Page 1

Technical Brief: Vacuum System Design:

Technical Brief: How Vacuum Pumps Work

Operating / Installation Instructions:

Choosing The Correct Sized Tubing

VP 00-10-20-80-90 Venturi Vacuum Pump Series

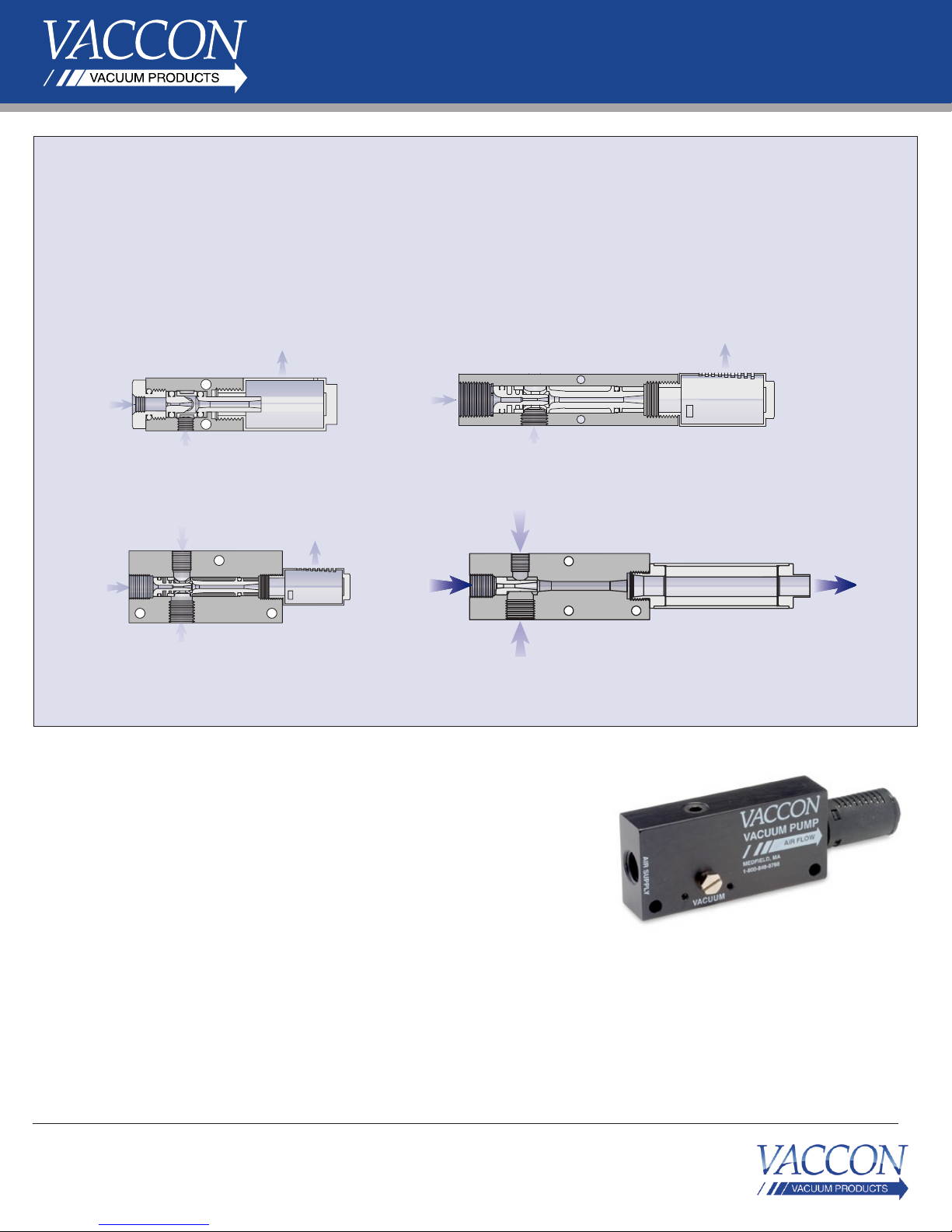

Principles of Operaon

Vacuum is produced by forcing compressed air through a liming orifice (nozzle). As the air exits the orifice it

expands, increasing in velocity to supersonic speed before entering the venturi secon (diffuser). This creates

a vacuum at the vacuum inlet port located between the nozzle and diffuser. The nozzle and diffuser combine

to create a venturi vacuum cartridge. The precise fit of the nozzle to the diffuser is crical to the pump

funconing properly.

Exhaust

VP10

Air

Supply

Vacuum

Vacuum

Exhaust

VP00

Exhaust

Air

Supply

Vacuum

Vacuum

Air

Supply

Vacuum

Drawings not to scale

VP20

Air

Supply

Vacuum

Exhaust

VP80/90

Operang and Installaon Instrucons:

1: Mount pump to your mounng hardware, end-of-arm-tool,

extrusion, etc. VP00 and VP10 model pumps have two

mounng holes that accept 4-40 (M3) screws. VP20, VP80, and

VP90 pumps have three mounng holes that accept 10-32 (M5)

screws (screws not supplied). Pumps work in any orientaon.

2. Aach air line to air supply port. Aach vacuum line to vacuum port if not directly aaching a vacuum

cup to the port. See chart on page 2 for minimum recommended sizes (tubing outer diameters are

listed).

3. Turn on compressed air and regulate to specified pressure (80 PSI standard, models with “-60”

designaon to 60 PSI – set regulator while pump is operang). The VP pump will generate vacuum

immediately.

9 Industrial Park Road, Medway, MA 02053 Phone: (508) 359-7200, US (800) 848-8788 Fax: (508) 359-0177

Visit Us Online at www.vaccon.com or email us at info@vaccon.com

© 2014 Vaccon Company

Proudly Made In The USA

Page 2

Technical Brief: Vacuum System Design:

Operating / Installation Instructions: VP 00-10-20-80-90

Choosing The Correct Sized Tubing

Modular Venturi Vacuum Pump Series

Technical Brief: How Vacuum Pumps Work

Addional Informaon

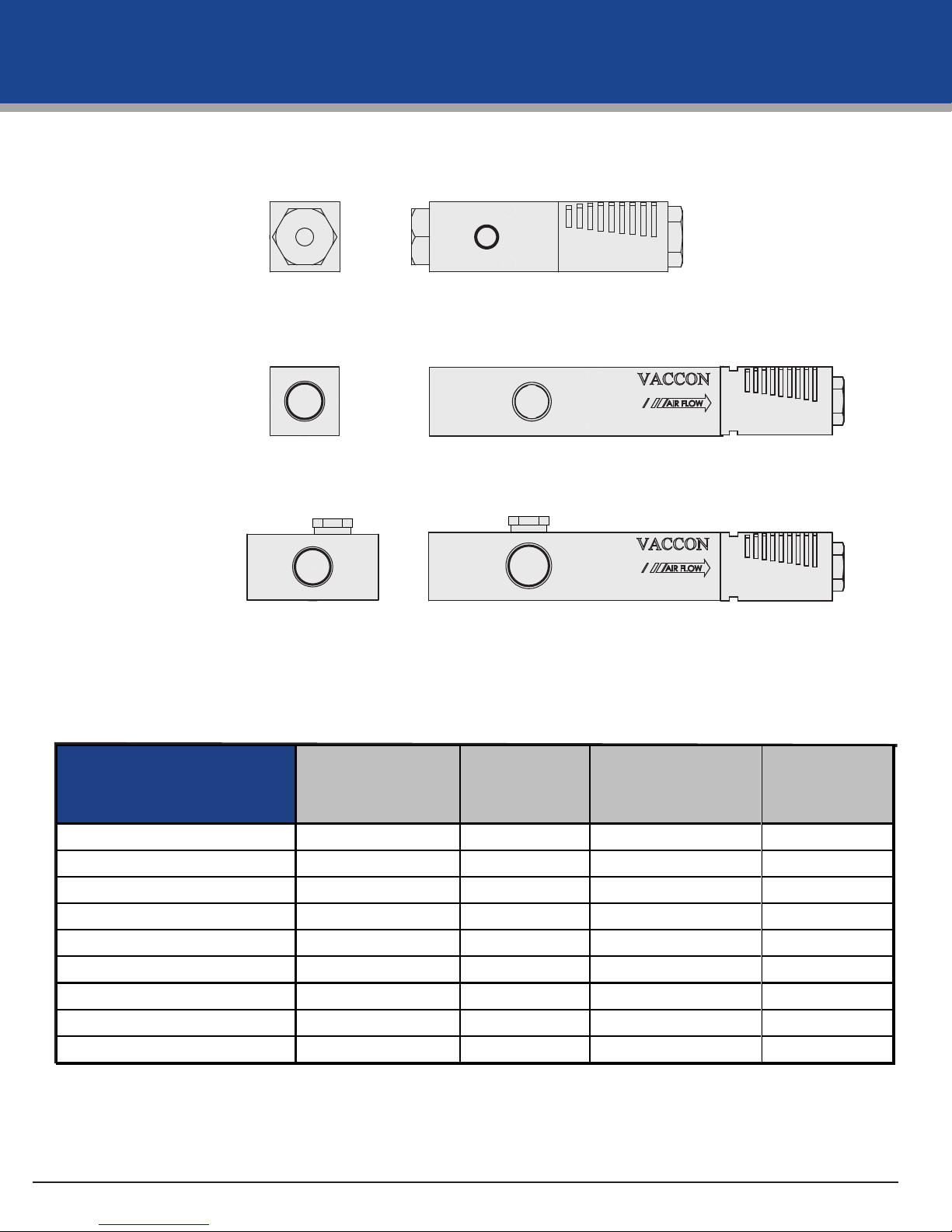

VP00

VP10

VP20/80/90

End Views:

Air Supply

Ports

VP Series

Model

VP00-60 (M,H) Series 10-32 UNC Female ¼" [6 mm] 10-32 UNC Female ¼" [6 mm]

VP10-(60,90) (L,M,H) Series ¼ NPT ¼" [6 mm] ⅛ NPT ¼" [6 mm]

VP10-(100,150) (L,M,H) Series ¼ NPT ⅜" [10 mm] ⅛ NPT ⅜" [10 mm]

VP20-(60,90) (L,M,H) Series ¼ NPT ¼" [6 mm] ¼ NPT ¼" [6 mm]

VP20-(100,150) (L,M,H) Series ¼ NPT ⅜" [10 mm] ¼ NPT ⅜" [10 mm]

VP80-200 (L,M,H) Series ¼ NPT ⅜" [10 mm] ⅜ NPT ⅜" [10 mm]

VP80-250 (L,M,H) Series ¼ NPT ⅜" [10 mm] ⅜ NPT ½" [12 mm]

VP90-300 (L,M,H) Series ⅜ NPT ½" [12 mm] ½ NPT ½" [12 mm]

Air Supply Port

Threads

Top Views:

Vacuum

Ports

Recommended

Air Supply Line

(outer diameter)

Vacuum Port

Threads

Recommended

Vacuum Line

(outer diameter)

VP90-350 (L,M,H) Series

The recommended tubing sizes are based on polyethylene or polyurethane tubing with 0.062” [/”, 1.5 mm] wall thickness

Note: Vaccon discourages the use of quick disconnect fings on all connecons

© 2014 Vaccon Company

⅜ NPT ½" [12 mm] ½ NPT ½" [12 mm]

Operating Instructions: VP 00-10-20-80-90 Series Modular Vacuum Pumps – 2

Loading...

Loading...