: 2009; E2-Commercial and Light Industrial Immunity

EN 61000-4-2: 1995 + Amendments A1: 1998 + A2: 2001 Electrostatic Discharge

EN 61000-4-3: 2006 + A1: 2008 Radiated Immunity

EN 61000-4-4: 2004 + Corrigendum 2006 Electrical Fast Transients

EN 61000-4-5: 2006 Surge Immunity

EN 61000-4-6: 2009 Conducted Immunity

EN 61000-4-11: Second Edition: 2004 Voltage Dips, Interrupts and Fluctuations

Annex A of EN 55103-2: 2009

Note: For strict compliance to FCC, ICES-003 and CE radiated emissions standards, please use the provided Laird 100ohm,

¼” snap on rectangular ferrite on the DC cable of the power supply.

ProductionVIEW HD MV Manual - Document Number 342-0241 Page 28 of 32

Page 29

ProductionVIEW HD MV

Warranty Information:

Hardware* Warranty: One year limited warranty on all parts. Vaddio warrants this product against defects in materials and

workmanship for a period of one year from the day of purchase from Vaddio. If Vaddio receives notice of such defects during

the warranty period, they will, at their option, repair or replace products that prove to be defective. Please see Vaddio’s

Service Terms and Conditions at vaddio.com for specific details and policies.

Exclusions: The above warranty shall not apply to defects resulting from: improper or inadequate maintenance by the

customer, customer applied software or interfacing, unauthorized modifications or misuse, operation outside the normal