Vac-Star SX, GX User Manual

SX & GX

Program Controller

Version 0.04

Vacuum Packaging Machines

All table top machines and mobile models

www.vac-star.com

Before placing into operation

Important: Before placing the machine into operation, please check

the oil level of the vacuum pump.

Connect and set the gas cylinder (GX only)

The machine features a facility for inert gas ushing allowing pressure-

sensitive products, such as grated cheese, pasta products and salad

etc., to be packed under vacuum.

You will require the following accessories in order to add inert gas to

the vacuum packaging:

1 gas cylinder with foodstuff gas (e.g. N2/CO2 mixture)

1 reducing valve (operating range 0-1.5 bar)

1 hose (table models: hose-Ø

(mobile models: hose-Ø

2 barbed hose ttings

These accessories are not included in the scope of delivery!

CAUTION!!!

Only gas mixtures with a pure oxygen (O2) content of less than 25 %

may be used for gas ushing.

Otherwise, the pump would be at risk of explosion!

Please contact your gas supplier should you have further questions!

inside

inside

≈6 mm)

≈8 mm)

Note: The procedures described below for setting the gas pressure

relate to reducing valves sold by us together with the machine.

Consequently, the setting instructions for valves made by other

manufacturers may differ from these instructions and you should

thus contact your sales agent.

Fit the reducing valve to the gas cylinder and open the cylinder’s main

valve. Then slowly set the regulating screw on the valve to approx.

0.5 bar until gas can be heard to escape.

Caution: If the pressure gauge with the regulating screw is turned

over 1.5 bar, this could damage the reducing valve and the machine1.

Connect the hose to the reducing valve and connect the other end

of the hose with the barbed hose tting to the rear of the machine.

Secure the hose with the barbed hose ttings to prevent it slipping.

2 www.vac ‑star.comEN

2. Program controller

2.1 Working with the packaging machine

Press the green key on the operating panel in order to switch on

the controller.

The machine is now ready to operate.

2.2 Changing the values

Remark: The following explanations will be shown on a “GX” panel.

2.2.1 Language

Language can be set to German, English, French and Spanish.

Press key and together several times until desired language is

shown.

2.2.2 Vacuum “VAC“

Press key for at least 2 seconds.

The value for vacuum will be displayed inverse.

Change value with or key (in steps of 1%).

SX & GX

3EN

If new setting is done the inverse displayed value is shown for 3

seconds.

Then screen will change to standard display and new value is stored.

2.2.2.1 Additional functions

If the displayed value for vacuum is inverse the key can be pressed

again to activate additional functions:

a. Vacuum delay time.

This time can also be change by pressing the or keys.

b. Continuos running.

If continuous running is activated machine will run until

key is pressed during operation.

c. Automatic boiling point detection “Boil”.

If “Boil” is activated the vacuum sensor is set very sensitive for

packing of liquids.

4 www.vac ‑star.comEN

2.2.3 Temperature “Temp.“

Press key for at least 2 seconds.

The value for sealing time will be displayed inverse.

Change value with or key (in steps of 0.1 seconds).

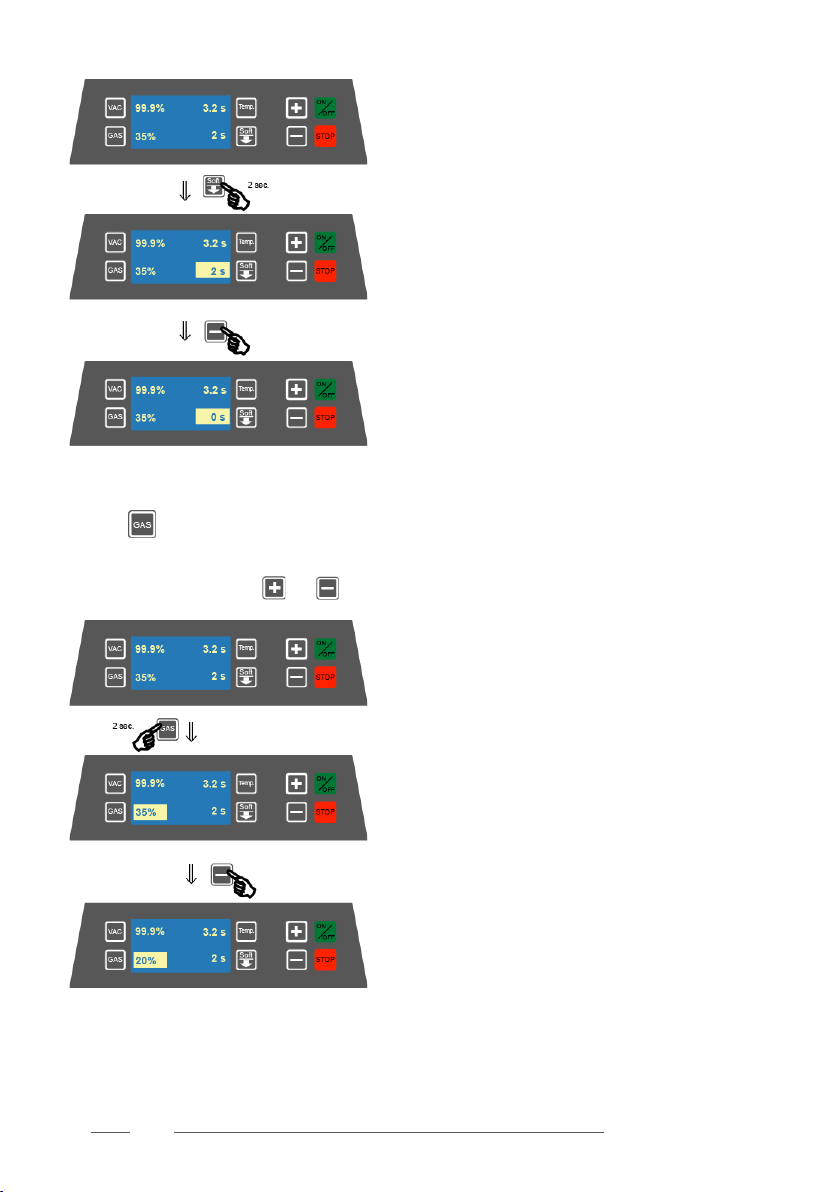

2.2.4 Soft air “Soft”

Press key for at least 2 seconds.

The time for soft aeration will be displayed inverse.

Change value with or key (in steps of 1 second).

SX & GX

5EN

2.2.5 Gassing “GAS”

Press key for at least 2 seconds.

The value for the gas amount will be displayed inverse.

Change value with or key (in steps of 1%).

6 www.vac ‑star.comEN

Loading...

Loading...