Page 1

V200 POSITIONER

www.vacaccessories.com/v200

Valve Accessories & Controls

V200 EXTERNAL OPTION

Installation,

Operation and

Maintenance

Instruction

1 V200 External options IOM r2

Page 2

Page 3

V200 POSITIONER

www.vacaccessories.com/v200

CONTENTS

1 INTRODUCTION ................................................................................. 4

1.1 Air quality recommendations.................................................. 4

1.2 Safety Instructions ................................................................ 4

2 INST ALLA TION .................................................................................. 5

2.1 Installing external IP converter on V200P .............................. 5

2.2 Installing external IP converter on V200E .............................. 6

2.3 Main supply filter for IP con verter .......................................... 7

3 SP ARE PARTS.................................................................................. 8

3.1 Exploded drawing external options ......................................... 8

3.2 Spare parts list external options ............................................ 9

4 SPECIFICATIONS ............................................................................. 10

4.1 Specifications external options .............................................. 10

5 DIMENSIONS .................................................................................... 11

7.1 V200 E 0-10V ........................................................................ 11

7.2 V200 EX and V200 EX-GA .................................................... 12

7.3 V200 FF................................................................................. 13

3 V200 External options IOM r2

Page 4

V200 POSITIONER

www.vacaccessories.com/v200

1 INTRODUCTION

1.1 Air quality recommendations

Poor air quality is one of the main causes of

premature functional problems with pneumatic

and electropneumatic equipment. The pilot

valve and IP converter are precision instruments, and are therefore the most sensitive

parts of the positioner.

a) W ater in the supply air is a natural occurrence. This happens when air is compressed.

The compression heats the air and the natural

degree of water in the air can remain as moisture. When the air cools in pipes etc.

the moisture condenses and becomes liquid

water . Large quantities can build and sometimes flood small water separators. This excess water will eventually reach the control

valve and positioner. This can cause corrosion

damage to the IP conv erter, causing the

unit to malfunction.

We strongly recommend the use of water

separators with adequate capacity. Coalesing

filters from a reputable manufacturer is an

inexpensive way to help prevent unit malfunctions or failures, and add life to the product.

These filters remove particles and moisture

from air lines.

b) Oil in the supply air usually is from the main

compressor. Oil can clog the small nozzles and

disturb the flapper in the IP converter. It can

also cause the spool to “drag” within the pilot

valv e . The result is poor control or in the worst

case, failure.

To ensure normal operational safety with VAC

positioner products, we recommend that a

water separator and a <80 micrometer filter are

mounted as close to the product as possible.

If large amounts of oil are present an oil separator should be installed as well.

To further increase operational safety, w e

recommend that the working air is clean, dry

and free of moisture, water , oil, particles and

other contaminants, in accordance with the ISA

Standard ISA S7.3-81.

1.2 Safety Instructions

CA UTION: Beware of moving parts

when positioner is operated!

CA UTION: Be ware of parts with

live voltage!

A voltage, which is normally not

dangerous, is supplied to the

positioner.

Avoid touching live parts and bare

wires as well as short circuiting live

parts and the housing.

CA UTION: Do not dismantle a

pressurized positioner!

Dismantling a pressurized positioner

will result in uncontrolled pressure

release. Always isolate the relevant

part of the pipeline. Release the pressure from the positioner and the piping. Failure to do this may result in

damage or personal injury.

c) Particles in the air usually occur because of

corrosion. Dirt and particles can block the

small nozzles of the IP converter.

They can also cause the pilot valve to malfunction. The unit may completely fail.

V200 External options IOM r24

CAUTION: Do not exceed the

positioner performance limitations!

Exceeding the limitations marked on

the positioner may cause damage to

the positioner , actuator and v alv e.

Damage or personal injury may result.

Page 5

V200 POSITIONER

www.vacaccessories.com/v200

2 INSTALLATION

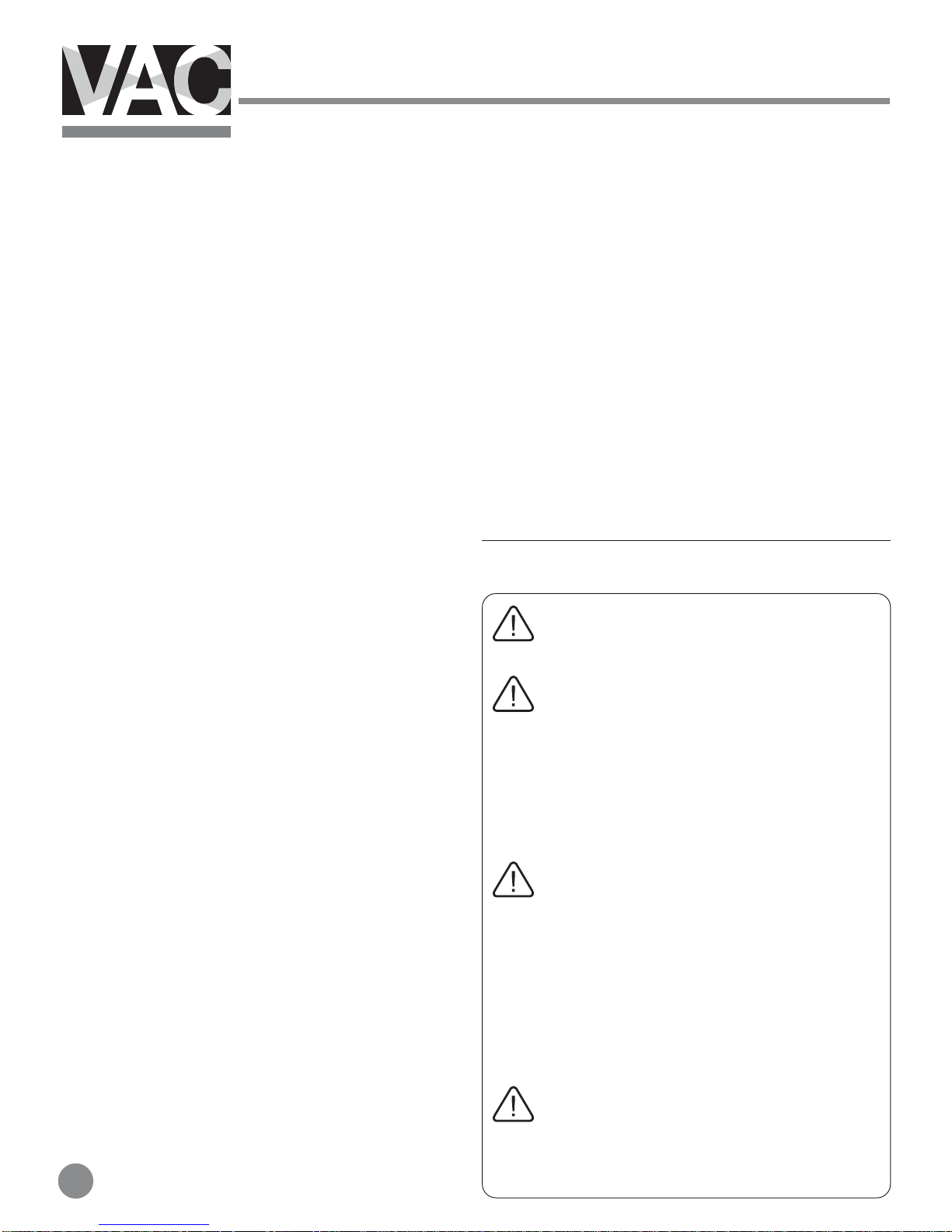

2.1 Installing external IP converter on V200P

NOTE! This instruction is for use when

converting from V200P to V200EX, V200FF or

other external IP converter .

When converting from V200E please follow the

instruction in section 2.2.

1. Loosen the two screws(1) and remove the

plate(2).

2. Make sure there are three O-rings(3) in the

positioner housing.

1

2

3. Install the IP converter(4) and tighten the

screws(5).

4. Install the 1/4” plug(6) in the port marked I.

5

4

1

2

3

6

5 V200 External options IOM r2

Page 6

V200 POSITIONER

www.vacaccessories.com/v200

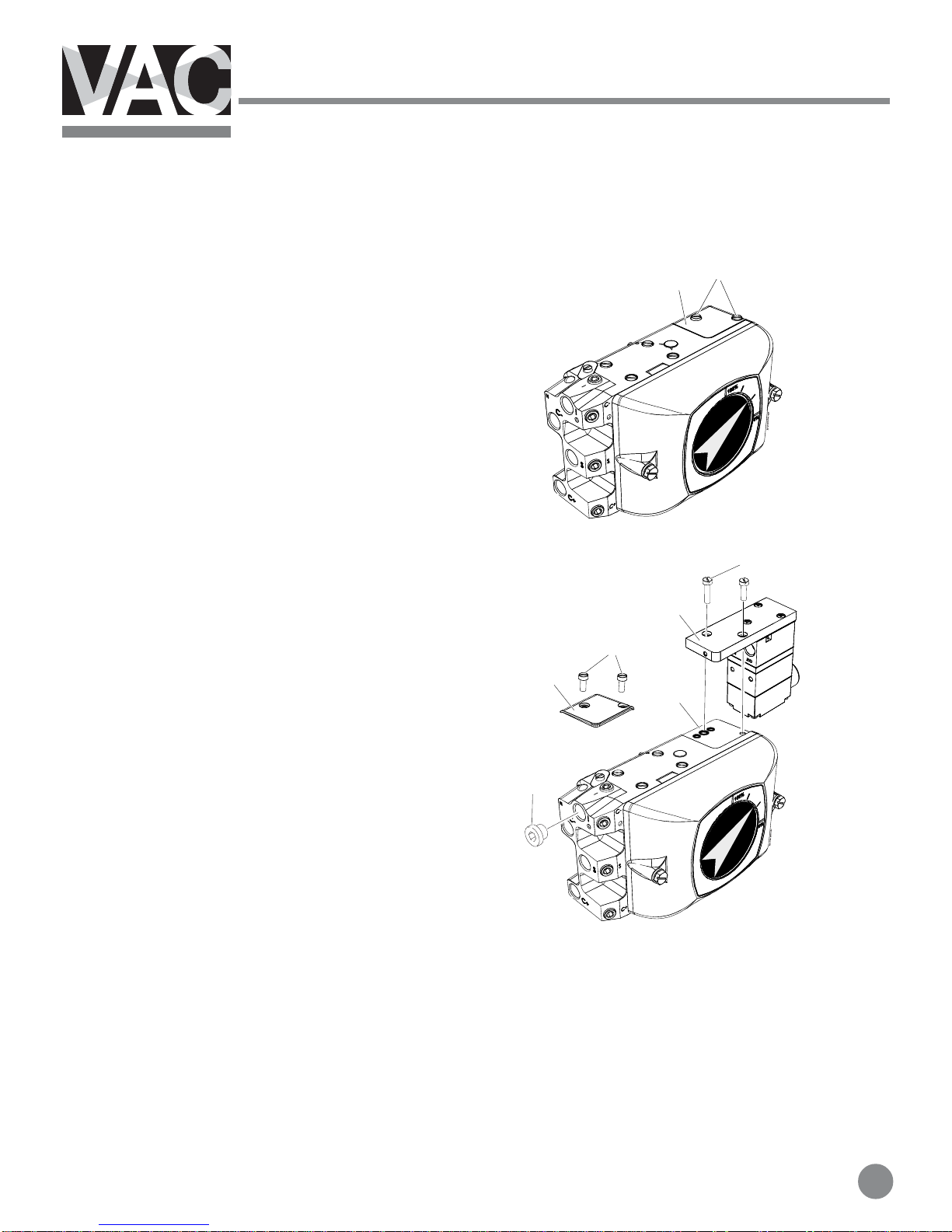

2.2 Installing external IP converter on V200E

(which has the internal IP inside the unit).

1. Loosen the two screws(1) that secure the internal

IP converter(2) and remove the internal IP.

2. Make sure the two O-rings(3) are still in the

positioner housing.

3. Install the pneumatic sealing plate(4) and tighten

the screws.

4. Check that the 1/4”plug(5) is installed in the port

marked I.

5. Continue with the instruction 2.1 (page 5)

1

2

5

4

3

V200 External options IOM r26

Page 7

V200 POSITIONER

www.vacaccessories.com/v200

2.3 Main supply filter for IP converter

Changing the filter

1. Turn off or disconnect the main air supply.

Should air supply not be disconnected or

turned off, the pressure may cause the

filter cover to eject from the unit.

2. Loosen the screw(1) and remove filter

cover(2)

3. Cautiously remove the filter (3) with a

sharp pointed object e.g. a pocket knife.

4. Press the new filter(3) into the housing.

2

1

5. Check the O-ring(4) and replace if

needed.

5. Install the filter cover(2) and tighten the

screw(1)

If the filter(3) shows traces of

oil or water, check the water/oil

separator in the supply line.

Oil and water can cause

functional problems in

the IP converter .

3

4

2

7 V200 External options IOM r2

Page 8

V200 POSITIONER

www.vacaccessories.com/v200

3 SPARE PARTS

3.1 Exploded drawing external options

V200 External options IOM r28

Page 9

V200 POSITIONER

www.vacaccessories.com/v200

3.2 Spare parts list external options

Item Description Material Part no Qt y

1 ...... External IP module 0-10V ............................................ 93016 .............. 1

1..... IP 0-10V ....................................................................... 400119 ............ 1

2..... Mounting Kit external IP 0-10V ...................................91011 .............. 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Mylar Washer ...................... Plastic <PA> ................. 90048 .............. 2

...... - Screw #8-32 UNC 2B x 0,5 . Stainless Steel .............83 2UNC13 ....... 3

...... - Rubber Gasket CA900X...... Nitrile Rubber ................90094 .............. 1

...... - Mounting Plate CA900X ...... Aluminum, painted ........ 90078 .............. 1

2 ...... External IP Module EX ................................................. 93017 .............. 1

1..... IP EX ........................................................................... 400117 ............ 1

2..... Mounting Kit external IP EX........................................91012 .............. 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Mylar Washer ...................... Plastic <PA> ................. 90048 .............. 2

...... - Screw NPT 1_4 ................... Stainless Steel.............90089 .............. 2

...... - O-ring Ø14x2 NBR70 .......... Nitrile Rubber................OR14x2NBR.... 4

...... - Mounting Plate CA950XP .... Aluminum, painted ........90079 .............. 1

3 ...... External IP Module Gas Approved ............................... 93026 .............. 1

1..... IP Gas Approved ........................................................400118 ............ 1

2..... Mounting Kit external IP Gas Approved......................91012 .............. 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Mylar washer ....................... Plastic <PA>.................90048.............. 2

...... - Screw NPT 1_4 ................... Stainless Steel.............90089 .............. 2

...... - O-ring Ø14x2 NBR70 .......... Nitrile Rubber................OR14x2NBR.... 4

...... - Mounting Plate CA950XP .... Aluminum, painted ........90079 .............. 1

4 ...... External IP Module Fail Freeze ....................................93019 .............. 1

1..... IP Fail Freeze ............................................................... 92070 .............. 1

2..... Mounting Kit external IP Fail Freeze ........................... 91014.............. 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Screw ISO 1207 M5x18 ...... Stainless Steel .............1207051818 .... 1

...... - Mylar Washer ...................... Plastic <PA> ................. 90048 .............. 2

...... - Screw ISO 4762 M4x40 ...... Stainless Steel .............1207064040 .... 2

...... - O-ring Ø3x2 NBR 70 ........... Nitrile Rubber................OR3x2NBR ...... 2

...... - Mounting plate WS 420FF ... Aluminum, painted ........ 90084 .............. 1

9 V200 External options IOM r2

Page 10

V200 POSITIONER

www.vacaccessories.com/v200

4 SPECIFICATIONS

4.1 Specifications external options

Electropneumatic 0-10V Electropneumatic EX Electropneumatic Fail Freeze

V200 0-10V V200EX V200FF

Input Signal: 0-10VDC (Max:Ri 10K Ohm) 4-20mA (Max:Ri 250 Ohm) 4-20mA (Max:Ri 250 Ohm)

Supply Pressure: <100 PSI (<1MPa) 21.8-100 PSI (0.15-1MPa) 21.8-145 PSI (0.15-1MPa)

Linearity error: <0.8% f.s <0.8% f.s <1.2% f.s

Hysteresis: <0.5% f.s <0.5% f.s <0.9% f.s

Repeatability: <0.4% f. s <0.4% f. s <0.8% f. s

Temperature range: -40° to +160 F -40° to +158 F* -20° to +158 F

-40° to +71C -40° to +70°C* -28° to +70°C

*Temp.range depending on certification

Pressure gain:

@87 PSI (600kPa) 300:1 300:1 300:1

Bleed Rate: SCFM (SLPM) SCFM (SLPM) SCFM (SLPM)

@87PSI (600kPa) 0.38 (11.9) 0.42 (11.9) 0.36 (10.2)

Air Delivery SCFM (SLPM) SCFM (SLPM) SCFM (SLPM)

@87 PSI (600kPa) 28.3 (800) 28.3 (800) 28.3 (800)

Air connections: 1/4” NPT (optional G threads) 1/4” NPT (optional G threads) 1/4” NPT (optional G threads)

Gauges: 1/8” NPT (optional G threads) 1/8” NPT (optional G threads) 1/8” NPT (optional G threads)

Cable entry: 1/2” NPT (optional M20x1.5) 1/2” NPT (optional M20x1.5) 1/2” NPT (optional M20x1.5)

Ingress & corrosion

protection: NEMA 4X and IP66 NEMA 4X and IP66 NEMA 4X and IP66

Standard coating: Polyester Polyester Polyester

Weight: 3.9 lbs (1.76kg) 5.3 lbs (2.40g) 5.4 lbs (2.45kg)

Weight with gauges: 4.3 lbs (1.94kg) 5.7 lbs (2.58kg) 5.8 lbs (2.63kg)

Valve types Normal Gain High Gain Super High Gain

Pressure Gain: @ 29 PSI (0.2MPa) P output / Pinput 100 270 370

@ 87 PSI (0.6MPa) Poutput / Pinput 300 800 1100

@ 145 PSI (1.0MPa) Poutput / Pinput 500 1330 1830

Pressure Gain: Any %Poutput / %Pinput 20 52 72

Acc. to ISA S75.13

Air Delivery: @ 29 PSI (0.2MPa) SCFM/(SLPM) 9.4 / (270) 10.6 / (300) 10.6 (300)

@ 87 PSI (0.6MPa) SCFM/(SLPM) 28.3 / (800) 31.8/ (900) 31.8 (900)

@ 145 PSI (1.0MPa) SCFM/(SLPM) 47.1 / (1330) 53.0 / (1500) 53.0 (1500)

Bleed Rate: @ 29 PSI (0.2MPa) SCFM/(SLPM) 0.12 / (3.4) 0.18 / (5.0) 0.24 (6.7)

@ 87 PSI (0.6MPa) SCFM/(SLPM) 0.35 / (10.0) 0.53/ (15.0) 0.71 (20.0)

@ 145 PSI (1.0MPa) SCFM/(SLPM) 0.59 / (16.7) 0.88 / (25.0) 1.18 (33.3)

Options: Feedback Spring for 6-30 PSI (40-200kPa) input signal.

Gauges. Stability kit, feedback modules

V200 External options IOM r210

Page 11

5 DIMENSIONS

5.1 V200E 0/10V

V200 POSITIONER

www.vacaccessories.com/v200

11 V200 External options IOM r2

Page 12

5.2 V200EX and V200EX-GA

V200 POSITIONER

www.vacaccessories.com/v200

V200 External options IOM r212

Page 13

5.3 V200FF

V200 POSITIONER

www.vacaccessories.com/v200

13 V200 External options IOM r2

Page 14

Page 15

Page 16

Loading...

Loading...