Page 1

I

V

ADDIO

™ A

UTO

T

RAK

Camera Tracking System

Featuring Automatic Pan/Tilt/Zoom Camera Tracking

Part Numbers:

AutoTrak 2.0

Camera Tracking System: North America

999-7250-000: AutoTrak 2.0-Dual HD-18 Kit with Quick-Connect

DVI/HDMI Interface-North America

999-7260-000: AutoTrak 2.0-HD-18 & HD-20 Kit with Quick-Connect

DVI/HDMI Interface-North America

AutoTrak 2.0

Camera Tracking System: International

999-7250-001: AutoTrak 2.0-Dual HD-18 Kit with Quick-Connect

DVI/HDMI Interface-International

999-7260-001: AutoTrak 2.0-HD-18 & HD-20 Kit with Quick-Connect

DVI/HDMI Interface-International

NSTALLATION AND USERS GUIDE

2.0

Optional:

EasyTalk AutoTrak 2.0 Wireless Audio Interface:

998-7230-000: EasyTalk AutoTrak 2.0 Wireless Audio Interface-North

America

998-7230-001: EasyTalk AutoTrak 2.0 Wireless Audio InterfaceInternational

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 with EasyTalk Wireless Audio Interface - Document Number 342-0382 Rev. A

Page 2

AutoTrak 2.0 Camera Tracking System

Inside Front Cover - Blank

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 2 of 47

Page 3

AutoTrak 2.0 Camera Tracking System

p

AutoTrak 2.0 System Overview

The AutoTrak 2.0 System is an IR tracking system that consists of an IR

lanyard attached to a rechargeable belt pack that is worn by a presenter

or instructor. Within the lanyard’s cloth cover, there are fifteen (15)

850nm wavelength IR LEDs on a flat flex circuit that emit IR light that is

tracked by an HD-18 PTZ IR Reference Camera with special IR filters.

The IR position is relayed to the AutoTrak 2.0 CPU which in turn controls

the HD-18 PTZ Tracking Camera and follows the presenter and keeps the

presenter framed in the camera shot throughout the presentation

environment. The Tracking Camera is based on the Vaddio high

definition, HD-18 with 1/3-type, 1.3 mega pixel CCD image sensor which

operates well in low light and reproduces color accurately with vibrant

detail and clarity.

Note: Add the two versions: two- HD-18 and one HD-18 and one HD-20

999-7250-000: AutoTrak 2.0-Dual HD-18 Kit with Quick-Connect DVI/HDMI Interface-North America

999-7260-000: AutoTrak 2.0-HD-18 & HD-20 Kit with Quick-Connect DVI/HDMI Interface-North

America

The AutoTrak 2.0 System is also available with the optional EasyTalk

AutoTrak 2.0 Wireless Audio System.

The HD-18 cameras and HD-20 cameras use the Vaddio Cat-5e cabling

systems for ease of set up and installation. The system can be

permanently installed or configured as a cart system for portability and

ease of positioning in the largest of lecture halls. Each system includes a

dual camera mount which can be wall mounted or mounted on top of the

Vaddio Edge series video carts.

The optimum operating range or the system (from the IR Lanyard to the IR

Reference camera) is between 12’ (3.65m) and up to 40’ (12.2m). System

positioning is critical for proper and consistent operation.

The AutoTrak 2.0 can be installed as a standalone system or can be used in conjunction with myriad

Vaddio Presenter controlled solutions including AutoPresenter™, PresenterPOD™, ControlVIEW XHD™,

TouchVIEW™, AutoVIEW™ IR, StepVIEW™ Mats, MicVIEW™ and the Vaddio Video Whiteboard. As an

added benefit, once the AutoTrak 2.0 system is configured the Mouse, Keyboard and Monitor I/O devices

can be removed from the system to ensure the system isn’t subject to unauthorized modification.

Intended Use:

Before operating the device, please read the entire manual thoroughly. The system was designed, built

and tested for use indoors, and with the provided power supply and cabling. The use of a power supply

other than the one provided or outdoor operation has not been tested and could damage the device

and/or create a potentially unsafe operating condition.

Important Safeguards:

Read and understand all instructions before using. Do not operate any device if it has been dropped or

damaged. In this case, a Vaddio technician must examine the product before operating. To reduce the

risk of electric shock, do not immerse in water or other liquids and avoid extremely humid conditions.

Use only the power supply provided with the system. Use of any unauthorized

power supply will void any and all warranties.

Please do not use “pass-thru” type RJ-45 connectors. These pass-thru type connectors do not

work well for professional installations and can be the cause of intermittent conn ections which

can result in the RS-232 control line failing and locking up, and/or compro mising the HSDS™

signals. For best results please use standard RJ-45 connectors and test all cables for proper

in-outs prior to use and connection to Vaddio product.

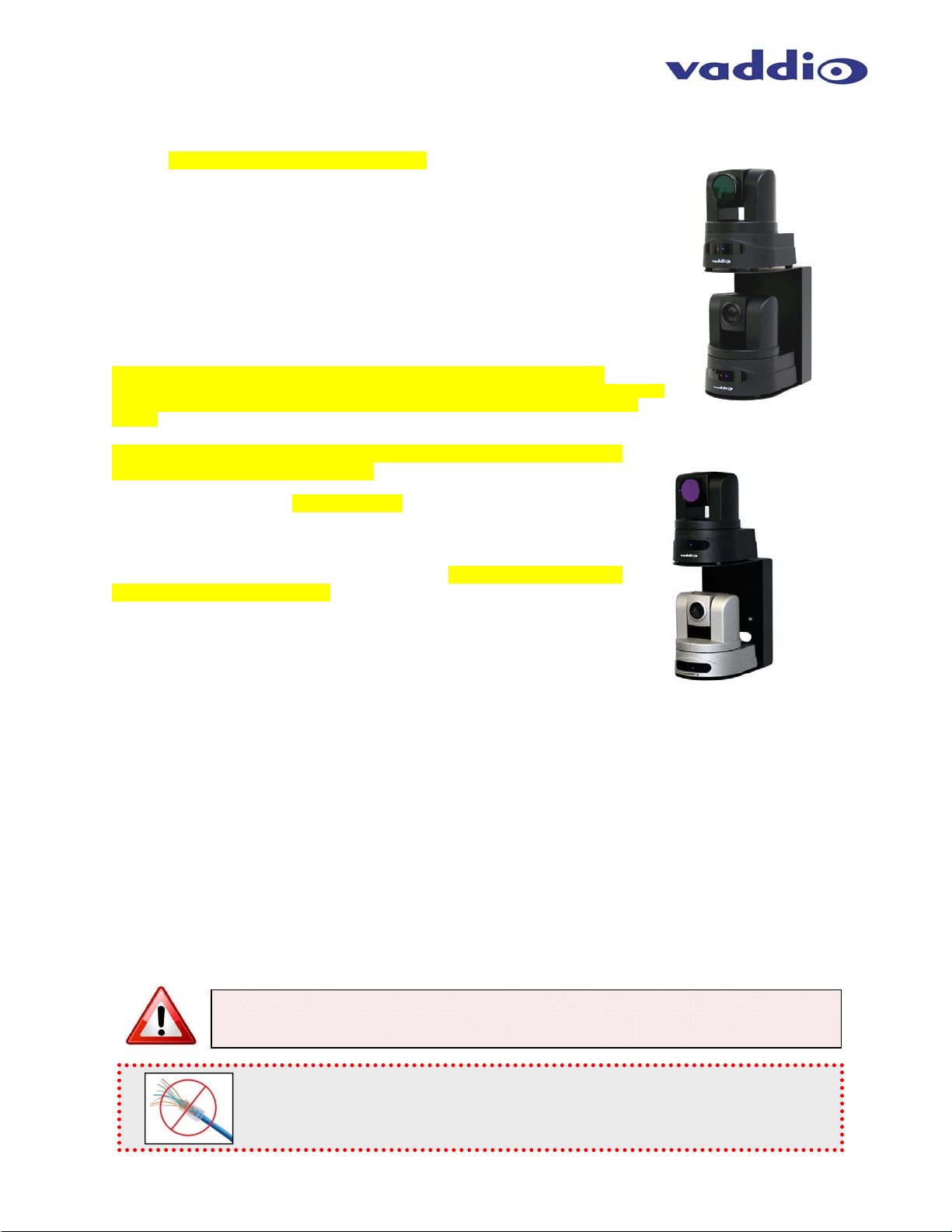

AutoTrak 2.0 999-7250-000

Dual HD-18 Cameras

AutoTrak 2.0 999-7260-000

HD-18 IR and HD-20

Tracking Camera

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 3 of 47

Page 4

AutoTrak 2.0 Camera Tracking System

Save These Instructions:

The information contained in this manual will help you install and operate your product. If these

instructions are misplaced, Vaddio keeps copies of Specifications, Installation and User Guides and most

pertinent product drawings for the Vaddio product line on the Vaddio website. These documents can be

downloaded from www.vaddio.com

UNPACKING:

Carefully remove all of the parts for the AutoTrak 2.0 999-7250-000 Dual HD-18 Kit with Quick

Connect DVI/HDMI Interface (North America Only) packaging:

One (1) AutoTrak 2.0 CPU (closed system preloaded with AutoTrak 2.0 software and video card)

One (1) AC Cord Set for AutoTrak 2.0 CPU

One (1) PS/2 Keyboard

One (1) PS/2 Mouse

One (1) IR and Audio Lanyard with attached 32” cable with 5-pin mini XLR connector

One (1) Belt Pack Unit “BPU” with 1” RP-SMA straight antenna and attached belt clip with rechargeable lithium-ion battery

pack and USB charging power supply

One (1) Vaddio PowerRite 12 VDC, 1A Switching Power Supply

One (1) AC Cord Set - North America

AutoTrak 2.0-Dual HD-18 Kit:

One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

One (1) Quick-Connect SR Interface (998-1105-016) for Tracking Camera

One (1) 24VDC, 2A, 100-240V, 50/60Hz 110-240V Switching Power Supply

One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded – IR Reference Camera

One (1) 37mm female lens ring adapter for HD-18 attached to HD-18 Camera

One (1) 37mm to 58mm adapter ring

One (1) 58mm polarizing filter

One (1) 58mm band-pass IR filter

One (1) AutoTrak 2.0 Quick-Connect Box (998-1105-020)

One (1) Standard Quick-Connect Box (998-1105-001)

One (1) 24VDC, 2A, 50/60Hz 110-240V Switching Power Supply (451-2000-0024)

One (1) 18”/45.8cm Video Cable (BNC to RCA)

One (1) 12”/30.48cm Cat 5e Patch Cable

One (1) 998-2100-000 - Vaddio IR Remote & Manual (2-AAA batteries not included)

One (1) **535-2000-233 Stacked Gusseted Mount for two (2) HD-18 and Mounting Hardware

Three (3) 998-1001-232 Control Adapters

One (1) 998-7200-232 Control Adapter for use with the AutoPresenter - (Only needed when used with the AutoPresenter

for Tracking Camera PTZ Presets)

Documentation and Manuals (Document Number (342-0382)

For the 999-7260-000 System - Start with the 999-7250-000 System

Remove: One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

Add: One (1) *HD-20 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

UNPACKING:

Carefully remove all of the parts for the AutoTrak 2.0 999-7250-001 Dual HD-18 Kit with Quick

Connect DVI/HDMI Interface (International Only) packaging:

One (1) AutoTrak 2.0 CPU (closed system preloaded with AutoTrak 2.0 software and video card)

One (1) Euro Power Cord for AutoTrak 2.0 CPU

One (1) UK Power Cord for AutoTrak 2.0 CPU

One (1) PS/2 Keyboard

One (1) PS/2 Mouse

One (1) IR and Audio Lanyard with attached 32” cable with 5-pin mini XLR connector

One (1) Belt Pack Unit “BPU” with 1” RP-SMA straight antenna and attached belt clip with rechargeable lithium ion battery

pack and USB charging power supply. International USB charging supply includes both EU and UK plug interfaces.

One (1) Vaddio PowerRite 12 VDC, 1A Switching Power Supply

One (1) Euro Power Cord

One (1) UK Power Cord

AutoTrak 2.0-Dual HD-18 Kit:

One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

One (1) Quick-Connect SR Interface (998-1105-016) for Tracking Camera

One (1) 24VDC, 2A, 100-240V, 50/60Hz 110-240V Switching Power Supply

One (1) Euro Power Cord

One (1) UK Power Cord

One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded – IR Reference Camera

One (1) 37mm female lens ring adapter for HD-18 attached to HD-18 Camera

free of charge.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 4 of 47

Page 5

AutoTrak 2.0 Camera Tracking System

One (1) 37mm to 58mm adapter ring

One (1) 58mm polarizing filter

One (1) 58mm band-pass IR filter

One (1) AutoTrak 2.0 Quick-Connect Box (998-1105-020)

One (1) Standard Quick-Connect Box (998-1105-001)

One (1) 24VDC, 2A, 50/60Hz 110-240V Switching Power Supply (451-2000-0024)

One (1) Euro Power Cord

One (1) UK Power Cord

One (1) 18”/45.8cm Video Cable (BNC to RCA)

One (1) 12”/30.48cm Cat 5e Patch Cable

One (1) 998-2100-000 - Vaddio IR Remote & Manual (2-AAA batteries not included)

One (1) **535-2000-233 Stacked Gusseted Mount for two (2) HD-18 and Mounting Hardware

Three (3) 998-1001-232 Control Adapters

One (1) 998-7200-232 Control Adapter for use with the AutoPresenter - (Only needed when used with the AutoPresenter

for Tracking Camera PTZ Presets)

Documentation and Manuals (Document Number (342-0382)

For the 999-7260-001 System - Start with the 999-7250-001 System

Remove: One (1) *HD-18 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

Add: One (1) *HD-20 PTZ Camera with AutoTrak 2.0 Software preloaded - Tracking Camera

*Note 1: The Vaddio HD-18 and HD-20 cameras are preloaded with AutoTrak 2.0 control protocols which differ from

the “VISCA” type control normally used in the stock HD-18 PTZ Camera. The HD-18 cameras will work with the

Vaddio IR Remote but is recommended that the PTZ positions of the camera be set with the AutoTrak 2.0 Software.

The HD-18 AutoTrak 2.0 cameras will not work with any other controller besides AutoTrak 2.0 at this time.

**Note 2: The stacked camera arrangement is required for the AutoTrak 2.0 software to track properly.

AutoTrak 2.0 Components:

AutoTrak 2.0 CPU

Note: The AutoTrak 2.0 CPU may be subject to change in cosmetics due to the turbulent nature of the

PC industry, parts availability and model year upgrades. If changes are made, Vaddio will be certain to

make changes in the documentation accordingly. The AutoTrak 2.0 CPU is a 1-RU rack mount computer

that will come preloaded with the AutoTrak 2.0 software. The exact specifications are subject to change

and any changes that will be made will be in the spirit of product improvement only. The AutoTrak 2.0

CPU uses an Intel® Atom™ Dual Core Processor, Intel Graphics Media Accelerator, 1GB DDR2 Memory,

four (4) RS-232 Ports, six (6) USB 2.0 ports, two (2) PS/2 interfaces for keyboard/mouse, 16GB Compact

Flash and Video capture card.

An important feature: After the AutoTrak 2.0 CPU and software is configured using the mouse, keyboard

and monitor, these I/O devices can be removed to prevent any unauthorized access to the system. To

reattach the mouse and keyboard, the system will need to be rebooted to recognize these devices.

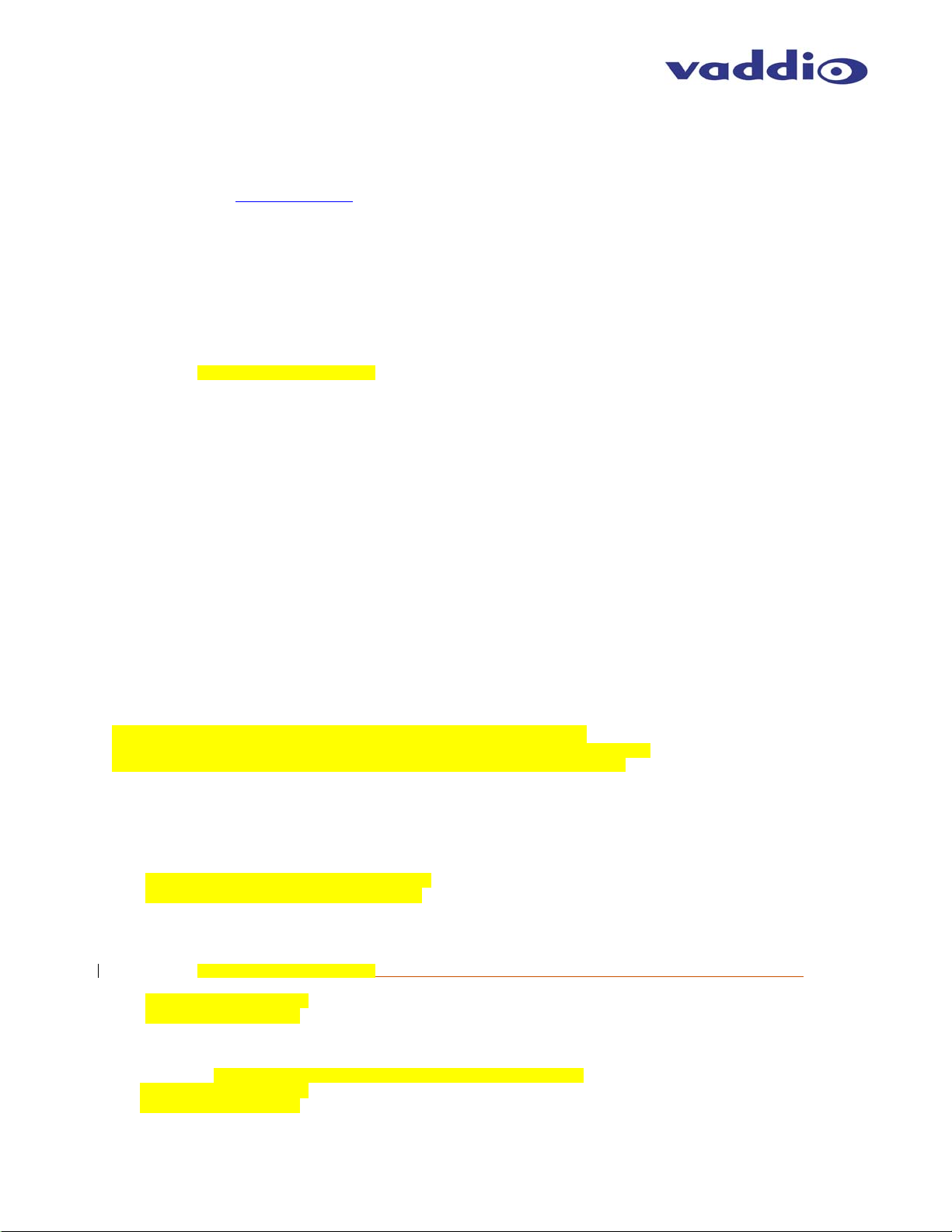

Front Panel Controls of AutoTrak 2.0 Worldwide CPU:

①②

③

④

1) Power Indicator: Illuminates when power in on

2) Hard Drive Activity Indicator: Indicates when hard drive is active

3) Recessed Reset Switch: Resets the system without removing power to the CPU

4) USB Ports: Two (2) Front Panel USB Ports

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 5 of 47

Page 6

AutoTrak 2.0 Camera Tracking System

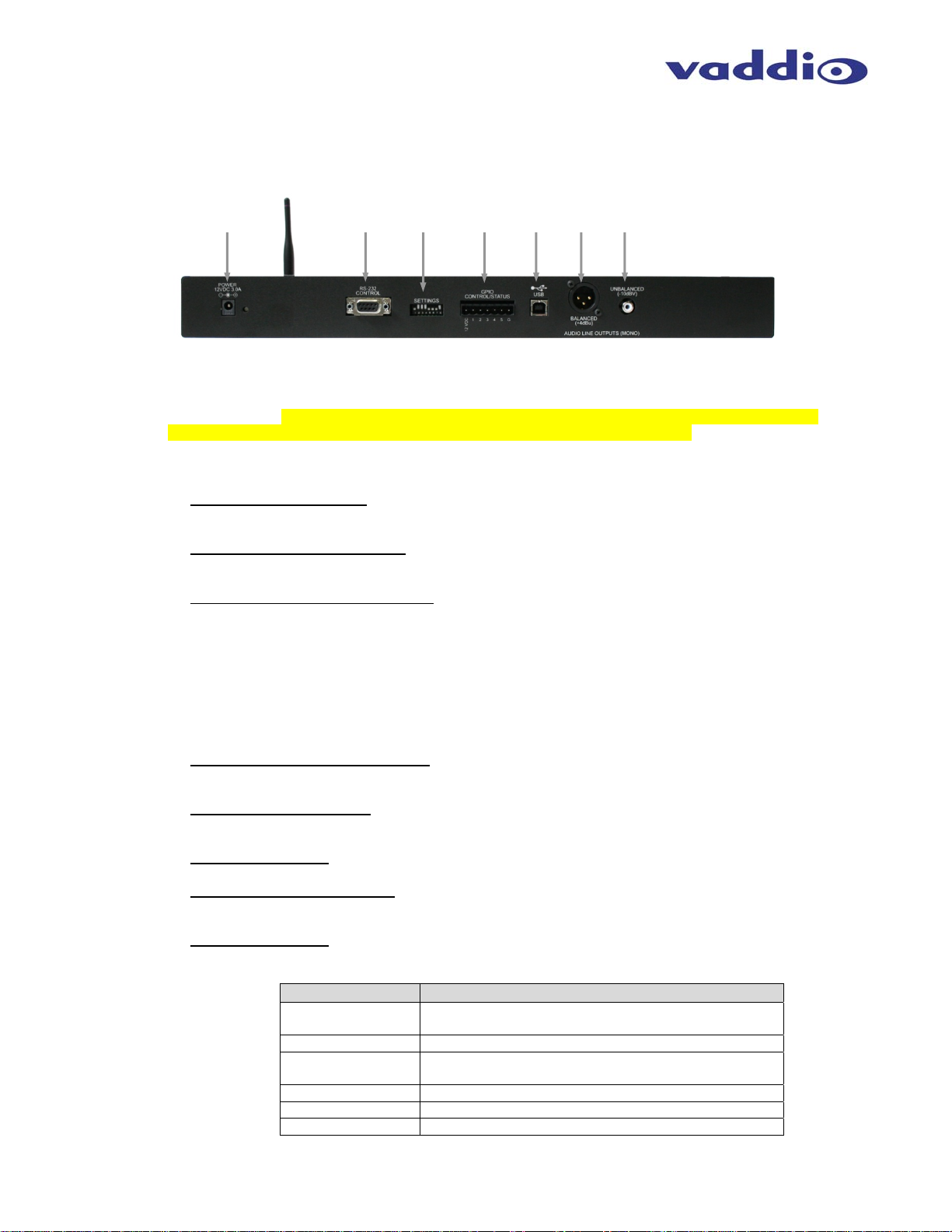

Rear Panel of AutoTrak 2.0 Worldwide CPU:

①

1) Power Receptacle: IEC60320 C14 for power cable

2) Power Switch: Turns ON/OFF AutoTrak 2.0 CPU

3) COM PORT 1: RS-232 Port for HD-18 IR Reference Camera

4) COM PORT 2: RS-232 Port for HD-18 Tracking Camera

5) COM PORT 3: Use RS-232 Port 3 when AutoTrak 2.0 is used with the AutoPresenter

6) RGBHV (on DE-15) Output: To setup and view software menus (800 x 600 @ 60Hz)

7) Ethernet Ports: Not used with AutoTrak 2.0 Application

8) USB Ports: Four USB Ports on the back panel for use with Keyboard, Mouse and USB Flash Drive

9) Audio I/O: Not used with AutoTrak 2.0 Application

10) Video Input Port: Plug the HD-18 IR Reference Camera into the center yellow composite video connector

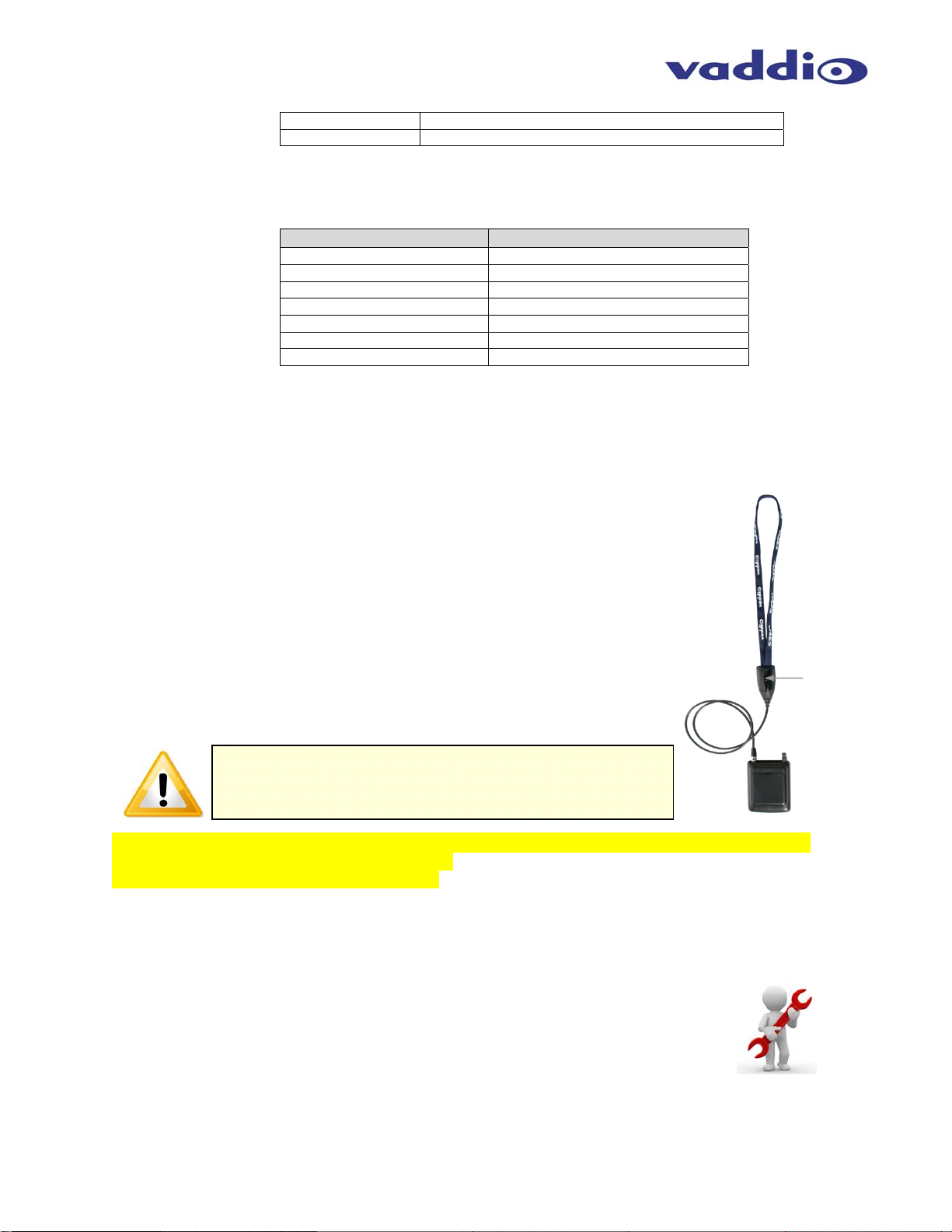

The IR Lanyard and Belt Pack for use with the AutoTrak 2.0 Camera Tracking Systems:

999-7250-000 and 999-7260-000 North America

999-7250-001 and 999-7260-001 International

1) IR Lanyard: Cloth covered flat flex circuit with IR LEDs terminates at the Central Medallion

2) Central Medallion: Supplies a connection point for the flat flex cable, contains an integrated condenser

microphone and a rubber over-molded cable strain relief that attaches the 32” cable.

3) 32” (813mm) Cable: Terminates the Central Medallion to the Belt Pack with a 5-Pin Mini XLR-F connector.

4) Belt Pack: Holds power circuitry, wireless microphone transmitter, transmitter frequency control switches

(see pages 6-7) and rechargeable lithium battery pack.

5) Belt Pack Front Panel Controls: The System on/off controls and LED indicator as well as the Microphone

on/off controls are located on the Belt Pack Control Panel (see page 6-7).

6) Belt Clip: To clip the Belt Pack on a belt like device that the presenter wears.

7) Antenna: 1” (25.4mm) RP-SMA straight antenna to transmit RF wireless audio at 2.4 GHZ utilizing

Adaptive Frequency Hopping (AFH) from the integrated unidirectional microphone element.

②

⑤

③

⑥

④ ⑤

⑥

⑦

⑧

⑨

⑦

④

②③

Note: Do not fold the Lanyard Necklace at an y time as it contains a flexible

circuit that may cease to work if the necklace is hard folded. Folding the

Lanyard

Flex Circuit will void any and all warranties.

⑩

①

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 6 of 47

Page 7

AutoTrak 2.0 Camera Tracking System

Belt Pack Control Panel

1) Lanyard Cable Connector (5-pin mini XLR - M): Plug the cable attached to the Lanyard into the mini XLR

connector to allow audio to be received by the Belt Pack and for power to be provided to the IR LEDs in the

Lanyard.

2) Radio: This LED indicates an active radio link with the EasyTalk AutoTrak 2.0 Wireless Audio Interface.

Solid blue LED indicates connection with the AutoTrak 2.0 Wireless Audio Interface. Flashing blue LED

indicates radio link has been lost.

Note: Radio link operates up to 100 feet line of sight of the AutoTrak 2.0 Wireless Audio Interface.

3) System Power: To use the Belt Pack or IR Lanyard, turn the SYSTEM POWER switch to the on position

and the LED will illuminate. Be sure to turn off the SYSTEM POWER switch when the system is not in use

to save the battery life. Rechargeable Lithium Ion Battery Pack provides up to eight (8) hours with full

charge.

Note: It is highly recommended that the battery pack be fully charged prior to using the Belt Pack for

the first time!

4) Microphone ON/OFF: This switch turns the wireless microphone on or off at the belt pack allowing the

Presenter to use a hand-held or podium microphone instead of the built in microphone, or for momentary

microphone muting. The System Status light on the Audio Interface will light if a microphone signal is

detected. If the Microphone is turned off at the Belt Pack, the System Status light will not light.

5) Antenna: Used to transmit the wireless microphone audio back to the AutoTrak 2.0 Wireless Audio

Interface.

①

Belt Pack Battery Compartment:

1) Removable Battery Compartment Cover: To open: Carefully pry the top of the Removable Battery Cover

at the small opening.

2) Rechargeable Lithium Ion Battery: The battery is housed and attached inside the Battery Compartment

and under normal use should last up to eight (8) hours. The battery pack is connected to the J3 connector

on the circuit board.

3) Micro-B USB Charging Port: The Belt Pack rechargeable battery can be charged by the micro-B USB

connector on the bottom side of the belt pack enclosure. A USB charger is included with the Belt Pack. The

Belt Pack can also be recharged by using a micro-B USB to USB adapter which can be connected to a PC

or Laptop USB port for recharging. A charging LED indicator is co-located with the micro-B USB connector.

When the LED is green, the battery is fully charged. A red LED indicates low battery. Use USB charger

included in the package

①

②

⑤

③④

②

④

③

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 7 of 47

Page 8

AutoTrak 2.0 Camera Tracking System

4) Dip Switches: There are two (2) 4-position dip switches located on the circuit board, SW4 and SW5. They

provide configuration settings for Microphone Gain Control, Filtering, Compression and Microphone Filtering

and Pairing of the Wireless Belt Pack to the AutoTrak 2.0 Wireless Audio Interface.

5)

Procedure for Belt Pack Pairing with the AutoTrack 2.0 Wireless Audio Interface:

Note: If the AutoTrak 2.0 System and the Optional AutoTrak 2.0 W ireless Audio Interface are o rdered

at the same time for delivery, the Belt Pack will be paired with the AutoTrak 2.0 Wireless Audio

Interface at the factory.

Pairing Procedure:

1) Place the Belt Pack in close proximity to the AutoTrak 2.0 Wireless Audio Interface.

2) Remove the Battery Compartment Cover: To open: Carefully pry the top of the Removable

Battery Cover at the small opening.

3) Locate Pairing Button Switch labeled SW2: Press the button and release. The Radio LED on

the Belt Pack should begin blinking at a slow rate.

4) Press the Pair Button on the front panel of the EasyTalk AutoTrak 2.0 Wireless Audio

Interface:

Important Note: The button on the AutoTrak 2.0 Wireless Audio Interface must be pushed

within ten (10) seconds of pressing the pairing button SW2 on the Belt Pack or pairing will

not occur.

5) Th e Belt Pack and the AutoTrak 2.0 Wireless Audio Interfac e will automatically sync with

each other: The blue LED’s on the Belt Pack and the AutoTrak 2.0 Wireless Interface will turn solid

blue indicating they are paired.

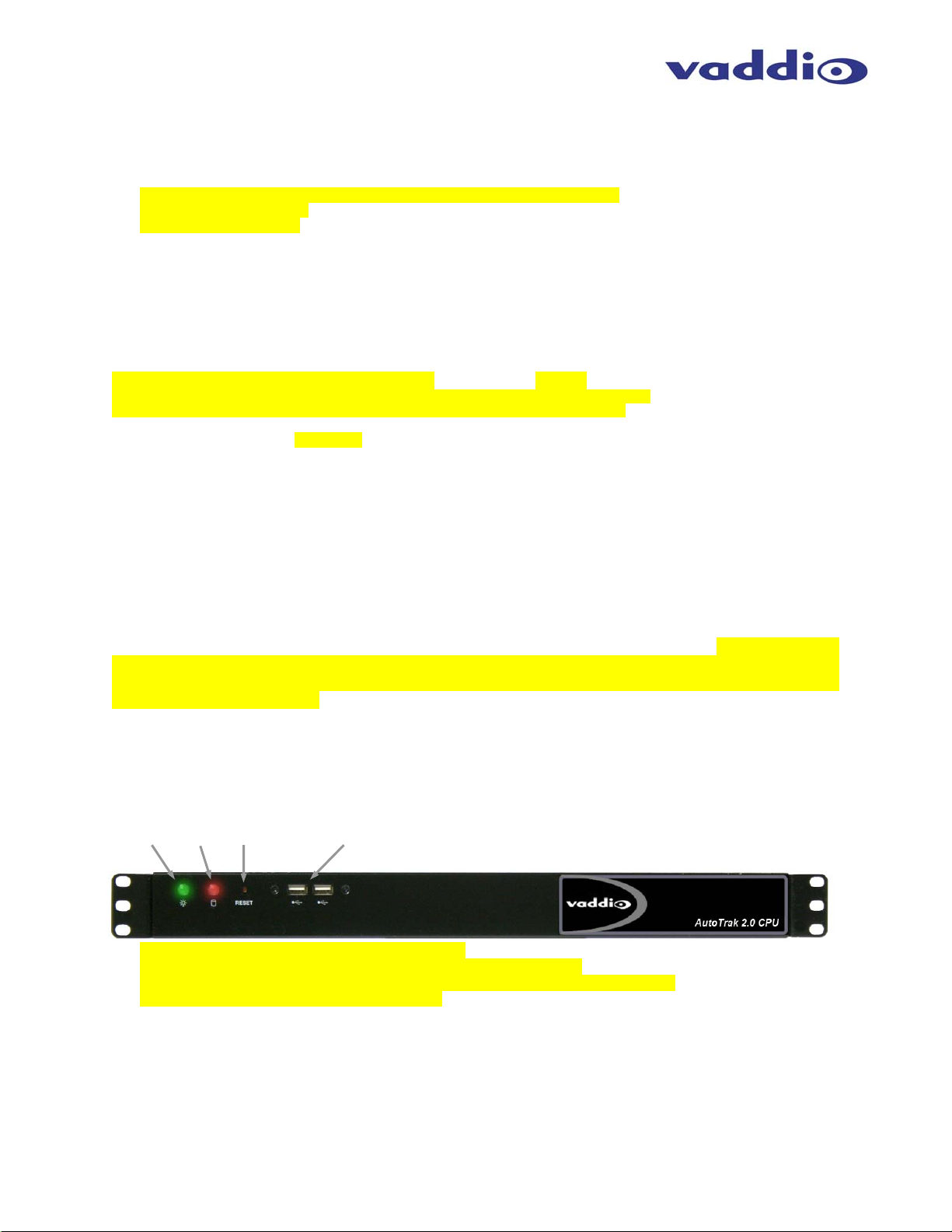

Belt Pack Dip Switch Settings:

Switch

SW 4: Dip Switch Settings

Function

Number

1 Enable/DisableBandpassAudio

Filter

2 Enable/DisableIRTransmitterin

Lanyard

3 Enable/DisableRadioinBPU

4 NotUsed

Switch

Number

SW 5: Dip Switch Settings

Function

1 3dBGainBoostonMicrophone

2 6dBGainBoostonMicrophone

3 9dBGainBoostonMicrophone

4 AutomaticGainControlMode

Optional Belt Pack Configuration Settings:

Note: The Belt Pack has a number of custom settings that can be enabled or disabled for specific

application needs. These settings can be applied by activating dip switch settings on the two (2) 4 position dip switches SW4 and SW5 located on the Belt Pack Circuit Board.

SW4: Dip Switch 1/ Bandpass Filter:

brighter sound for speech. Disable turns it off.

SW4: Dip Switch 2/ IR Transmitter:

Disable turns off the IR Transmitters in the Lanyard and the camera tracking will not function.

SW4: Dip Switch 3/ Radio in Belt Pack: Enable turns on the Radio circuit in the Belt Pack. Disable will

turn off the Radio circuit-which will extend the battery life of the Belt Pack if you are not using the

optional EasyTalk AutoTrak 2.0 Wireless Audio Interface with the AutoTrak 2.0 System.

SW4: Dip Switch 4/ Not Used:

Note: The following Gain Boost Switches 1-3 can be used individually or in combination. Ex: If Dip

Switch 1/ 3dB Gain and Dip Switch 2/ 6dB Gain are enabled, they will add a total of 9 dB of gain.

SW5: Dip Switch 1/ 3-dB Gain Boost:

Disable provides zero gain.

SW5: Dip Switch 2/ 6-dB Gain Boost:

provides zero gain.

SW5: Dip Switch 3/ 9-dB Gain Boost:

Disable provides zero gain.

Enable adds a Bandpass Filter to the microphone to emphasize a

Enable turns on the IR Transmitter LED’s in the IR Lanyard.

Enable adds a three (3) dB gain to the microphone audio.

Enable adds a six (6) dB gain to the microphone audio. Disable

Enable adds a nine (9) dB gain to the microphone audio.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 8 of 47

Page 9

AutoTrak 2.0 Camera Tracking System

SW5: Dip Switch 4/ Automatic Gain Control: Enable adds Automatic Gain Control-a function that

maintains a constant audio level to regulate soft talkers as well as loud-talkers. Disable turns off

Automatic Gain Control.

Optional AutoTrak 2.0 Wireless Audio Interface for AutoTrak 2.0 Systems:

998-7230-000: EasyTalk AutoTrak 2.0 Wireless Audio Interface-North America

998-7230-001: EasyTalk AutoTrak 2.0 Wireless Audio Interface-Internationa l

Front Panel Controls

① ② ③ ④⑤ ⑥⑦

1) Power ON/OFF: This switch turns the power for the AutoTrak 2.0 Wireless Audio Interface on or off. To use,

push the power button until the blue LED is lit and the system is ready for operation.

2) Pair: This button initiates the automatic pairing (Pairing is the setting of the same Radio Frequency Hopping

Spread Spectrum (FHSS) channel hopping sequence for both devices) for the Belt Pack Radio Transmitter and

the AutoTrak 2.0 Wireless Audio Interface Radio Receiver in the AutoTrak 2.0 Wireless Audio Interface.

3) Mute: This control mutes (turns off) the audio outputs of the AutoTrak 2.0 Wireless Audio Interface.

4) Volume: the + (plus) and – (minus) buttons are used to raise and lower the audio outputs (Balanced and

Unbalanced) from the AutoTrak 2.0 Wireless Audio Interface.

5) Audio Level: This LED display will indicate the relative audio level output (from all sources) of the AutoTrak

2.0 Wireless Audio Interface. Red Line at the top of the LED Display indicates clipping of the audio signal.

6) Radio, EQ Filter and Compressor Status LED’s:

Radio LED: Solid blue light indicates normal operations. Fast flashing indicates no link established with

the Belt Pack Wireless Microphone. Slow flashing indicates the Pairing cycle is in progress.

EQ Filter: Blue light on indicates the EQ Filter is turned on. Blue light off indicates the EQ Filter is off.

When EQ Filter is enabled, it helps increase speaker intelligibility for voice applications.

Compressor: Solid blue light indicates that the Compressor is on. No light indicates that the

Compressor is off. Compressor on minimizes the potential of “clipping” by attenuating the audio signals

that exceed the maximum output levels.

7) Antenna: The antenna is tuned to receive 2.4 GHZ signals from the IR Lanyard Belt Pack Microphone. Note:

If the AutoTrak 2.0 Wireless Audio Interface is installed deep inside a metal equipment rack or is surrounded by

other metal cased equipment, the antenna may need to be extended away from the rack to improve reception.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 9 of 47

Page 10

AutoTrak 2.0 Camera Tracking System

r

AutoTrak 2.0 Wireless Audio Interface:

Rear Panel Connections

①②③④⑤⑥⑦

1) 12 VDC, 1.0 Amp Power Connector: The 5.5mm OD and 2.5mm ID power connector should be plugged

into the PowerRite power supply provided by Vaddio. Use of any unauthorized power supplies will void any

and all warranties.

2) RS-232 Control: The DB-9 female connector is provided for 3

Audio Interface Application Protocol Interface (API). See Command List on page ##.

3) Settings (8-Position Dip Switch): The eight position dip switch is used for system configuration of the

AutoTrak 2.0 Wireless Audio Interface:

Dip Switch 1/Compressor: Enable adds a Compressor for the Audio Line Level Outputs (balanced or

unbalanced). Disable turns it off.

Dip Switch 2/Speaker EQ Filter:

voice applications. Disable turns it off.

Dip Switch 3/USB Conference Mode: Enable creates the desired audio mixing (Near and Far ends) for

USB conferencing applications such as Skype. Disable turns off the USB Conference Mode.

o Note: In the USB Conference Mode, the PC USB Speaker Audio is sent to the balanced

and unbalanced audio line outputs which allows the Far End Audio to be presented in the

room. The Belt Pack Wireless Microphone Audio is also sent to the PC to send to the Far

End.

o The AutoTrak 2.0 Wireless Audio Interface will also be recognized as a USB Audio Device

by the PC with Recording (the Belt Pack Wireless Microphone Audio) and Playback (the

Speaker Audio) capabilities. Disable turns the USB Conference Mode off.

Dip Switch 4/Baud Rate Selection:

Disable sets the Baud Rate at 9.6K.

Dip Switch 5/Radio On-Off:

turns it off.

Dip Switch 6/Unused

Dip Switch 7/Software Control:

Interface for the Belt Pack Wireless Microphone. Disable turns it off.

Dip Switch 8/Unused

Enable adds a specialized output filter for improved intelligibility for

Enable sets the Baud Rate of the RS-232 Port at 38.4K and

Enable turns the Radio Receiver for the Wireless Microphone on. Disable

Enable turns on the Radio Receiver in the AutoTrak 2.0 Wireless Audio

Eight Position Dip Switch Settings

rd

party control systems using the Wireless

Switch Number Function

1 Enable/Disable Compressorfor the Balanced and

Unbalanced Audio Outputs

2 Enable/Disable Speaker EQ Filte

3 USB Conference Mode (Skype-type PC

applications)

4 Baud Rate Selection: 9600-Off/38.4K-On

5 Disable Radio (1-Off)

6 Not Used

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 10 of 47

Page 11

AutoTrak 2.0 Camera Tracking System

V

V

7 Software Control

8 Not Used

4) GPIO Port: The GPIO Port provides the ability to interface with external control systems. Inputs are logic

level low. Output is an open collector.

GPIO Port Pin Configuration

Pin Function

1 Power (12Vdc)

2 Mute (Input)

3 Mute Status (Output)

4

5

olume Up (Input)

olume Down (Output)

6 Not Used

7 Ground

5) USB Type B Connector: This connector is used to interface with the Host PC for Skype type applications.

6) Audio Outputs: There are two (2) Audio Outputs on the rear panel:

Balanced Audio Output Jack: Balanced Line Level (on XLR - M connector) +4dBu

Unbalanced Audio Output Jack: Unbalanced Line Level (on RCA-F connector) -10dbV

Lanyard, Belt Pack Controls:

The central medallion of the lanyard has an attached, strain-relieved, 32” cable that

terminates to a 5-pin mini XLR female connector. Attach the 5-pin mini XLR to the 5-pin

mini XLR male connector on the belt pack. The microphone element is on the top of the

central medallion. The lanyard material houses a flat flex type circuit where the IR LEDs

are mounted. After the initial setup is complete, the presenter should slip the lanyard over

their head and position the medallion away from the presenter and face the Vaddio logos

on the lanyard cloth cover out, toward the cameras. Clip the belt pack onto the clothing,

belt or waistband securely. Please avoid dropping the belt pack.

24”

Lanyard

Necklace

Power to illuminate the IR LEDs is supplied from the Belt Pack and if the System Power

Switch is ON, the IR LEDs will illuminate at 850 nanometers (out of the range of visible

light for humans). Each Lanyard has 15 IR LEDs spread out evenly throughout the

Central

Medallion

Lanyard Necklace. This invisible light is picked up by the IR reference camera of the

AutoTrak 2.0 System and information is sent to the Tracking Camera in order to follow the

presenter throughout the presentation environment.

Do not fold the Lanyard Necklace at any time as it contains a

flexible circuit that may cease to work if the necklace is hard

folded. Folding the Lanyard Flex Circuit will void any and all

warranties.

32”Cable to

Belt Pack

Installation and Operating Instructions for AutoTrak 2.0 with Belt Pack Unit and IR Lanyard

999-7250-000 and 999-7260-000 North America

999-7250-001 and 999-7260-001 International

1) Connect the 12 VDC, 1.0 Amp power supply to the Audio Interface.

2) Connect the 6.5” RP-SMA Antenna to the back of the Audio Interface.

3) Connect the Audio outputs to a mixer/amp.

4) Select a frequency to transmit and receive audio from the Belt Pack Unit on the back of the Audio Interface.

5) Touch the Power button on the Audio Interface and the blue LED inside the power switch will illuminate

6) Turn the Audio Level on the front panel to “1”.

7) Connect the Lanyard to the Belt Pack

8) Move the System Power and the Microphone switches on the Belt Pack to the “OFF” position

9) Remove the battery door on the Belt Pack:

a. Set the 3-position dip switch to the same frequency (position) as the Audio Interface

b. Carefully matching the polarity markings; install four (4) AA batteries (not included)

c. Return the battery door cover

10) Move the System Power and the Microphone power switch on the Belt Pack to the “ON” position.

11) The System Status LED on the Audio Interface should illuminate.

12) Make sure that the Mic Mute LED on the front panel is not lit.

13) Adjust the mic volume by moving the Audio Level potentiometer until the desired output level is reached.

Mic

Element

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 11 of 47

Page 12

AutoTrak 2.0 Camera Tracking System

14) Test the mic ON/OFF switch on the Belt Pack and also the Mic Mute switch on the Audio Interface for proper

operation.

Notes:

The IR LEDs cannot be seen (if you are human - since the 850nm LED light is outside of human optical sensory

range) so make sure that the System Power on the Belt Pack Unit is off when it is not in use.

If the Audio Level output is set to a high level, please avoid touching the mic element on the central medallion.

If the System Power LED on the Belt Pack turns red, then the battery is low and a battery recharge is required.

If Microphone LED on the Belt Pack flashes, then a fault condition is present (i.e. bad IR LED in the lanyard

necklace or a bad fold in the lanyard necklace etc…). Cycle the power, check the lanyard to Belt Pack cable

connection and check the batteries. If checking these conditions and recycling power does not clear the

problem, then call Vaddio Technical Support Team.

Inside the Belt Pack there is a 6-position Dip switch. The first 3 positions are used to set the transmit frequency,

switches 4 and 5 are unused/future and switch 6 can be used to turn off the IR LEDs in case the Presenter wants

to use the Lanyard, Belt Pack and Audio Interface as a wireless mic only. If switch 6 is activated, the system will

not track the lanyard.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 12 of 47

Page 13

AutoTrak 2.0 Camera Tracking System

(

)

y

(

)

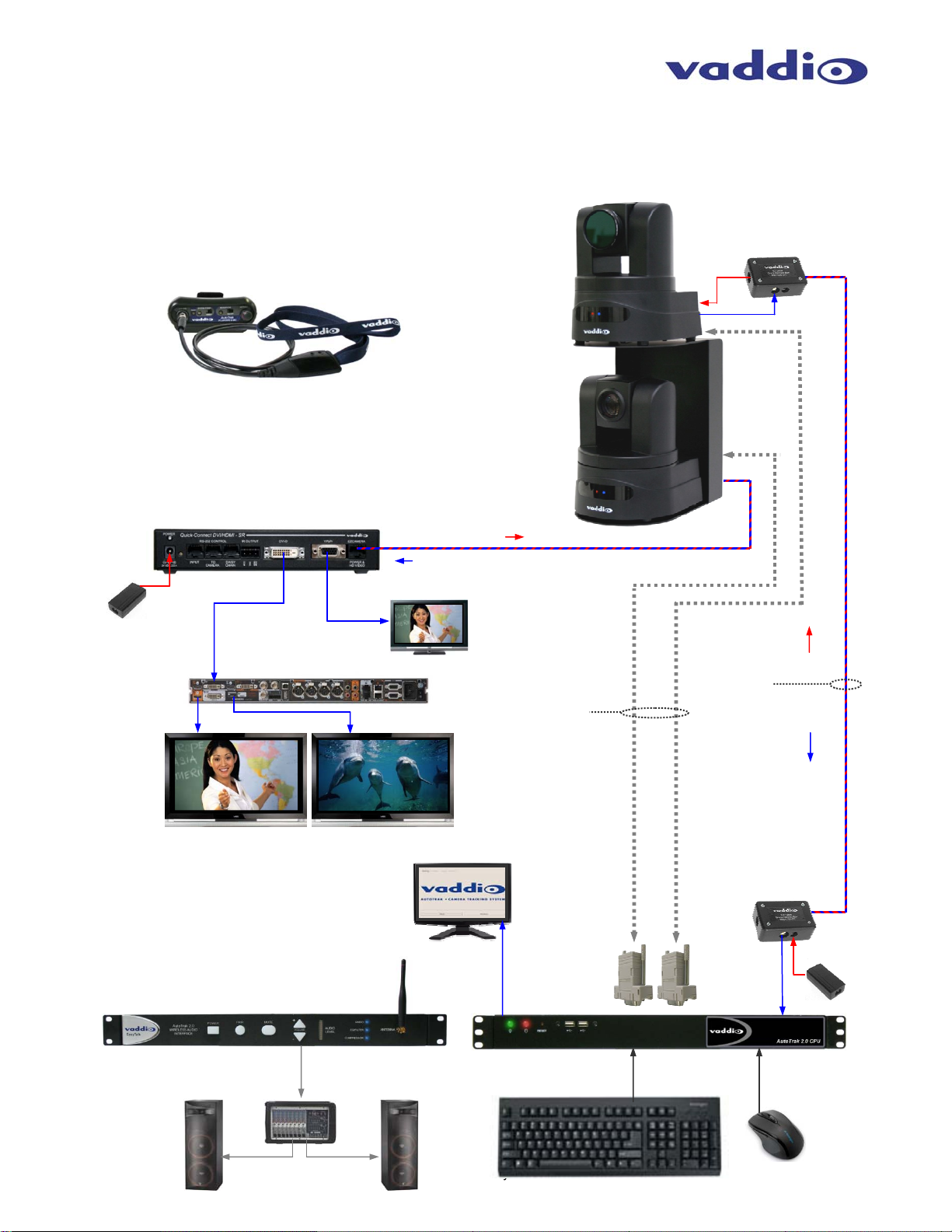

Basic System Configuration 1:

AutoTrak 2.0 999-7250-000 Dual HD-18 Kit with Quick Connect DVI/HDMI Interface (North America Only)

AutoTrak 2.0 IR Lanyard,

attached cable, Rechargeable

Belt Pack and 1-inch RP-SMA

HD-18

IR Reference

Camera with

Adapters and

Filters

Composite Video

feed to AutoTrak

2.0

Note: Belt Pack capable of

Transmitting Wireless Mic

Audio at 2.4 GHz to Optional

Talk AutoTrak 2.0 Wireless

Eas

HD-18

Tracking Camera

PWR

Supply

Quick-Connect DVI/HDMI - SR

Interface 998-1105-018

Cat-5e

Power to Camera

YPbPr (1080p/60) from Camera

Cat-5e Cable to EZ Power Video Port

DVI-D or

HDMI with

adapter

(1080p/60)

YPbPr

(1080p/60)

Instructor’s Confidence

(Not Included)

Monitor

Simulated Video Feed

HDMI

Video

T C60 Codec

Not Included

RS-232

Cat-5e

HD Video Monitors

Simulated Video Feeds

(Not Included)

EasyTalk AutoTrak 2.0 Wireless Audio Interface

Receiving Audio from Wireless Belt Pack at 2.4 GHz

Optional-Not Included:

RGBHV Monitor

Not Included

4” RP-SMA

Antenna

RGBHV

Serial to Cat-5e

Control Adapters

Use Adapter P/N:

998-1001-232 on

these Ports

Port 2

Balanced Line Level (on XLR +4dBu) or

Unbalanced Line Level (on RCA -10dBV)

AutoTrak 2.0 CPU

Keyboard & Mouse

AutoTrak 2.0 Quick-Connect

Box 998-1105-020

Cat-5e

Power to

EZ

Port

CVBS

BNC to RCA

Cat-5e

AutoTrak

Dual HD-18

Cat-5e

Cat-5e

Std Quick-Connect

Box 998-1105-001

CVBS in

Video 2

Port 1

2.0

Mount

Cat-5e

Power to

Camera

CVBS

from

Camera

PWR

Supply

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 13 of 47

Sound System

(Not Included)

Page 14

AutoTrak 2.0 Camera Tracking System

(

)

y

(

)

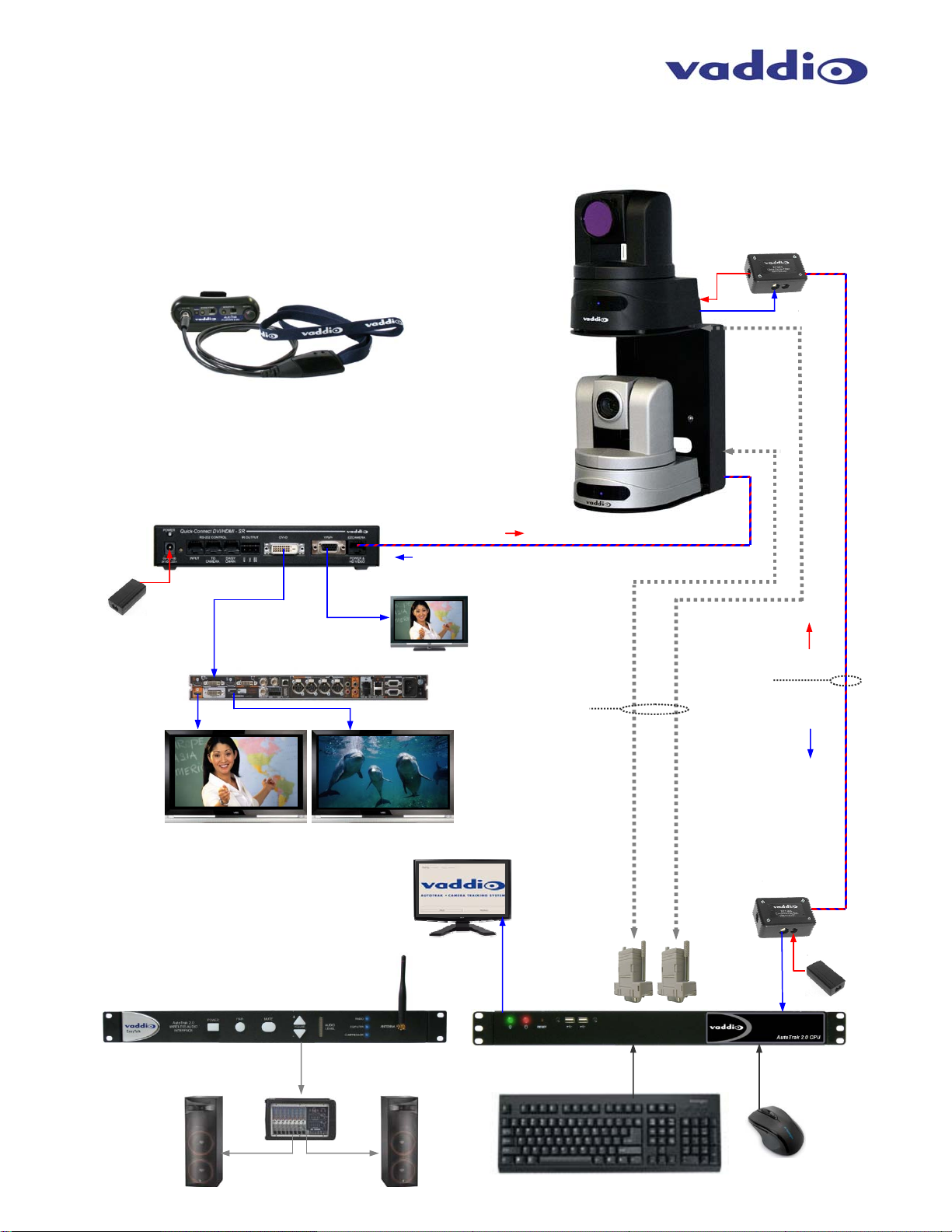

Basic System Configuration 2:

AutoTrak 2.0 999-7260-000 HD-18 IR Reference Camera and HD-20 Tracking Camera Kit with Quick Connect DVI/HDMI

Interface (North America Only)

AutoTrak 2.0 IR Lanyard,

attached cable, Rechargeable

Belt Pack and 1-inch RP-SMA

HD-18

IR Reference

Camera with

Adapters and

Filters

Composite Video

feed to AutoTrak

2.0

Note: Belt Pack capable of

Transmitting Wireless Mic

Audio at 2.4 GHz to Optional

Talk AutoTrak 2.0 Wireless

Eas

HD-20

Tracking Camera

AutoTrak 2.0 Quick-Connect

Box 998-1105-020

Cat-5e

Power to

EZ

Port

CVBS

BNC to RCA

Cat-5e

AutoTrak

2.0

HD-18-

HD-20

Mount

Cat-5e

PWR

Supply

Quick-Connect DVI/HDMI - SR

Interface 998-1105-018

YPbPr

DVI-D or

HDMI with

adapter

(1080p/60)

(1080p/60)

Cat-5e

Power to Camera

YPbPr (1080p/60) from Camera

Instructor’s Confidence

(Not Included)

Monitor

Simulated Video Feed

Cat-5e Cable to EZ Power Video Port

HDMI

Video

T C60 Codec

Not Included

RS-232

Cat-5e

Cat-5e

HD Video Monitors

Simulated Video Feeds

EasyTalk AutoTrak 2.0 Wireless Audio Interface

Receiving Audio from Wireless Belt Pack at 2.4 GHz

Optional-Not Included:

Balanced Line Level (on XLR +4dBu) or

Unbalanced Line Level (on RCA -10dBV)

(Not Included)

RGBHV Monitor

Not Included

4” RP-SMA

Antenna

Serial to Cat-5e

Control Adapters

Use Adapter P/N:

998-1001-232 on

RGBHV

AutoTrak 2.0 CPU

these Ports

Port 2

Std Quick-Connect

Box 998-1105-001

CVBS in

Video 2

Port 1

Keyboard & Mouse

Cat-5e

Power to

Camera

CVBS

from

Camera

PWR

Supply

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 14 of 47

Sound System

(Not Included)

Page 15

AutoTrak 2.0 Camera Tracking System

The AutoTrak 2.0 CPU, Camera and Software Operating Instructions

The AutoTrak 2.0 CPU is a 1-RU rack mount

computer that comes preloaded with the

AutoTrak 2.0 software. It is a closed system

based on a Linux operating system.

The AutoTrak 2.0 CPU uses an Intel® Atom™ Dual Core Processor, Intel Graphics Media Accelerator,

1GB DDR2 Memory with six (6) USB ports, four(4) RS-232 Ports, two (2) PS/2 interfaces for

keyboard/mouse, 16GB Compact Flash and Video capture card. CPU specifications and cosmetics are

subject to change.

Getting Started:

1) Take the AutoTrak 2.0 CPU out of the box to start the system connection.

2) Connect two (2) of the 998-1001-232 control adapters (check part numbers carefully) to serial com

ports 1 and 2. The IR Reference camera will be connected to Port 1 and the Tracking Camera will be

connected to Port 2.

3) Connect the Keyboard and the Mouse to the AutoTrak 2.0 CPU using USB ports

4) Connect the computer monitor (not included) to the DE-15 (HD-15) on the AutoTrak 2.0 CPU.

5) Connect the AC Power Cord, but do not turn on the computer yet.

Mounting the Cameras and Distance Limits:

The AutoTrak 2.0 systems are shipped with

either a dual HD-18 camera mount or an HD-18

and HD-20 Camera that can be mounted to a

wall permanently or be mounted to an optional

cart system. The vertically stacked camera

AutoTrak 2.0

HD-18

IR Reference

Camera with

Adapters and

Filters

AutoTrak 2.0

HD-18

IR Reference

Camera with

Adapters and

Filters

arrangement is required for the AutoTrak 2.0

software to track properly

Consider the placement of the cameras

.

Dual Mount

Dual Mount

carefully; the range of use is from 12’ (3.65m)

and up to 40’ (12.2m). System positioning is

critical for proper and consistent operation. If

the distance from the presenter to the wall

mounting location is greater than 40’ (12.2m),

then an optional portable cart system is

AutoTrak 2.0

HD-18

Tracking

Camera

AutoTrak 2.0

HD-20

Tracking

Camera

recommended to place the cameras in range of

the IR Lanyard, which is required for the tracking

system to acquire the IR LED light in order to

track the presenter.

AutoTrak 2.0 999-7250-000

Dual HD-18 Cameras for

IR Reference and Tracking

Cameras

AutoTrak 2.0 999-7260-000

HD-18 IR Reference

Camera and HD-20

Tracking Camera

Mount the cameras with the IR Reference

Camera on the top shelf of the dual mount and

mount the Tracking Camera on the lower shelf

of the dual mount.

Please mark and test the cables prior to termination. Please do not connect these

cameras up to the Quick-Connect systems using the “guess/trial and error” method.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 15 of 47

Page 16

AutoTrak 2.0 Camera Tracking System

Installing the PTZ Cameras

The IR Reference Camera requires two (2) Cat-5e cables run from the head-end

equipment; one for composite video and power, and one for control. The installation steps for the IR

Reference Camera are as follows:

1) Identify the IR Reference Camera, the HD-18 with the 37mm lens adapter on the lens

2) Screw on the 37mm to 58mm adapter ring

3) Screw on the 58mm polarizing filter

4) Screw on the 58mm band-pass IR filter.

5) Mount this camera to the top shelf of the dual mount with the supplied ¼”-20 screws.

6) Connect the 18”/45.8mm BNC to RCA Video Cable to the Composite (CVBS) BNC-M video connector on

the back of the camera and connect the RCA-M connector to the RCA–F connector on the AutoTrak 2.0

Quick-Connect Box 998-1105-020.

7) Connect one side of the 12”/30.48cm Cat-5e Patch Cable to the EZ Power Video RJ-45 connector on the

camera and the other end of the cable to the AutoTrak 2.0 Quick-Connect Box 998-1105-020 to the end

marked “IR Reference Camera”. This connector is only providing power to the EZ Power Video Port.

8) Connect the 1

1105-020 to the RJ-45 port labeled “AutoTrak 2.0”. This Cat-5e cable is terminated at the head end to the

other Quick-Connect Box (998-1105-001) RJ-45 connector.

9) Take the composite output of the Quick-Connect Box 998-1105-001 and connect it to the AutoTrak 2.0 CPU

composite video input (you’ll need a RCA-M to RCA-M cable, which is not supplied) to the center yellow

composite input on the back of the AutoTrak 2.0 CPU.

10) Connect the 2nd Cat-5e cable (up to 100’ /30.5m - not supplied) to the RS-232/IR port on the camera, and at

the head-end connect it to the Control Adapter that is on COM PORT 1 on the CPU.

11) Connect the 24VDC power supply to the 998-1105-001 Quick-Connect Box.

st

Cat-5e cable (up to 100’/30.5m not supplied) to the AutoTrak 2.0 Quick-Connect Box 998-

The Tracking Camera requires two (2) Cat-5e cables run from the head-end

equipment; one for YPbPr video and power, and one for control.

1) Identify the HD-18 Tracking Camera (the normal camera without the 37mm lens adapter).

2) Mount this camera on the lower shelf of the mount with the supplied ¼”-20 screws

3) Run one Cat-5e (up to 100/30.5m) cable between the EZ Power Video Port on the HD-18 camera to the

EZCamera Power & HD Video Port on the 998-1105-016 HD-18 Quick-Connect SR Interface.

4) Connect the HD Video YPbPr output to a high definition monitor (if using the HD-18 Quick-Connect SR

Interface) or the DVI-D or the YPbPr output (or both) to a HD monitor.

5) Run the 2nd Cat-5e from the RS-232/IR port on the back of the HD-18 camera to Control Adapter that is

connected to COM PORT 2 on the CPU

6) Connect the 24VDC Power supply to the HD-18 Quick-Connect Interface.

Booting up the System and Initial Set-up:

1) With the AutoTrak 2.0 Belt Pack on (at least the system power switch on) and the lanyard plugged

into the belt pack (with known good batteries), place the lanyard/belt pack in a centered location

approximately 20’ (6.096m) from the AutoTrak 2.0 stacked camera assembly and about 5’ (1.524m)

off the floor to imitate the height of a presenter/instructor.

2) Turn on the cameras and AutoTrak 2.0 CPU. The AutoTrak 2.0 CPU should boot up to the AutoTrak

2.0 application automatically. Click the Pause button to enter setup. The screen shot is below.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 16 of 47

Page 17

AutoTrak 2.0 Camera Tracking System

3) Plug the IR Reference Camera into a monitor for set-up purposes. With the IR Reference plugged

into a monitor, the IR LEDs should be visible as white dots on a black background. These LEDs will

be tracked as the presenter moves around the room. To aid in set-up, a temporary RCA Y-cable may

be used to split the signal between the monitor and CPU.

4) Select the Presets Tab①, then the Reference Camera Tab②. Use the Position③ buttons to Center

the IR lanyard in the monitor display horizontally and vertically.

5) Use the Zoom④ buttons (tele & wide) to increase the size of the lanyard in the display until the is

approximately 1/3 the size of the video image on the monitor. Use the Position③ up/down buttons to

locate the lanyard in the upper 1/2 of the screen so the presenter’s head is in the top ½ of the screen.

6) Click the Save⑤ button to save this default zoom and tilt position for the IR Reference Camera. The

Load⑥ button is for recalling a previously saved preset.

①

②

③

④

⑥

⑤

7) Plug the composite video from the IR Reference Camera back into the middle yellow RCA-F jack on

the back of the AutoTrak 2.0 CPU.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 17 of 47

Page 18

AutoTrak 2.0 Camera Tracking System

8) With the Tracking Camera plugged into a monitor, select the Presets① Tab and then the Tracking

Camera② Tab. Adjust the Position③ buttons and the Zoom④ buttons to tilt/zoom the camera to the

desired presenter framing. Set the zoom position and the tilt angle of the Tracking Camera and click

on the Save Preset Button⑤ to store the System Tracking Preset. The Load⑥ button is for recalling

a previously saved preset.

①

②

③

④

⑦

⑥

⑤

Note: The AutoPresenter Camera Presets ⑦ are supported by AutoTrak 2.0 when used in

conjunction with an AutoPresenter 6x1 Seamless switcher and Automated Camera Preset Controller.

A later section explains the connectivity and set-up when using these devices together.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 18 of 47

Page 19

AutoTrak 2.0 Camera Tracking System

9) On the Tuning① / Tracking② Camera page, Camera Select③ automatically detects the camera is

being used as the Tracking Camera. The auto-detect choices are between the HD-18 and HD-20.

10) The Iris④ control allows the user to set the specific f-stop (iris value) of the camera for challenging

lighting environments or use the system in Automatic mode. The system will auto set this value.

11) The Auto Focus Type⑤ allows the user to select the type of auto focus that is preferred. The Low and

Bright Light setting is effective for bright to low light conditions. The Low Light setting allows for faster

focusing in low light conditions. The system will auto set this value.

12) The Tilt Correction⑥ angle is to compensate for the different heights of the camera lens when the

HD-18 cameras are mounted in a co-linear stacked array which is a highly preferred and

recommended configuration. This correction angle is automatically figured by the system when the

Tracking Camera Preset or the Reference Camera Preset is saved assuring that both cameras are

pointing at the same target.

13) The Zoom Position⑦ is a reference position stored as part of the system Tracking Camera Preset.

14) The Pan Correction⑧ parameter should only be used if; there is absolutely no way that the

cameras can be stacked in a co-linear array and have to be used side by side. The side by side

configuration is not recommended. The stacked configuration is highly preferred.

①

②

③

④

⑤

⑧

⑥

⑦

⑨

To start AutoTrak 2.0 click the Resume⑨ button.

15) After twenty about (20) seconds the IR Reference Camera will search and locate the IR lanyard.

The lanyard was placed earlier at a specific central location and height and distance from the

cameras in previous steps.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 19 of 47

Page 20

AutoTrak 2.0 Camera Tracking System

16) Once the lanyard is located, the Tracking Camera will acquire a shot of the lanyard. A slight

manual adjustment may be necessary if the lanyard is not centered in the shot. To make the fine

adjustment, loosen the ¼-20 screw(s) holding the Tracking Camera to the mount and move the

Tracking Camera until the lanyard is centered in the display monitor. Re-tighten the ¼-20 screw

and initial setup is complete.

Important Notes Regarding AutoTrak 2.0

When setting up the IR Reference Camera, avoid the lights on the ceiling or

other bright light sources. Bright light from any source or sunlight can overwhelm

IR reception in the camera, making it impossible to distinguish the lanyard from

the background light. Tilt the Reference Camera down and away from ceiling

light cells to limit the stray light.

The IR Reference Zoom Field of View (FOV) should be as wide as possible.

When the IR Reference Camera is zoomed in too far on the tele end, the pan

search speed must be slowed down, which could cause the acquisition of the

presenter’s lanyard to take a much longer time.

The AutoTrak 2.0 CPU is a computer running a Linux OS. Please do not remove

power from the AutoTrak 2.0 CPU without first shutting the system down, as you

would any other business computer. After the AutoTrak 2.0 CPU is shut down it

is safe to remove power. Also note that a quick power cycle can also wreak

havoc with the AutoTrak 2.0 CPU, just like any other computer.

When the system is not being used, please note that the System Power on the

belt pack should be turned off and the blue LED should be off to save battery life.

The Lanyard battery life is expected at 6 to 8 hours, so please change or

recharge the batteries regularly to insure proper IR LED light levels.

Refer to the Control Parameter Descriptions table for definitions of the

terminology used in the AutoTrak 2.0 Software

Using the AutoTrak 2.0 as an Input to the AutoPresenter for Camera Presets

(If the AutoTrak 2.0 and AutoPresenter are not being used together in a system – skip this section)

AutoTrak 2.0 Tracking Camera presets require configuration in both AutoTrak 2.0 and

AutoPresenter.

In the AutoTrak 2.0, the actual camera preset positions are determined and stored. Each preset

is selected based on a Preset Index and a Preset Trigger (AutoPresenter trigger number).

In AutoPresenter, Presets (Input only) are identified and stored to a trigger number (1-72). A

menu item (“AutoTrak 2.0 Input”) must be set identifying which video input select (1-6) is to be

used with AutoTrak 2.0 video output.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 20 of 47

Page 21

AutoTrak 2.0 Camera Tracking System

The AutoPresenter will send a command to the AutoTrak 2.0 when a Preset Trigger is tripped

with AutoTrak 2.0 input select.

To Connect the AutoTrak 2.0 to AutoPresenter

system):

(skip this section if an AutoPresenter is not part of the

1) Take the supplied 998-1001-232 Control Adapter and attach it to COM PORT 3 on the CPU.

2) Attach the 998-7200-232 Control Adapter to the RS-232 THRU port on the back of the AutoPresenter.

3) With a Cat 5e cable (not supplied) connect the two (2) control adapters list in steps 1 & 2 above.

4) A system shutdown and reboot will be required for the AutoTrak 2.0 to recognize the AutoPresenter.

For reference, the AutoPresenter port is identified on the Tuning/Setup screen.

To Set the Tracking Camera Presets in AutoTrak 2.0 to be activated by AutoPresenter:

1) In the AutoPresenter Menus, select the menu item “AutoTrak 2.0 Input” and select which input (1-6)

to which the AutoTrak 2.0 will be connected. This way up to six (6) trigger inputs, between 1 and 72,

can be dedicated to preset positions for the AutoTrak 2.0 Tracking Camera. These presets can be

incorporated into the system and use the Vaddio trigger devices such as PresenterPOD, StepVIEW

mats, AutoVIEW IR Sensors, MicVIEW push to talk mics or TouchVIEW RF buttons.

2) To set Tracking Camera presets, put the system in pause mode to get at the menus and click on the

Presets① tab and then the Tracking Camera② tab.

a. Adjust the Position③ (Pan/Tilt) and Zoom④ controls for the desired preset position.

b. Assign this position Preset⑤ # (1-6) under the AutoPresenter Camera Presets area.

c. Assign Trigger⑥ # (1-72) that is associated with the AutoPresenter trigger preset.

d. Click on the Save⑦ button.

e. To recall a preset position, set the Preset⑤ # (1-6) and click on Load⑧.

①

②

③

④

⑤

⑥

4

⑧

⑦

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 21 of 47

Page 22

AutoTrak 2.0 Camera Tracking System

3) As an example, if the AutoPresenter video input for the AutoTrak 2.0 is Input 6, the AutoTrak 2.0

preset is #1 which is triggered by input trigger #4 with a trigger device. Then anytime the presenter

trigger input #4, the AutoPresenter will switch to Input 6 and the AutoPresenter will communicate to

the AutoTrak 2.0 which will send the Tracking Camera to go to Preset #1.

Updating the System Software:

1) To update the system software, contact Vaddio Tech Support or go to the

Vaddio website to get the Zip File. Copy the file to Root Directory of USB

Flash Drive (not included).

2) Turn off AutoTrak 2.0 CPU.

3) Insert the USB flash drive into any available USB port of the AutoTrak 2.0

CPU.

4) Turn ON the AutoTrak 2.0 CPU. When the system recognizes a valid update

file, a dialog box will open and ask the user to confirm or cancel the firmware

update.

5) Confirm the update request and the update will be applied.

6) The system will reboot and be ready to operate.

7) Remove the USB flash drive and the update process is complete.

Note: On earlier versions of the software, the Update Tab is used to start the update.

The About Tab:

The About Tab’s purpose in life is to provide information on the Software Revision, supply Technical

Support contact information and certain acknowledgements.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 22 of 47

Page 23

AutoTrak 2.0 Camera Tracking System

All Menu Screen Shots and Control Descriptions:

Tracking/Main Page

Control Action Description

Pause/Resume Button Click/Press Stop/Interrupt tracking

Shutdown Button Click/Press Close/Shutdown system

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 23 of 47

Page 24

AutoTrak 2.0 Camera Tracking System

All Menu Screen Shots and Control Descriptions (continued):

Presets: Reference Camera

Control Action Description

Camera Control Position Up

Button

Camera Control Position Down

Button

Camera Control Position Left

Button

Camera Control Position Right

Button

Camera Control Position Home

Button

Camera Control Zoom Tele

Button

Camera Control Zoom Wide

Click/Press and hold Direct Reference Camera Up

Click/Press and hold Direct Reference Camera Down

Click/Press and hold Direct Reference Camera Left

Click/Press and hold Direct Reference Camera Right

Click/Press and hold Direct Reference Camera Home

Click/Press and hold Direct Reference Zoom In (Tele)

Click/Press and hold Direct Reference Zoom Out (Wide)

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 24 of 47

Page 25

AutoTrak 2.0 Camera Tracking System

Button

System Reference Load Preset

Button

System Reference Save Preset

Button

Pause/Resume Button

Shutdown Button

Click/Press Load Reference Camera Preset

Click/Press Save Current Zoom/ Tilt Reference

Camera Preset

Click/Press Pause or Return to Tracking

Click/Press Close/Shutdown system

All Menu Screen Shots and Control Descriptions (continued):

Presets: Tracking Camera & Presets for use with AutoPresenter

Control Action Description

Camera Control Position Up Button

Camera Control Position Down Button

Camera Control Position Left Button

Camera Control Position Right Button

Camera Control Position Home Button

Camera Control Zoom Tele Button

Camera Control Zoom Wide Button

System Tracking Load Preset Button

System Tracking Save Preset Button

AutoPresenter Presets - Preset: # Click/Press Up/Down Select AutoTrak 2.0 preset index (1-

AutoPresenter Presets - Trigger: # Click/Press Up/Down Select AutoPresenter Trigger( 1-72)

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 25 of 47

Click/Press and hold Direct Tracking Camera Up

Click/Press and hold Direct Tracking Camera Down

Click/Press and hold Direct Tracking Camera Left

Click/Press and hold Direct Tracking Camera Right

Click/Press and hold Direct Tracking Camera Home

Click/Press and hold Direct Tracking Zoom In (Tele)

Click/Press and hold Direct Tracking Zoom Out (Wide)

Click/Press Load Tracking Camera Preset

Click/Press Save Current Tilt & Zoom as Tracking

Camera Preset

6)

Page 26

AutoTrak 2.0 Camera Tracking System

AutoPresenter Presets Load Button

AutoPresenter Presets Save Button

Pause/Resume Button

Shutdown Button

Click/Press Load selected preset

Click/Press Save selected preset

Click/Press Pause or Return to Tracking

Click/Press Close/Shutdown system

Note 1: AutoPresenter Presets Trigger Number “0” denotes no presets present.

Note 2: Status bar shows the Tracking Camera Pan/Tilt/Zoom positions and Pan/Tilt Speeds.

All Menu Screen Shots and Control Descriptions (continued):

Presets: Setup Speeds

Feature Action Description

Pan Speed Click/Press Up/Down Select Pan Speed

Tilt Speed Click/Press Up/Down Select Tilt Speed

Save Button Click/Press Save Pan/Tilt Speeds

Pause/Resume Button Click/Press Pause or Return to Tracking

Shutdown Button Click/Press Close/Shutdown system

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 26 of 47

Page 27

AutoTrak 2.0 Camera Tracking System

All Menu Screen Shots and Control Descriptions (continued):

Tuning: Algorithm

Control Action Description

Luminance Threshold

Max Luminance

Density

Search Left Limit

Search Right Limit

Move Left Limit

Move Right Limit

Search Pan Speed

Search Tilt Position

Projection Time

Click Up/Down

Slider Left/Right

Click Up/Down

Click Up/Down

Click Up/Down

Click Up/Down

Click Up/Down

Click Up/Down

Click Up/Down

Minimum illumination to be considered a valid target (1-255)

Max luminance points to be considered a valid target (1-

9999)

The Left most location, in degrees, to search for target.

The Right most location, in degrees, to search for target.

The Left most location, in degrees, camera can move.

The Right most location, in degrees, camera can move.

Pan search speed and max tracking camera speed

Reference camera tilt angle, in degrees

Tracking speed adjustment where higher value reduces

speed.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 27 of 47

Page 28

AutoTrak 2.0 Camera Tracking System

Window Width

Max Blind Time

Max. Reacquisition

Time

Load Button

Save Button

Pause/Resume Button

Shutdown Button

Click Up/Down

Click Up/Down

Click Up/Down

Click/Press

Click/Press

Click/Press Pause or Return to Tracking

Click/Press Close/Shutdown system

Wider Window Width reduces left-right movement. Narrow

Window Width increases the left-right movement of the

camera

Time, in sec, to wait after target loss to begin target reacquisition

Time, in sec, to search for target before going into standby

mode.

Load all tuning setting

Save all tuning setting

All Menu Screen Shots and Control Descriptions (continued):

Tuning: Reference Camera

Feature Action Description

Iris Click Up/Down Manual Mode allows Iris adjustment in steps (f-stops)

Auto Gain Click Up/Down Brightness gain used to make IR lanyard more visible (0-

30)

Zoom Position Slider

Left/Right

Zoom position, in steps (0- 9984), auto-stored when

Reference Camera Preset is saved.

Load Button Click/Press Loads previously saved settings

Save Button Click/Press Saves tuning settings for IR Reference Camera

Pause/Resume

Click/Press Pause or Return to Tracking

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 28 of 47

Page 29

AutoTrak 2.0 Camera Tracking System

Button

Shutdown

Click/Press Close/Shutdown system

Button

All Menu Screen Shots and Control Descriptions (continued):

Tuning: Tracking Camera

Feature Action Description

Camera Select Click On The system will auto-detect if a HD-18 Tracking Camera or HD-20

Tracking Camera is being used.

Iris Click Up/Down Auto Mode

Manual Mode allows Iris adjustment in steps (f-stops)

The system will auto set this value to start.

Auto Focus Type Click Up/Down Select Between “Low and Bright Light” Conditions or

“Low Light” Conditions. The “Low and Bright Light” setting works

best in rooms with bright spots and reflections (uneven lighting). The

“Low Light” Setting works best in low to medium, even lighting

environments and focusing is faster.

The system will auto set this value to start.

Pan Correction Click Up/Down Value, in degrees, to adjust reference location used to move

Tracking Camera. (FOR USE ONLY WITH SIDE BY SIDE CAMERA

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 29 of 47

Page 30

AutoTrak 2.0 Camera Tracking System

INSTALLATIONS - THIS CONFIGURATION IS NOT

RECOMMENDED)

Tilt Correction Click Up/Down Value, in degrees, to adjust reference Tilt location used for the

Tracking Tilt.

Zoom Position Slider Left/Right Zoom position, in steps (0- 9984), auto-stored when Tracking

Camera Preset is saved.

Load Button

Save Button

Click/Press Loads previously saved settings

Click/Press Saves tuning settings for Tracking Camera

NOTE: Bright and natural sunlight containing too much IR light can hinder AutoTrak 2.0’s

performance.

All Menu Screen Shots and Control Descriptions (continued):

Tuning: Setup

Feature Action Description

System Description Type # and letters Names file for Exporting Parameters

Pan Speed Click Up/Down Max Pan speed, in degrees/Sec

Tilt Speed Click Up/Down Max Tilt speed, in degrees/Sec

Zoom Speed Click Up/Down Max Zoom speed

Auto Presenter Port Drop Down Select Device Name for AutoPresenter Serial Port

Reference Camera Port Drop Down Select Device Name for Reference Camera Serial Port

Tracking Camera Port Drop Down Select Device Name for Tracking Camera Serial Port

Restore Factory Defaults*

Export Parameters

Import Parameters

Click Sets all parameters to factory preset defaults

Click/Press Opens dialogue box to allow user to export (save or store)

current AutoTrak 2.0 parameters to local or flash drive

Click/Press

Opens dialogue box to allow user to export (store) current AutoTrak

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 30 of 47

Page 31

AutoTrak 2.0 Camera Tracking System

2.0 parameters. A USB drive must be inserted before clicking this

button. The default location is the USB drive (a path such as

/media/sdxx). Alternatively, the parameter file can be saved locally

at /home/Vaddio.

Load Button

Save Button

Pause/Resume Button

Shutdown Button

Click/Press Loads previously saved settings

Click/Press Saves Setup Page settings

Click/Press Pause or Return to Tracking

Click/Press Close/Shutdown system

*Pop-up Warning for Restore Factory Defaults:

If the Restore Factory Defaults button is selected, then the “Are You Sure” dialog box will pop up to

protect the previously stored presets and make sure that resetting to the factory defaults is truly intended.

All Menu Screen Shots and Control Descriptions (continued):

Tuning: Setup

Feature Action Description

System Description Type # and letters Names file for Exporting Parameters

Pan Speed Click Up/Down Max Pan speed, in degrees/Sec

Tilt Speed Click Up/Down Max Tilt speed, in degrees/Sec

Zoom Speed Click Up/Down Max Zoom speed

Auto Presenter Port Drop Down Select Device Name for AutoPresenter Serial Port

Reference Camera Port Drop Down Select Device Name for Reference Camera Serial Port

Tracking Camera Port Drop Down Select Device Name for Tracking Camera Serial Port

Restore Factory Defaults*

Export Parameters

Import Parameters

Click Sets all parameters to factory preset defaults

Click/Press Opens dialogue box to allow user to export (save or store)

current AutoTrak 2.0 parameters to local or flash drive

Click/Press

Opens dialogue box to allow user to export (store) current

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 31 of 47

Page 32

AutoTrak 2.0 Camera Tracking System

AutoTrak 2.0 parameters. A USB drive must be inserted before

clicking this button. The default location is the USB drive (a path

such as /media/sdxx). Alternatively, the parameter file can be

saved locally at /home/Vaddio.

Load Button

Save Button

Pause/Resume Button

Shutdown Button

Click/Press Loads previously saved settings

Click/Press Saves Setup Page settings

Click/Press Pause or Return to Tracking

Click/Press Close/Shutdown system

*Pop-up Warning for Restore Factory Defaults:

If the Restore Factory Defaults button is selected, then the “Are You Sure” dialog box will pop up to

protect the previously stored presets and make sure that resetting to the factory defaults is truly intended.

Control Parameter Descriptions:

Refer to this table for definitions of the terminology used in the AutoTrak 2.0 Software

Luminance

Threshold

Max

Luminance

Density

Projection

Time

Max Blind Time

Search Left

Limit

Search Right

Limit

Move Left Limit

Move Right

Limit

Search Pan

Speed

Search Tilt

Position

Max

Reacquisition

Time

Window Width

Reference

Zoom Position

This is the minimum IR brightness level indicating the IR lanyard is present in the

video frame. The actual value is calculated from the video capture data received

from the camera. Default = 180 Range 1-255

This is the maximum number of light points to accept the current frame as containing

the lanyard. This value could be lowered to restrict false lanyard readings. When a

value is read higher then this value, it is ignored, and the “Find Lanyard” processing

is restarted. Default = 2000 Range 1-9999

This value is used to reduce the search pan speed based on the projected next

position. A larger value will increase the lag time when following the detected

lanyard, while lower values will increase the number of camera adjustments. This

parameter works in conjunction with the ‘Search Pan Speed parameter’. Default =

.25

This value defines the time to wait after the detected lanyard is lost before re-starting

the lanyard search. This parameter is used to account for temporary lanyard loss

due to a block condition. Increasing the value will delay the re-start of the Find

Lanyard search. Higher values may be counter productive where lanyard loss is due

to ‘Bright Spots’. Bright spots are non-lanyard light sources which mask out the IR

light. Default = 5 seconds.

This value, in degrees, is the leftmost point of travel for the camera lanyard search.

This value, in degrees, is the rightmost point of travel for the camera lanyard search.

This value, in degrees, is the leftmost point of travel for the camera to move.

This value, in degrees, is the rightmost point of travel for the camera to move.

This value indicates the maximum speed for pan movement.

This value, in degrees, defines the fixed Reference Tilt angle.

This value indicates the maximum find lanyard time. When this time expires, the

Reference and Tracking Cameras are returned to home. They will wait until IR is

received again to restart. Default = 60 seconds

This value, in degrees, is the “Close Enough Zone”. When the camera movement

reaches in this window, movement stops. A smaller width will provide more accurate

centering, while a larger width will reduce the number of camera movements.

Default = 20

This value, in steps, directs the zoom setting of the IR Reference Camera. A lower

number will make the camera movement appear smoother but the lanyard needs to

be large enough in the image to be recognized. The larger the number, the larger

the Lanyard but this reduces the overall capture size and will force a reduction in the

‘Search Pan Speed’ and an increase of the ‘Projection Time’ parameters to allow

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 32 of 47

Page 33

AutoTrak 2.0 Camera Tracking System

enough capture data received to recognize the Lanyard.

Auto Gain

Pan Correction

Tilt Correction

Tracking Zoom

Position

Setup Pan

Speed

Setup Tilt

Speed

AutoPresenter

Port

Reference

Camera Port

Tracking

Camera Port

Iris Control

Ref. Camera

Iris Control

Tracking

Camera

Camera Select

Auto Focus

Type

Details on the Vaddio AutoTrak 2.0 HD-18 Pan/Tilt/Zoom Cameras used in the AutoTrak 2.0

System:

①

②

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 33 of 47

This value increases the IR Camera gain to recognize the lanyard. Default = 30,

Range 0 – 30

This value, in degrees, overcorrects the Reference Camera target used to calculate

the Tracking Camera pan location when the configuration uses side by side cameras

(CONFIGURATION NOT RECOMMENDED).

This value, in degrees, overcorrects the Reference Camera target used to calculate

the Tracking camera tilt location. This parameter automatically adjusts the

Reference Tilt to compensate for the distance vertically between the cameras.

This value, in steps, directs the zoom setting of the tracking camera.

This value, degrees’ is used in the ‘User Interface’ to set camera presets.

This value, degrees’ is used in the ‘User Interface’ to set camera presets.

This string represents the Device name of the serial port used to communicate with

an AutoPresenter.

This string represents the Device name of the serial port used to communicate with

the IR Reference Camera.

This string represents the Device name of the serial port used to communicate with

the Tracking Camera.

This parameter is used to reduce the light and increase the contrast of the lanyard

IR emitters. Default value is in parenthesis.

This parameter is used to adjust the iris (f-stop) to prevent blooming between light

and dark areas in auto iris mode. The Default value is Auto mode, but if blooming

within the presenter area is a problem, switch to manual.

This parameter is used select either the AutoTrak 2.0 HD-18 or AutoTrak 2.0 HD-20

as the Tracking Camera (Iris values are different between cameras). Note: The HD18 is always the reference camera.

This parameter allows the user to select the Auto Focus method. The two (2)

options are; Low Light – works in average and even light conditions, Low and Bright

Light – works better in rooms with bright spots and reflections. Bright light

containing IR will hinder AutoTrak 2.0 operation.

Camera Features:

1) Camera/Sensor/Optics:

1/3-Type, Megapixel HD CCD image sensor is

combined with an 18x optical zoom lens, for

capturing high-quality HD video.

2) Tally Light:

A red tally light is illuminated when the camera

receives a VISCA command from an external

control system and tally is triggered.

3) IR Sensors:

IR sensors are built into the front of the

WallVIEW HD-18 to receive IR signals from the

④

IR remote control supplied with the camera.

4) Power Light:

A blue power light is illuminated when the

camera is turned on.

Page 34

AutoTrak 2.0 Camera Tracking System

③

Rear View of HD-18

Front View of Vaddio HD-18

HD PTZ Camera

⑤

⑨

⑥

⑩

⑦

⑪

⑧

⑫

5) RS-232 In & IR Out:

The RS-232 accepts modified Canon control protocol for camera control.

6) DIP Switch Settings:

Settings for IR remote, baud rate, SD output format, image flip can be configured on these switches. See

Page 31 for additional information switch settings.

7) HD Video Select:

A rotary switch allows the user to choose the component HD output video resolution and format. See

Page 31 for additional information on switch settings.

8) 12 VDC Input

NOTE: The power input is not used with the AutoTrak 2.0 system. This is only used on the standard,

ClearVIEW HD-18 camera.

9) YPbPr Video Output:

Component HD video is fed through the DB-15 connector.

10) SD Video Output:

Standard definition video is fed through the BNC connector.

11) EZ Power Video Port:

CAT-5e cable is connected to the HD-18 Quick-Connect SR Interface. The EZ Power Video Port supplies

power to the camera and returns component HD video up to 100’ (30.5 m)’.

©2012 Vaddio - All Rights Reserved. AutoTrak 2.0 Camera Tracking System - Document Number 342-0382 Rev. A

Page 34 of 47

Page 35

AutoTrak 2.0 Camera Tracking System

12) Slot for Optional Cards

Optional slot cards can be plugged into the WallVIEW HD-18 camera through the slot in the back of the

camera base.

Quick-Connect DVI/HDMI - SR Interface:

1-RU ½ Rack Size, used with AutoTrak 2.0 Systems 999-7210-000 and 999-7215-000

①

②

③

④⑤ ⑥

⑦

1) Blue LED Power Indicator.

2) 24 VDC Power Port: Coax Power Connector, 5.5mm OD x 2.5mm ID, Positive Center.

3) Recessed Color Space Conversion Switch: Toggles between HDMI YCbCr and sRGB (RGBHV)

color space. Change the color space to accommodate either YCbCr or RGBHV monitors.

4) RS-232 Control Input (from joystick controller, codec or control system).

5) To Camera: RS-232 Control to & from Camera and IR signals returned from the camera.

6) Daisy Chain Control Port: Daisy Chain Control Emulation (DCCE) output to next Quick-Connect

DVI/HDMI SR Interface (does not function with the AutoTrak 2.0 System).

7) IR Output Port: Non-modulated (for hard connections) and Modulated for use with IR emitters.

8) DVI-D Output: High Definition Multimedia Interface (HDMI) Transmitter, HDMI (v 1.3 with deep color)

and DVI v 1.0 Compliant.

9) YPbPr Output: Analog Component Video Output on DE-15F (HD-15F) Connector, Resolutions up to